The journey began for Don Vuylsteke and the station wagon when he was just 10-years-old. Don’s parents, Roger and Jeanette Vuylsteke, were in the market for a new family car. At the time, they were driving a souped‑up Dodge Coronet—a 2‑door hardtop with a 4‑speed manual transmission and bucket seats. It worked well enough when the household consisted of just their two boys, Meacheal and Don. But that changed when Jeanette became pregnant with twins. She looked at Roger and said, “This car isn’t going to cut it anymore.” With that, the Coronet was traded in for a brand‑new 1969 AMC Rebel SST wagon.

Roger decided to order the Rebel SST, the top trim level for 1969. With AMC discontinuing the 550 and 770 models that year, the SST stood out with its updated look, including wrap-around taillights, a redesigned grille, and fresh trim and ornamentation. Roger also chose to upgrade from the standard 290‑cu in, 200‑hp V8 to the stronger 343‑cu in V8 topped with a 4‑barrel carburetor, bumping output to roughly 280hp.

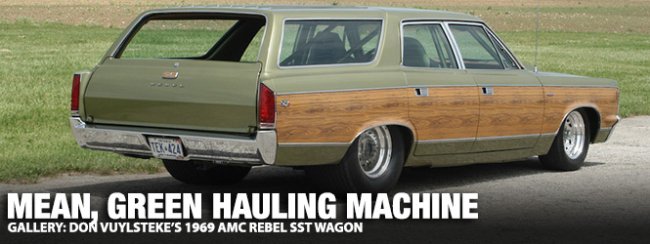

The Rebel wagon came equipped with standard 4‑wheel drum brakes and manual steering, and this particular car featured AMC’s clever dual‑gate design, allowing the tailgate to open conventionally or swing out from the left side. It took about a month for the wagon to arrive from Kenosha, Wisconsin, and it was one of just 9,256 built for 1969. Finished in Willow Green Metallic with faux woodgrain vinyl sides, it would go on to serve the Vuylsteke family faithfully as their daily driver for many years.

The time finally arrived when the parents handed the wagon down to Don’s older brother, Meacheal. “My brother tried really hard to beat the snot out of that car,” said Don. Don would be next in line if the car survived his brother’s hot-rodding ways. When Don turned 17 years old, he finally received the wagon. The Rebel was well past worn out when he got the keys. The Rebel now had over 100,000 miles on it and several body jobs. The imitation “tree bark” was long gone, and the car was painted two-tone brown. Like most Canadian cars in this region, the winters were brutal on them. The constant bath of salt in the winter showed rust on the floors, fenders, and rear quarters.

Don was a man with a plan and had a decent job during the summer, working the tobacco fields. With cash in hand, he purchased new quarters and fenders from a nearby AMC dealership. A local body shop put the new quarters on. The car still needed work, but at least Don could drive it back and forth to school. Don found a 401 engine from a wrecked ‘71 Javelin and replaced the worn-out 343 motor. He added a lumpy cam and headers to give the car a bit more attitude. Being the only kid in high school with an AMC and a station wagon to boot, he was teased relentlessly. This had a positive effect on Don because he wanted to build a car that would blow their doors off with a “How do you like me now?” attitude. No doubt, he left some of his rivals with their tails between their legs.

Shortly thereafter, Don met the love of his life, Denise. The Rebel wagon was even used at their wedding. Like all things in life, Don got busy with family and work, and with the car half torn apart, it would not be worked on for the next 20 years. Despite that, Don always remained a car guy. He was a licensed auto mechanic by trade and was always wrenching on cars. He did have other cars that he played with as well, such as a 1969 Javelin 390. That car is still in the family today and is owned by his younger brother.

Don loves speed and the things that make it happen. It was for this very reason that he ended up building and campaigning a 1976 Plymouth Duster from 1984 to 1987 for a local friend named Bob Cain. The car was called “Raisin Cain” and had a ‘67 440 cu in with a Six Pak that was enlarged to a 452 cu in and could do 10.40 in a quarter mile. It was with that experience behind the wheel that Don decided he wanted to build a Pro Street racing car out of the Rebel SST wagon.

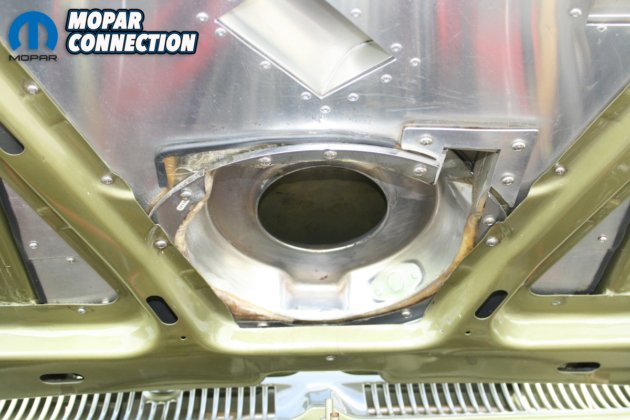

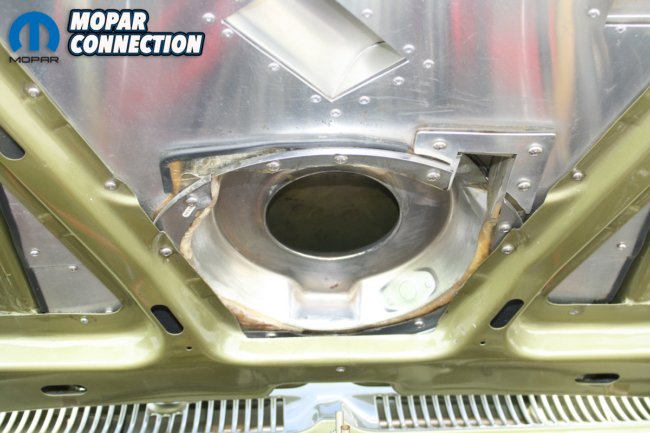

It was now 2006, and Don was ready to tackle this project. One of Don’s goals was to hide and build the car around the 3” exhaust. This would be a huge undertaking because of the unibody construction. When the car was put on the hoist, the doors would not close properly. The unibody needed to be strengthened, especially for what he was going to use it for. The car was set up on shop stands and braced while the stock floor was removed and replaced with new metal. A beaded custom floor pan was constructed that ran from the front firewall to the rear tailgate and included the transmission tunnel and wheel wells. Don and his brother Tim did the work in their shop.

Both the front and rear subframe rails were dropped 3.5 inches. This would help with the stance of the wagon. The front subframe was made from 4×2 mild steel tubing. A C4 Corvette front cradle and suspension were used, along with a Corvette composite monoleaf shock completed for the front suspension. A power rack and pinion from a 1990s T-Bird was used for steering control. The rear used a Bear 2×3 mandrel-bent rear subframe. A Bear FAB9 sheet metal rear axle housing was used for the Ford 9” Fab9 third member with 4:56 gears and True-Trac Posi traction.

To transfer the power to the wheels, Strange Engineering Hy-Tuf 28-spline axles were used. The rear axle was hung onto a Bear Performance Chromoly 4-link setup with adjustable coil-over AVO shocks and a strong wishbone mount atop the differential, which adds more stability and traction. The car has a hatch to access the four-link suspension from above. To keep the car from flexing, custom connectors tied the two subframes together along with a 12-point roll cage.

Since the quarter panels and fenders were still in good condition, there was no need to replace them. The roof rack was removed, and the holes were filled in to give it a more streamlined look. Don’s brother Tim notched the rocker panels to accommodate the NASCAR-style exhaust. Tim also did a one-of-a-kind styrene grill to simulate a hideaway headlight effect. A 1969 Chevy Camaro steel hood cowl was grafted onto the Rebel hood. The cowl is functional and is fully sealed to the carburetor.

All the replacement floors, body work, body prep work, and final paint were performed at Don’s home shop. Helping with painting duties was George DaSilva, who transformed the wagon to a fresh factory color of Willow Green Metallic with single-stage paint. Since the original vinyl woodgrain was no longer available, A1 Auto Detailing of Hagersville, Ontario, recreated the woodgrain using vinyl wrap material. The chrome and stainless are all O.E.

For the interior, a 1977 AMC Matador dash was used because it was more upscale than the original Rebel dash. Custom gauges for oil, water, and voltage are mounted in the middle section of the dash. The Autogage tachometer rests on a handmade center floor console. Don found the buckets at a car swap meet and had them recovered. Because of space limitations with the new floor redesign, boat seats were used for those who wanted to ride in the back. The headliner, seats, and custom door panels were covered in saddle brown.

The carpet was hand stitched in a celery color. It is better that way if you spill celery when getting groceries, I guess. All the interior work was done by the owner of Steve’s Custom Canvas in Tillsonburg, Ontario. The door handles for the door panels came from an overstock supply of large RV grab handles. The tilt steering column came from the same 1977 Matador and has a custom-fabricated hard rock maple steering wheel insert. Well, Don wanted real wood for his Woodie wagon.

To power this mean machine, Don replaced the old 401 mill with an AMC 390 cu in short block stroker that was stretched to 433 cu in. Aftermarket aluminum Indy 401-1 heads have been ported and shaped to 58 cc by Konigshofer Brothers. A ‘71-74 forged 401 crank was milled and balanced for 6” rods. Attached to those rods are forged pistons with full floating pins. It has a Reed solid roller cam (.720 lift/269 duration on the intake and .277 on the exhaust @ .050) with Johnson roller lifters and 3/8 Indy 2-piece push rods.

An Indy High Rise intake was used with a Holley 1000 cfm 4150 series carburetor. The compression ratio is 10.8:1. To keep the carburetor fed, a Holley electric fuel pump was used. Indy-polished aluminum valve covers and the Bulltear Serpentine Belt System add some jewelry under the hood. All this power needs an aftermarket aluminum radiator with a shroud and a 2-speed Volvo truck fan to keep everything cool.

The exhaust gases go through a hand-built Hedman Husler U-Build kit for big-block Mopars. There is a 2” primary that goes to a 4” collector that flows into the 3” stainless custom exhaust into Flowmaster 40 series mufflers. Then finally, the gases exit out the side in a NASCAR-style stock car exhaust before the rear tires. The fabrication work on the exhaust was performed by DS Auto in Delhi, Ontario.

To get the power to the meaty rear wheels, it must go through the TCI AMC 727 3-speed auto with a reverse manual shift valve body. To control the transmission, a Cheetah SCS shifter sits between the bucket seats. A TCI 5000 stall converter was used along with a TCI trans brake and line loc. With that said, Don still has issues with the tires gripping and plans to upgrade the tires so he can unleash the 600 horsepower. Right now, the car runs in the mid-11s, but Don knows it has more potential.

For stopping power, Don used C4 Corvette 11” rotors with GM single-piston calipers and a TCI line loc unit. In the rear Lincoln Versailles, cast iron single-piston calipers were used with vented Ford 11” rotors. The wagon rides on Centerline Warrior aluminum rims. The 15X6 rims have BFG T/A 235/60R15 on the front, while the 15X15 rims have Mickey Thomson Sportsman Pro 28X18.5X15 in the rear. The wagon uses a stock fuel tank that has been modified and holds 14 gallons.

Don finally completed the car in 2016. It took another 2 years to get all the bugs ironed out of the car to where it is now. This car turns heads and makes a grand entrance whenever it goes with its thumpa-thumpa sound. He has won Best Custom Car and Judges’ Choice at the Otterville Mill Classic Car Show and Best AMC at the Delhi Harvest Fest Car Show. I believe that he has not only shown what this AMC wagon can do but also given it a little “How do you like me now?” attitude to go with it. “I have always wanted to make something out of nothing,” Don said. Mission accomplished. It’s mean, it’s green, and yes, this machine hauls.