Our “Sick Fish” ’73 Plmouth ‘Cuda continues to evolve into a reliable long-distance cruiser and drag-and-drive event competitor. Part of preparing for those adventures is having confidence in the parts we install that will survive the thrashing levied during long-distance driving and drag-racing events.

As we readied for Sick 66, which would take us on a 3,000-mile adventure with six days of drag racing, we contemplated what components may leave us stranded.

Above: Moser Engineering has developed a beautiful fabricated 8 3/4″ housing (MO875) that is stronger and more attractive than the factory housing. Several upgrades are built into the Moser rear end. We knew it was the correct rear end for our Sick 66 1973 ‘Cuda.

Even though the ‘Cuda’s small block pushes around 560hp, we were resolute that our TCI Streetfighter transmission with an ATI 8-inch converter was sufficient. Our new Gear Vendors Overdrive allowed us to cut the RPM down on the highway, but we were not sure about the rear end.

Our ‘Cuda had a factory 8 3/4″ rear end with 3.55 gears, stock axles, and wheel studs. The planned events would require new axles and wheel studs at a minimum. We never opened the housing to see the condition of the rear gears, but it leaked oil out of the pinion seal. Additionally, we wanted to change the gear ratio since we had the overdrive.

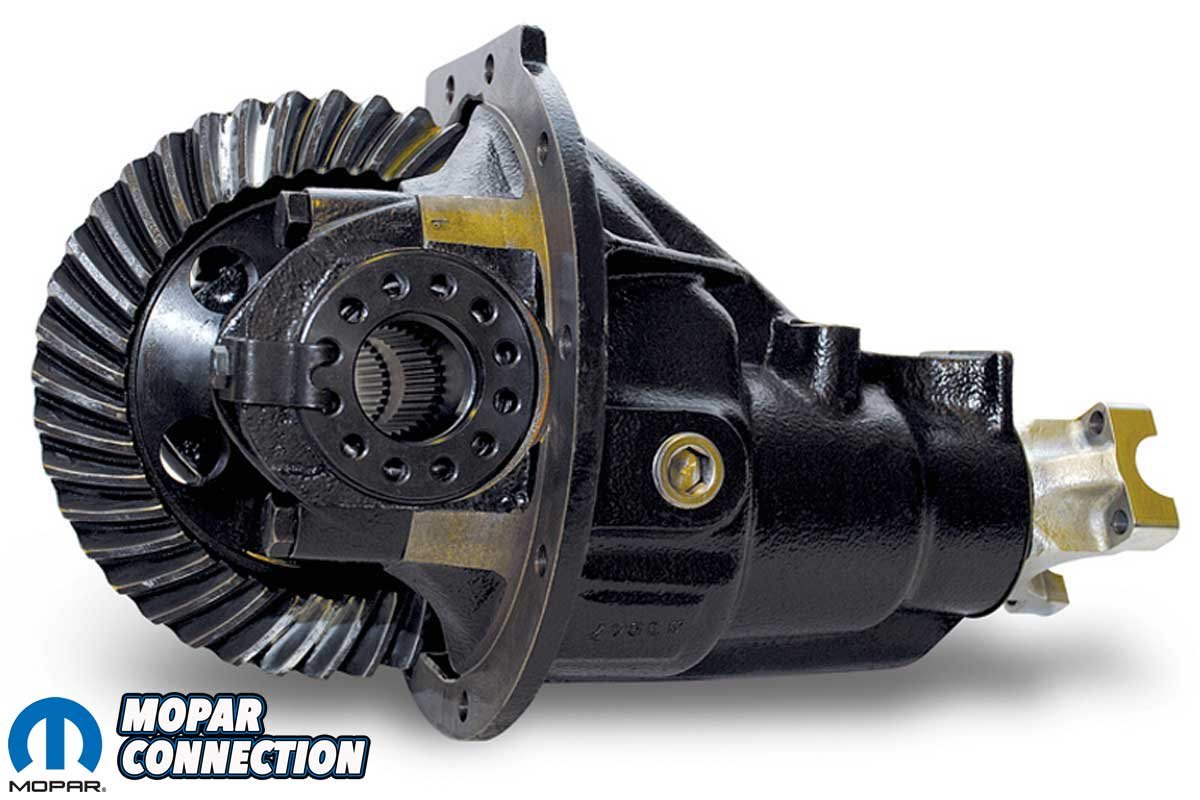

Above: The Moser MO875 kit included a new Yucon 489 housing with 3.91:1 gears, which we felt would work best with our combination and our Gear Vendors overdrive.

Our dilemma was solved with a USA-constructed Moser MO875 fabricated Mopar 8 ¾” Musclepak rear end. The MO875 housing incorporates OEM-located mounting provisions. It has 3-inch OD, 1/4-inch tubes, a 1/8-inch mild steel triangulated section for the center housing, and a 3/8-inch mild steel face plate for the third member mounting surface.

Above Left: The Moser MO875 showed up in a wooden crate. A Dana 60 rear end, which we considered installing before finding out about the MO875, rests in the background. Above Right: We weighed the MO875 when we pulled it from the crate. In its “ready to install” condition, it was slightly heavier than the factory 8 3/4″ rear end, which we found out later.

The center housing section also has an optional back brace for high horsepower applications. When ordering an axle kit, enthusiasts have endless choices, which include:

• Custom Alloy Axles

• Yukon 489 Housing

• Timken Bearings

• Wheel Studs

• Seals

• Heavy-Duty Retainer Plates

• Housing Ends

• Grade 8 hardware

• Limited Slip Differential

• Multiple Gear Ratios

• 1350 Series Pinion Yoke

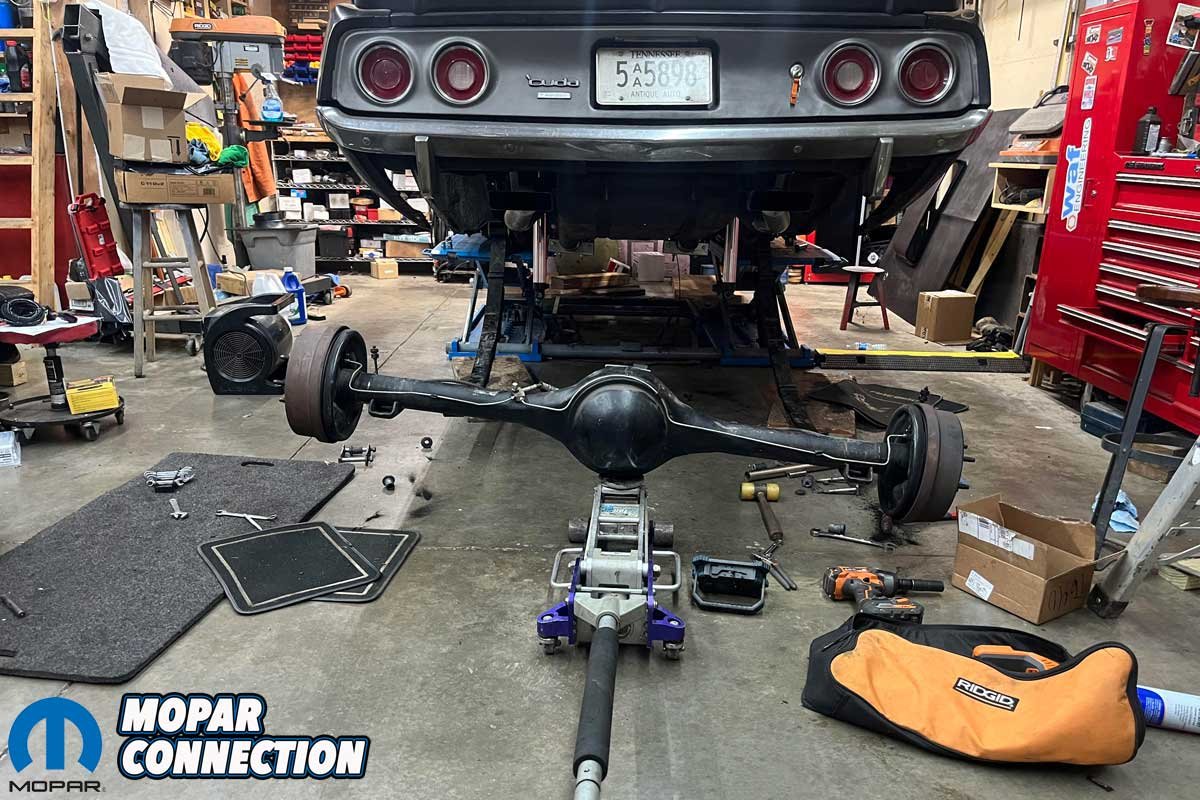

Above: Dropping the factory 8 3/4″ rear end from most muscle-car era Mopars is straightforward. Several components must be disconnected, and a floor jack is necessary, but it is not difficult. Our scissors jack lift made the task more manageable, but it could be performed on jack stands.

Each unit is finished with one of several drum or disc brakes options. Brake lines, clamps, and emergency brake cables are also included. After discussing our rear-end requirements with the Moser reps, we designed the following:

• Fitment for 1970-1974 E-Body Mopar

• 5 x 4 1/2” Bolt Pattern

• ½” x 20 x 2” Screw in Studs

• 3.91:1 Gear Ratio

• 33-Spline Truetrac

• New Drum Brakes

• Semi-Gloss Black Powder Coating

Above Left: The shocks, U-bolts, sway bar end link brackets, rubber brake hose, park brake cables, and the drive shaft needed to be disconnected before supporting the housing and disconnecting the leaf springs. Above Right: With everything removed or detached, we lowered the ‘Cuda to a height where we could slide in a floor jack to support the rear end. Once we disconnected the spring shackles, the rear end would slip out from under the car.

Mopar Connection’s Editor-in-Chief, Kevin Shaw documented our unit’s construction so we could also watch that process. He also took viewers on a grand tour of the Moser facility, which you should view by clicking here or watching below (above the photo gallery).

With the MO875 on site, we unboxed it, and it was perfect. To start the disassembly, we removed the handful of bolts on the rear valance for our ‘Cuda to make accessing the rear leaf spring shackles easier. With the car supported at the front leaf spring hangers, we disconnected the driveshaft, rear shocks, rear brake line at the rubber line to the body, rear sway bar end links, and axle U-bolts.

Above: With some planning and luck, we carefully rolled the factory 8 3/4″ rear end from the ‘Cuda’s chassis. Chrysler did an excellent job with the design of the 8 3/4″, but the Moser MO875 expands the technology to the 21st century.

After placing a floor jack under the 8 3/4-inch housing, we disconnected the leaf springs at the shackles and lowered them to the floor. We rolled the housing out from under the ‘Cuda.

We used the same procedure in reverse to install the Moser housing. Our primary concern during the installation was not to damage the housing’s beautiful powder coating. The MO875 slipped in and was secured with all the factory fasteners that located the factory axle.

Above: We compared the MO875, the OEM 8 3/4″, and an E-body Dana 60. The MO875 weighed 240 lbs., the factory 8-3/4″ unit 220 lbs., and the Dana 262 lbs. We added 20 lbs. but gained strength, so the tradeoff in our opinion is a win.

With our drum brake selection, the rear end came with Lokar parking brake cables that were 15 feet long. Since we still had all the factory park brake cables/bracketry under our car, we removed the Lokar cables and swapped them with the factory cables from the OEM rear end. During the exchange, we took the opportunity to paint the drums.

After installing the rear end, we topped it off with oil, a more user-friendly process with the fabricated housing. We removed the fill plug on the center section but filled the unit via the uncapped fill hole at the top of the housing. With the car on a lift, the rear end will drop sufficiently to hold a gear oil bottle upright. The oil will pour in without difficulty with a flexible hose.

Above Left: The Moser unit balanced nicely on our floor jack. Our primary concern during the installation was not to damage the powder coating. Above Right: Once we swung the leaf spring shackles into place, we raised the ‘Cuda to gain access to all the components we needed to reinstall. Everything lined up and fit correctly. However, we reused the factory park brake cables rather than installing the Lokar cables included in the rear-end kit.

We added limited-slip gear oil until it dribbled out of the center section’s fill hole. The new Yukon case came with an Allen head plug, which we did not like, so we replaced it with a square drive plug, more typically seen on a factory 8-3/4″ center section. After bleeding the brakes, the rear-end swap was complete.

Above: We listed a few differences between the OEM rear end and the Moser MO875 unit. We still had to add the brake line distribution block and brake hose and massage the brake lines to flow the contours of the MO875.

Since we like to keep track of the weight of parts being added or removed from our car, we weighed our factory 8-3/4″ rear end, the Moser MO875, and an E-body Dana 60. Our factory 8 3/4″ unit weighed 220 lbs., the Moser 240 lbs., and the Dana 262 lbs. For most, the weight of the rear end is inconsequential, but the data may be valuable to a serious racer.

Above Left: The cast look of the drums looked fine, but we wanted to dress them up with a bit of color. Above Right: The MO875 fill hole in the housing worked great. With the ‘Cuda supported on our lift and the rear end hanging, an entire bottle of gear lube fit between the gas tank, floor pan, and housing. With the aid of a rubber hose attached to the bottle, we quickly squeezed in the correct fluid volume.

After the installation, we took the ‘Cuda for a drive. The new 3.91 rear gearing was much more fun on the street. After covering a few hundred miles, we drained the oil, added new gear oil, and checked that all the fasteners were tight. Then, we headed to our local track, where we had no concerns. The rear end performed flawlessly – nice smokey burnouts and 3,000-plus RPM launches were no problem.

Now for the real test: Sick 66. Of course, it all started with getting to the event. We hooked our little trailer up to the ‘Cuda and set off from Nashville, Tennessee to Springfield, Missouri, the event’s starting location. The eight-day event covered a lot of ground, and by the last day, we finished in Roswell, New Mexico.

Above: On our 3,000-mile trip, the Moser housing and Yukon gears operated flawlessly. The taller rear tires and the Gear Vendors overdrive made cruising a pleasure even with the aggressive 3.91:1 gears.

The racing was a blast, and the cruising portion of the event was almost entirely on old Route 66. It was fun but a very rough ride. We completed approximately 3,000 miles of driving and made over fifty passes down the track. The Moser MO875 worked flawlessly throughout the entire event. After the event ended, we had so much fun that we turned the drive home into another three-day cruise.

Why did we select the MO875 instead of a Dana 60? The Dana is super strong but drag-and-drive events require the car to be driven to the track and not towed. If something breaks, it has to be fixed at the track, on the side of the road, or in the hotel parking lot.

Above: On the track, the ‘Cuda excelled. Big smokey burnouts and hard-charging runs put the Moser rear end through its paces. After dozens of 1/4-mile passes over several days, we do not have a single complaint with the MO875.

For Sick Week or Drag Week participants, it is common for racers (using 9-inch rear ends) to carry spare center chunks. The MO875, just like the 9-inch, has a strong housing and the ability to have a spare center chunk. If something were to go wrong, swap the spare chunk and continue on.

If you are in the market for a new rear end or are curious about the Moser MO875 Musclepak, contact the Moser Engineering representatives for more information HERE.