In 1989, Callies Performance Products was founded with its specialty in manufacturing high-performance crankshafts. As the years passed, the company expanded into developing and producing high-quality connecting rods and camshaft cores. Callies has also entered the engine manufacturing business through its sister company Energy Manufacturing Ltd. (Energy).

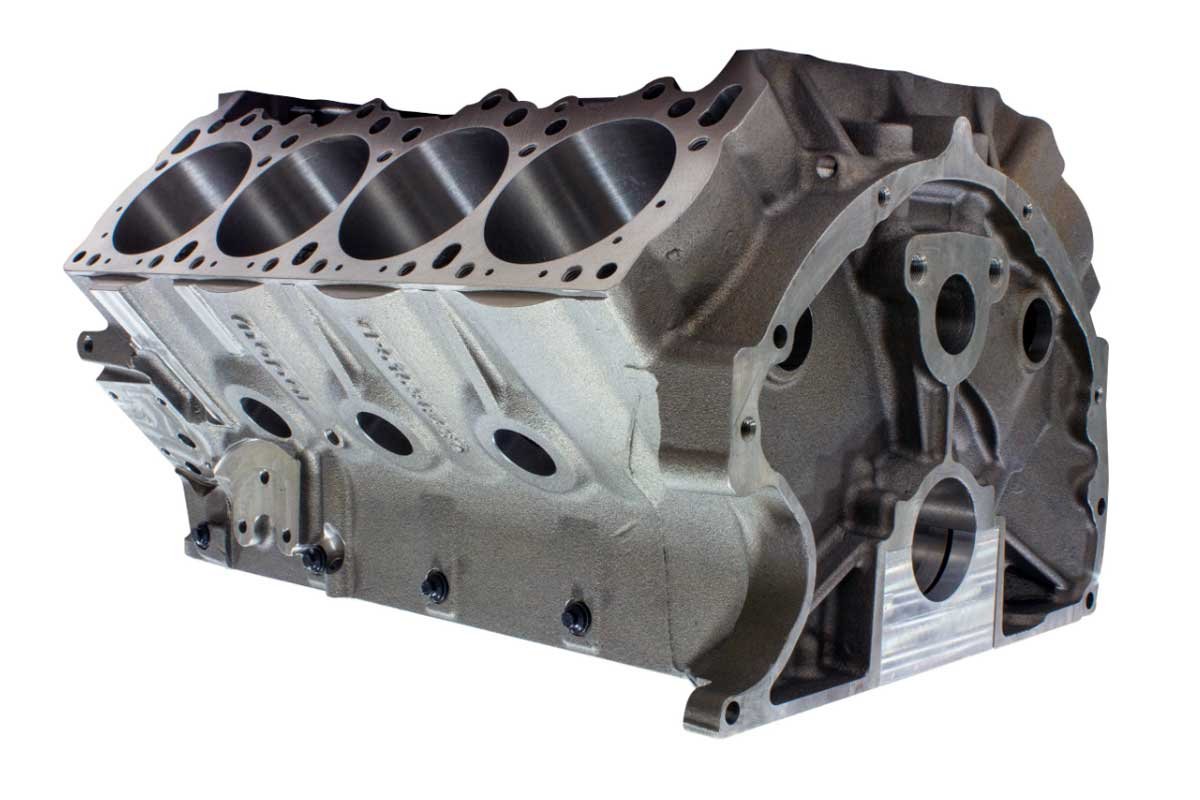

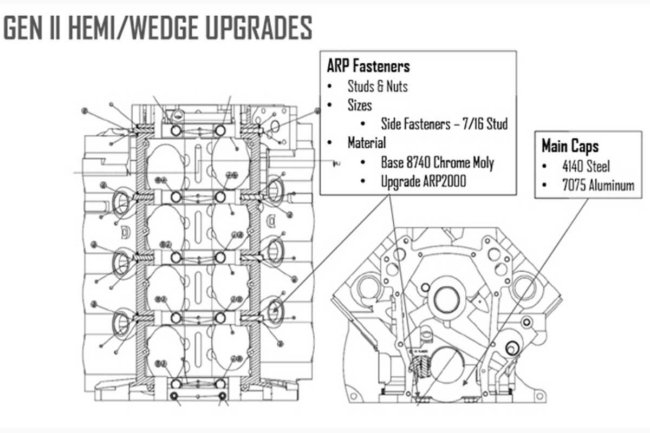

Above: Callies and Energy have developed a Gen II Hemi block that addressed a few factory concerns and added new features unavailable during the original Gen II Hemi’s reign of the mid-60s until 1971.

Callies and Energy have a licensing deal with Fiat Chrysler Automobiles (FCA) to manufacture and distribute the Gen II 426 Hemi (and 440 Wedge) cast iron blocks. Energy produces the blocks at its Fremont, Ohio, foundry, and Callies manufactures the rotating assemblies and componentry at its Fostoria, Ohio, manufacturing facility.

Each Mopar Original Licensed Product (OLP) block will carry the authentic Mopar part numbers and be produced from the original molds and cores. In addition, each engine block comes with the following components:

An engine block with main caps and rear oil seal retainer (assembled)

Block plug kit (uninstalled)

Camshaft bearing kit (uninstalled)

(2) 0.040-inch oil gallery restrictors (uninstalled)

½-inch oil pickup tube adapter (uninstalled)

(4) AN10 valley plugs (uninstalled)

Bronze distributor bushing (uninstalled)

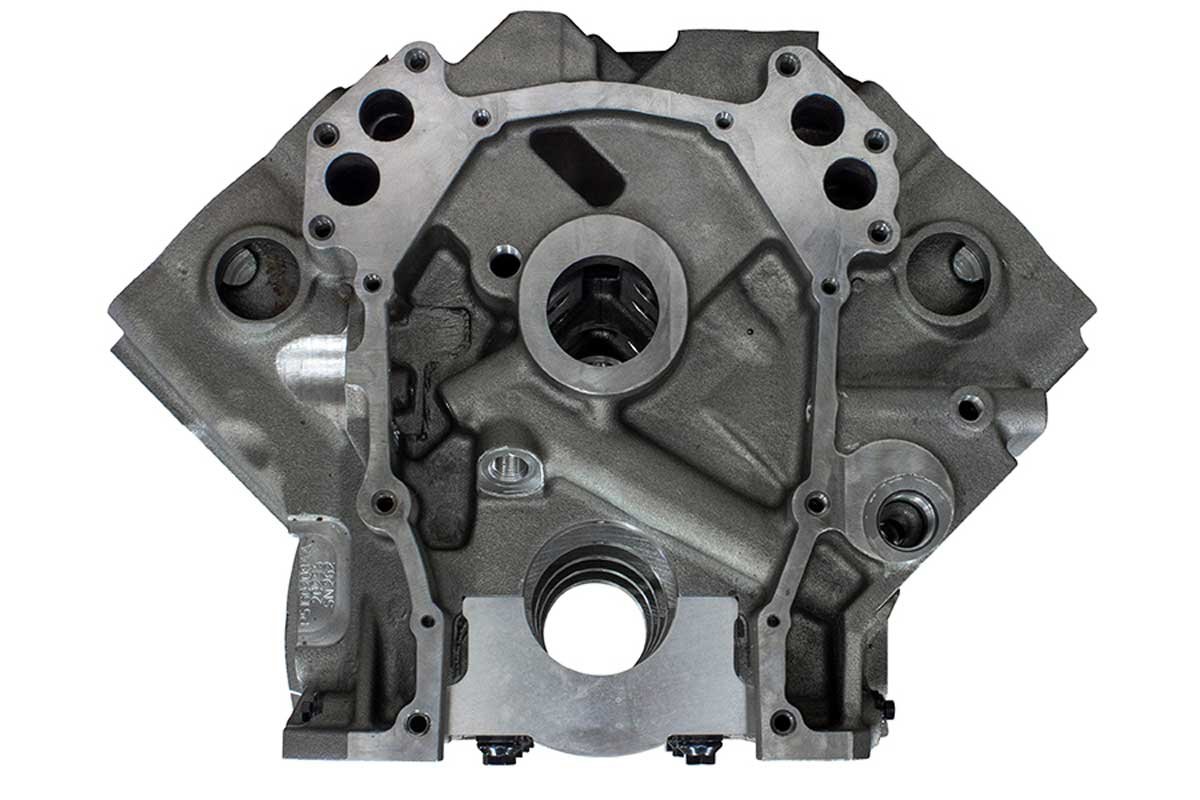

Above: There are three unique block castings, all with a Mopar part number. Although there are a few differences between the three castings, all the castings have thick decks, high-strength main caps with ARP bolts, and fuel pump and oil bypass bosses cast into the block.

The Hemi blocks are cast in three different configurations. First, part number P5160208AA is a gray iron casting with a rough bore of 4.492- to 4.495 inches. All the camshaft lifter bores are finished to 0.9055- to 0.9061 inches and have been machined for tie-bar roller lifter clearance. The second casting is part number P5160210AA, which is identical to the previous casting, except it has a 4.242- to 4.245-inch rough bore. Lastly, part number P5160211AA has the 4.242- to 4.245-inch bore size but does not have machined roller lifter tie-bar provisions.

Each block has a Siamese water jacket design, which can accommodate a maximum overbore of 4.600 inches. However, it is recommended to have the block sonic-checked if the overbore exceeds the as-shipped bore dimensions. The blocks are machined to a stock raised block (RB) deck height of 10.725 inches, providing a super thick deck of 0.600 inches.

Above: The blocks have four (of the five) main caps cross-bolted, factory provisions for the engine mounts, and the standard deck height of a raised block (RB) engine. The blocks accommodate factory-style bearings or can be machined to accept larger 60mm roller bearings. The bellhousing area is stock, which allows any Mopar or aftermarket bellhousing with that pattern to attach without modification.

The Energy block has cross-bolted main caps on mains one, two, three, and four. The main caps are machined to accommodate factory bearings, with the bearing tangs located toward the driver’s side of the Hemi. Additionally, the castings have the factory bolt pattern and accept any factory or aftermarket bellhousing designed for a Gen II Hemi. On the other end of the block, the Energy casting has provisions to fit a factory-cast iron or aluminum-style water pump.

A factory oil pan will fit the Callies block, but a high-capacity pan will most likely be installed. The block comes with an adapter to house the stock oil pickup tube.

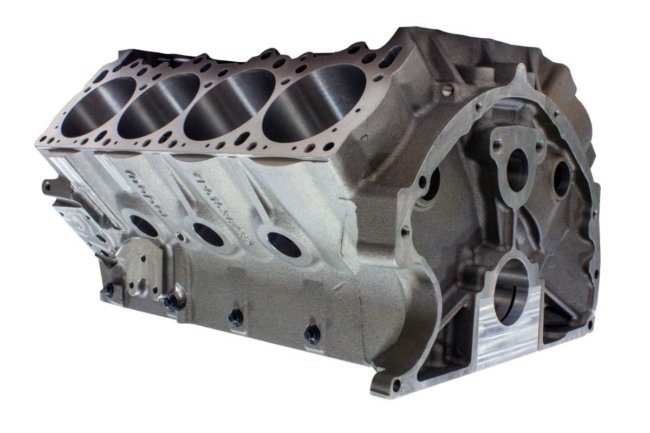

Above: If used, the Callies block has an AN-12 boss for a pickup bypass. The design bypasses the irregular and restrictive stock internal oil passages. Instead, the oil pump pickup is optimally placed, and the oil flows freely through the external braided line to the oil pump. A static or swivel-style pickup can be used if a competition oil pan is installed.

The casting is also fitted with an AN-12 boss machined on the front lower face of the block that connects to the inlet side of the oil pump. An AN-12 can be installed into the boss to connect externally to the oil pickup tube in the oil pan. If the external connection is employed, a ½-inch pipe plug (not included with the block) must be threaded into the oil pickup tube adapter in the casting.

Callies includes oil feed restrictors with the casting. Installing the 0.040-inch restrictors to control the oil flow to the valve train is recommended. Oil restrictors reduce windage created as excess engine oil drains past the rotating assembly. However, consult a qualified machinist before installing the restrictors if the engine is to be used on the street.

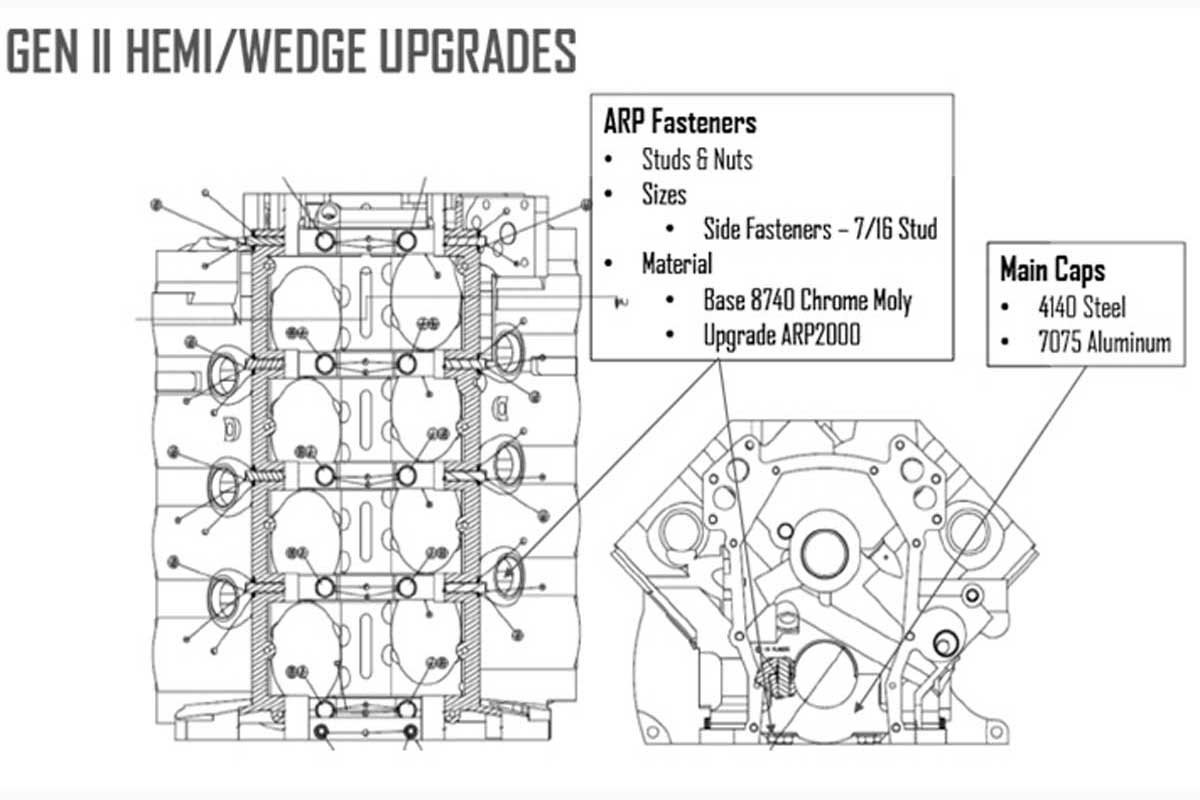

Above: Additional upgrades over a factory block include ARP fasteners employed throughout the block.

The block is developed to fit stock cam bearings, but for racers that need 60mm roller bearings, the engine block has enough material to accommodate the oversized cam bearings. Additionally, all the stock camshaft drive components can be employed with a factory-style camshaft at the factory cam-to-crank height. Finally, the stock front cover and ignition timing indicator are in the factory location.

Callies installs a rear seal that is offset and exclusive to this block. If a stock mechanical fuel pump is needed, Energy casts a boss for the pump in the stock location. If, however, an electric fuel pump is used, an off-the-shelf block-off plate is available from many sources.

Lastly, all factory cast iron and aftermarket cast iron or aluminum assembled heads will bolt to the block without any modifications necessary. Energy casts the block with head bolt holes that do not extend into the water jackets.

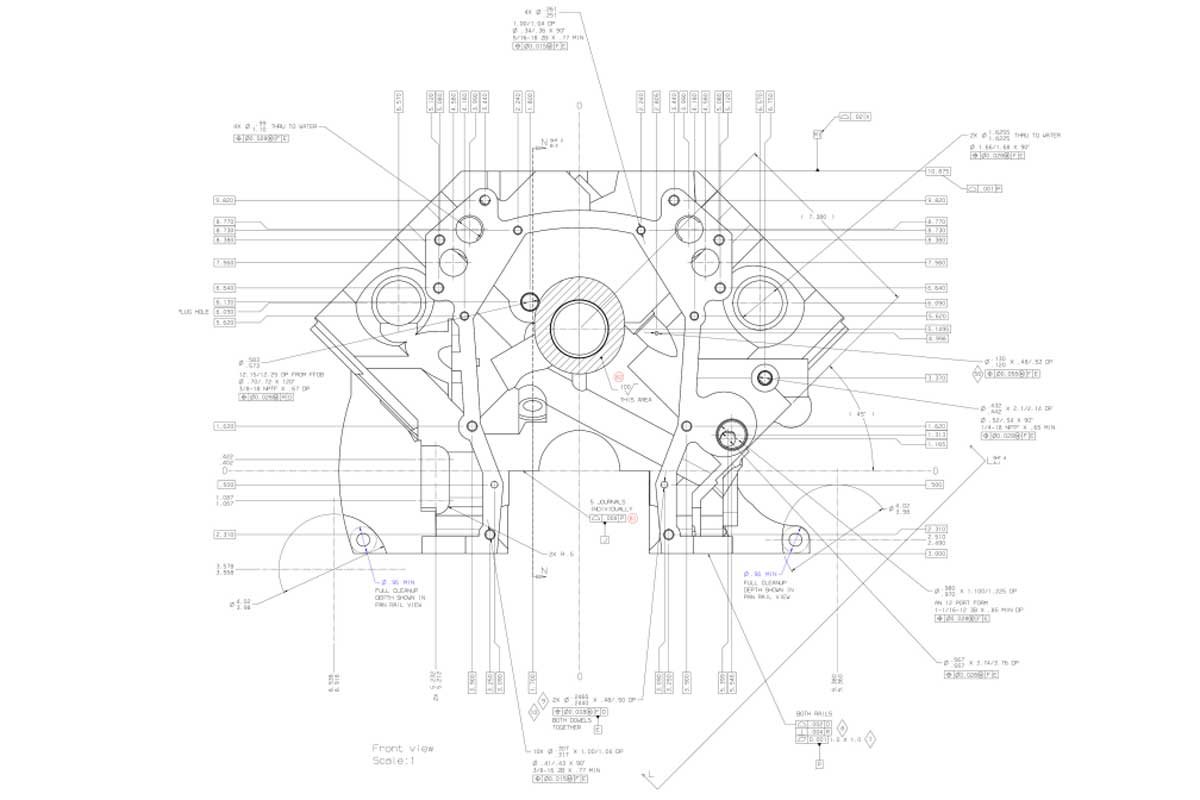

Above: Although difficult to read in a 4″ x 6″ image, the blueprint layout of the Hemi block (or any block) is something to behold when laid out on a 6′ x 10′ table. The details are incredible.

Each head bolt hole is blind tapped, but the treads should be chased during the machine shop machining procedures. Additionally, longer than stock studs are needed for the valley attachment to the block. Whoever builds the engine must determine whether the fasteners have enough thread engagement to prevent studs from pulling from the casting.

Besides the extra metal designed into the casting at the mains, deck, and valley where the heads are attached, Energy uses a higher quality metal than the factory blocks for added strength and rigidity. To learn more about the multiple changes of the Energy blocks, other than what has been described in this editorial, devised to fix the minor factory flaws, the Callies’ helpful representatives are just a phone call away at 419-435-2711. Tell them you need your Gen II Hemi fix, and that Mopar Connection Magazine sent you!