“Of course it is,” I laughed, holding the opened box in my hands. Topher McGinnis had managed to wholly restore and return the 3-speed wiper motor from our derelict 1970 Dodge Super Bee – which we’ve named “ZomBEE” – back within two months’ time. The irony that the first completed item of this seemingly never-ending project car was the wiper motor was not lost on me.

Squirreled away in a quiet corner of Gastonia, North Carolina, McGinnis has made a name for himself as The Headlight Motor Man within the Mopar community by painstakingly restoring a variety of oddities; electric headlight door motors, 6-way adjustable seat tracks, and of course, wiper motors (and other things – I’ve found it’s easier just to ask, “Hey Topher. Ever messed with one of these before?” The answer is usually “You bet!”).

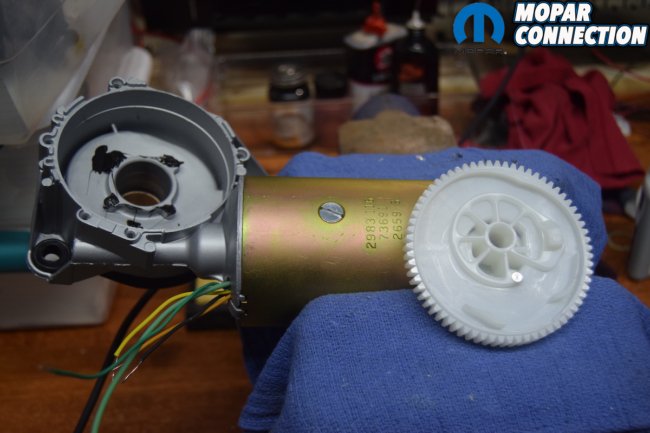

Above left: While definitely not the worst that Topher McGinnis has seen, the 3-speed wiper motor from “ZomBEE” definitely needed a full restoration. This is how it arrived to Topher. Above right: Into the vise for disassembly and de-soldering the switch plate wires.

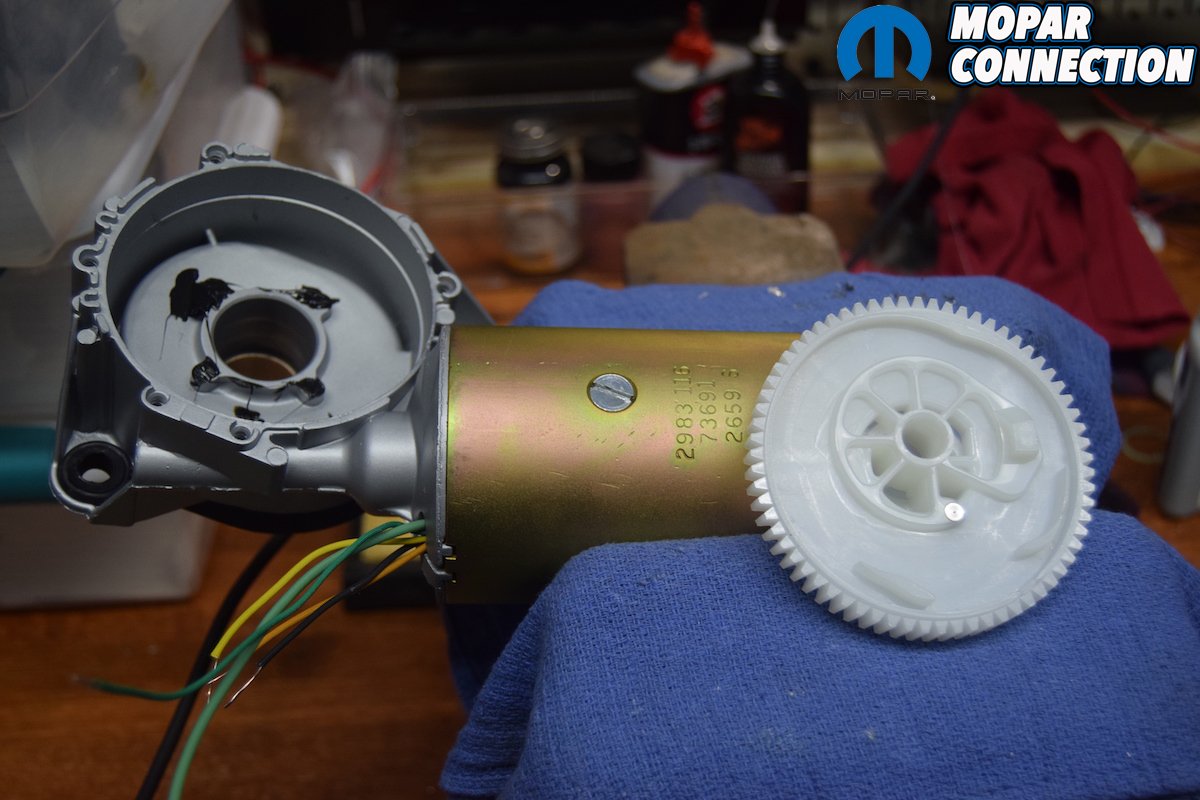

Above left: With the switch plate freed, Topher was able to get a better look at the condition of the gears. Although they weren’t cracked or broken, modern plastics are more durable and wear-resistant, so replacing them was on the to-do list. Above right: Now the barrel can be taken apart.

Topher just so happens to be a friend of Dave Chamberlain of All Classics Restorations, who’s currently neck deep in replacing a fair percentage of ZomBEE’s sheetmetal before straightening the car and painting it in Chrysler Ceramic Blue. So with Dave’s blessing, I happily sent off the wiper motor, half expecting it to vanish for most of the year. Nope. That sucker was back in my hands within a couple of months.

I chided Topher, saying “Hey man, don’t give the magazine any special treatment.” He replied, “There’s no special treatment. I just had a batch ready to go to the plater. You just made the cut in time.” And that’s really the catch. Getting these premium-option wiper motors looking Chrysler-correct requires re-plating armature barrel in factory dichromate zinc, giving it that greenish-gold hue that pops off of the firewall.

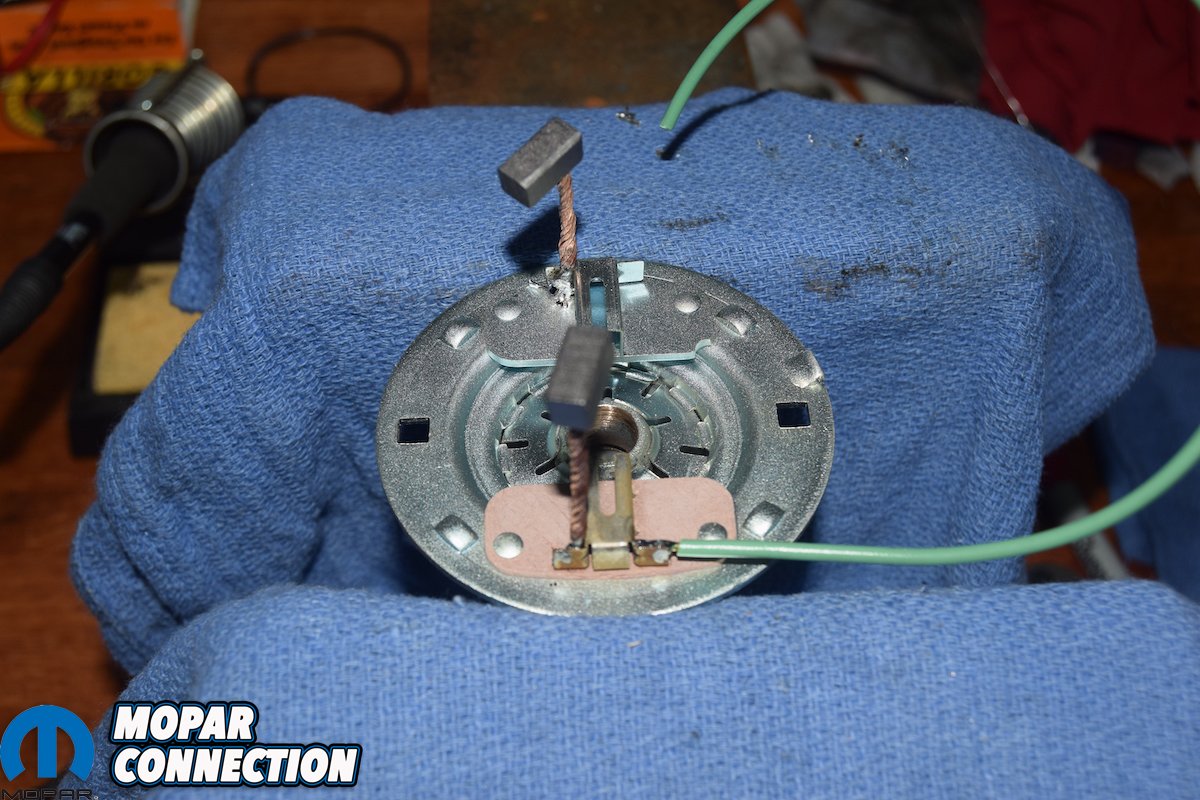

Above: With the barrel removed from the transmission, Topher can carefully remove the barrel cap and begin removing the armature.

Above: Every scrap of electronics from inside of our wiper motor was removed and looked over to evaluate the condition of the wiring, rotator and armature. The windings were cleaned and wrapped in new wire sheathes before re-installation.

The base trim-level Chryslers – as well as down-trimmed cars like Super Bees and Road Runners – typically came with a simple two-speed wiper motor, while higher-optioned models came with the 3-speed. A cursory search on eBay Motors showed that these wiper motors (in equally rough shape as ours) went for a few hundred dollars, so it was both unique that our ‘Bee came with one, and well-worth having Topher restore it.

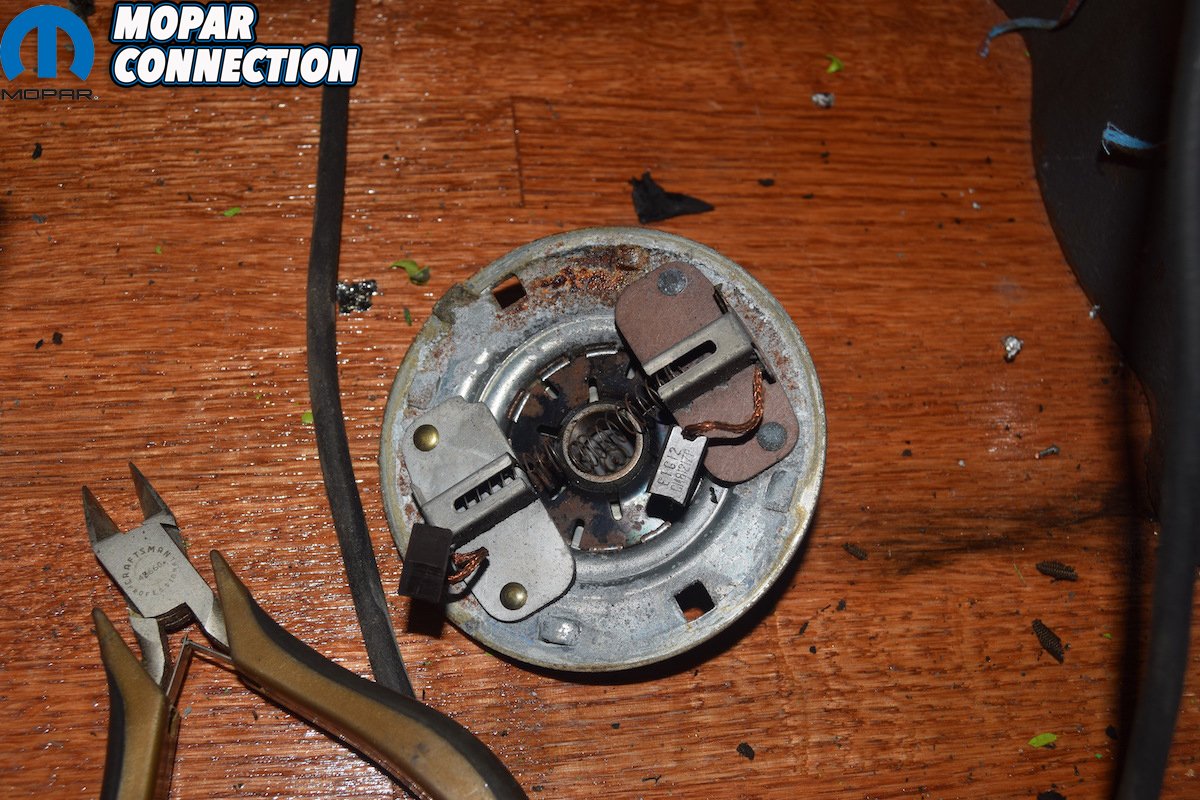

When our 3-speed wiper motor arrived, Topher noted that the armature barrel’s factory dichromate zinc plating had all but faded over its 50 years. Unprotected exposure to the elements corroded all the internal components. The rust on the rotator, cracked and/or completely non-existent shrink wrapping on the wires, and broken connections detailed why this motor wasn’t working.

Above left: As Topher noted before, our motor arrived just in time to join another batch of wiper motors he had in process. The barrel was sent through the bead blaster (using 80 grit glass beads to preserve details like the stampings). Above center: Once blasted, off they went to the plater. Above right: And no back from plating you can see how dichromate zinc plating is supposed to look when fresh.

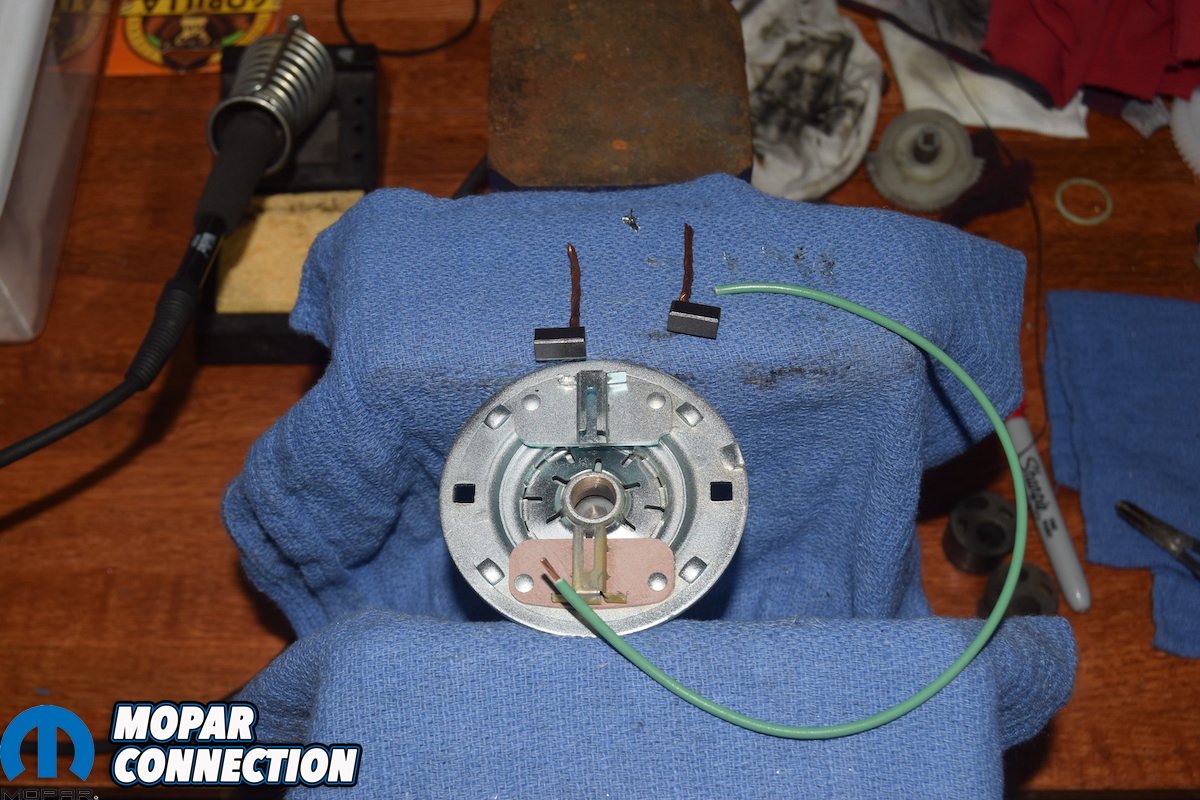

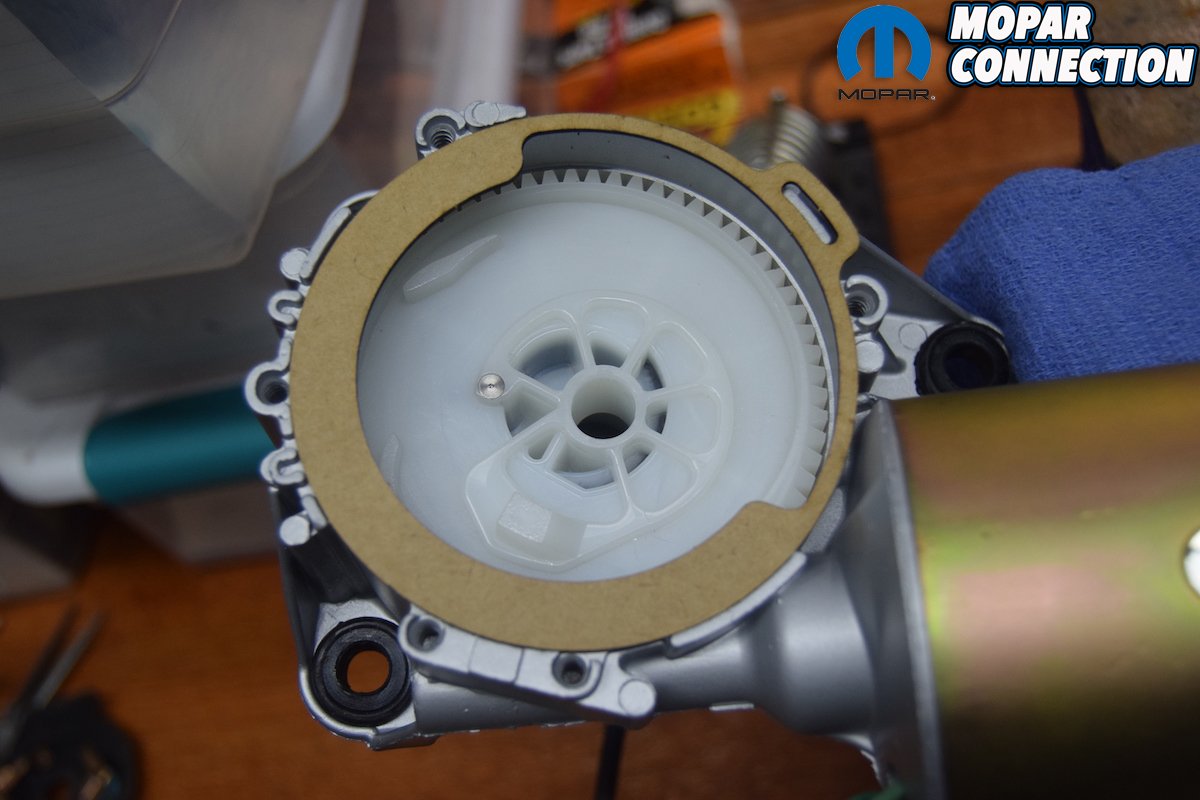

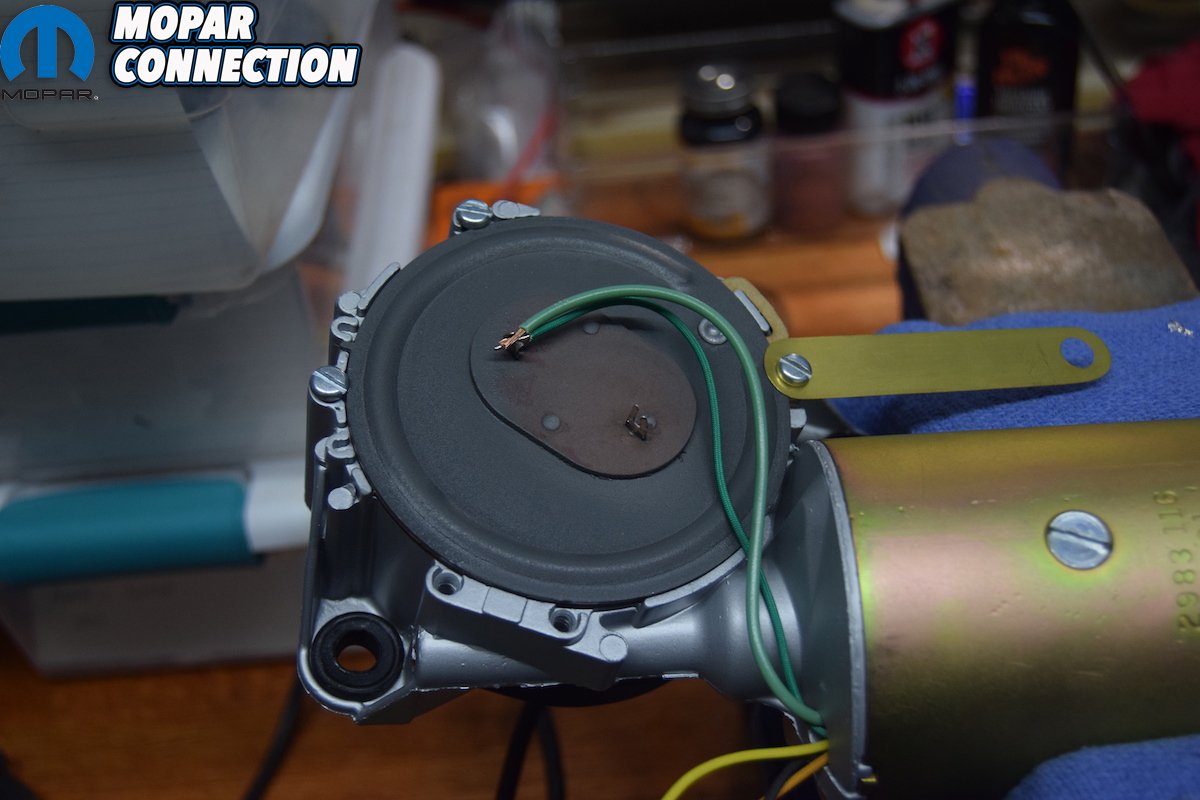

Above left: Here Topher has begun installing the new fields. New protective cardboard sleeves were slipped in between the armature base and the rotator before seating the barrel. Above right: New brushes and switch plate wire are installed.

Thankfully, the poor condition of my wiper motor was primarily cosmetic, saving Topher valuable time. Prior to replating armature’s barrel, it needed to be media blasted to bring it back to as-new, as was the end plate and motor plate. The motor body was also cleaned and glass bead blasted and replated to regain its as-new luster. New gears, gaskets, brushes and cardboard sleeves were ordered as well.

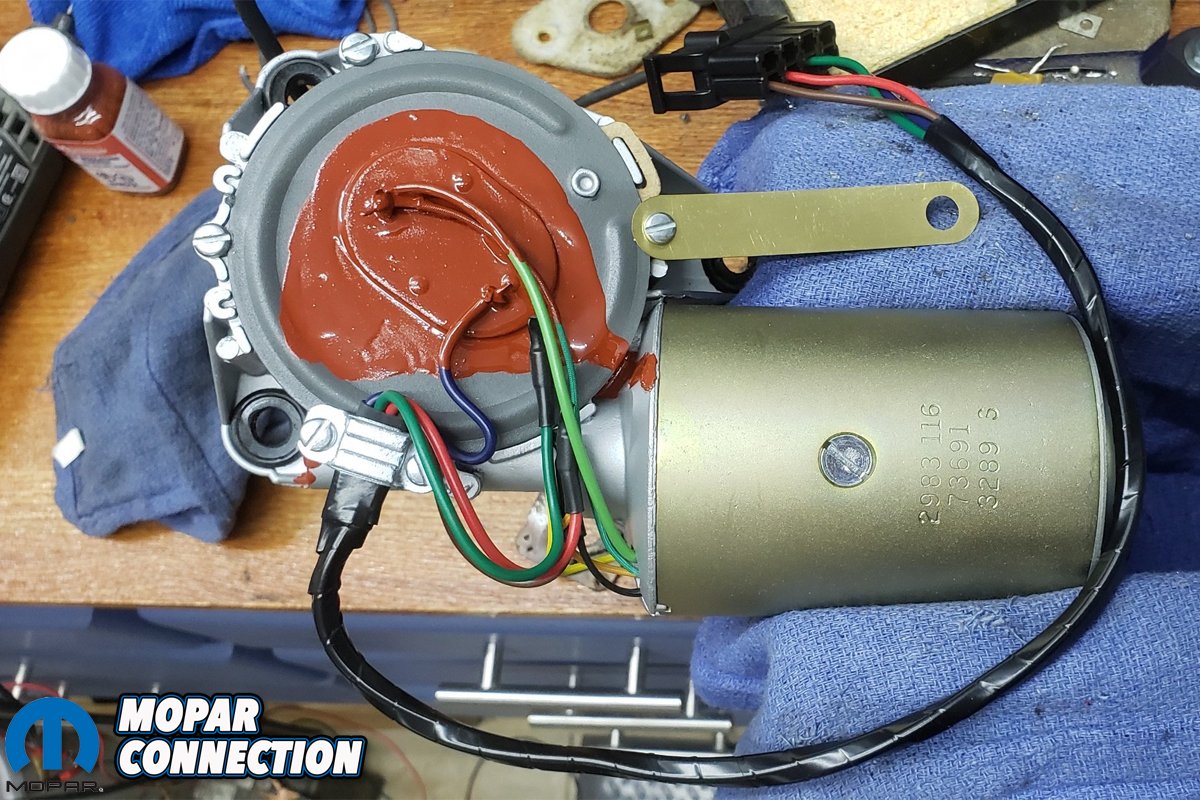

Next, the replated base plate was attached to the rotator. Then, the wire windings were cleaned and rewrapped in new sheathes. Topher began reassembling the wiper motor back to original condition using new brushes, brush springs, wire insulation, shrink caps, and gaskets. Following the factory process, Topher used both plastic shrink wrap and nylon sleeves to rewrap the wires. Even factory-correct shrink end caps were used to complete the wiring.

Above: Time for new rubber gaskets (for A and B-bodies, Topher uses from Steele Rubber. For E-Body motors he gets a new foam gasket from Detroit Muscle Technologies).

Above: The freshly plated in dichromate zinc armature barrel was polished to remove any blemishes before being reinstalled. With the brush plate and transmission installed, it was time to install the new gear.

With the armature fully assembled, Topher tightened down the two long screws that run the length of the barrel and thread into the aluminum motor body. Reassembling the motor drive went together rather effortlessly as he’s restored hundreds wiper motors over the years. With the head reinstalled with a new replacement worm gear and restored shaft, all of the components were properly greased and capped with a new switch plate gasket.

The switch plate was then rewired with each of the new wires soldered in their original factory locations. With both the armature and motor reassembled, Topher buttoned up the wiper motor, and installed a new OE-correct foam gasket for where the wiper motor mates to the firewall. Even when ZomBEE is complete this wiper motor is likely to be the most “correct” item in it. No doubt, Topher McGinnis, The Headlight Motor Man did an amazing job, and is worthy of all of the praise his career has earned him.

Above left: A new switch plate gasket from Detroit Muscle Technologies is next. Above right: Now the switch cam is installed.

Above left: Switch plate is re-installed. Above center and left: A new harness constructed using high-quality, color-matched wires ensuring zero breaks or cracks like our 50-year-old wiring.

Above left: Once completed, our new harness is installed. Above center: All of the new terminals are soldered on. Above right: Not wanting to reuse the cracked and broken plastic connector, a new Bill Evans connector was installed.

Above: The final step in the restoration of our 3-speed wiper motor was a liberal dollop of ochre-hued insulating varnish was applied. This keeps the soldered wire points from the elements.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by