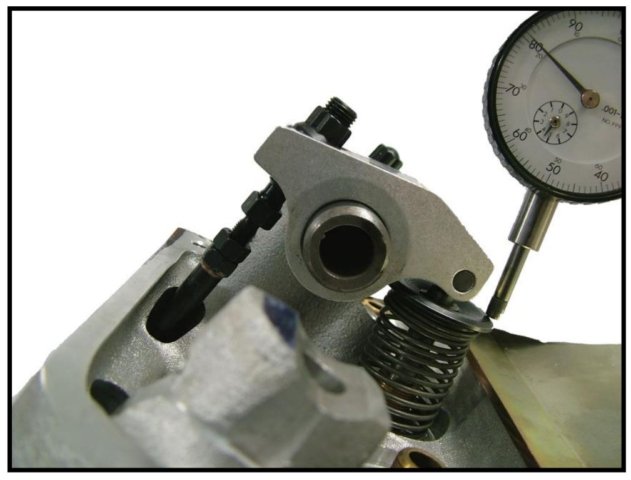

Valvetrain geometry need not be some mystical black art. Most of the magic comes from properly measuring pushrod length although, unfortunately, too many DIY engine builders skip this critical step.

Valvetrain geometry need not be some mystical black art. Most of the magic comes from properly measuring pushrod length although, unfortunately, too many DIY engine builders skip this critical step.

Hughes Engines has heard a call or two from an unhappy customer with a tad too much tippity-tap coming from somewhere up top in their fresh engine. Luckily, it’s avoidable as long as one understands the basics of how an aftermarket cam gets ground and how that grind affects downstream components.

Dave Hughes, never one to mince words, put it oh-so-succinctly in a Wedge World tech tip and it’s worth mentioning that Hughes has a pushrod length checking section in their catalog for this very reason.

Dave Hughes, never one to mince words, put it oh-so-succinctly in a Wedge World tech tip and it’s worth mentioning that Hughes has a pushrod length checking section in their catalog for this very reason.

“My rockers (pushrods or lifters) are rattling since I put in a new higher lift cam.”

Cams with higher lift DO NOT HAVE A HIGHER LIFT. They have a SMALLER BACE CIRCLE and since the lift is the difference between the base circle and the top of the lobe the lifter drops down in its bore. The lower lifter position means you now have greater (a lot greater) clearance in the valve train (that means noise to the chatter). This extra clearance must be made up with longer or adjustable pushrods, adjustable rockers, or both. We usually have both available. Pick up the phone and give us a call!!