A while back our 1970 pro touring Super Bee started making a little bit of noise in the rear end along with not always engaging both wheels during a burnout. We found some down time and decided to tear into the 8.75 rear axle.

After removing the rear brakes and sliding the axle shafts out, we noticed that the ends of the splines on the axles were damaged. We continued on and removed the third member to further inspect. When draining the fluid there was a heavy silver tint and knew that was not a good sign.

Once we removed the third member, the issue was pretty clear. Somehow a spider gear had broken and has been slowly getting chewed up by the ring and pinion. This is not what we are wanting to see, especially since our first event, the Motor State Challenge, of the year was coming up in just a matter of a few weeks.

Knowing that we wanted to replace the gears and axles with something that could take a beating, we reached out to Moser Engineering. They have been industry leaders for their differentials and axles for many years. We knew if anyone could help, it would be them.

Moser Engineering has a long list of Mopar components and they keep a huge inveroty of parts on hand. If they need custom axles, that’s no big deal as they can cut and spline custom axles in just a couple of days.

When we first spoke to them, we explained that this was not your ordinary 1970 Super Bee, and that we do a lot of autocross and road course events like DriveOPTIMA series and others alike. We had the current setup in the car a while and wanted to know what would be the best solution for our style of racing and driving the car.

They knew right away what parts would fulfill our needs. They suggested an 8.75 489 case center section with 3.23 gears from Yukon. We opted for a natural finish on the casing, but Moser Engineering offers multiple powder coating options when placing your order.

Moser installed and set up the Yukon gears in the new center section to save us a lot of time and worry about anything being set wrong. As you can see in the picture, there is yellow paste on the gears to verify correct gear contact.

We stuck with this gear ratio because with the 8HP70 transmission, the first 3 gears are very short. Mind you the newer Chargers and Challengers with the 8HP70 come with 3.09 ratio from the factory.

Keeping the power equally to both wheels we used an Eaton Truetrac. It will make sure when hitting the tight corners on the auto cross or road course that the power will be planted coming out of the corner. They suggested the Truetrac due to its simplicity and low maintenance.

We could run what ever rear different oil we wanted and did not have to worry about any additives. The Truetrac will work the same on day 1273 as it did on day 1. We liked the sound of low maintenance and longevity.

Since the axle shafts were damaged, we also grabbed a set of Moser Engineering 33 spline axles with green bearings attached. Yes we know, green bearings will not hold as much side load around corners but the last pair gave us 20,000 miles and if we have to replace bearings every 20,000, so be it.

We knew that Moser keeps a lot in stock, but we were still surprised that everything was in stock and would be on our door step in about 3 days. Mind you, it helps that we are also located in Indiana.

We took a close look at our housing and thankfully it seemed to still be straight . Since everything was out of the housing, we made sure to do a thorough cleaning to get any debris out before installing the new center section.

If we happened to have bent or cracked our housing, Moser Engineering also offers multiple housing options. The housings they offer are fabricated or stamped and they come powder coated in just about any color you want.

The center section comes with what looks like a brass spacer. This spacer will be needed if you are running factory adjustable wheel bearings. The spacer helps prevent the axle shafts from moving in and out. Since we are running green bearings, we do not need this spacer.

Once we had the housing cleaned out, we used a little bit of RTV on the provided gasket from Moser Engineering and bolted the center section in place. The rest was just as simple as sliding the axle shafts back in and reassemble the brakes.

Our drive shaft length did not change, but the u-joint did. We had to see our friends at Action Machine Shop in South Bend, Indiana to get the correct u-joint installed in our driveshaft to mate with the new Moser center section.

After the drive shaft was installed, we topped off the fluid with Lucas 80w-90 gear oil. It is not recommended to use synthetic gear oil for the Eaton TrueTrac and 80w-90 weight is specified. It is also noted that you should not run a friction modifier like you do in other rear ends.

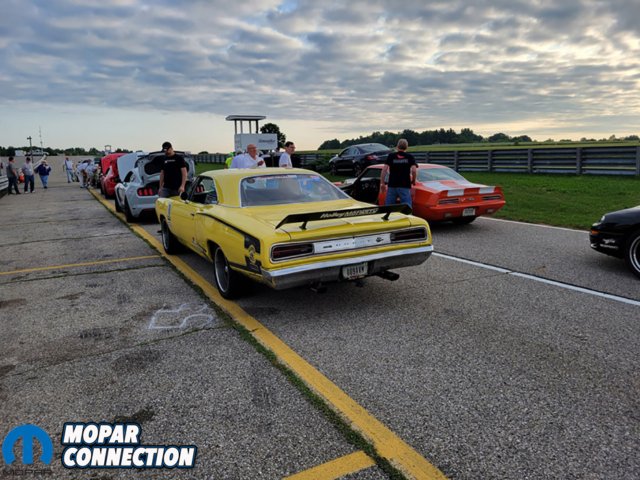

With the rear end full of fluid and the wheels torqued, we dropped the car down off the jack stands and headed to the Motor State Challenge. We are only a couple hours from Gingerman Raceway and drove the Super Bee to the race.

There is not a break-in procedure for the rear end or the Eaton Truetrac. The gears do like a little time and heat to mesh them together. We took new oil and did a drain and refill at the track before we started racing just to ensure we get any contaminates out from the gears wearing in on the couple hour drive.

Out on the track the rear end never made any noise. There was A huge difference on the track when coming out of the corner, the Super Bee felt more planted and had more traction than before.

The Eaton truetrac provided enough slippage going into the corner to allow max grip. When getting into the throttle, the Truetrac would engage and allow us to drift out using all of the track. The green bearings survived the track day. This was a much needed upgrade that we did not know that we needed.

This year at the Motor State Challenge, we were the only Mopar in attendance. If you are looking to get your car out on a track and want to dodge some cones on a short course, this is the perfect place to start. There is no pressure to win and everyone is friendly and willing to help with questions.

The event starts off on a Thursday with a cruise to prove you are a streetcar with a dinner at Weko Beach on Lake Michigan. Friday is the track day at Gingerman Raceway. The event finishes up with an auto cross at Tire Rack in South Bend, Indiana on Saturday.

We have raced this event multiple times in our Superbee and in Orange Crush. You can read more about both cars attendance on the site or check out Motor State Distributing website. Check out our other articles at Mopar Connection for more information and how to get involved. Thanks to the help of Moser Engineering, we were able to attend this event again this year.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by