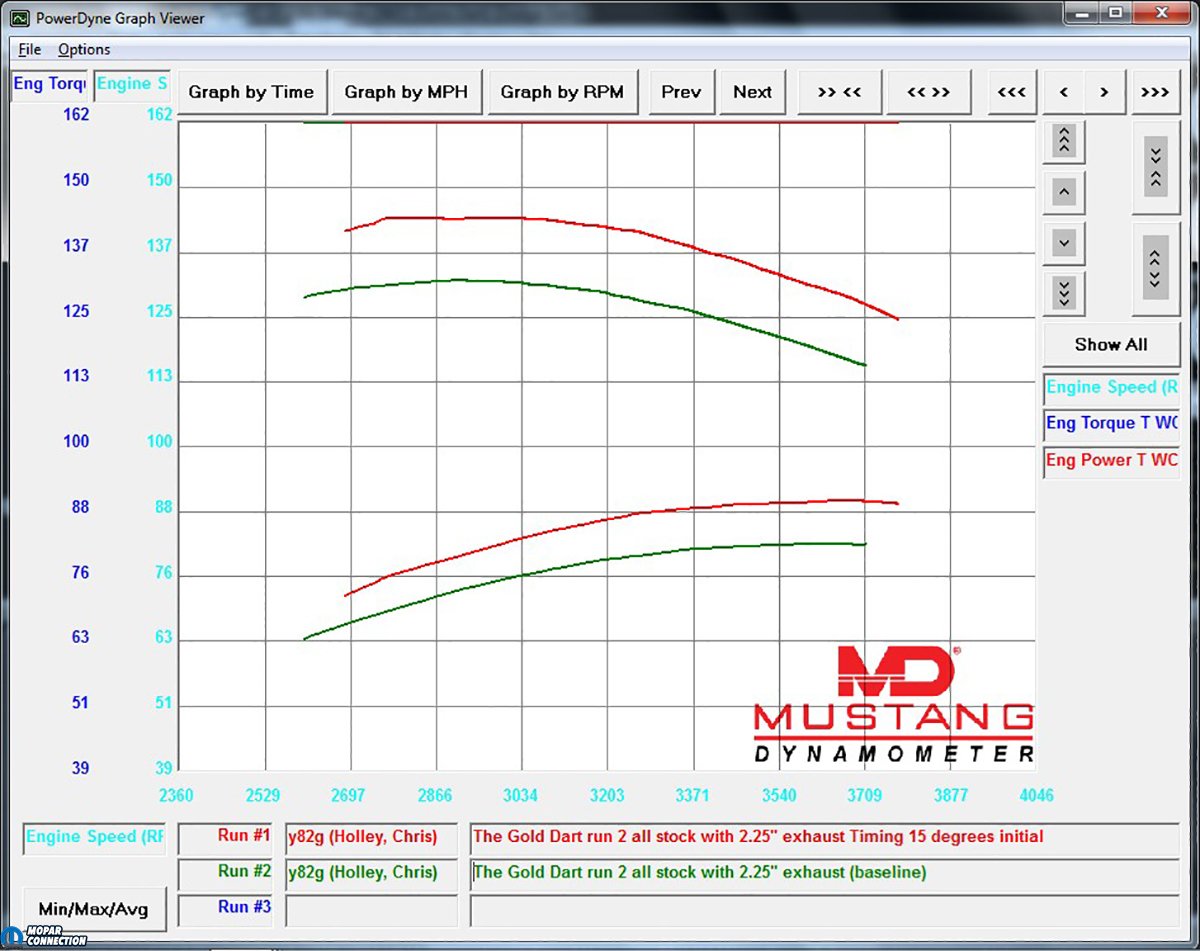

Previously we discussed how to find power by merely optimizing the distributor in More Power For Your Leaning Tower. In the story, we found the minimum initial timing and total ignition timing of Pennsylvania College of Technology’s (Penn College) 1967 Dodge Dart test vehicle. We ran the Dart through a series of three runs on a Mustang chassis dyno. In the end the peak torque was up 26 lb/ft to 143 lb/ft at 2900 rpm, and the peak horsepower had increased 14 hp to 89 horsepower at 3600 rpm. Encouraged with the power modifications, we moved our focus to the economy aspects of distributor tuning.

To test the economy of distributor tuning, we would need a vehicle that could be driven on public roads, and the Penn College Dart was not licensed; therefore, an alternative vehicle was required. We did not have to look far as the author owns a 1975 Dodge Dart with a similar 225 slant six combination.

Above: Pennsylvania College’s 1967 Dart and our 1975 Dart both with Slant Six motors.

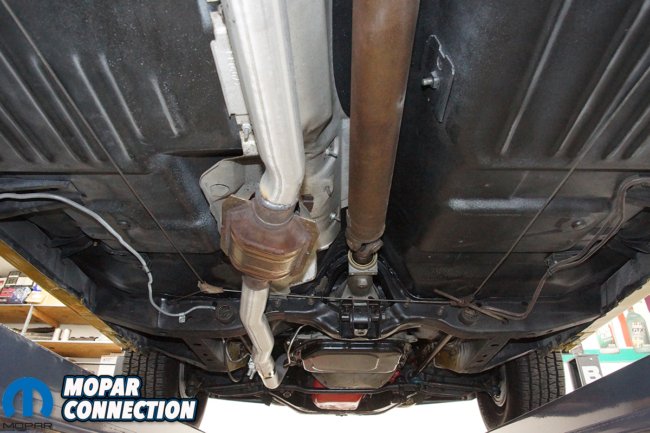

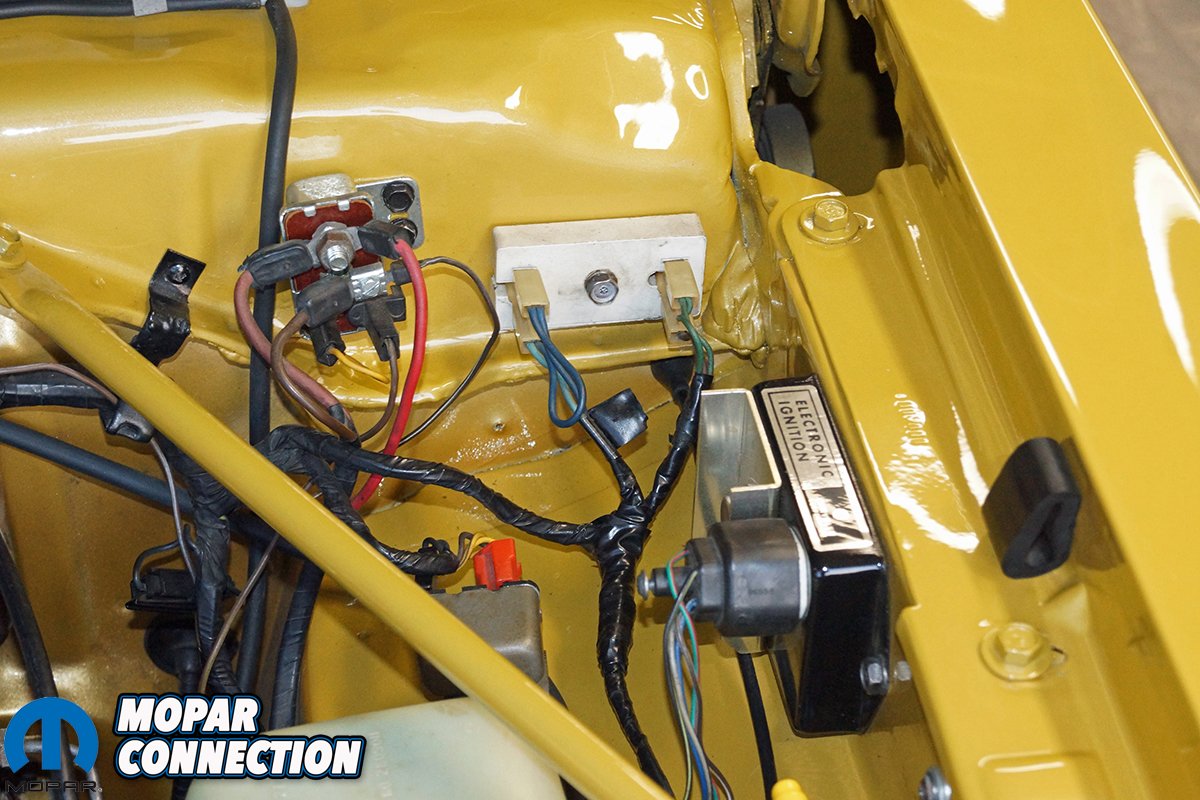

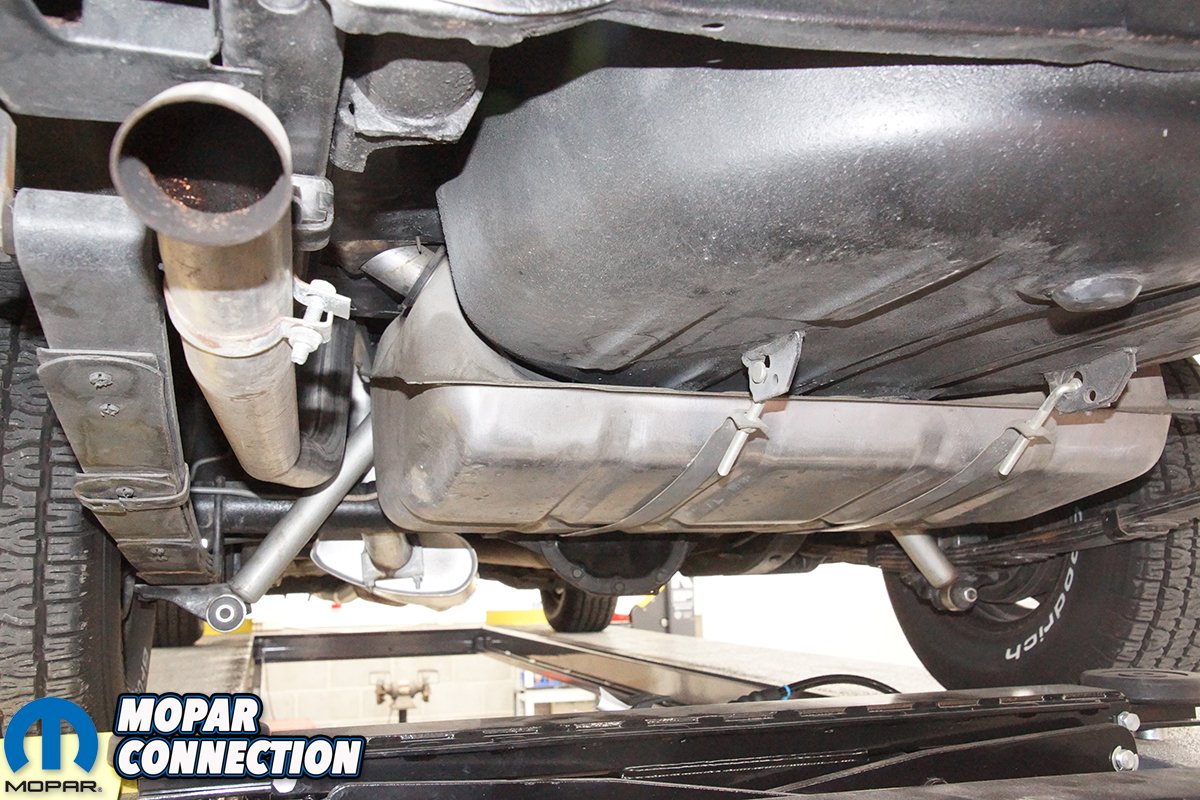

The slant six was gone through in 2011, and has accumulated less than 9,500 miles since the rebuild. The engine is 100% stock; it has the factory standard bore, an 8.4:1 compression ratio, the factory rods, pistons, crankshaft, camshaft, and the cylinder head was rebuilt to factory specs. The carburetor is a Holley model 1945. The ignition is a factory electronic ignition with a dual-ballast resistor and 5-pin ignition module. A single deviation from a stock condition exists. The exhaust has been replaced with an Accurate Exhaust 2.25” system run from the exhaust manifold to the exhaust tip at the rear bumper. There is a factory replacement (monolith style) oxidation catalytic converter installed in the exhaust.

Before any dyno evaluations or distributor modifications could begin, we had to confirm the harmonic balancer mark truly indicated top dead center (TDC). It turns out our balancer, although the 43-year-old original, was in perfect shape. We performed a quick once over of the Dart, and then we executed three baseline runs on the Penn College Mustang chassis dyno that all were within 1% of each other. The baseline runs provided a peak torque of 125 lb/ft at 2700 rpm and a horsepower peak of 77 hp.

Top: The test mule, our 1975 Dodge Dart with a 225 Slant Six motor. Bottom Left: While the engine of the 1975 Dart remained stock, the exhaust was enhanced with 2 ¼” pipe from Accurate Exhaust. Bottom Right: To mimic the factory exhaust, a catalytic converter was added to the exhaust.

After the dyno tests, we determined the minimum initial timing that the slant six desired. This engine was quite content with 15° before TDC (BDTC) initial ignition timing. We established that the 1975 225 preferred 33° of total timing, and the distributor had way too much centrifugal advance built into it, which required the distributor to be pulled from the 225 and proceeded with our modifications to limit the centrifugal advance to 18°.

During the process of the mods to the distributor, we installed the same governor advance weight springs that proved most successful in our Mopar Power For Your Leaning Tower. After the makeover of the distributor, and it was reinstalled. We performed several tests on chassis dyno, and although the numbers were encouraging, we felt there was more to be found. We ended up making several spring changes, and we discovered that not only did this lower compression engine want more total timing, but also it wanted it much earlier.

Above Left: The slant six received new bearings, rings, and gaskets in 2011, and has less than 9,500 miles since the refresh. Above Right: The ignition is a factory electronic ignition with a dual-ballast resistor and 5-pin ignition module.

The slant six’s advance started coming in at 1750 rpm, and the total 18° was in by 3000 rpm. The peak torque was up 16 lb/ft to 141 lb/ft at 2700 rpm, and the peak horsepower jumped up 12 hp to 89 horsepower at 3600 rpm. The average torque was up 10.70%, and the horsepower average rose up 11.97% over the baseline. Happy with the results, we changed focus to our economy part of our distributor testing.

The speedometer readings were critical to our testing because the odometer would be monitored for the fuel mileage. To certify that the mileage improvements were valid, the speedometer had to be tested to establish the percentage of difference between the Dart’s instrument cluster speedometer gauge reading and the actual road speed. The Dart was ran on the chassis dynamometer, and speedometer tests were run from 30 mph to 70 mph in ten mph increments. If the speedometer was off by 5% or more through all the speeds, the transmission’s speedometer cable pinion gear would require a replacement with a different sized (tooth count) pinion gear that would provide a more accurate speedometer gauge reading.

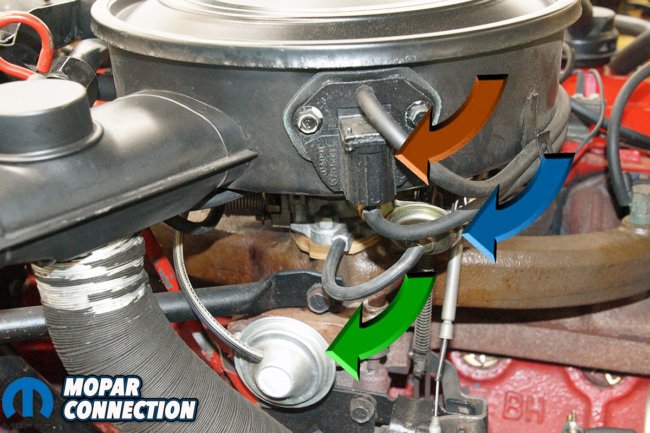

Top: As noted on the display of the timing light, the slant was very happy with 15° initial timing. Bottom Left: This is an Orifice Spark Advance Control (OSAC) valve. The OSAC valve was used in the 1970s to delay the distributor’s vacuum advance for about 15 seconds. This OSAC has been “gutted” and now no longer has any function other than to look stock. Bottom Right: The previously mentioned OSAC valve delayed vacuum to the vacuum canister on the distributor in an attempt to control oxides of nitrogen (NOx) (red arrow). Additional emission components found on the 1975 slant are the choke pull-off and the exhaust gas recirculation (EGR) valve. The choke pull-off valve keeps the choke from closing too much when the vacuum drops down as the engine rpm increases (blue arrow). The EGR valve also attempts to control NOx by leaking a small portion of exhaust into the incoming fresh air charge, thus reducing the cylinder temperatures and controlling NOx (green arrow).

During the restoration of the Dart, the best speedometer cable pinion gear had been selected to match the 2.73:1 gears paired with the 225/70R14 tires. It provided a 2.07% variance (speedometer was slower than the actual speed) through the 30-70 mph range. The 10-20 mph range was excluded from the variance measurement due to common excessive low speed inaccuracies on older Mopars (Table 1).

After completing the speedometer tests, we moved to the vacuum advance timing. We dialed in the ignition timing for wide-open throttle (WOT) on the dyno, but on the street, the Dart may never see WOT (ok maybe 1% of the time). The other 99% of the time the engine operation will occur under conditions where the throttle plate is less than wide-open.

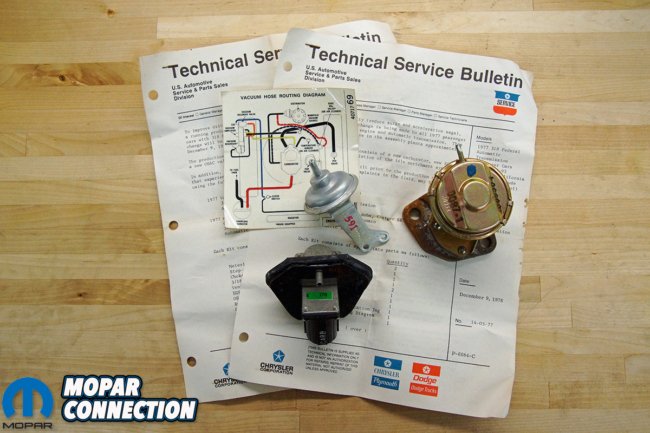

Top Left: In an attempt to improve drivability of the emissions laden 1970s Chrysler products, several technical service bulletins (TSB) were issued in regards to the OSAC valve, the choke pull-off, and the EGR valve. Top Right: The 1970s manufacturers over utilized vacuum for most of the emissions components. We used the capped port for our vacuum gauge. Bottom: The Dart spent long hours on the dyno.

When the engine is cruising the vacuum is high, the air-fuel ratio is lean, which requires that the initiation of the spark must occur substantially early (46°-53° BTDC) to ignite the much slower burning fuel to complete the combustion process by about 15° after TDC (ATDC). If the engine is run under normal stop and go driving without the vacuum advance connected, the unburned fuel from the incomplete combustion will result in carbon build up on the piston tops and in the combustion chambers.

The unburned fuel will also wash past the rings, which will result in cylinder wall and ring wear leading to oil burning and oil dilution that will decrease the bearing, crankshaft, and camshaft life. The unburned fuel will also make its way through the exhaust, leading to increased tailpipe emissions coupled with poor fuel economy. Lastly, high exhaust gas temperatures (EGT) (due to the late combustion process blowing out into the exhaust) could burn exhaust valves, and the high EGTs could increase the operating temperature of the coolant.

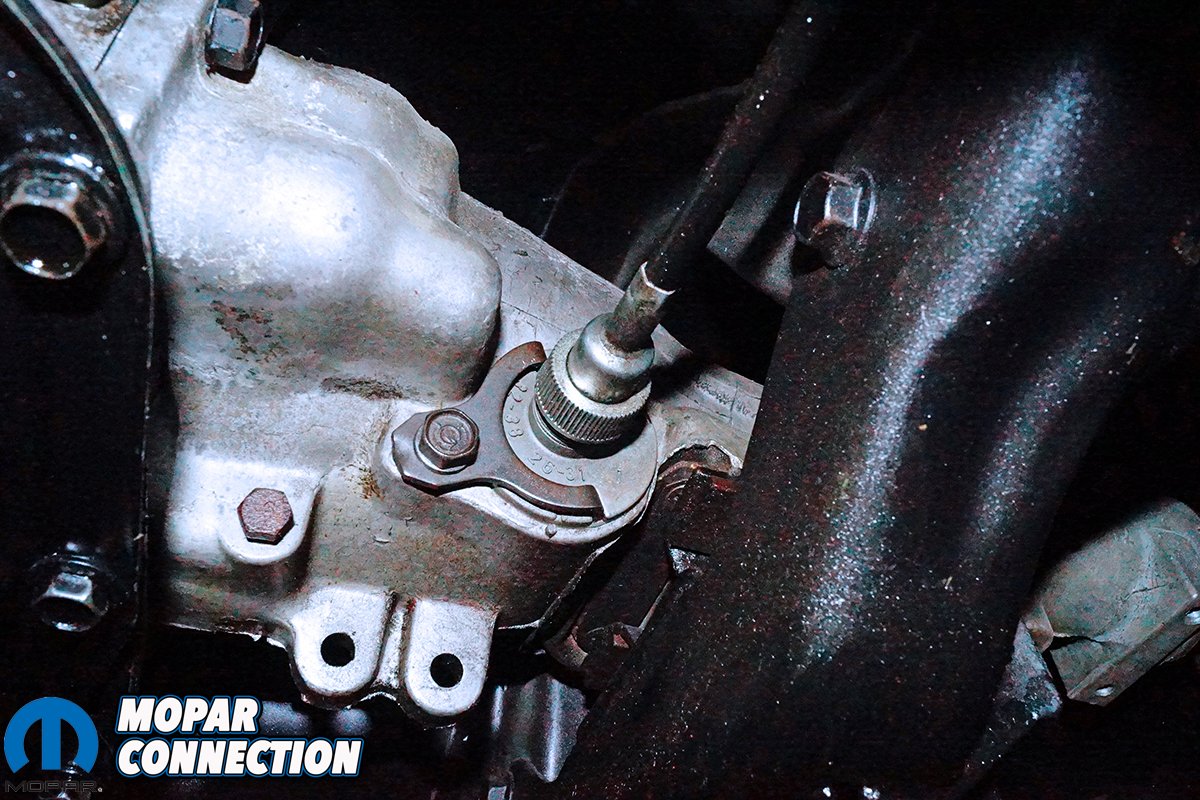

Top: Determining the correct gear to use can be aided by a factory shop manual (FSM) but since all of the older vehicles came with bias-ply tires and now likely run on radial tires it still might have a slight variance. Bottom Left: If the variance had been significantly off, we would have had to replace the speedometer pinion gear in the transmission with a pinion gear that had a different tooth-count. Bottom Right: The speedometer’s odometer was used for mileage calculations, and it was off by 2.07%. Included in this table are the air-fuel ratios while cruising at each 10 mph increment.

When it comes to vacuum advance canisters, there are two factors to consider. The first is the advance rate, and the second is the advance limit. If the engine is content with the total advance (advance limit) applied during high vacuum, light-load applications, but detonates at a transitional point from light-throttle to part-throttle, the advance rate needs to be slowed down.

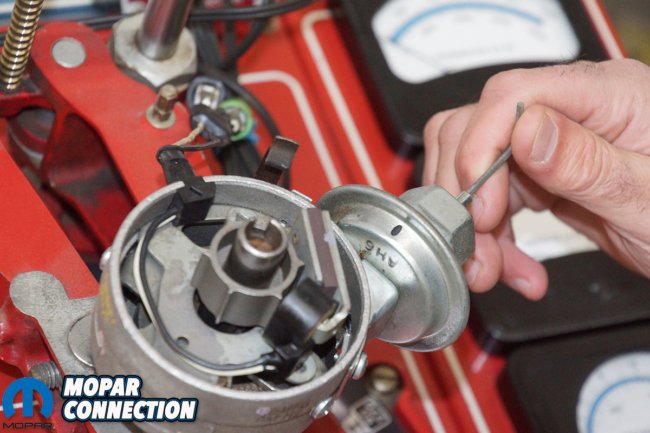

This can be achieved by removing the vacuum hose at the canister and inserting a 3/32” Allen wrench into the nipple of the canister. A simple turn of the wrench counter-clockwise (CCW) will slow the advance rate or equally, a turn clockwise (CW) will speed up the advance rate. On the other hand, if the engine detonates in light-load applications, the advance limit is too great, and a vacuum canister with less advance must be installed. In most cases, the advance rate will be the factor that needs attention.

Top Left: To dial in the distributor for peak performance, a quality dial-back timing light was a necessity. Top Right: The baseline centrifugal advance curve is represented in blue on the graph. The modified curve represented in red was faster and as a result provided much more torque throughout the entire rpm curve. Bottom Left: Our vacuum advance canister has 11R listed on the arm, and that translates into 22° of advance measured at the crankshaft which turned out to be a bit much. Bottom Right: We settled on an 8.5R vacuum canister, which should have provided 17° of advance.

With the initial timing and the centrifugal advance providing a total timing of 33° BTDC, we attached a vacuum gauge to a manifold vacuum port on the slant six, grabbed a pad of paper and a pencil, and set out to navigate the beautiful scenery of central PA while benchmarking the vacuum advance requirements of the slant six.

While the slant responded well to the initial timing and the WOT ignition total timing, the factory Chrysler vacuum canister did not function as expected with the initial light-throttle test drives. The advance was too abundant, and there was a persistent light-throttle rattle (detonation) at about 17” of vacuum. The advance limit was too great, so a new-old stock (NOS) factory vacuum canister (part #3874082) with less advance was located and installed.

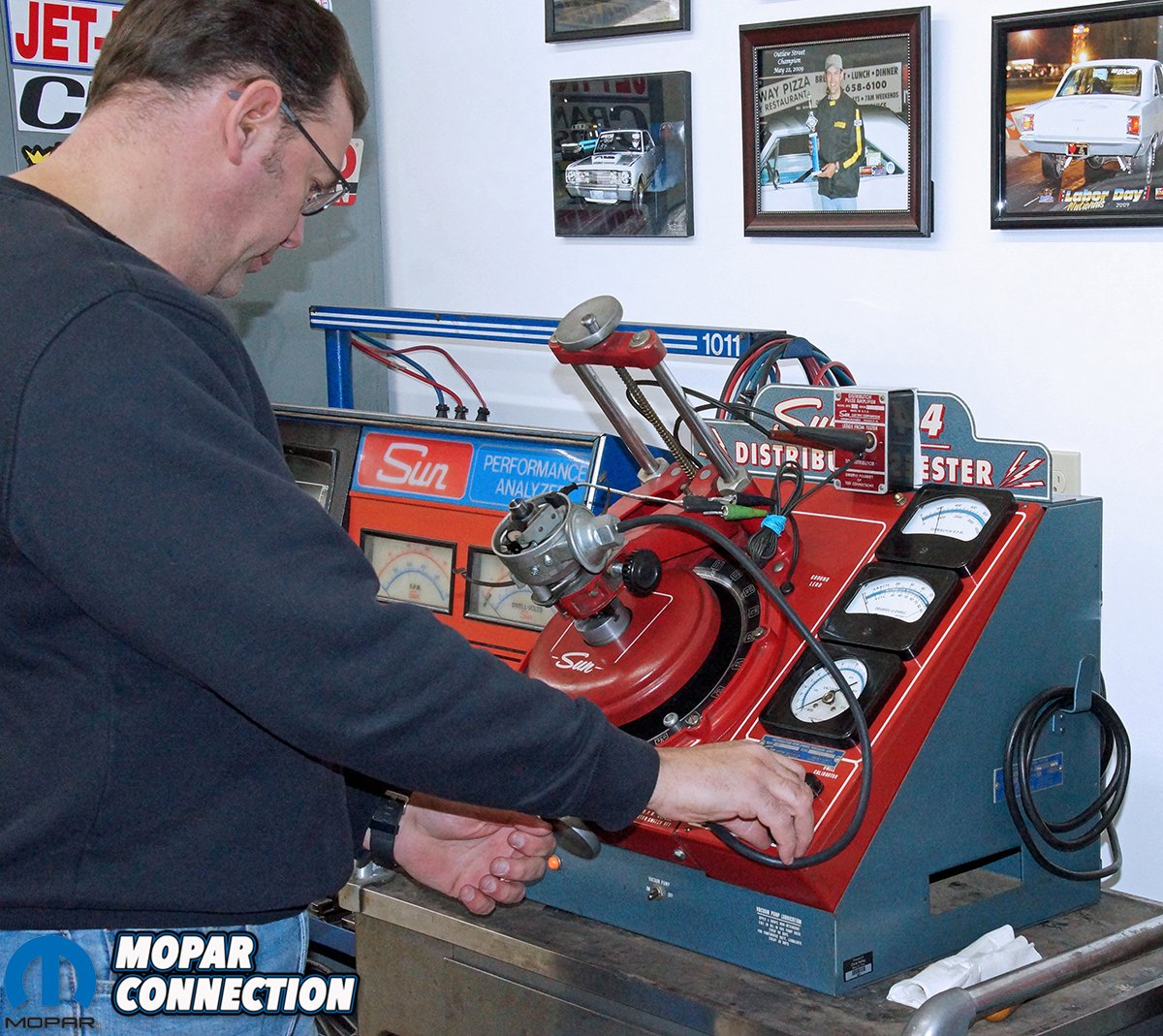

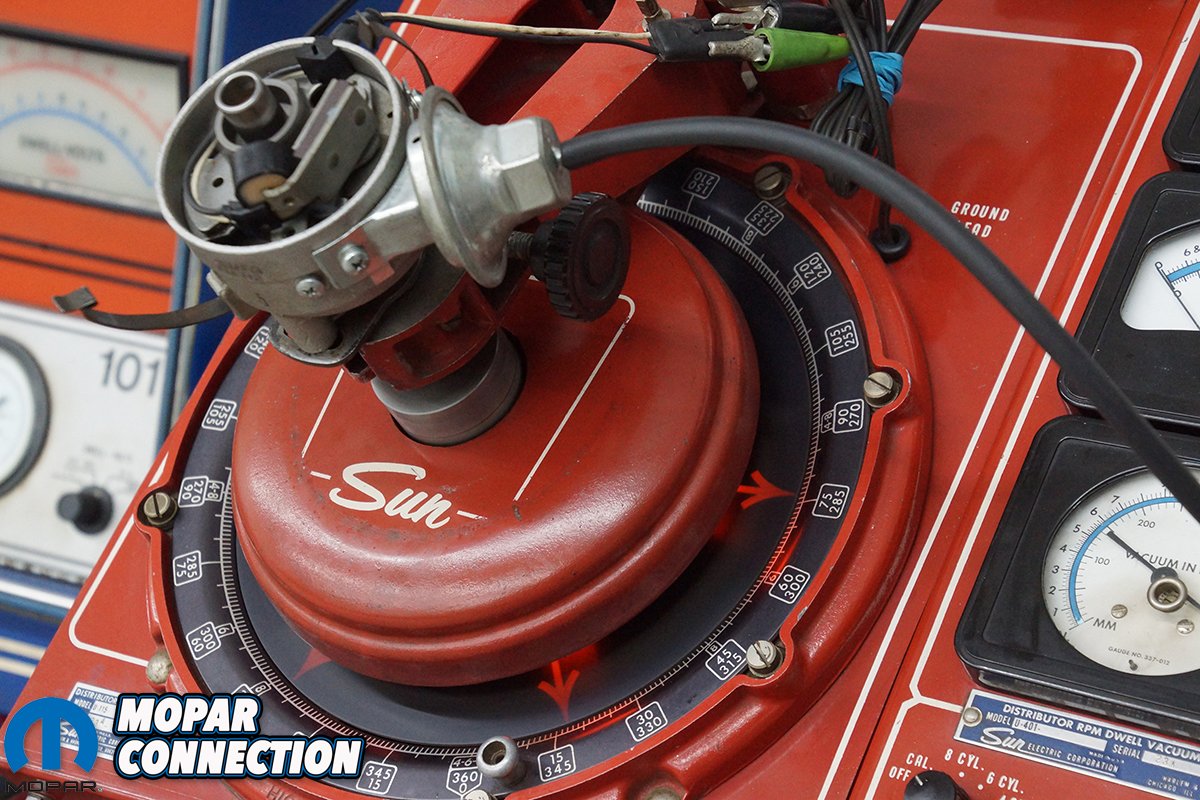

Top: We put the Sun 404 distributor machine to work on the vacuum advance modifications of the distributor. Bottom Left: With the distributor running at 500 rpm crankshaft speed, we had zero advance as noted by the arrow pointing at the 4-6-8 0/360° mark to the left of the knob on the 360° ring on the face of the Sun machine. Bottom Right: At about 1750 rpm crankshaft speed, the centrifugal advance started advancing the timing and by 3000 rpm all the advance was added. The centrifugal advance was 9° at the distributor or 18° at the crankshaft.

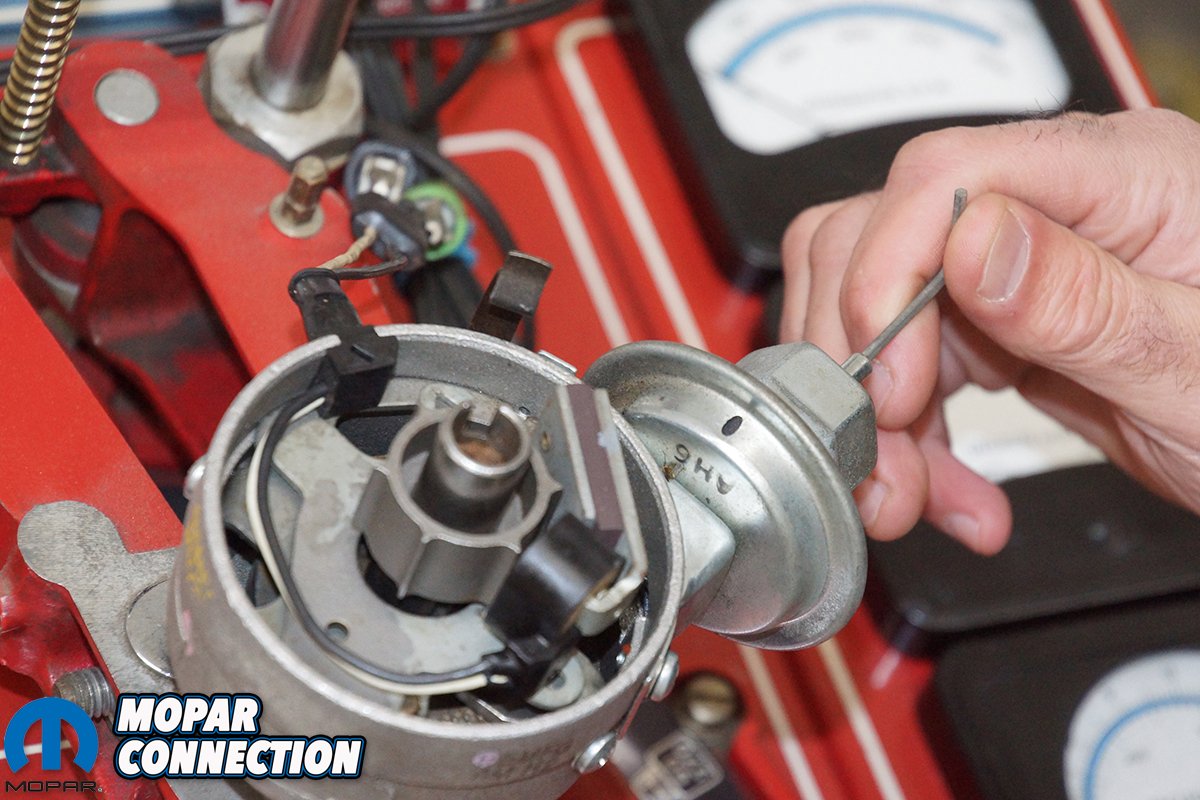

The new canister was designed to add 0.5° – 2.5° advance at the distributor (multiply by two to get the crank degrees) at 7.0” hg and add 7.0° – 10.0° advance at the distributor at 11.5” hg. The distributor performed as advertised when checked on our Sun 404 distributor machine. With the new vacuum canister installed and the distributor slipped back into the 225, a series of 30 to 70 mph drives on roads varying from level to fairly graded (up to 7%) was performed. Whenever the faintest pinging was heard, the vacuum gauge reading was noted. After several days of testing and with a pile of notes, we parked the Dart in the garage, and the vacuum advance adjustments proceeded.

In our case, the advance rate was too aggressive. To tame the advance rate, we removed the vacuum hose from the distributor and inserted a 3/32” Allen wrench in the vacuum canister nipple. The Allen wrench was rotated two full turns CCW, which pulled the advance rate from 11.5” hg to 14.0” hg. Another series of drives resulted in much better part-throttle performance with no audible ring of detonation.

Above Left: The 3/32 Allen wrench was rotated counter clockwise (CCW) to slow the advance rate down. Conversely, rotating the Allen wrench clockwise (CW) sped up the advance rate. Above Right: We adjusted the advance rate from 11.5” hg to 14.0” hg before settling on 13” hg, which provided the best vacuum advance rate without a hint of detonation.

We wanted to see if we could get by with a more aggressive advance rate by adjusting the canister CW one turn, which moved the advance rate to 12.0” hg. The 12.0” resulted in very slight pinging in the midrange rpm under part-throttle. To counteract the pinging, we rotated the Allen wrench about one half of a turn CCW to move the advance rate to 13.0” hg. All of our subsequent drives provided us with a very contented slant six that ran flawlessly. Our total timing, including the vacuum advance, was 51° (15° initial, 18° centrifugal advance, 18° vacuum advance) (Table 2).

Finally, we had come to the part where we could evaluate the economy of the slant six while still monitoring for any detonation concerns. The distributor modifications were actually completed almost three years ago, thus there has been plenty of fuel run through the engine, and there is sufficient data from which to refer. We have data that includes 93 tank fills and almost 9,500 miles to review (before and after the modifications). Before any adjustments to the distributor, the Dart averaged 15.8 mpg just as advertised in 1975. However, the 1975 mpg of 15.8 was calculated with “real” unleaded fuel (E0 – no Ethanol (alcohol)) opposed to the E10 (up to 10% Ethanol) that the slant six must consume today.

Top Left: After adjusting the vacuum advance to the optimum point of tune, we decided to give the entire ignition a once over. We screwed in a fresh set of NGK 6630 plugs, gapped at .035”. These plugs are for the tapered seats. If the head has the drool tubes, a different NGK plug will be needed. Top Right: After approximately 3500 miles, the plugs look decent. Bottom: All the mileage factoring was done based upon the actual speedometer odometer readings divided by the fuel consumed.

The Environmental Protection Agency states E10 lowers fuel mileage by only 3% based upon the stoichiometric differences of pure gasoline and Ethanol. A quick check of the internet found claims of much higher numbers, up to 10% or more, but for our testing the 3% mpg loss will be accepted. Technically, the Dart was getting slightly better fuel economy than the factory based upon the 3% mileage loss due to the E10 fuel. The pre-distributor modifications slant six was never a real pleasure to drive. It seemed that the right foot was continuously jabbing the throttle to maintain speed to keep up with traffic. The Dart felt slothful and pitiful, and it did not meet our performance or economy expectations.

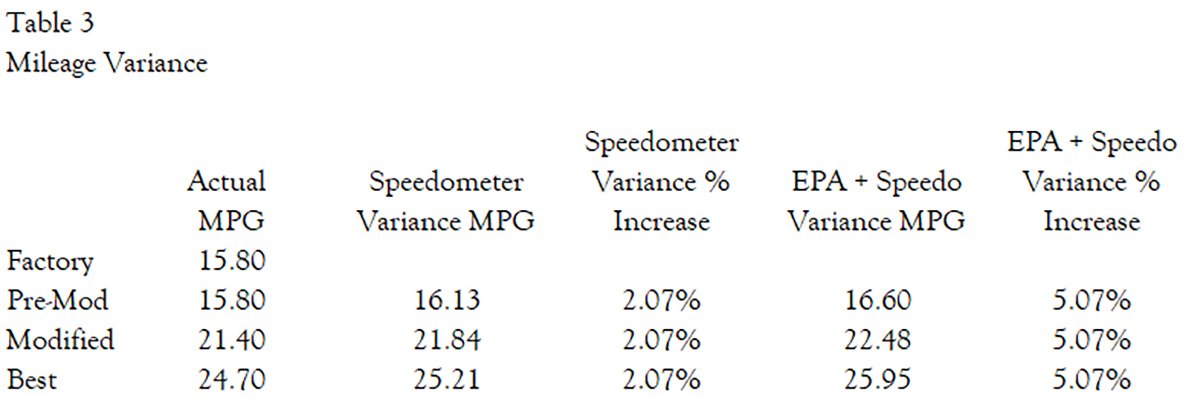

After the distributor modifications, including the vacuum canister, the mpg significantly improved. The mpg soared to an average of 21.4 mpg with a best mileage of 24.7 mpg based strictly upon miles traveled divided by fuel consumed (Table 3). We experienced a monstrous 26.17% increase over the factory mpg rating (15.8 mpg vs. 21.4 mpg). The added torque from the distributor mods makes the Dart a fun car to drive, and the added benefit of better fuel economy reduces the hit in the wallet.

Top: The mpg increased to an average of 21.4 mpg (not including the 2.07% speedometer variance or the additional 3.0% Environmental Protection Agency’s (EPA) offset for alcohol fuel) with a best mileage of 24.7 mpg based strictly upon miles traveled divided by fuel consumed. Bottom Left: The stock distributor tune provided subpar performance (green trace). The modifications to the distributor pepped up the slant six. The Dart went from a slug on the road to a spirted ride with the distributor power mods (red trace). Bottom Right: Even though the path to get the power out of the slant sixes was different, the results of the Penn College 1967 Dart (green trace) and the 1975 Dart (red trace) are extremely similar. Both slant sixes had an increase of torque and horsepower of about 15 to 20% over the stock distributor tune.

It is a bit of a stretch to say the slant six is now a lively mill, but the Dart easily keeps up with traffic. No longer is merging onto the interstate a white knuckled WOT acceleration affair. Now with just a moderate application of the throttle pedal, the slant six has the torque to merge into traffic. A tailpipe sniffer inspection (run on the chassis dyno) showed that the well-tuned slant six would pass the current Pennsylvania State emissions standards, but due to the Dart’s age, mileage usage per year, and antique status, it is exempt from emissions inspections.

With the inclusion of the vacuum advance, we have a sense of satisfaction and success, and the best result is to drive a responsive, fuel efficient, emissions compliant, smooth running Mopar. The slant is reactive to throttle application, starts with ease, and runs well. There are some cynics that will state all this time was wasted on a feeble 225, but the same testing could be employed on a 340 or 440 engine with an expectation that similar results would be obtained. With better drivability and a bump in fuel economy, you could get more enjoyment and pleasure from your Mopar. After the “dizziness” of all this information wears off, get to work on properly tuning the distributor, and let the good timing roll!