BluePrint Engines is more than just a name in the industry. It is a story of passion and dedication that started in a humble garage over 40 years ago. Its founder and CEO, Norris Marshall, began by building engines for local customers, including racers, before expanding the business into a larger-scale operation. Today, BluePrint is an OEM and Performance engine manufacturer with a state-of-the-art facility that builds approximately 100 engines daily using all-new components.

Above: BluePrint Engines starts its Hemi-compatible engine builds with brand-new Stellantis Hellcat blocks.

BluePrint Engines’ unwavering commitment to quality sets it apart from other OEMs and aftermarket manufacturers. BluePrint does not rely on core blocks or rebuild used engines, unlike its counterparts. Instead, each engine is meticulously assembled with 100% new components, many designed and manufactured in-house. This dedication to quality ensures that every engine that leaves its facility is not just dependable but also high performing. BluePrint Gen III engines are a reliable choice for automotive enthusiasts and engine builders.

Above: Each block receives extensive modifications to meet BluePrint’s high-quality standards and accommodate the increased length stroker crank. Once complete, the engine will match the displacement of the King Elephant Gen II 426 Hemi.

The BluePrint Gen III engine is a significant advancement in the automotive business, matching the legendary Gen II 426 displacement. BluePrint Engines starts with a brand-new Hellcat block acquired from Stellantis. Each block is filled with a BluePrint rotating assembly, which includes a quality-designed forged crankshaft, rods, and pistons, creating a powerplant that revolutionizes the industry. Each Gen III Hemi-compatible engine built is a testament to BluePrint’s commitment to quality.

Above: BluePrint Engines builds nearly 100 engines per day, and each engine gets its turn on the engine dynamometer. This supercharged Hemi-compatible has all the dyno accessories installed and awaits its turn.

Johnny McDevitt, Director of Product Management at BluePrint Engines, is not just a professional in the automotive industry but also has a deeply personal connection to it. His background is steeped in all things Mopar. With his father having worked for and subsequently retired from Chrysler, he developed a love of Mopars early. McDevitt’s house and garage resemble that of a Chrysler dealership. He has filled it with late-model and classic Mopars, highlighting his lifelong passion and commitment to the industry.

McDevitt’s career in the automotive industry exemplifies his expertise and unwavering dedication. He followed in his father’s Mopar footsteps, purchasing a 1974 Dart at the age of 16 and transforming it into a 10-second street car. Two decades later, he still regularly drives it as the weather permits. His career has been dedicated to the automotive performance business. He worked at a drag strip and several well-renowned performance parts retailers before joining BluePrint eight years ago.

Above: Johnny McDevitt, BluePrint’s Director of Product Management, has had an affinity for Mopars his entire life. At 16, he purchased his ’74 Dart. Over the years, he improved the Dart, and now, twenty years later, it is a consistent 10-second car that he still regularly drives on the street.

Upon his employment at BluePrint, McDevitt almost immediately became known as the “Mopar guy.” Initially, he continued to push the envelope of the BluePrint Chrysler-compatible 408 small blocks. As the BluePrint small-block program flourished, McDevitt quickly pivoted his focus. “I’m pretty sure I started pitching Gen III at my job interview,” stated McDevitt. He became the voice of the customers looking for Gen III Hemi-compatible engines for their Mopar vehicles.

The development process was extensive to create the BluePrint Hemi-compatible engine. McDevitt articulated,

“Our biggest changes from initial designs on paper to today were extensive. I always had aspirations of the engine being 426 cubic inch displacement (CID) vs. a 392. The stroke of the engine, paired with the block design at the bottom of the cylinder bore, really made that difficult. We’re [BluePrint] no stranger to stroker engines, so luckily, we have experts on staff who have an amazing understanding of how piston pin location and rod length can be positioned to prevent pistons from rocking at the bottom of the bore.”

Above: To start its Hemi-compatible project, BluePrint Engines’ engineers had to design all the tooling necessary to make the engine. Additionally, the support components had to be purchased or built in-house.

Overcoming the engine block challenges required the BluePrint engineers to work closely with its piston suppliers to meet the needs of engine builders and customers. The custom pistons are designed to operate effectively in normally aspirated engines or with applications with plenty of boost. Additionally, all the pistons meet BluePrint’s stringent longevity requirements.

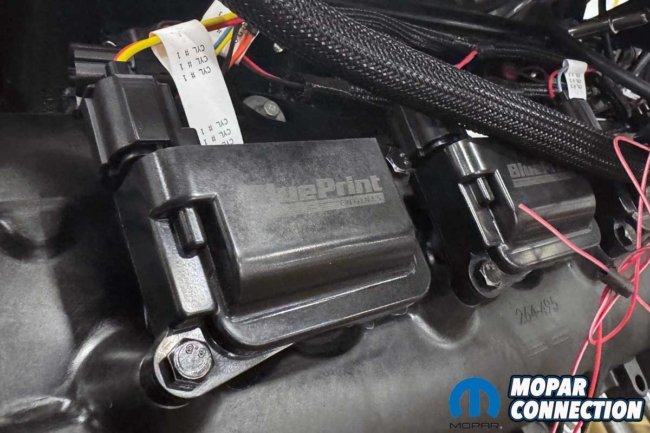

Above: All the harnesses, computers, and sensors must be installed to run the engine on the dyno. Many components are built by BluePrint engines or massaged by its technicians to bring them up to BluePrint standards.

Furthermore, pushing the displacement of the Gen III from 392 CID to 426 CID was a significant challenge for BluePrint. As previously mentioned, the first hurdle was the problems encountered with the block design and the limitations of fitting a longer stroke crankshaft. Fitting the crankshaft required extensive engineering processes and internal block machine work to provide clearance for the crankshaft counterweights and connecting rods. McDevitt shared,

“The stroke combo was a hiccup that had us close to settling on a 392. We have built strokers forever, using all engine platforms, so you would think it would be easy as any other stroker we build, but the OEM Chrysler block features some interesting machining processes at Stellantis before it comes to us. We’re [BluePrint] lucky to have an amazing team that made this engine arguably the strongest powerplant we build today, with the highest HP per CID in the BluePrint Lineup. It just took some extra design and engineering to ensure we got that extra stroke required of a 426.”

Above: While the photos are similar, the background of each image shows the seriousness of the BluePrint Engines team. The inventory of parts and pieces ready to install on the Hemi-compatible engines is mind-boggling.

The second challenge to developing the Hemi-compatible engine is the lack of aftermarket products compared to the LS platform. The aftermarket continues to provide enthusiasts with new components such as swap headers, engine mounts, pulley kits, electronics, and controllers. Still, there are fewer products than other engine platforms. Component pricing can be higher than comparable components with limited available products. McDevitt stated,

“Something as simple as a Variable Valve Timing (VVT) block-off or Multi-Displacement System (MDS) block-off plugs can add as much as $150 to the engine at retail prices. I would rather design and manufacture our own components and pass those savings on to our customers. I absolutely loathe the “Mopar tax” that seems to find its way into the retail cost of Chrysler-compatible parts, and having paid that myself for years, I do everything I can to pass on savings, rather than markups, to our customers.”

Above: Rolling down the assembly line is a small portion of that day’s supercharged Hemi-compatible engines. These images provide additional background views of the components and materials BluePrint Engines builds in-house or purchases from reputable aftermarket suppliers.

An example of the problems BluePrint Engines encountered was the “bolt-on-ready” intake manifolds it purchased for the engines. After acquiring the manifold, its finished quality was often well below BluePrint’s standards. As a result, BluePrint Engines had to apply several machine processes to true the mating surfaces.

Above: BluePrint Engines offers naturally aspirated and supercharged Hemi-compatible engines with horsepower ratings between 610 and 872 hp.

Additionally, PCV provisions had to be added, the mounting holes needed to be tapped, and injector spacers were required. After re-machining the manifold, it was ready for installation. Then, just as BluePrint was launching the new Gen III engine, the aftermarket supplier discontinued the part, which delayed the launch of the engines. Luckily, this turned out to be a blessing in disguise. Since BluePrint was now so familiar with what went into making an intake manifold fit and function well on a Gen III, it rapidly developed an intake with all of the required features, benefits, and machining steps to end up with an even better solution.

Above: An enthusiast can purchase a Hemi-compatible engine and have it fitted to a 4L80 automatic transmission or a T56 manual transmission. By purchasing the transmission with the engine, the BluePrint Engine professionals complete all the aligning, test-fitting, and assembly, allowing the owner to simply install the engine/transmission assembly and enjoy.

To bring the Hemi-compatible engine to fruition, BluePrint had to build everything needed to support the project after all the plans moved to the design board. Since BluePrint Engines is an OEM and dynos each Gen III, specialized stands, machining fixtures, valve spring compressors, and many other components unique to the engine had to be sourced or built in-house. The time to launch was considerably lengthened because of the need to design and manufacture all the support products.

Above: BluePrint Engines is known for its high-horsepower engines, but another less-known aspect, which is equally essential to its engines, is longevity. BluePrint wants its customers to enjoy the engines for many years without failure.

BluePrint introduced the Gen III at SEMA in 2022. The Hemi-compatible engine took five years to go from an idea to an approved project, design, and actual reality. Today, BluePrint has a complete lineup of Gen III Hemi-compatible engines, using 100% new parts, in everything from a 600+ horsepower long block to a turnkey, supercharged, 860HP+ package complete with pulleys, electronics, and even a transmission, if desired, for a complete chassis powertrain swap.

The BluePrint Hemi-compatible engine is a genuine contender for replacing the Mopar small and big blocks and even a factory Gen III. With aftermarket manufacturers’ continuing investment in Gen III parts, installing a Hemi-compatible engine in an A-, B-, C-, or E-body is possible. Just imagine all the fun that will be had with the addition of a 426 Gen III in a daily driver or 10-second weekend warrior.

Above: While this is the last Hemi-compatible engine of the day, plenty will be made in the future. Anyone seeking a high-quality engine with significant performance numbers and an even greater potential for longevity, contact the BluePrint Engines’ representatives.

BluePrint passionately believes that its customers deserve value and quality without being charged a high price. To grow the Gen III platform and the market, BluePrint provides products at a sensible price, allowing its customers to feel good about their purchase, share their experience with friends, and keep their classic automobiles on the road motivated with Gen III power.

For more information about the BluePrint Hemi-compatible engine, visit online or contact its technical representatives.