Chrysler’s introduction of the Gen3 Hemi almost two decades ago unleashed possibly one of the most popular performance and economical V8 engines ever fitted into a vehicle. However, if you own a late-model Hemi, you have probably come across websites and blogs imparting horror stories about the Chrysler Multi-Displacement System (MDS).

The information from these sites would have you believe that every 5.7-liter Hemi ever produced has ended up with a damaged camshaft due to a failed roller tappet. While this is certainly not the case, we elected to work with Blackstone Laboratories to evaluate the condition of our 5.7-liter in a 2006 Police Pursuit Charger by supplying an oil sample.

Above Left: The free Blackstone Laboratories oil sample kit arrived with everything needed to collect our Charger’s oil. Above Right: Our Police Pursuit Charger has 98K-miles on the chassis, but the 5.7L was replaced at 53K-miles. The Hemi has the characteristic “Hemi tick.”

For some history, the Charger was auctioned off in 2014 by a rural Pennsylvania Township after eight years of service. The 80K-mile Charger came with an 82-page list of service and repairs that had been performed at a local Dodge RAM dealership.

A few significant repairs consisted of a new Hemi (long block) at 53K-miles, a new NAG1 automatic transmission at 65K-miles, and plenty of PCMs and related electrical hardware. Since the purchase, the Charger has accumulated 18K-miles.

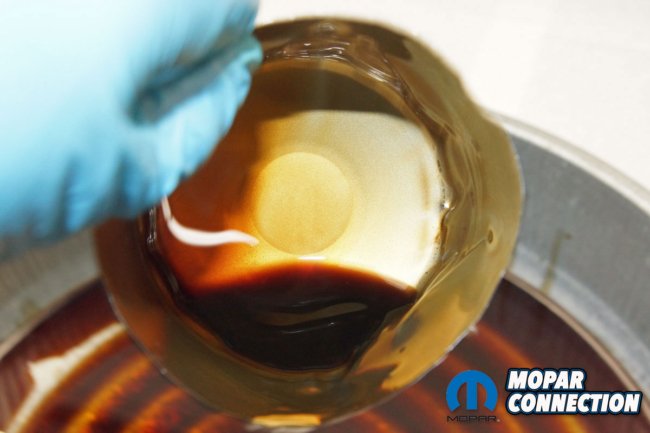

Above Left: With the engine up to temperature, we captured about 3-ounces of oil into the collection container. Above Right: If the factory filter was good enough for the manufacturer, it is good enough for us. Since we have owned the Charger, Mopar filters have worked well for us.

The 5.7-liter has the famous “Hemi tick,” and that clatter has always been a minor concern that something may be failing internally in the engine. However, the engine tick has not changed in severity since we purchased the Charger.

In 2017, with a now-defunct Mopar magazine, we chassis dynoed the Charger to evaluate the performance improvements with Amsoil lubrication products throughout the drivetrain. Mopar Connection Magazine is not endorsing one oil over another, but we have elected to continue using Amsoil in the engine, transmission, and rear end since the testing.

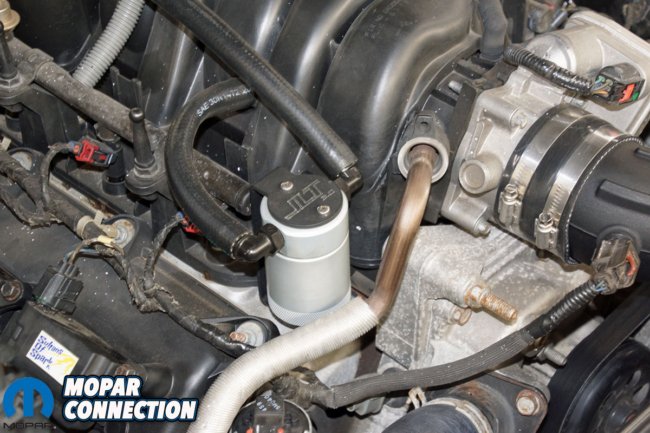

Above Left: Part of our oil change on the Charger includes emptying the JLT Performance Oil Separator. Above Center: The container had a minimal volume of oil in it. So we emptied and reinstalled it. Above Right: We use Amsoil products in the Charger. We poured in seven courts of 5w-20.

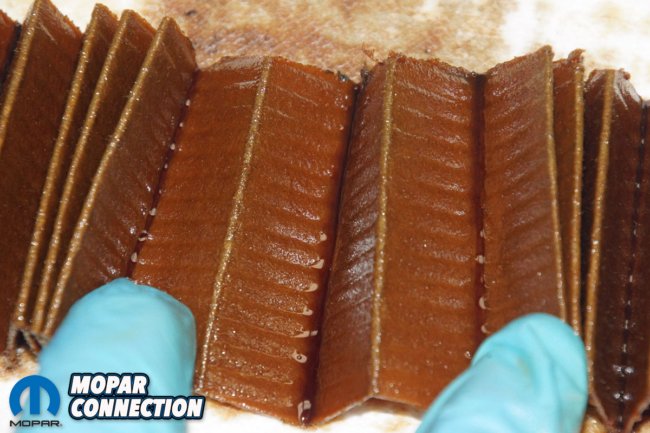

As part of the oil change routine, we cut the used oil filter open to inspect any debris removed from the oil. Years ago, a former college instructor told our first-year engine class, “When it comes to the remnants found after cutting open an oil filter, glitter is good, chunks is bad.”

While grammatically incorrect, you get the idea. The filter does its job if glitter is present as minor wear occurs within an operating internal combustion engine. However, a filter that has collected chunks of metal (or other debris) that can be felt between a finger and thumb indicates an engine in trouble.

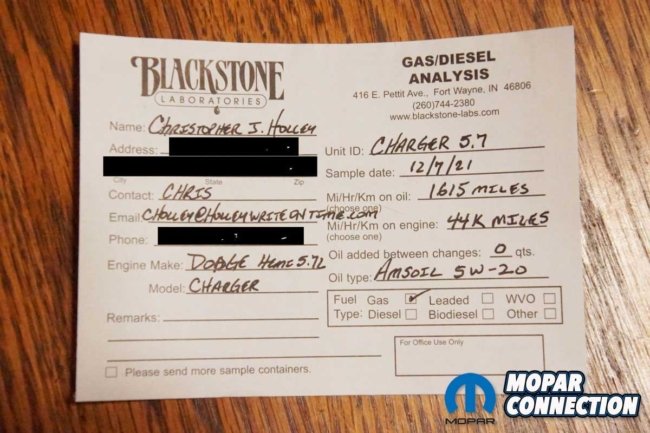

Above Left: The front side of the analysis card was filled out with data about the Charger and the oil used. Above Right: The reverse side of the card required payment and testing information.

Because an extended trip was planned for the Charger, we contacted Blackstone Laboratories for a free oil analysis test kit to complement our regular oil filter inspection and offer peace of mind about any engine concerns.

The kit came with two sealed containers (one fits inside the second), a zip lock bag, an absorbent mat, paperwork, a return envelope, and humorous instructions on how to complete the process. Although the kits come for free, Blackstone Labs (like any business) requires a fee for the analysis review.

Above Left: The sample was capped, wrapped, and sealed. Above Center: The analysis card and the captured sample were placed in the larger container. Above Right: The containers were placed in a USPS prepaid envelope and sent to Blackstone Laboratories.

When it came time for the next oil change, which with Amsoil products is up to 25K-miles or once a year, the Blackstone instructions suggested to have the engine up to temperature and to retrieve the oil mid-flow. So, that is just how we did it.

The drain plug was unthreaded on the warmed engine, and we waited a few moments before slipping the plastic catch container under the stream of oil spilling to the oil drain pan. Once the plastic container was filled, we removed it from the oil stream and capped it. The rest of the oil change was completed as usual, including emptying the JLT Performance Oil Separator. The used oil filter was set aside to be cut open.

Above Left: An oil filter removal tool and cutter are needed to cut open a filter. Once cut open, a box cutter is used to cut the filter media. Above Right: The oil filter cutter has a sharp cutting disc that easily cuts through an oil filter without introducing debris into the filter.

We completed the process to send the sample to Blackstone by writing the author’s name and order number upon the cap of the sample container. Next, the container was wrapped with the absorbent pad, and then the covered container was placed in the zip lock bag. After finishing the required analysis paperwork (two-sided index card), the zip-locked bag was wrapped by the paperwork. The sample, bag, and paperwork were placed into the second larger container. Lastly, the larger container was placed in a pre-paid envelope.

Above Left: The cutter split open the filter without difficulty. Above Right: We pulled the oil filter element from the oil filter housing.

With Blackstone Labs, there is an option to include check or credit card information with the sample or take care of all the processing fees online. We elected to pay for everything via the secure website. For the basic test, the cost was $30. Blackstone offered additional options with extra costs, but we felt the extensive base testing would be sufficient for our situation. Satisfied we had completed everything required by Blackstone Labs, we dropped the envelope at the post office.

Above Left: The oil bypass spring (plate) was removed from the bottom of the housing. Above Right: With everything out of the housing, we inspected the oil for debris. We found minimal “glitter” in the filter.

We cut the oil filter open during the oil change, and there were negligible amounts of glitter and no chunks, so we expected the Blackstone Laboratories results to be superb¬. Two weeks after sending in the sample, we received an analysis via email (one was also sent via the post office), and the results on our year-old but low-mileage oil were as expected.

Above Left: We cut the filter element from the support tube. Once removed, we opened each pleat of the element to look for debris. Again, we found nothing of concern. Above Right: The objective of the filter is to remove debris. Our aim is to look for any of that debris.

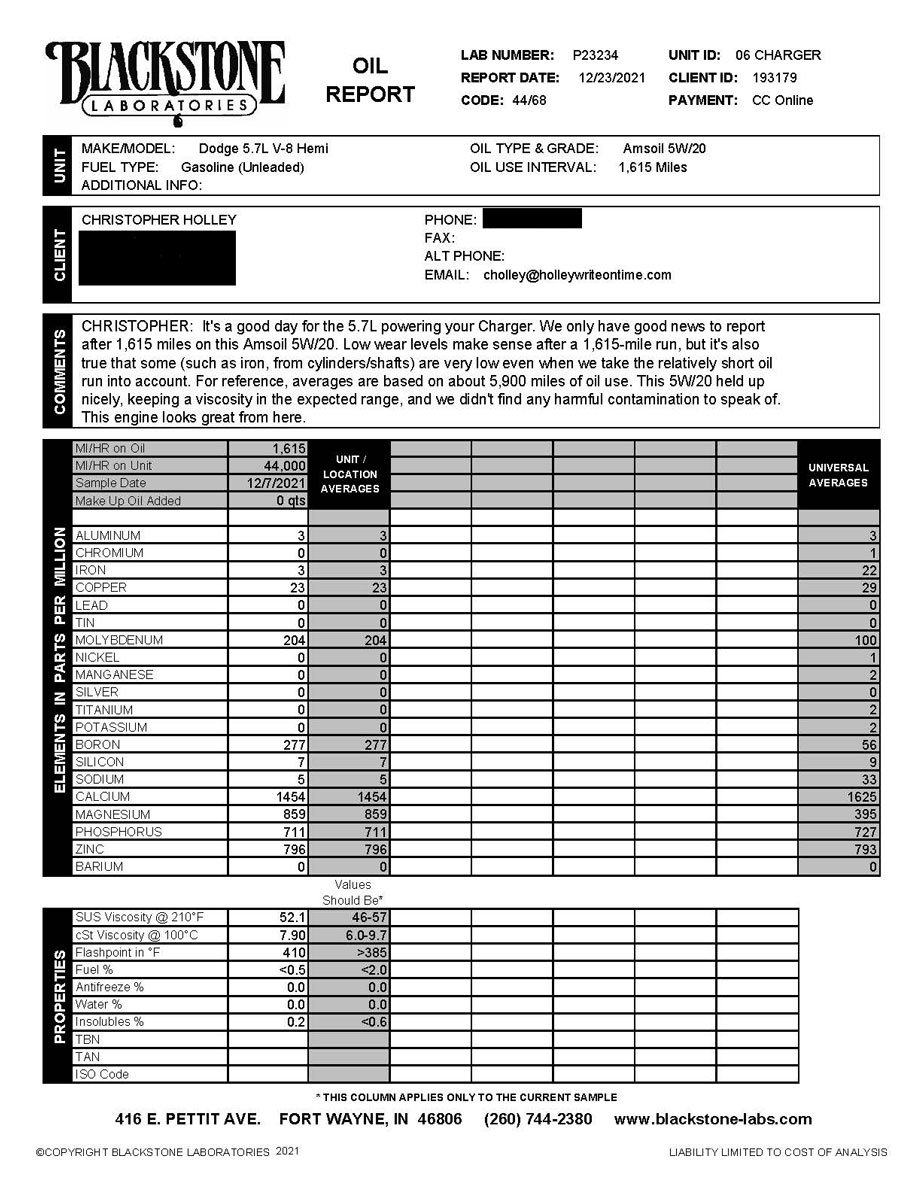

Blackstone provided a detailed list of elements in parts per million and particles in the oil, along with comparison averages. Also included was a detailed write-up about the status of the engine. The Hemi was in great shape. Blackstone provided the following description of the engine:

CHRISTOPHER: It’s a good day for the 5.7L powering your Charger. We only have good news to report after 1,615 miles on this Amsoil 5W/20. Low wear levels make sense after a 1,615-mile run, but it’s also true that some (such as iron, from cylinders/shafts) are very low even when we take the relatively short oil run into account. For reference, averages are based on about 5,900 miles of oil use. This 5W/20 held up nicely, keeping a viscosity in the expected range, and we didn’t find any harmful contamination to speak of. This engine looks great from here.

Above: Blackstone Laboratories provided us with a detailed sheet of information about what is going on in our Hemi. It turned out we were in great shape. Everything was within the “normal” values, and there were not any concerns with iron or steel from a damaged camshaft.

Even if you do not desire a lab analysis, it is highly recommended that a quality engine oil of the proper viscosity and matching high-quality oil filter be used. In addition, it is imperative to maintain the correct oil and filter change interval. Lastly, purchasing an oil filter cutter tool and cutting open the filter after each oil change will give you an idea of the engine’s condition. If lab analysis is enticing, but the cost is higher than expected, a single yearly examination should be more than enough to keep tabs on the internal operation of your engine.

The entire process with Blackstone Laboratories was an excellent experience. We received the sample product collection components quickly, the gathering and mail-in procedure was easy to perform, and the results were easily understood and provided in a timely fashion. If there is a concern about your Hemi or any other engine, a professional lab analysis is an excellent way to ease any apprehensions about your engine’s condition.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by