Dan Pino had a problem. He had a numbers-matching RB440 block for his 1969 1/2 A12 Super Bee that, by all accounts, was a boat anchor. Per Pino, “[The] guy raced it pretty much [right off of] the showroom floor. [He] blew it up and set it in the corner of his garage on a dirt floor. It remained there from the early 1970s until I tracked it down a couple [of] years ago. Unfortunately, he washed his car in his garage since […] and all the soapy water collected around the block.”

The result was an all but unsalvageable heap of cast iron. Well, that’s what most would think. Dan hunted down Jon Reed of Cast Iron Fusion Inc. who took on the project that no one else would. Pino joked, “If he […] said no, the block would be in my man cave as a table.”

Above: The engine block belonging to Dan Pino’s numbers-matching 440 Six-Pack A12 1969 1/2 Super Bee had spent decades face-down in a puddle in the back of a dirt-floored barn. To most, this 440 was a lost cause.

Mopar Connection reached out to Reed at Cast Iron Fusion Inc. to get his side of the story: “I’ve been repairing cast iron since 1973. I have mostly been repairing heavy iron like Caterpillar engines, transmission cases and cylinder heads.”

“As I have gotten older, I have done a lot of high performance cylinder heads and high performance blocks,” Reed continued. “I have done 426 Hemi racing blocks and Hemi heads that have dropped valves. I [also] spent three years in Saudi Arabia working for a member of the Royal family teaching repair procedures to the Saudi military and for other companies such as ship engine repair companies. That endeavor took me throughout that part of the world and lasted from 2000 through 2003.”

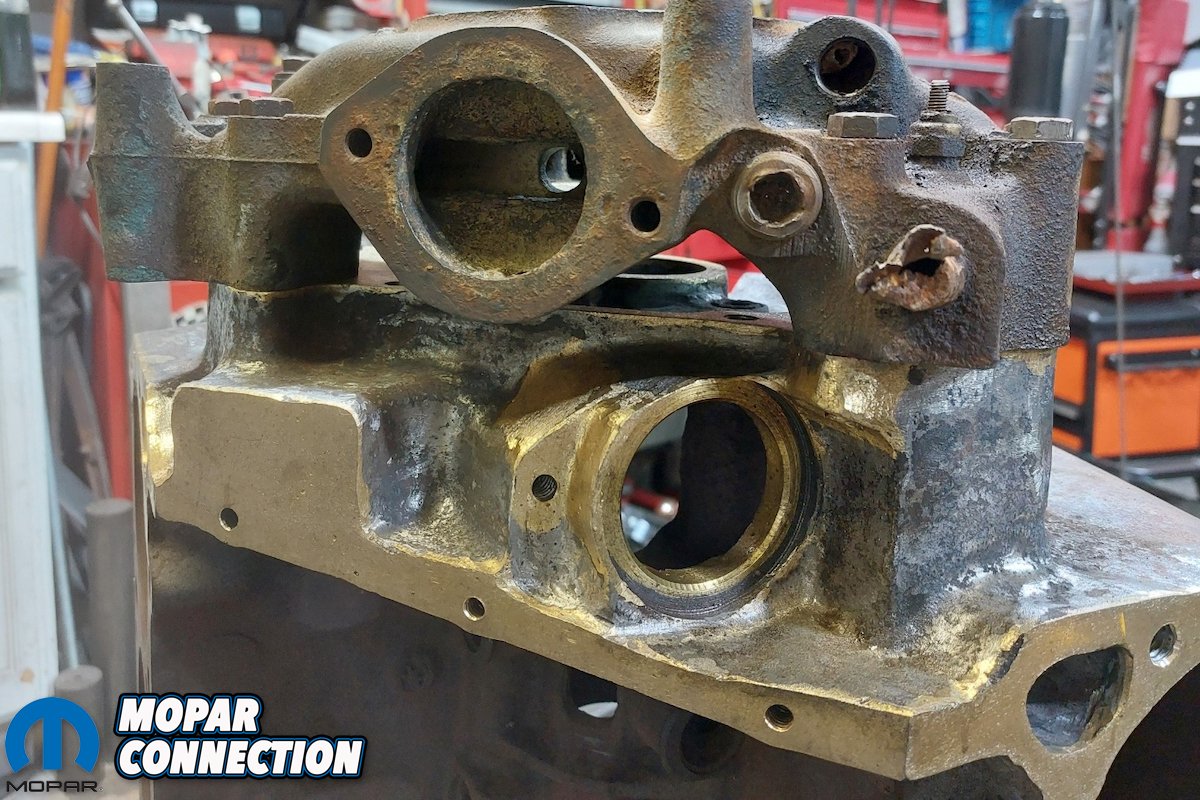

Above: Nearly every major surface – including sensitive machined surfaces – we heavily scaled, pitted and pock-marked. No machine shop would look at Pino’s 440 with a second glance…until he found Jon Reed of Cast Iron Fusion, Inc.

Wanting something to do when he retired, Reed opened up Cast Iron Fusion in 2018 out of his home garage in Farr West, Utah. Diagnosed with Leukemia in 2022, Reed retired from the industrial casting repair business and kept busy restoring antique Harley Davidson, Indian and Henderson motorcycle cases and cylinder heads as he beat back the cancer. Now cancer-free, Reed continues repairing of cast aluminum, ductile iron castings, etc.

“There isn’t much that I haven’t done before. I like to do things that others can’t do,” Reed shrugged. At 71-years-old now, Reed maintains Cast Iron Fusion as a one man shop.””I have a Bridgeport mill and a large metal lathe so I can machine most of what I fix. I’ve [restored] many antique Harley Davidson Knucklehead cylinder heads […] and other parts on bikes from the ’30s through the mid ’40s. A lot of it requires removing previous repair attempts and starting over using cast iron.”

Above: Cast Iron Fusion Inc. began by dipping, scraping, flushing, and finally shot-peening the damaged surface area. Regulated to mainly the front 5-to-6 inches of the block, the rest of the engine could be lightly restored if Reed could save the front surfaces.

“Cast iron fusion welding is not taught in any schools that I am aware of,” Reed noted. Few are as proficient in cast iron fusion welding, furnace brazing and metal stitching with the Lock-N-Stitch process these days. Reed’s own brother has a metal stitching business, mechanically repairing cast iron without any heat (meaning no distortion). Otherwise, cast iron welding requires heating the material to exorbitant temperatures. Furnace brazing requires 900-degrees Fahrenheit as fusion welding demands 1,800 degrees F.

After discussing his plans for the engine block, Pino had the block in Reed’s hands. Pino explained that the process took several months, as the block needed to be dipped, scraped, flushed, and shot-peened before Reed could begin the fusion process. Reed admitted, “The repair wasn’t hard, just time consuming.”

Above: Even the #1 crank boss needed repair. Oil holes needed to be built back up and drilled out, as did every bolt hole, tapping new threads into the restored material.

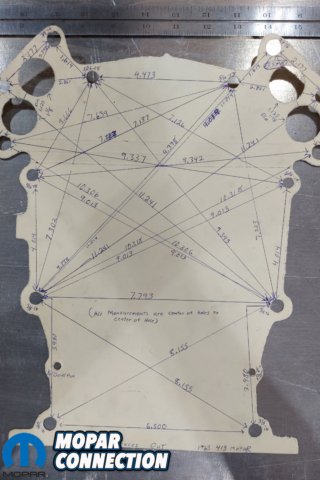

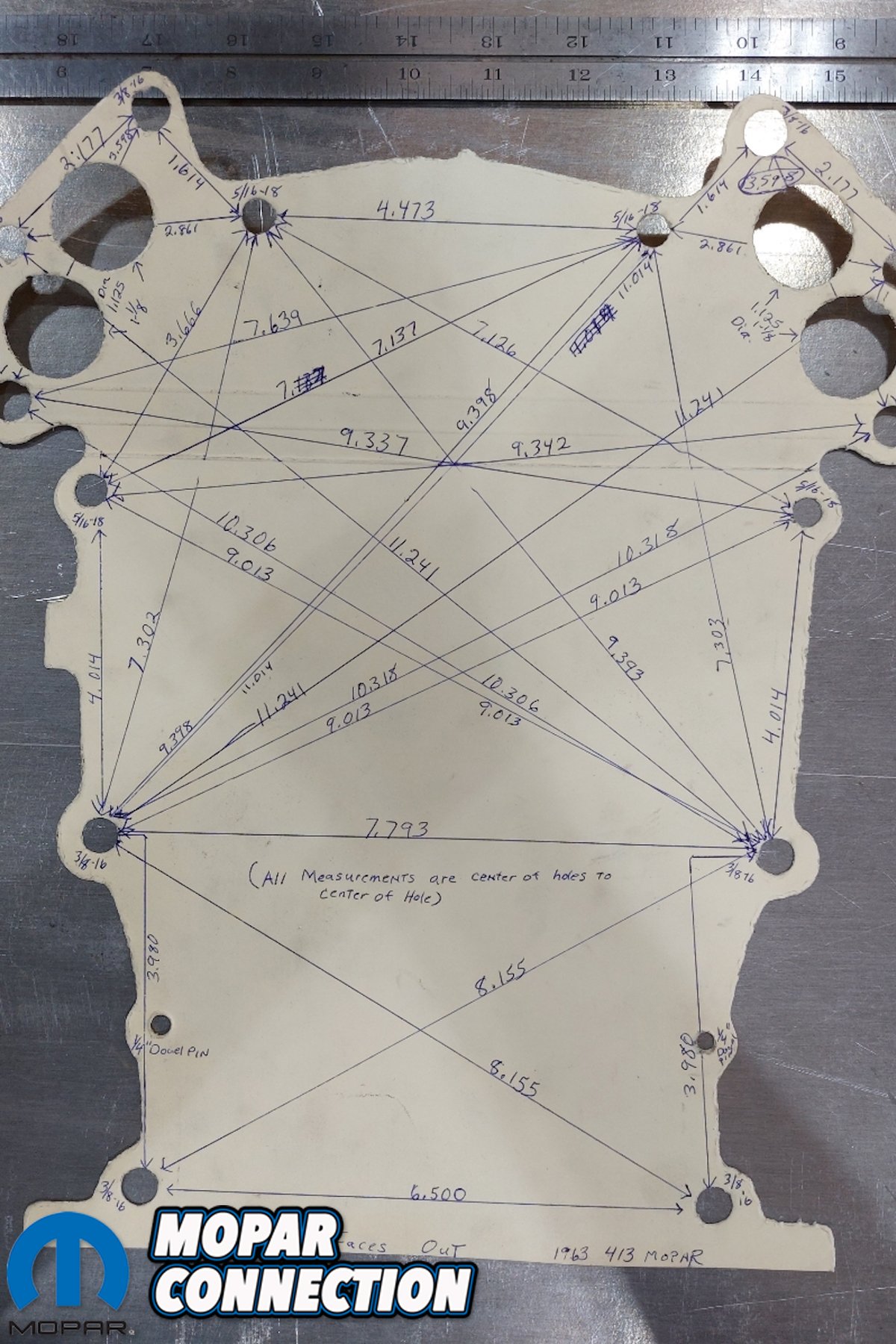

Pino’s 440 block presented another unique challenge. The amount of erosion left a lot of dimensions lost. Reed was able to reverse engineer the block using some 440, 426 Wedge and 413 blocks that he was already working on at the same time. A paper template with all the factory geometry and measurements was made by Reed to ensure everything was machined properly.

After the final brazing, Reed left .020-inch of extra material on the surfaces, so it could be machined flush when Pino was ready to build the engine. “I have a particular fondness for old Mopars,” Reed confessed. “I like to put old iron back on the road. I had a 1969 Charger R/T with a 440 in 1971 through 1974. My brother has a beautiful ’69 Charger R/T too – all restored now.”

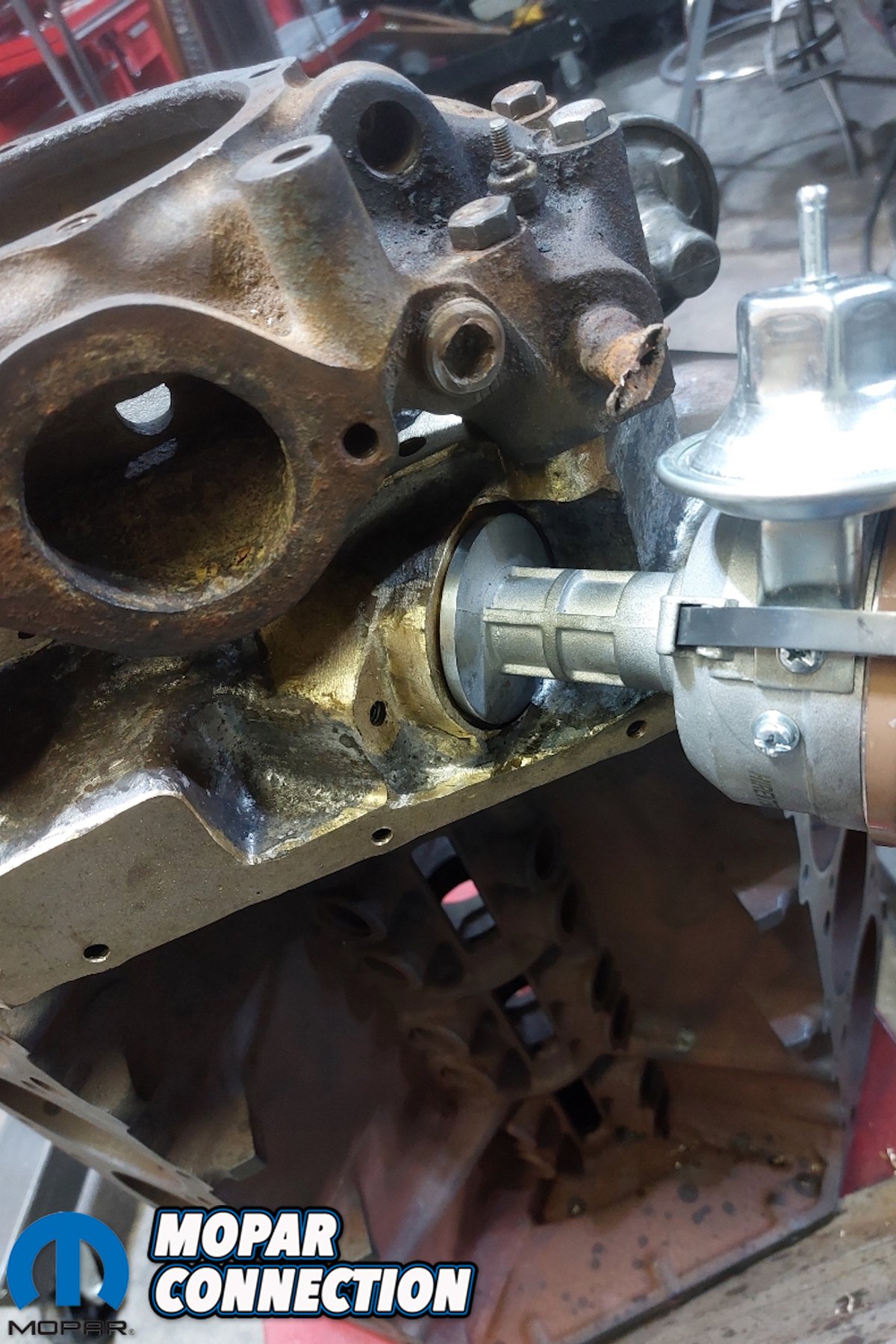

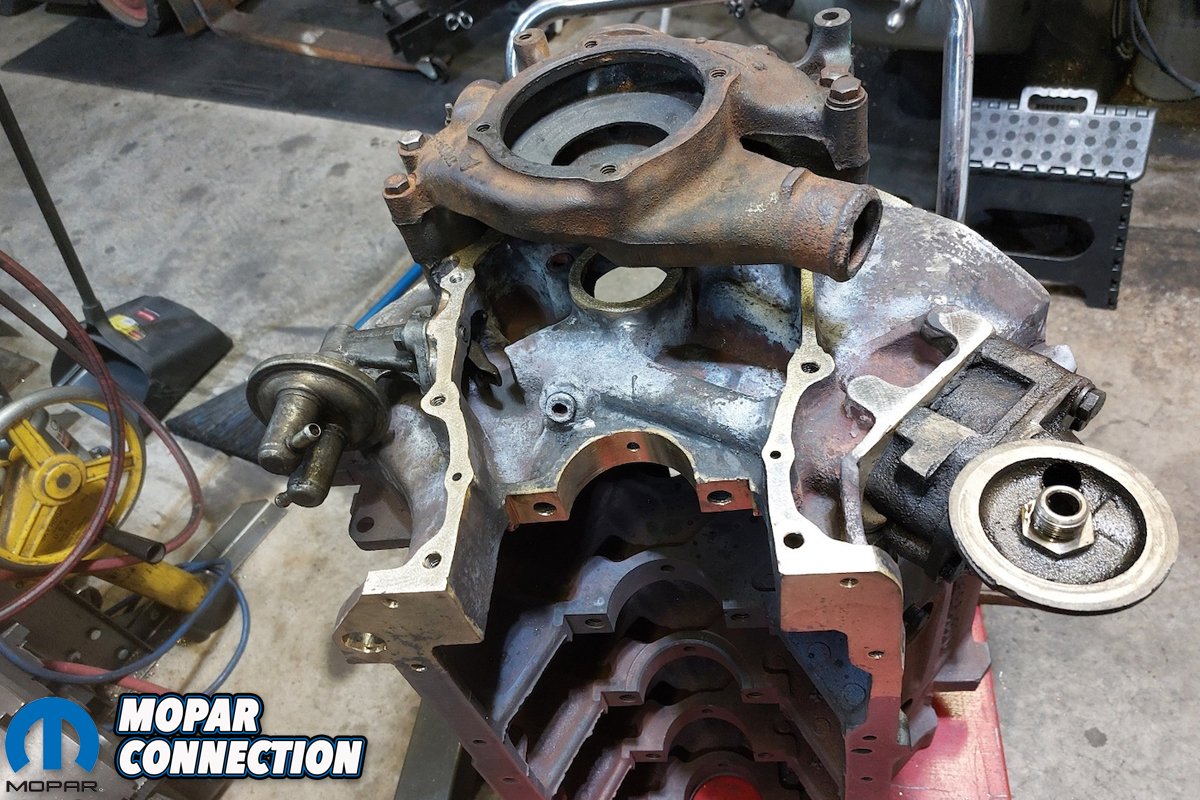

Above: The image above shows Pino mocking up the water pump, oil pump and fuel pump, all fitting perfectly and accepting the factory hardware. Yes, Reed even re-tapped all of the bolt holes.

The final result is breathtaking, especially when considering what Reed had to work with. While some of the cast surfaces still show the excessive pitting from sitting in water for so long, the sensitive machined surfaces – including the #1 cradle perch – are almost completely restored.

As Pino said, Reed left the surfaces a little thick so the block can be trued at a machine shop prior to the Six-Pack engine’s complete reassembly and restoration. For those needing similar help, do not hesitate to call or email Jon Reed of Cast Iron Fusion Inc. As you can see, this man knows how to perform miracles with cast iron.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by