A type of point-contact transistor was invented in the late 1940s, and a low-amperage point-operated transistorized ignition was an option on some General Motors vehicles in the early 1960s. In 1968, Fiat evaluated electronic ignition on limited models, and Jaguar followed in 1971 with limited success.

Above: Chrysler’s two-page advertisement in Life Magazine in 1972 stated the benefits of an electronic ignition. The new ignition had plenty of benefits for the customer and no drawbacks, and it became an industry-leading design.

Still, electronic ignitions were not mass-produced until 1972, when Chrysler introduced them in most of its cars and a few pickup truck models. The electronic ignition system was a significant advancement over traditional breaker points ignition systems, improving the ignition’s reliability and efficiency.

Electronic ignition systems replaced mechanical breaker points with solid-state electronic components, considerably enhancing the ignition system’s consistency. Unlike points, electronic components were less prone to wear and degradation over time, leading to more stable engine operation and improved driveability.

Above: The electronic ignition relied on an ignition module that housed a transistor. The ignition dwell was consistent, and the electronic ignition’s reliability reduced tune-up frequencies and maintenance costs.

Customers benefited from the more precise control of ignition timing afforded by electronic ignition. Proper ignition timing resulted in better engine combustion efficiency, improved fuel economy, reduced emissions, and enhanced engine performance.

One of the main advantages of electronic ignition was the reduction in maintenance requirements. A traditional points system required regular adjustments and component replacement to ensure proper ignition timing. Electronic ignition eliminated the need for frequent adjustments, reducing maintenance time and costs.

Above Left: Chrysler ignition modules have remained relatively unchanged in appearance since its introduction. The unit in the foreground is an original 1970s module, while the back row consists of a pair of Mopar Performance “Chrome boxes” and an “Orange box.” Above Right: The late-model (left) ignition modules use a 4-pin module and a single ballast resistor. The original units (right) had a 5-pin design and a dual ballast resistor.

The electronic ignition systems were more durable in harsh operating conditions. They were less susceptible to wear caused by engine vibrations and contamination, leading to a longer lifespan for the ignition components.

The July 1972 Life Magazine advertisement stated that “electronic ignition systems often performed better during cold weather, or any weather starts.” They offered consistent and reliable spark delivery, which was particularly beneficial in colder climates or after extended periods of engine inactivity. A consistent spark was the trademark of the Chrysler electronic ignition system.

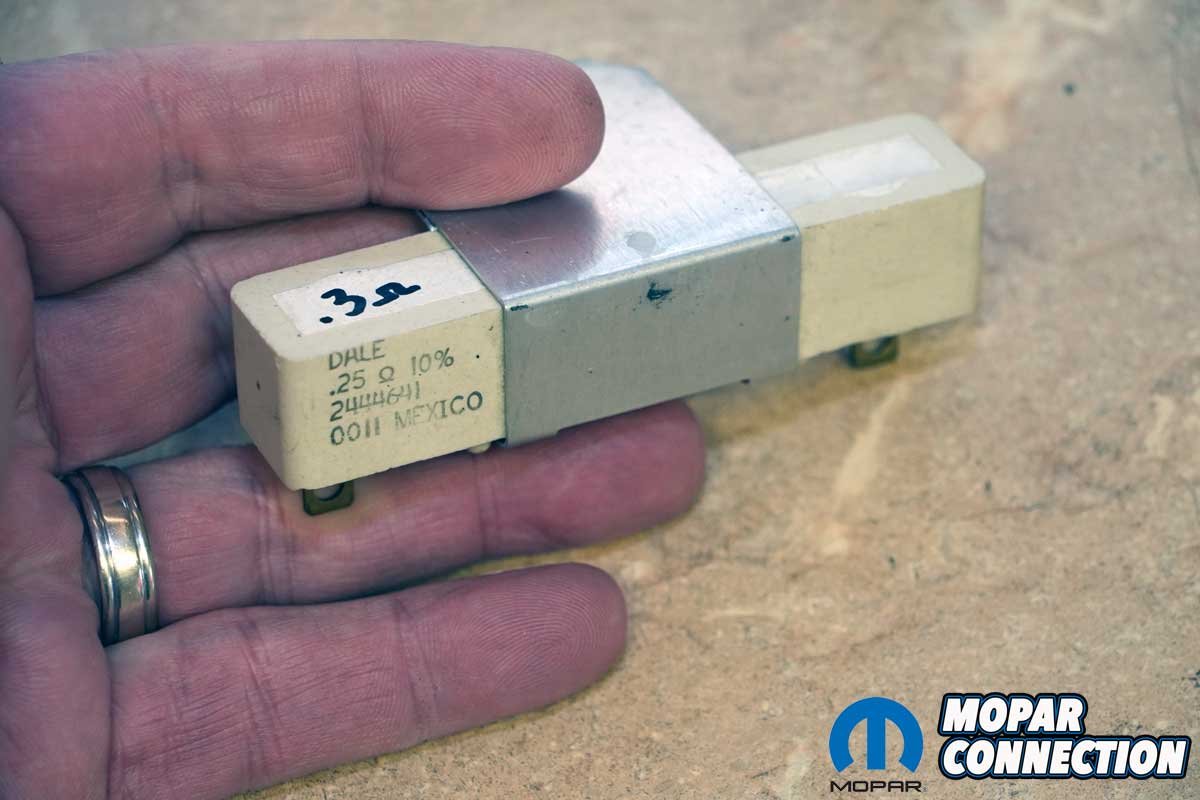

Above Left: Single ballast resistors come in several different appearances but perform the same task. The ballast resistor in a Mopar limits the amperage through the coil while the engine is running, thereby extending the life of the coil. With a 4-pin module, when the ignition key is in the start position, the total current is applied (ballast bypassed) to the coil and increases the voltage to the spark plugs. Above Right: Mopar electronic ignition systems with a stock coil should use a ballast with 1.2 – 1.4 ohms resistance, but race coils can work with higher amperage and a ballast with a lower resistance value. The ballast resistor in the photo has a resistance value of 0.3 ohms.

Chrysler’s adoption of electronic ignition in 1972 was part of an industry-wide trend toward more reliable and efficient ignition systems. Due to its significant advantages over traditional points-based ignition systems, the technology eventually became standard in all vehicles among all manufacturers.

Above: In 2018, we picked up a 1967 Dodge Dart GT with a 273. Prior to our purchase, the breaker-point ignition had been swapped to a mid-1970s factory ignition, which included a 5-pin ignition module, a dual ballast resistor, a distributor, and all the necessary wiring.

Because of the advantages of electronic ignitions, racers, and street enthusiasts began removing their points distributors and installing factory electronic distributors, adding a dual-ballast resistor, a factory 5-pin ignition module, and related wiring. The demand for performance-related Mopar electronic ignition parts expanded from those early days. Mopar and several aftermarket companies noted the demand for electronic ignition and developed it into the system we recognize today.

Above Left: Mopar Performance offers a complete 4-pin electronic ignition kit that allows every component to be swapped from a point ignition. Above Right: Mancini Racing has several kits. Some of the kits include a coil and plug wires.

Mopar, Mancini Racing, PROFORM Race Series, and FireCore 50 have systems with a distributor, single ballast resistor, and a 4-pin ignition module. Some even added a coil and spark plug wires to the package. Most distributors come with a performance advance curve, but again, there are plenty of aftermarket providers with different spring rates to tailor the curve to a specific engine’s needs.

Above Left: PROFORM has a Race Series ignition system that will fit the needs of most street or race enthusiasts. Above Right: FireCore 50 has a kit that includes an FBO ignition module with a rev-limiter control.

If you have yet to transition to electronic ignition (51 years later) and this article sparked your imagination, check out Mancini Racing for its custom kits designed for slant sixes, small blocks, and big blocks. Mancini also carries the Mopar, PROFORM Race Series, and FireCore 50 lines, so regardless of your preference, you will be covered.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by