Charlie hit the jackpot when he found the golden ticket to enter the world of Willie Wonka’s Chocolate Factory. He was overwhelmed by all the choices presented before him. I got my hands on a golden ticket of sorts when I was treated to a tour of Currie Enterprises. Much like Charlie, I was impressed by the size and scope of their factory operation, just instead of chocolate we had axle housings galore!

When working to build a company that serves the industrial, street car, and off-road markets, innovation is key. The aftermarket automotive industry is ever-changing and new products and new features are essential for captivating generations of gearheads. Young companies with new ideas often come and go as innovation moves on and the market surpasses their original great idea. Currie Enterprises has thrived in these markets for nearly sixty years due to their ability to always be on the cutting edge. Their massive facility in Corona, California operates at a staggering pace and I went down to see if I could keep up.

Above: Currie Enterprises is located in Corona California and while they have moved from the original building, Currie is still a local Southern California operation.

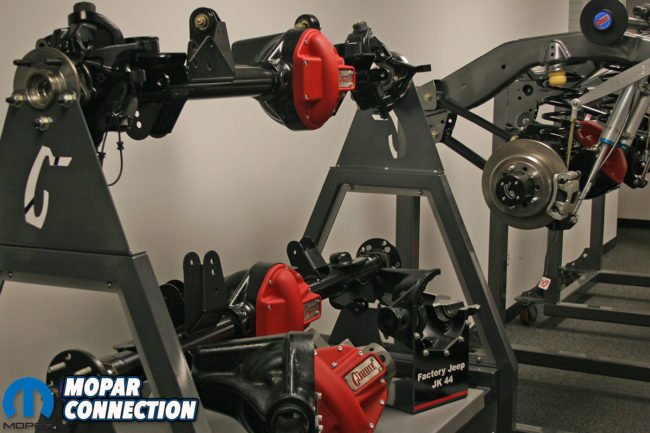

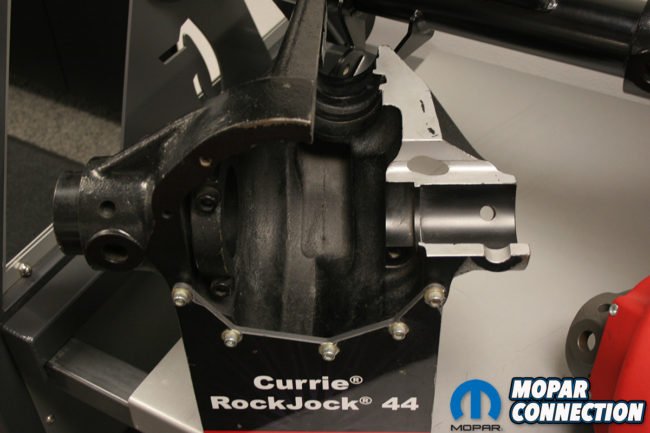

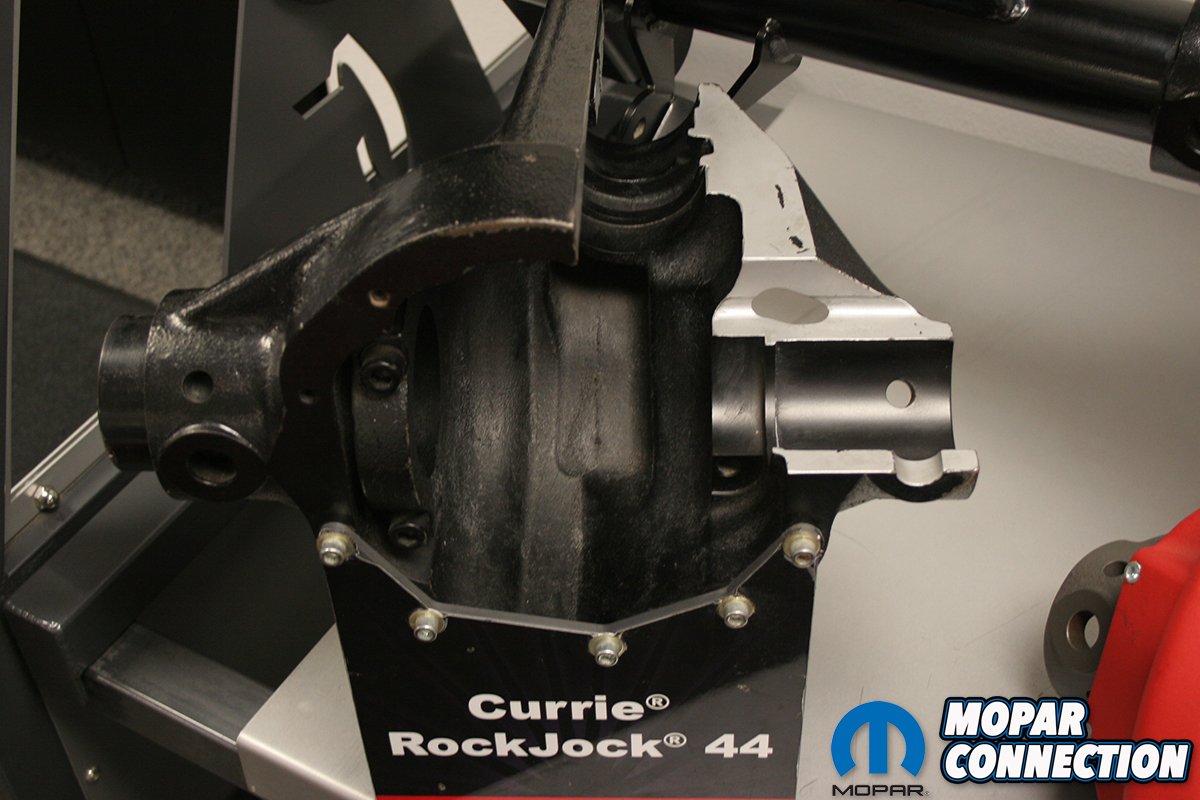

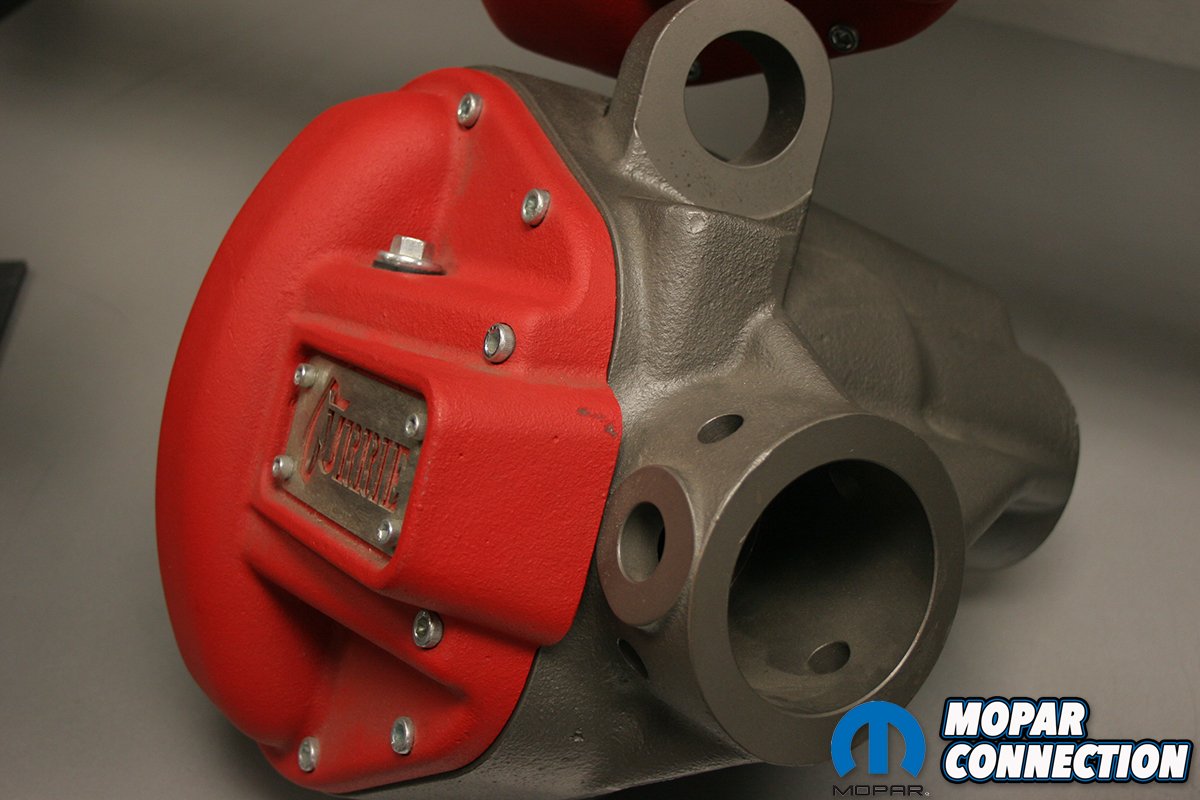

Above left: Displays are a major resource for potential customers to check out Currie’s products up close. Above right: The RockJock 44 axle center section.

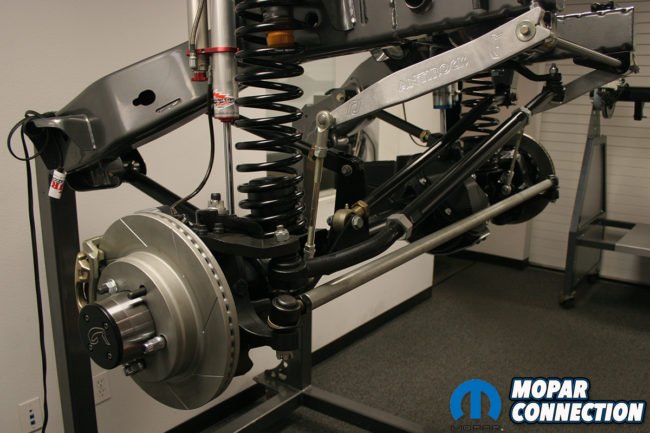

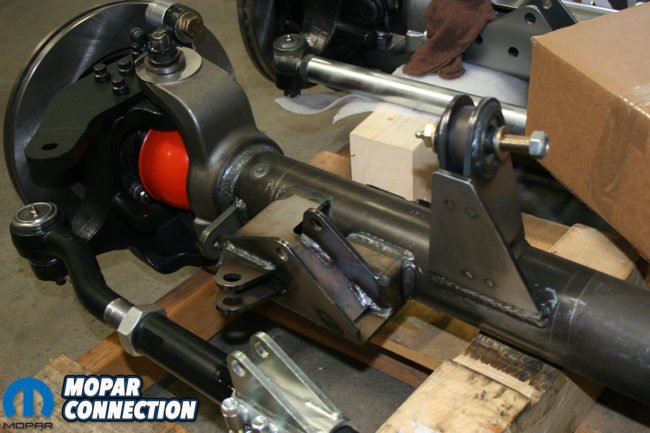

Far left: A Jeep JK specific bolt in RockJock 60 front end, shown here with a Jeeps front frame section to show just how well the front end is set up to work. Middle left: A cutout of the Jeeps stock Dana 44 front end shows the flimsy casting. Middle and far right: A complete fabricated housing with 9″ center section set up the the likes of a ’69 Chevelle

In 1959, when Frank Currie opened the doors of Currie Enterprises for the first time, it was a company that supplied rear ends for Taylor-Dunn Manufacturing. After a short time, Frank’s passion for hot rods worked its way into the company, and rear ends for street cars started being built. Today Frank’s company still supplies a large number of axles to industrial manufacturers, but Currie Enterprises has become a household name for automotive enthusiasts all across the country.

Currie’s commitment to sturdy components has earned them a reputation in the off-road market place. Currie Enterprises has been a huge supporter of the off-road community and we have yet to attend a major off-road event without Currie’s presence. Currie has impressive displays of their products that allow onlookers the chance to get up close and personal with all Currie’s new products. Currie makes displays that show the difference between stock Jeep JK Dana 44 center sections and the completely reworked Currie Rock Jock center sections. They have displays to showcase the difference between 27 or 35 splines and full versus semi float axles.

Above: With the two side by side the difference in the RockJock 60’s massive 35 spline axles and the shafts for a jeep specific 44 unit is easy to see.

Above: When visiting Currie Enterprises, seeing some rad Jeeps in the parking lot is almost guaranteed.

Above: Beefy rear ends are all over the place waiting to get finished up.

Touring around the shop floor, the sheer magnitude of Currie’s operation is apparent. Currie makes axles for vehicles from Ford Anglias to trophy trucks. Supplying rear ends for customers all over the world means Currie literally has bins full of center sections and wracks loaded with complete housings ready for their new homes. The manufacturing of nearly every component larger than bearings for their axles takes place in house. Workers operate full-time, welding housing brackets and trusses while around the corner others are cutting splines for the axle shafts. The shop is laid out to allow employees to stay in their area as much as possible and avoid wasted transport time.

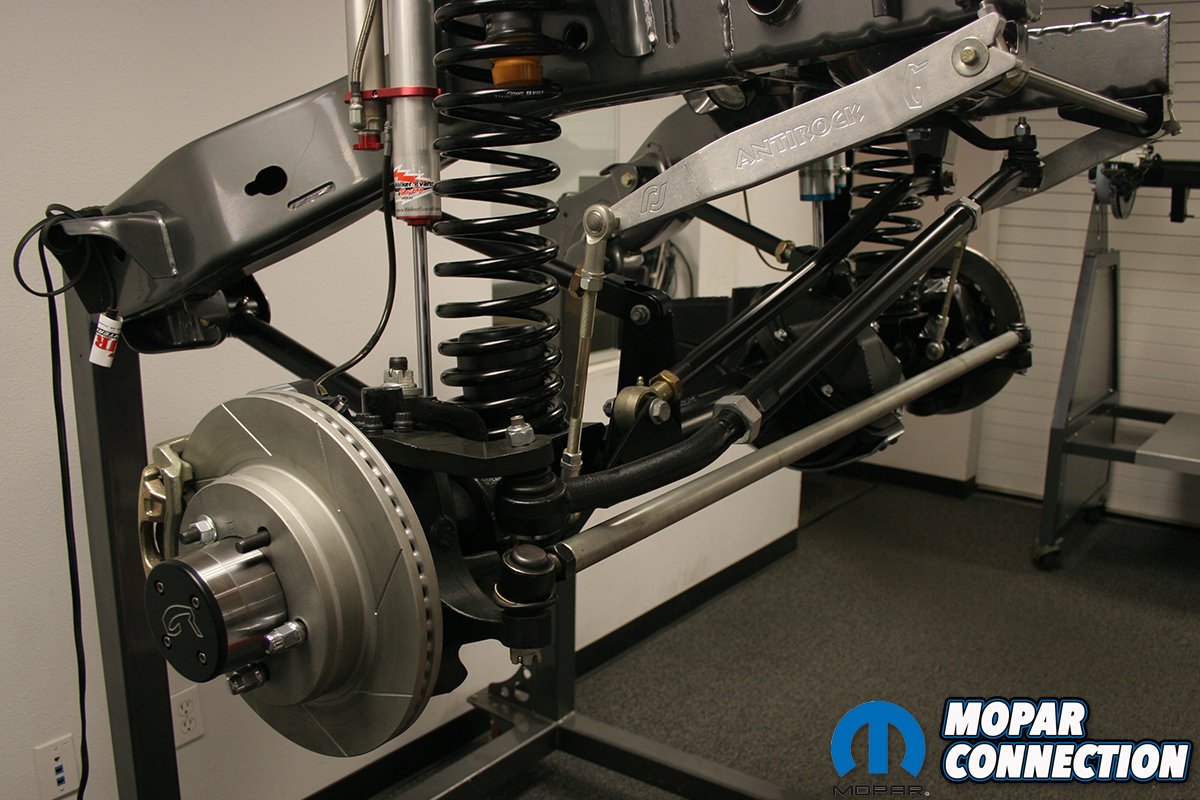

Axles are where Currie got its start, but now they have grown into a company that offers a myriad of components for street cars and off road machines. Currie’s anti rock sway bar has been a solution for Jeep handling and now these variable rate sway bars have worked their way onto full race rigs. Currie has made itself known in the autocross and drag race communities as well with control arms made to tighten up handling of early muscle cars for track duties. I got a closer look at the making of Currie’s Johnny Joint, the first flex joint suspension end the market had seen. Though they employ no geese, bad eggs aren’t an issue as Currie Enterprises stands by all their products.

Above: One of the new RockJock VXR 60’s set up for a Jeep JK ready to be picked up. We plan to do a story on this innovative front end in the near future.

Above: One of the “shop truck” JK’s parked outback that is loaded with Currie Enterprises mid price range components.

Currie Enterprises has a rich history of putting their products to the test and naturally that meant that the shop had a number of Currie equipped Jeeps on site. These Jeeps are show quality, but show signs that they are actually being used. Perhaps the best part of touring the shop is seeing the will call area where pallets of complete axles are waiting to be picked up. In one place was more than fifty thousand dollars of high performance axles awaiting their turn to be installed in hard core drag cars, rock crawlers, and street rods.

In the end of Roald Dahl’s story, Charlie inherited the chocolate factory. While I wasn’t quite as fortunate to walk away with keys to the Currie Kingdom, I was thrilled to see where the magic happens and add a few components to my future build list.