The math behind solid lifter setup has always been pretty simple. By nature of the design, the only floating adjustment point is at the rocker arm. However, hydraulic tappets are a totally different animal, especially when used with aftermarket rocker assemblies. The squishy innards of said lifters add a variable that must be taken into account to achieve accurate geometry. Here’s how the team at Hughes Engines goes about it with their checking lifter (P/N HUG 8100):

The math behind solid lifter setup has always been pretty simple. By nature of the design, the only floating adjustment point is at the rocker arm. However, hydraulic tappets are a totally different animal, especially when used with aftermarket rocker assemblies. The squishy innards of said lifters add a variable that must be taken into account to achieve accurate geometry. Here’s how the team at Hughes Engines goes about it with their checking lifter (P/N HUG 8100):

When setting up the proper rocker arm geometry and pushrod length with a hydraulic lifter, it is important to use a checking lifter that is the same running length as the final assembly lifter. Chrysler lifters from different sources may vary in running length. This procedure and the checking lifter have changed slightly to make it easier to get good results.

To use the adjustable lifter:

Step #1: Measure the internal length of the lifter you intend to use for final assembly. This is best done with a 1.0”-2.0” or 2.0”-3.0” micrometer. If you are using the Hughes 5001 lifter make this measurement 1.650”. If you are using the Hughes 5003 lifter make this measurement 1.588”. If you are using any other lifter you must measure it yourself.

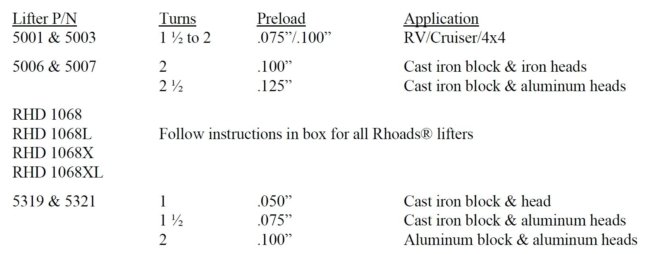

Step #2: For all lifters except for HUG 5003, determine the preload amount you will use during final assembly and subtract that from the internal length. This gives you the running length. Use the following chart to determine the proper preload. This preload is the amount the pushrod cup will be below the retaining ring when the engine is running. HUG 5003 note – The 5003 has a built-in preload and does not need the subtraction.

Step #2: For all lifters except for HUG 5003, determine the preload amount you will use during final assembly and subtract that from the internal length. This gives you the running length. Use the following chart to determine the proper preload. This preload is the amount the pushrod cup will be below the retaining ring when the engine is running. HUG 5003 note – The 5003 has a built-in preload and does not need the subtraction.

Step #3: Adjust the Hughes Engines adjustable lifter to match your running length by moving the set screw and nut to the length measured in Step #1 and with the preload (as shown above) subtracted. Note: The lifter does not come to you pre-adjusted.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by