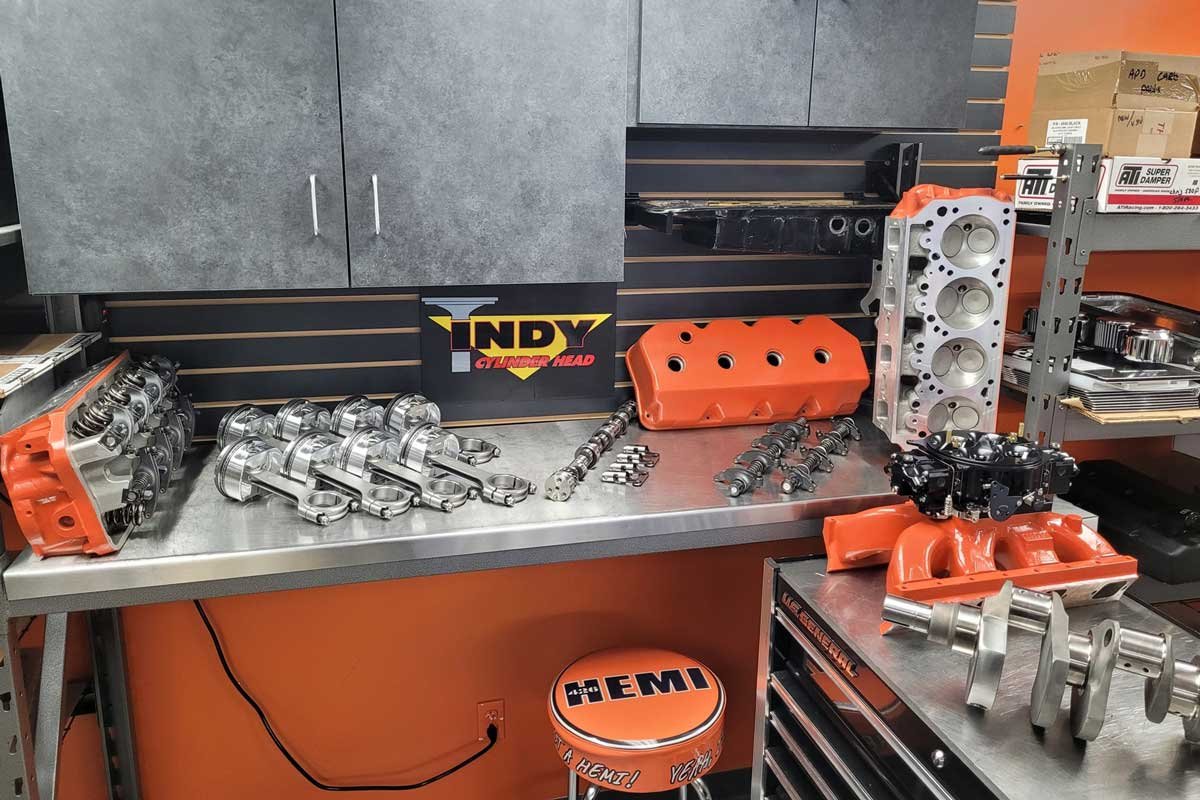

Indy Cylinder Heads has developed and supplied the Mopar aftermarket with high-quality engines and engine parts for over forty years. Indy’s engineering and extensive testing has rewarded Mopar enthusiasts with properly matched combinations of cylinder heads, camshafts, pistons, intake manifolds, engine blocks, and aftermarket parts, producing the ultimate power levels.

Indy Cylinder Heads continues to pump out outstanding, cutting-edge Mopar wedge and Hemi engines. Mopar Connection Magazine took some time to review three of Indy’s latest engine builds. One of the engines was an old-school style big-block wedge, and the other two were Hemis. Two engines were new builds, and one was a rebuild of an engine assembled in 2008.

Engine One – A Wedge

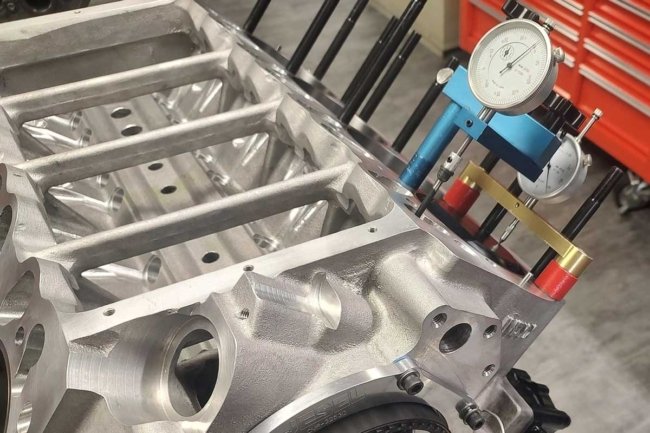

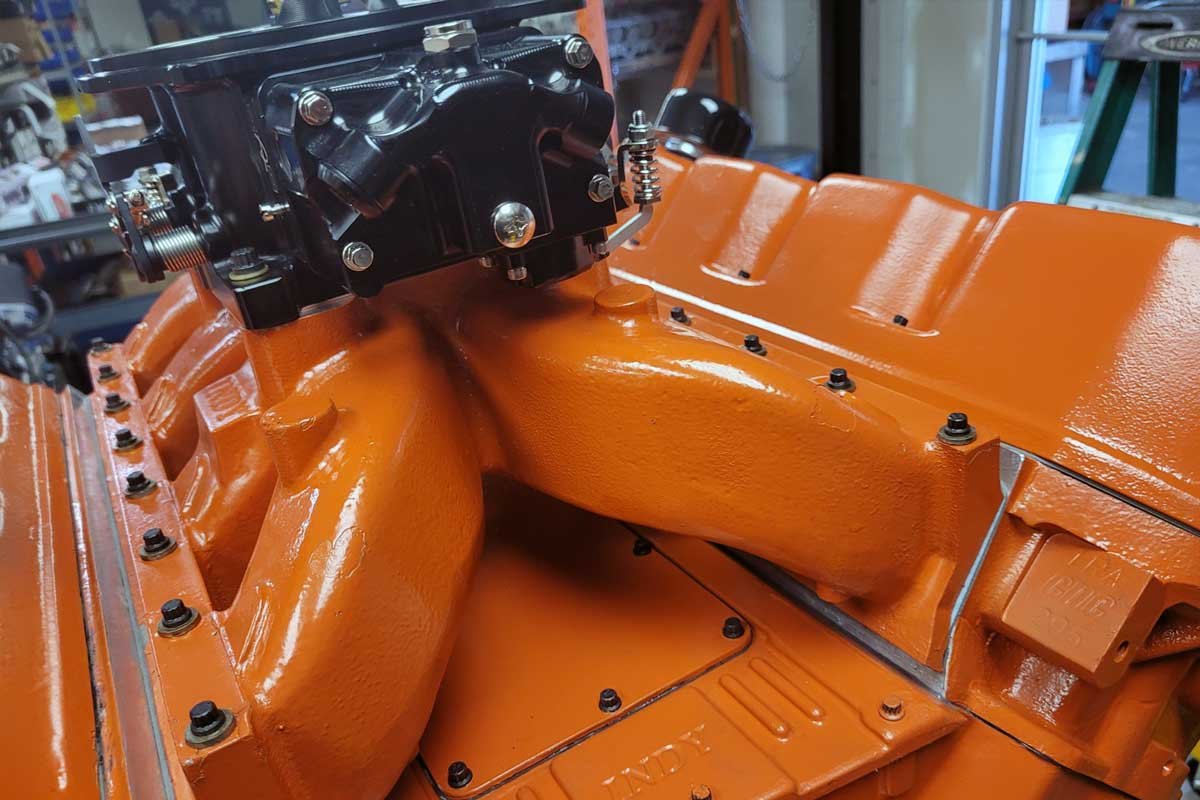

The first engine was a 500 cubic inch displacement (CID) street wedge, which was expected to see plenty of time at the drag strip. The engine was an all-out old-school build with an original equipment manufacturer (OEM) 400 CID block featuring a 4.375-inch bore (0.030-inch overbore) and a 4.150-inch stroke.

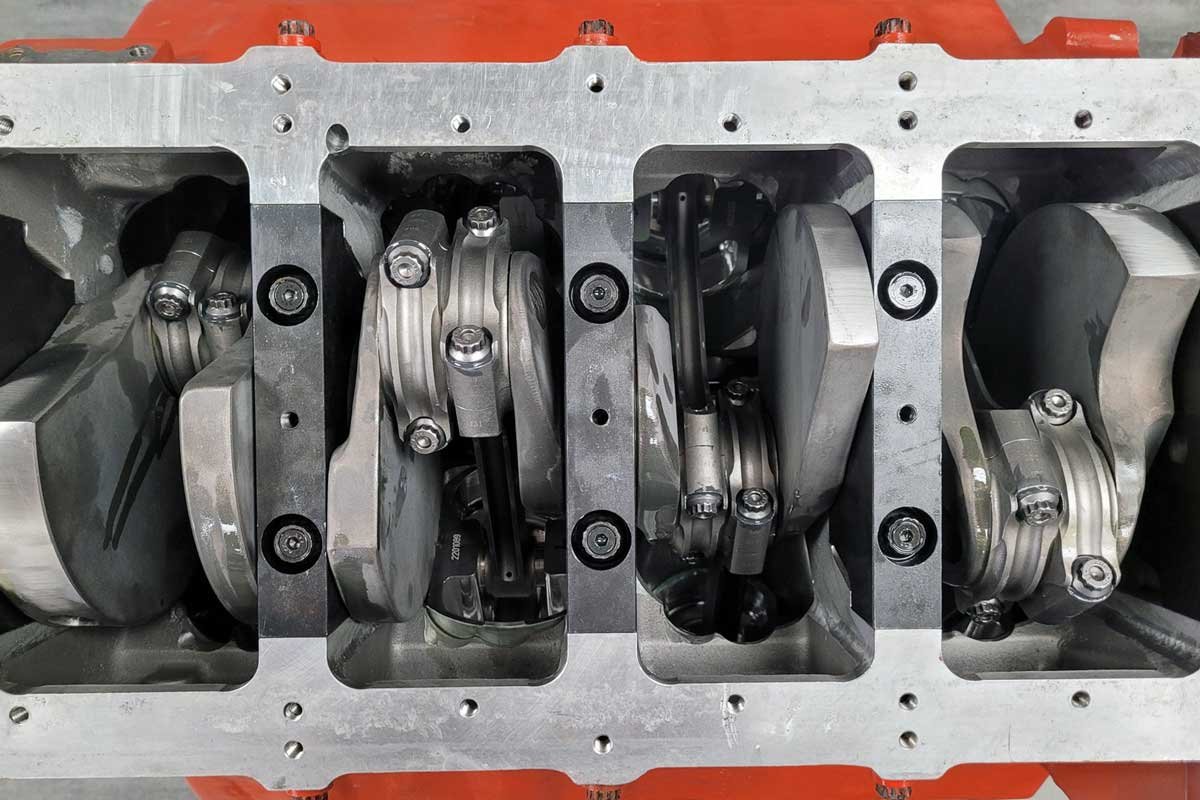

The 500-CID wedge had a 4340 steel Eagle Specialty Products 4.150-inch stroker crankshaft with 2.625-inch main journals and 2.375-inch rod journals. The crank was an internal balance unit with a target bobweight of 2500 grams and a total weight of 68 lbs. Swinging on the crankshaft was a set of 6.76-inch GRP connecting rods with a .990-inch wrist pin diameter and 12:1 compression ratio Diamond Pistons pistons.

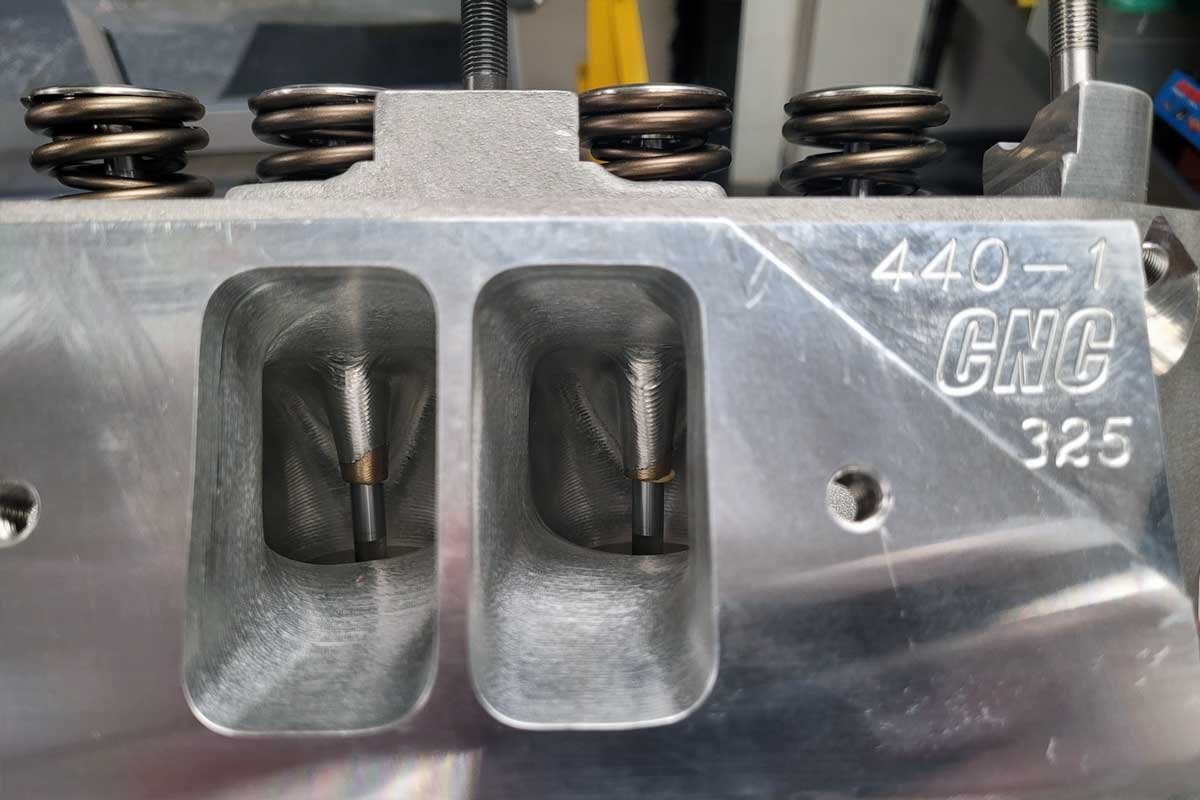

The wedge was topped by a pair of Indy 440-1 CNC ported heads with 2.19-inch intake and 1.81-inch exhaust valves. With a CNC treatment, the heads flowed 325 cubic feet per minute (cfm). The combustion chamber measured 75 cubic centimeters (cc). The wedge has a roller COMP Cams camshaft with 0.740/0.722-inch lift (intake/exhaust) and an intake duration that measures 282° and 286° on the exhaust.

The valves were actuated by BAM Products roller lifters with bushed wheels, 3/8-inch diameter Manton Pushrods with a 0.145-inch wall thickness, and Harland Sharp 1.6:1 intake and exhaust rocker arms.

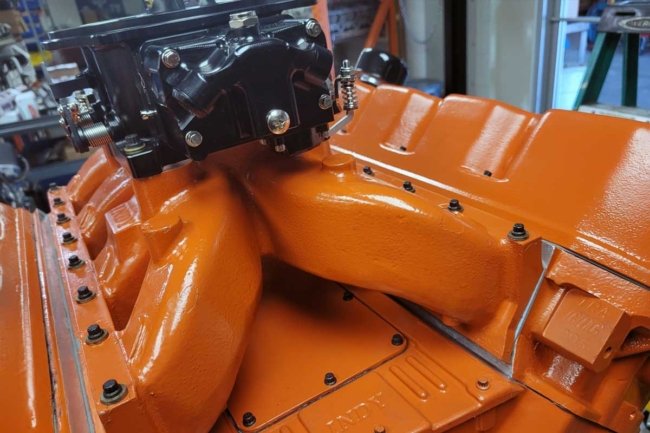

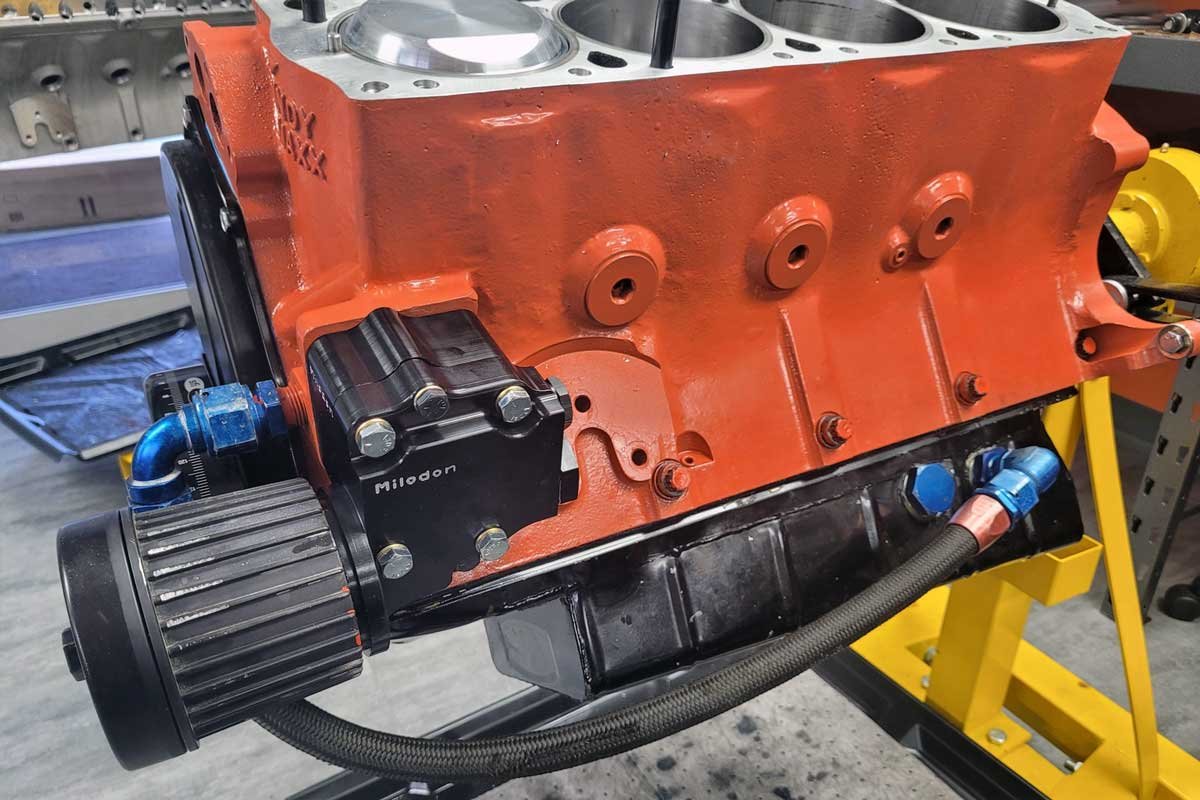

Indy placed a max ported, square top 400-3 intake manifold on the wedge and installed a Holley 1050 cfm carburetor. A Milodon 8-quart oil pan with a windage tray screwed to the block kept the 20W50 Driven Racing Oil in place. A Milodon billet oil pump moved the oil, and a ClearView Filtration system maintained the oil’s cleanliness.

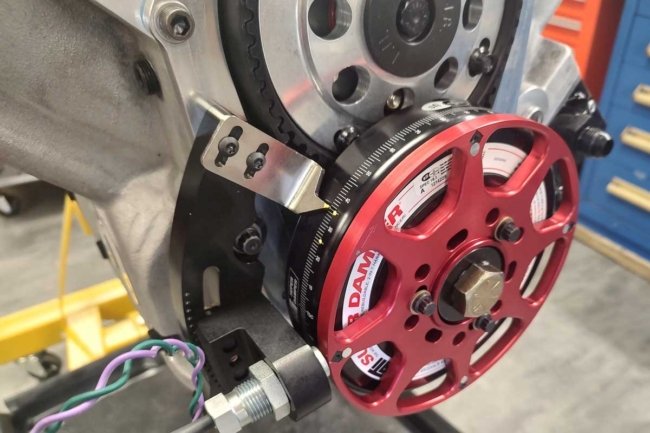

Indy installed an MSD distributor and Firecore Performance plug wires to fire off the cylinder’s air fuel. The engine had an ATI Performance Products balancer. The old-school 500-inch wedge pumped out 830 horsepower (hp) at 7400 rpm and 690 lb-ft of torque at 5900 rpm. Expect sub-nine-second elapsed times in a 3000 lb. Mopar with horsepower at that level.

Engine Two – A Hemi

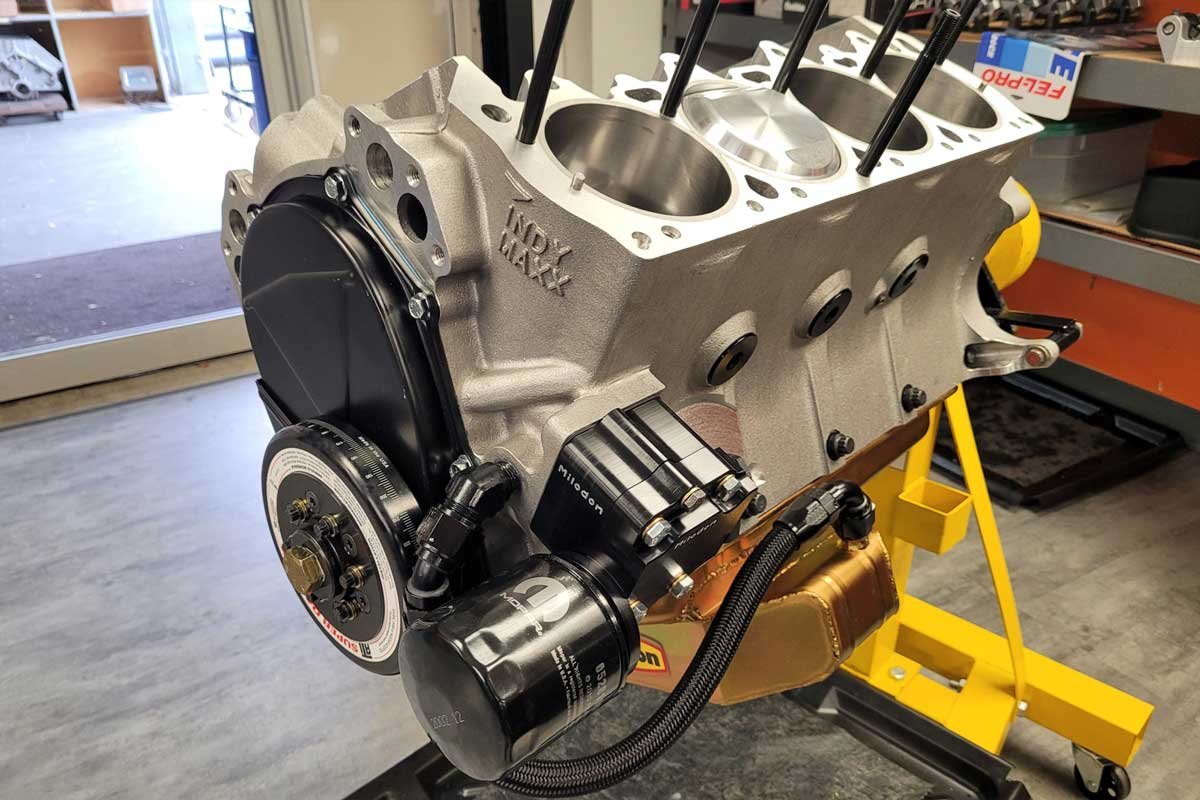

The second engine was a 572 CID Super Street Hemi, initially built in 2008. The customer returned the 900-horsepower Hemi to Indy for a refreshing and a detuning to make it more street suitable. The block was a Maxx Aluminum block with a 4.500-inch bore and a 4.500-inch stroke.

The Callies Performance Products/Compstar 4.500-inch crankshaft and 7.10-inch H-beam rods were cleaned, checked, and resized as necessary. A set of lower compression pistons from Diamond Pistons dropped the compression ratio to a pump gas friendly 10:1. The Hemi’s Indy 426-1RA CNC heads were rebuilt. These heads feature an exhaust valve relocated 2° toward the cylinder wall to gain valve-to-valve clearance. The 295 cfm, 167cc heads received new 2.40-inch intake and 1.94-inch exhaust valves actuated by 1.6:1 intake rocker arms and 1.55:1 rockers on the exhaust.

A new COMP Cams street roller camshaft with an intake lift of 0.622 inches and 254° duration and an exhaust lift of 0.614 inches with 260° duration was installed. Bushed wheel roller lifters from BAM Products were slipped into the freshly honed lifter bores.

To top the Hemi, Indy installed an Indy 426-3 intake manifold and an Advanced Product Design 1050 cfm billet street carburetor. The Hemi was fitted with an MSD distributor and Firecore Performance spark plug wires. Indy filled the Milodon oil pan with 20W50 Driven Racing Oil, filtered via a ClearView Filtration oil filter system.

Once on the engine dyno, the Hemi pumped out 741 HP at 6300 rpm and 700 lb-ft of torque at 4000 rpm on 92-octane pump gasoline. The engine is undoubtedly more streetable, but it still retains plenty of power to lay down solid 10-second runs at the strip.

Engine Three – A Hemi

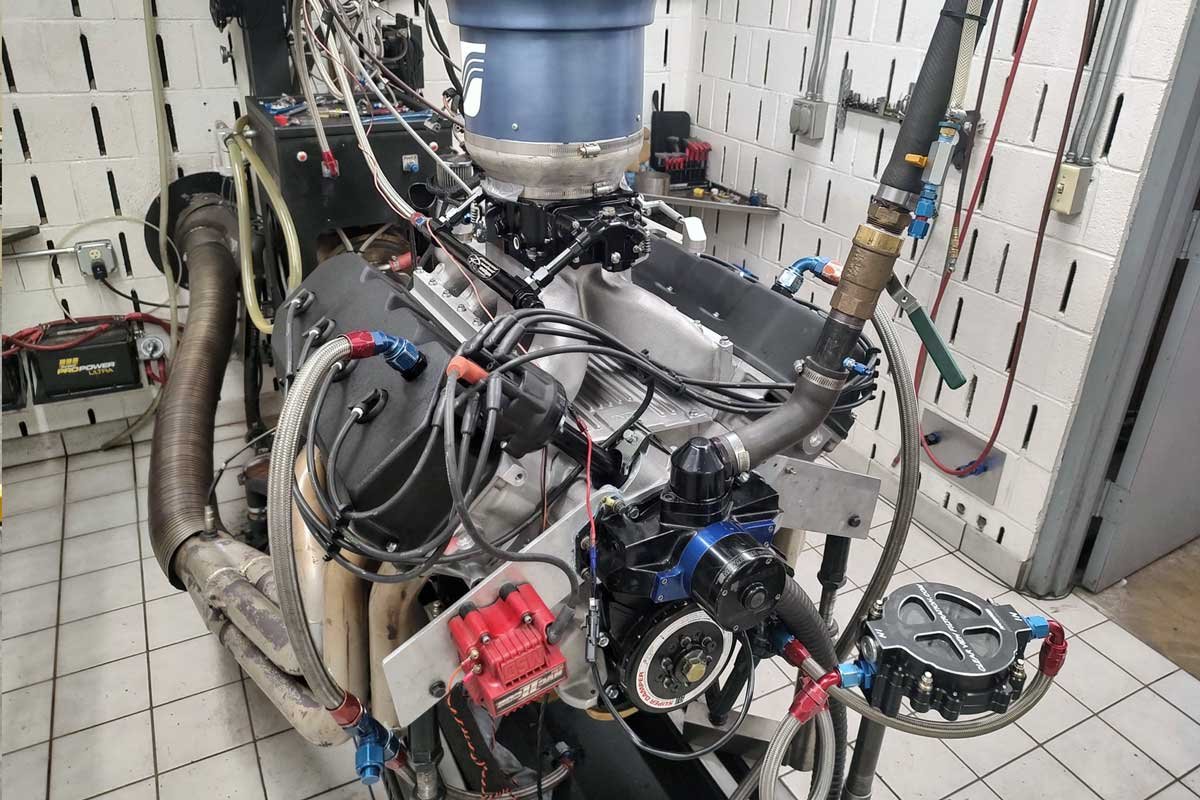

Engine three Indy labeled a “basic all-aluminum 572 pump gas street Hemi.” The Hemi block’s dimensions were a 4.500-inch bore and a 4.500-inch stroke. The engine was fitted with an Eagle Specialty Products’ 4.500-inch crankshaft with 2.200-inch rod journals and matching 7.100 H-beam rods attached to Diamond Pistons with a 10.5:1 compression ratio. The rotating assembly was internally balanced.

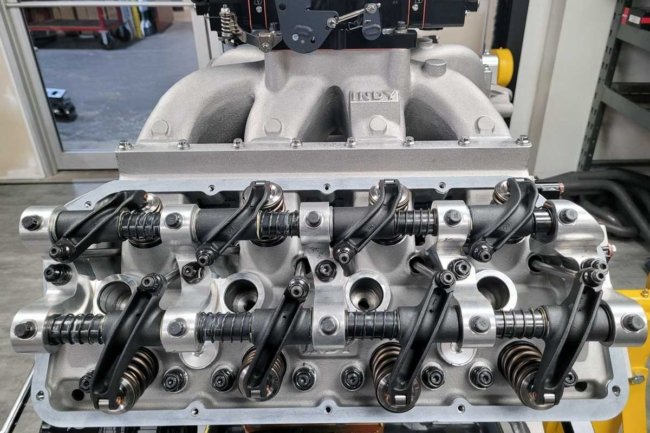

Mounted to the block were a pair of Indy 426-S/R aluminum Hemi heads equipped with 2.25-inch intake and 1.94-inch exhaust valves. The 170cc heads had complete CNC porting and were equipped with 1.6:1 intake and 1.55:1 exhaust rocker arms. Indy installed a COMP Cams roller camshaft with a 0.700-inch lift on the intake and exhaust coupled with 273°/278° (intake/exhaust) durations. BAM Products roller lifters with bushed wheels ride on the camshaft.

Indy installed a fully-ported 426-4 intake manifold and an Advanced Product Design 1050 cfm billet street carburetor. Like the previous Hemi, the oiling system consisted of a Milodon road race oil pan and a billet oil pump. A ClearView Filtration oil filter system filtered the 20W50 Driven Racing Oil.

Like nearly every engine from Indy Cylinder Heads, the Hemi has an MSD Pro Billet distributor, Firecore Performance spark plug wires, and an ATI Performance Products harmonic balancer. The 92-octane pump gas Hemi pumped out 753 hp at 6500 rpm and 690 lb-ft of torque at 4800 rpm. Moreover, the lightweight aluminum construction keeps the fully assembled engine’s weight below 500 pounds.

The coverage of these three engines is merely a ripple in the water compared to what Indy Cylinder Heads can build or supply. Anything a Mopar enthusiast needs, regardless of the desired use of the engine can be achieved. For more information about Indy’s parts, pieces, complete engine builds, and pricing contact the representatives at Indy Cylinder Heads.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by