While looking through a sea of Road Runners, Chargers, Darts, Challengers and even Ram trucks spread out across this year’s Mopar Nationals, we spotted a red candy apple metallic mid-century Chrysler looking like it was right from a cover of an early 1960s custom car magazine. We instantly had to check out this out, as it captured our attention immediately and we wanted to get the lowdown.

We noticed the traditional 354 Gen I Hemi was not residing in the engine bay of this 1956 Chrysler Windsor. What was there was Gen III 6.1L Hemi plucked from a 2006 SRT8. We thought it cool, but upon closer examination found that the whole drivetrain, suspension and even interior components were repurposed from a donor 2006 Charger SRT8 and grafted into this stunning example of when tailfins were all the rage.

We cornered the owner, Glen Dailey, who was showing it for the first time at this event. Glen grew up in the 1950’s and comes from the mindset that hot rodding was all about using one’s own skills and resources to build a street machine or hot rod. When Glen was growing up in rural West Virginia, there weren’t many speed shops or fabrication shops so everyone had to use their own talents and abilities to work with whatever was available, usually junk yard parts, to build up his car.

When Glen would go cruising around and see another hot rod, it was assumed (and expected) that the owner built it himself. “There was no real pride in driving a rod that someone else had built, or that daddy had bought new for you from a dealership. It really didn’t matter how perfect your rod was, it was just the joy of having something that you conjured up yourself,” said Glen.

It was that philosophy that Glen used as he began work on his stunning Chrysler Windsor. As with many projects, if Glen could fathom the true cost of building a cool street rod, he probably would’ve never started this one but, like many of us, it’s not about the money but rather, the passion. With a love of mid-50’s cars, Glen set out to find a Chrysler two-door hardtop for this project.

While surfing the internet, he found one on eBay and brought it home. Glen was going to go the traditional street rod route but that quickly changed when Glen’s son noticed complete front and rear suspension sub-assemblies from a 2006 Charger SRT8 for sale. After several days of analyzing the eBay pictures and doing additional research, Glen decided it would make a great suspension platform for the Chrysler.

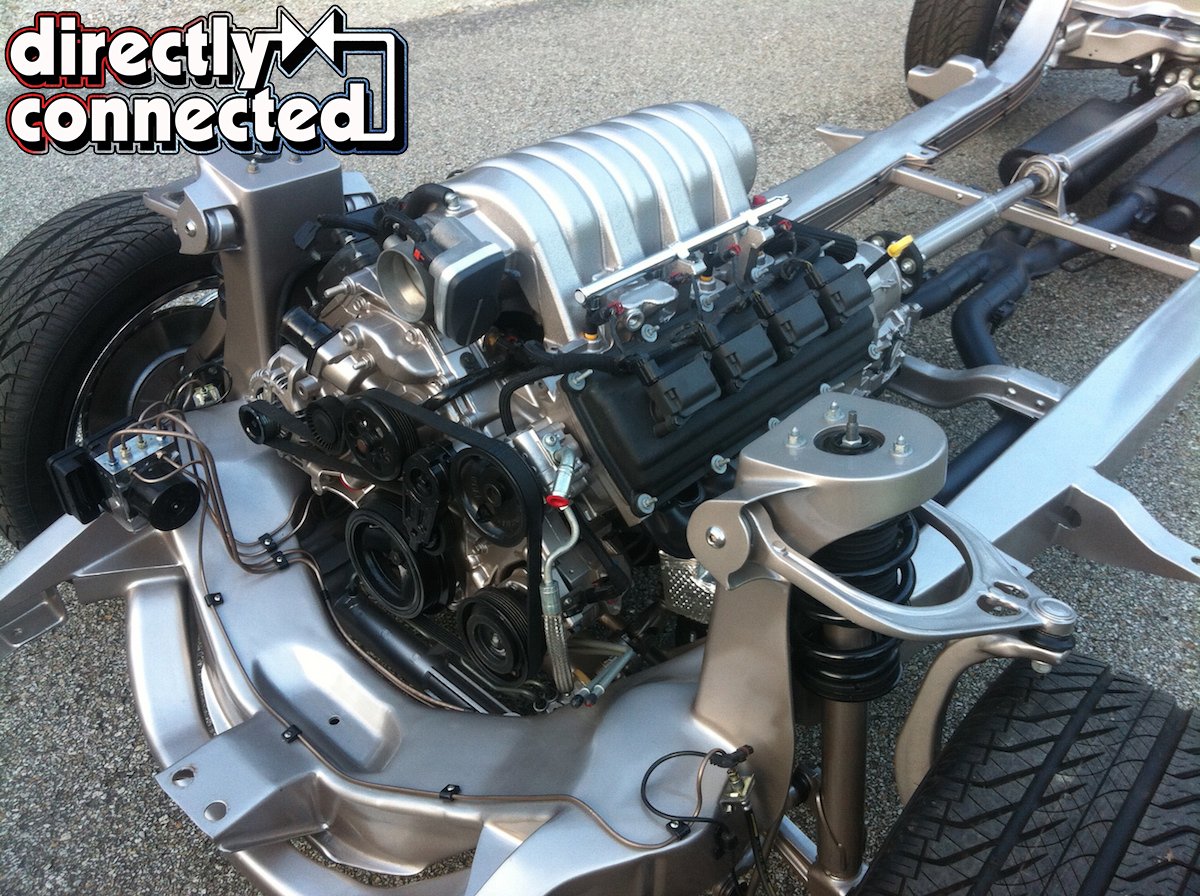

To make sure the ride stance would work on the ’56 Chrysler, Gen suspended the bare body and frame from four overhead winches and placed some donor wheels and tires within the wheel openings. With the desired frame-to-floor measurements for the front and rear determined, along with utilization of factory Chrysler frame alignment specifications for the 2006 Chrysler LX platform, Glen was able to determine where the subassembly mounting points needed to be located on the Chrysler’s frame. Many days and nights were spent measuring, cutting and fabricating to attain the correct mounting of the SRT8 subassembly frames.

Since the Chrysler’s original frame was already a well built and fully boxed, it was a great platform and worked exceptionally well to mount the SRT8 subassemblies. With the correct locations for wheelbase, ride height, and most critically, the correct factory geometry, the project was progressing nicely for Glen.

The only sizeable challenge that faced Glen was fabricating the mounting points for the SRT8 front upper A-arms and Bilstein shocks. Some “creative” engineering was used mount the upper A-arm pivots and struts on the vintage Chrysler. Luckily Glen found another LX car in a salvage yard with all the suspension components removed that allowed him access to all the necessary suspension mounting points.

After the remaining chassis fabrication of engine and transmission mounts were completed, the chassis was fully smoothed and painted in an oyster beige metallic, along with all the other suspension and drivetrain components. With the SRT8 suspension now raising the bar for the build, having the original 354 Hemi nestled between the fenders didn’t make sense.

That’s when Glen went “all in” and procured a Gen III 6.1L Hemi and five-speed NAG1 automatic from a wrecked 2006 Chrysler 300C SRT8. This offered the best of both worlds – modern Hemi power and reliability with fuel saving technology from the 3.06 rear axle gearing and overdrive trans. However, this to would be a daunting task for Glen and with modern engines come modern electronics and that can be a nightmare unto themselves. Luckily, the totaled Chrysler SRT8 had the complete wiring harness with PCM and TCM modules intact.

However, the factory PCM also needed to talk to the transmission module to effectively manage shift scheduling and performance. To get around that, Glen incorporated the CAN bus (that’s the thing which tells the microcontrollers to communicate to other functions without a host computer). Glen still had to find an antilock brake module and wheel speed sensors. That’s when it made sense to incorporate a complete 2006 Chrysler 300C dash but it went beyond that.

Glen’s ’56 Chrysler has all the modern creature comforts from the late-model 300C such as power tilt/telescopic steering column, steering wheel radio control, power adjustable pedals, factory console/shifter, cruise control, dual zone climate control, auto dimming headlights, navigation radio with Bluetooth, factory 320 watt amplifier with 7 speakers, video, and backup camera, delay wipers, door chimes, auto-diming interior lighting, and more.

Since the controller and wiring harnesses had provisions for power windows, door locks, and trunk release, Glen set out to make all of these features operable as well. The ‘56 Chrysler was a ‘crank’ window car, but Glen was fortunate to find original ‘56 power window mechanisms on eBay from a Chrysler Imperial.

For the power door locks, he modified the original door latches with some additional linkage that allowed him to wire aftermarket power door solenoids into the factory wiring. The original trunk latch was likewise modified to accept a power lock solenoid. These modifications facilitated the modern features of keyless entry, remote lock, trunk release, and even a vehicle security alarm (which Glen inadvertently and loudly discovered in his garage one day).

To keep things cool inside the Chrysler during those hot summer cruising days, Glen used the 2006 heater/AC unit but the coolest feature (in our opinion) is the function popup cowl vent on the ’56 Chrysler to pull outside in for ventilation. Here, Glen fabricated an air plenum under the cowl vent, ducted it to a fabricated port on the new AC box, and then equipped the cowl vent with an electronic servo that operated in harmony with the AC box that switched the vents for outside air. It’s quite neat to see the cowl went slowly rise when the outside air control is chosen. Even though the AC works fantastically, the 2-door hardtop inspires windows-down cruising for all but the hottest of days.

Now it was time to determine what color to paint the mighty Chrysler. Glen struggled over a color choice, but a candy apple red was settled upon. Working with his friend at a local paint supplier, Glen began formulating a basecoat red metallic that he liked. The ’56 Chrysler was painted with the custom red basecoat now formulated as ‘Dailey Red’, followed with 4-6 coats of clear. All of the pot-metal trim, door handles, bumpers, etc. were sent off for top chrome plating at Paul’s Chrome in PA. Although this was the most price-shocking element of the build, Glen knew you get what you pay for and the chrome turned out beautiful. Glen even modified the original three-piece rear bumper by doing some sectioning to improve the fit.

When it was time to cover the interior surfaces, Glen was interested in creating his own custom upholstery so he bought a used industrial ‘walking foot’ sewing machine and six hides of Austrian leather and he reupholstered every piece of the interior. Glen even made custom door panels to allow for better look, but also to house the power window switches and relocated speakers.

Realizing new front seats would be needed (factory LX seats wouldn’t fit well), Glen found a 2008 Chrysler Sebring convertible with power seats that would work well. They fold forward and also have shoulder belts built into the seat backs, making rear seat entry much easier. Glen then added some embellishments to the design and made new matching leather seat covers.

Glen’s been asked on several occasions what his favorite part of the build was and surprisingly, he tells folks it was the incorporation of the late model wiring and electronics into the project. It was indeed the most challenging. Second would be the upholstery work, which he had never done before. But for Glen, it has paid off, as his Chrysler Windsor is in his words, “A dream to drive, it handles like a modern SRT8 and is dead quiet except for the throaty growl of the 6.1L Hemi!”

After going with Glen for a short trip in his show-stopping Chrysler Windsor during the Mopar Nats, we second those thoughts.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by