So many of the high-performance engine builders hold their cards close to the vest, never divulging the top-secret tricks that help them make a couple more horsepower than the rest. Stealthy efforts make it such that all their expertise can’t easily be replicated but through the same arduous process of learning the hard way how a thousandth here or there can make all the difference.

Not Blackbird Performance. Geoff Turk and crew were one of the first outfits to really figure out the G3 Hemi and now they’re shouting their track-proven formulas from the rooftops. Cracking the code started way back in 2010 when Turk first worked with Tony Bischoff of BES Racing Engines on a 5.7L Hemi for his 1968 Plymouth Barracuda.

Things escalated quickly when he got his hands on a 2015 Dodge Challenger Drag Pak, the original Blackbird, and coaxed its Hemi to a 7-second quarter-mile pass. Then, his 2021 Dodge Challenger Drag Pak, Blackbird X, joined the Jesel 200-MPH Club with a 202.55-mph pass in 2023.

Those accomplishments are well-chronicled, but much more important are the fruits of those labors, highlighted by a lineup of Race Spec engine formulas that are chock full of Blackbird parts and wisdom.

Four naturally aspirated packages make up the foundation with power levels at 600+, 700+, 800+, and 900+ HP. And the best part is that the recipes are all laid out for anyone to build. That was Blackbird’s goal in developing and sharing these packages; they’re here to help G3 Hemi the world.

Don’t let the “race spec” moniker fool you into thinking these are strip-only powerplants. In fact, we might go so far as to call them “muscle spec” engines because they’re designed to be driveable, reliable, and, most importantly, powerful. All three features make them perfect for vintage iron, although we will admit that any naturally aspirated 900+ HP beast is likely on the borderline of being fit for Broadway duty.

The basis for all is the BGE (Big Gas Engine) 6.4L block. Well-known for its ability to handle four-digit horsepower right from the factory, it’s straight up sturdy. Actually, every Race Spec engine all the way up to the 1,650+ HP supercharged version uses the same BGE block as its core building brick.

Other common components for the naturally aspirated engines include Blackbird’s phaser delete adjustable timing set, cast front cover, cast aluminum valve covers, and Afterburner ignition system. Depending on application, a Milodon or Holley oil pan buttons up the bottom end. Standardizing as many parts as possible was a goal to help keep complexity and costs down so that money could be better spent where it counts.

But let’s dispel two Hemi-related talking points right off the top. First off, no, these engines aren’t likely to develop the “Hemi tick.” While more than a few have indeed wiped cam lobes over the years, it’s important to remember that those instances have been rare relative to the total volume of engines. Root cause has been speculated heavily with most laying blame on the MDS (Multi-Displacement System) or roller bearings that were too small.

The Blackbird engines all feature the latest OEM non-MDS lifters which are commonly referred to as Hellcat lifters. Also known as Mopar part number 05038784AD, these have not in any way been linked to the tick. Actually, it’s been quite the opposite as they’ve become the gold standard for G3 Hemi hydraulic lifters across the industry. Blackbird uses them all the way through their supercharged 1,450 HP powerplant. Yeah, that sounds pretty stout.

Secondly, let’s address the large contingent that shies away from computer-controlled engines. True enough, a factory 6.4L would come with a great many wires and boxes. The Blackbird engines do not, although EFI is an option. A standard carburetor up top is a welcome sight for simplicity.

Running the ignition is the Afterburner which hardly qualifies as a big, scary computer. It’s really not any more complicated than an MSD system. An MSD 6AL box has never been scoffed at as a “computer,” so we wouldn’t categorize the Afterburner as one either. Like the MSD, merely consider it a box that plugs in and helps distribute spark in a high-performance fashion.

And now, the meat and potatoes. Each one of these packages does have its own unique blend of sugar and spice to hit the horsepower plateaus. Open up the Rolodex, grab some notecards, and get these scribbled down because they’re pure prescription power.

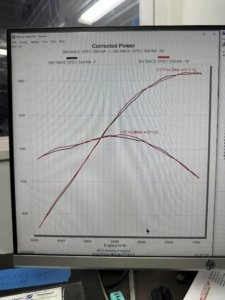

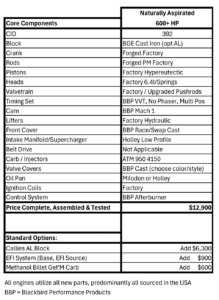

600+ HP Engine

This one’s easy. The 6.4L needs very little help to make the jump to 600 as proven by the recipe’s extensive use of out-of-the-box OEM components. The aforementioned block, crankshaft, rods, pistons, cylinder heads, rocker arms, lifters, and ignition coils are all straight from Ma Mopar. That also means a stock 10.9:1 compression ratio.

Where Blackbird steps in is with their Mach 1 camshaft. This is the most mild-mannered of the Mach bunch with 0.578” of theoretical lift and durations of 224 and 232 degrees at 0.050” on intake and exhaust, respectively.

Induction is handled by a hood-friendly Holley low profile intake manifold topped with an ATM 950 carburetor. Simple reliability is the name of the game there. Electronic fuel injection (EFI) or a billet Get’M carburetor are optional on this engine along with the rest of the naturally aspirated packages.

All of that added up to a proven 611 ponies during the development engine’s day at the dyno. Pricing for the turnkey, drop-in engine at the time of this writing is $12,900 for what is likely super street-friendly, reliable, and bulletproof.

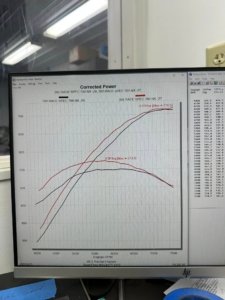

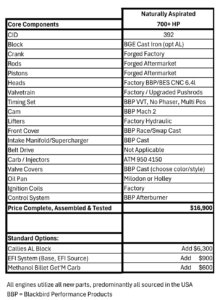

700+ HP Engine

Unsurprisingly, the 700 mark still really isn’t that much of a stretch for the 6.4L platform with a little bit more Blackbird magic. Obviously, a whole lot of airflow is needed and, therefore, provided by a set of CNC-ported cylinder heads paired with a Mach 2 camshaft.

This cam, as expected, is a little more aggressive with 0.635” of lift on both intake exhaust and durations of 236 and 246 at 0.050”. That’s healthy, but still well-within the range of streetable.

The rotating assembly gets an upgrade as well with forged aftermarket rods and pistons that add up to a 12.2:1 compression ratio which is still in earshot of pump gas when running aluminum heads. Up top is slated to be Blackbird’s own cast aluminum intake which will be along the same lines as the Mopar Drag Pak manifold.

The development engine made 717 HP on the dyno and, as far as bang for the buck, this formula is tough to beat at $16,900. Just ask Mark Dudley Jr.; his 1974 Plymouth Duster is packing this 700+ HP spec engine and has more than 110 eighth-mile passes on it.

“I’m one-hundred percent confident with my motor that I could just drive it down the road and have no issues with it. Idling, it’s not aggressive at all. But as soon as I crack the gas, that thing is hellacious,” Dudley says.

Dudley has absolutely beat on this thing without a hiccup, burp, belch, or breakage so far. It’s been solid as a rock and nothing short of impressive for a little ol’ 6.4L. But what if we were to go bigger…

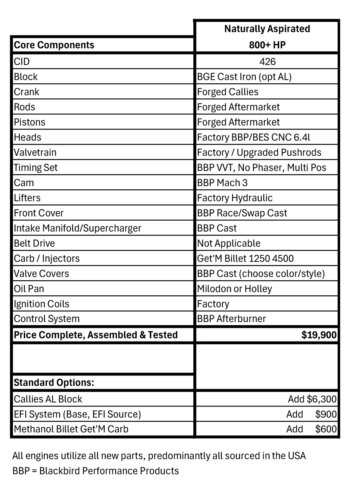

800+ HP Engine

800+ HP Engine

This is where a naturally aspirated 392 cubic inches will no longer do. Instead, a Callies-sourced forged stroker crankshaft pumps it up to 426 while a Mach 3 camshaft bumps the valves. As expected, duration gets another boost with 243 and 259 degrees at 0.050” on the intake and exhaust. Lift is staggered at 0.605” and 0.613”, respectively.

Rods and pistons make the step up to forged material, but note that a fair amount of factory goodies are still on the grocery list even at this power level. The lifters and rockers, for example, are box stock because Blackbird knows they’ll take it.

“We have not really had issues with stock rockers and shafts, up to fairly high levels of power / valvetrain aggressiveness. […] The factory stuff will get you a long way down the road, trouble free,” says Turk.

This monster is currently priced at $19,900 and, honestly, would still be almost streetable with a cam that’s more mild than what we’ve seen in some aggressive stroker big block wedges. It all comes back to having the right combination put together by the right people (Blackbird Performance, if you hadn’t noticed). But what if we went just a little bit bigger…

900+ HP Engine

We’ll cry uncle here because this kind of horsepower in naturally aspirated form is testing the limits of physics in an internal combustion engine that’s south of 500 cubic inches. Admittedly, Blackbird has more research and development to hone in on here as they wait on finalization of their own cast cylinder head.

North of 900, the only OEM piece remaining is the fabled BGE block. Everything else will be aftermarket, bumping the projected price to $23,900. But just think about what a naturally aspirated big block Mopar would have to look like to hit this kind of horsepower.

Could it be done with a 440? Sure, but to be any kind of reliable, it would probably cost twice as much to build. The fact that it’s even in the realm of possibility speaks to the 6.4L BGE Hemi’s potential and Blackbird’s know-how.

Turk sums it up pretty succinctly with, “It’s just incredible, the amount of power we’ve been able to find and make at very low cost…at costs that, like we’ve always said, show that Gen 3 Hemis can do everything LSs can at the same cost, if not lower.”

Turk sums it up pretty succinctly with, “It’s just incredible, the amount of power we’ve been able to find and make at very low cost…at costs that, like we’ve always said, show that Gen 3 Hemis can do everything LSs can at the same cost, if not lower.”

If you were looking for a sign to Hemi swap your Mopar muscle car, here it is and Blackbird is here to help. “Do It Myself” guys can call them for a shopping list, “Help Me Do It” guys can call for a partially-assembled powerplant, and “Do It For Me” guys can have a turnkey crate engine shipped to their door.

It’s all brought to you on the wings of Blackbird’s pavement-pounding success. This ain’t no armchair engine outfitter; these packages were built with a hand on the shifter and a right foot flat on the floor of a Hemi Challenger. Requesting permission for liftoff? Granted.