Earlier this year, Mopar Connection Magazine presented an original Plymouth AAR Cuda that Speedtech Performance updated with 21st- century technology. In that vein, Speedtech has taken a ‘60s Plymouth B-body and transformed it into a ‘70 Superbird with the latest hi-tech underpinnings. A vintage Superbird look with the road course handling characteristics of an NTT IndyCar Series vehicle resulted.

The Superbird is a tribute car that started as a ‘68 Road Runner. The current owner purchased the vehicle in its Superbird trim. The Road Runner was used as a testbed car for adapting Speedtech Performance’s proven suspension systems, the ExtReme Front Subframe (EFSF) and Torque Arm Rear Suspension (TARS), to the specific (’68-’70) B-body Mopars.

The Speedtech Performance design caters to the Gen III Hemi with the reasoning that enthusiasts updating to late-model suspension would want a modern powertrain to match. However, the Superbird was test fitted with a 440 big-block wedge to ensure that those who wish to run an old-school powerplant can be confident the engine will fit.

Speedtech plans, just like its E-body kits, to have engine mounting options to slip a 340 or 426 Hemi between the fenders to meet the powertrain needs of the most significant number of Mopar muscle car devotees.

For the early B-bodies, Speedtech Performance has eliminated the unique torsion bar front suspension and the, at times, finicky rear leaf springs. Instead, the computer-aided design (CAD) EFSF and suspension components correct the geometric concerns inherent with assembly-line mass-produced vehicles.

In addition, the EFSF front suspension optimizes the wheel travel and keeps the maximum tire contact patch on the pavement through all suspension cycles by correcting the factory angle problems.

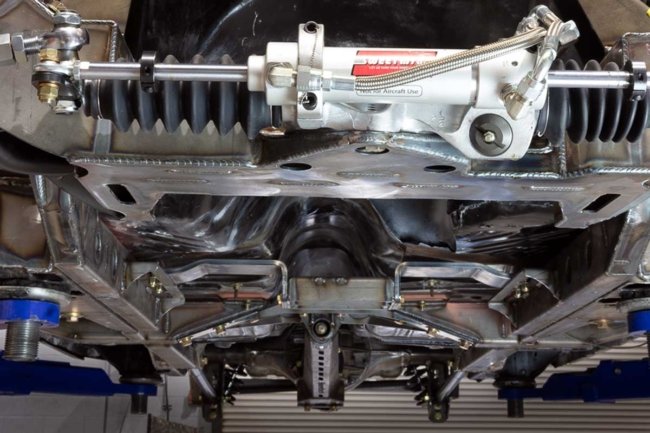

The EFSF provides comfort and control using tubular upper and lower control arms and coil-over shocks. Because of Speedtech’s reengineering, the EFSF offers a minimal bump steer ride with totally adjustable front suspension alignment angles. The EFSF uses Speedtech Performance’s exclusive 7075 aircraft forged aluminum tall spindles with heavy-duty C7 hubs and sealed wheel bearings.

The EFSF comes with a Sweet Manufacturing race tuned, high-strength power rack and pinion and an adjustable splined sway bar with an owner-selected spring rate. A pair of JRI single adjustable front coil-over shocks with custom Speedtech Performance valving are attached to the lower control arm and the subframe. The Draco coil-over springs are offered in owner-selected spring rates. Speedtech built the subframe transmission cross member to fit most transmission selections.

With the EFSF, the factory steering column may not be the correct length for a proper steering shaft angle. Therefore, Speedtech recommends an Ididit steering column to ensure the angles are acceptable. For the correct column, contact the Speedtech representatives for the part number for your application.

Zero body modifications are necessary to fit 325/30/19 tires under the front end. Even with the large tires, a steering angle of 30° exceeds the factory angle. Once the B-body’s unibody is updated with the Speedtech Performance parts, the EFSF is a removable bolt-in part of the chassis, which will simplify the installation of an engine and transmission assembly.

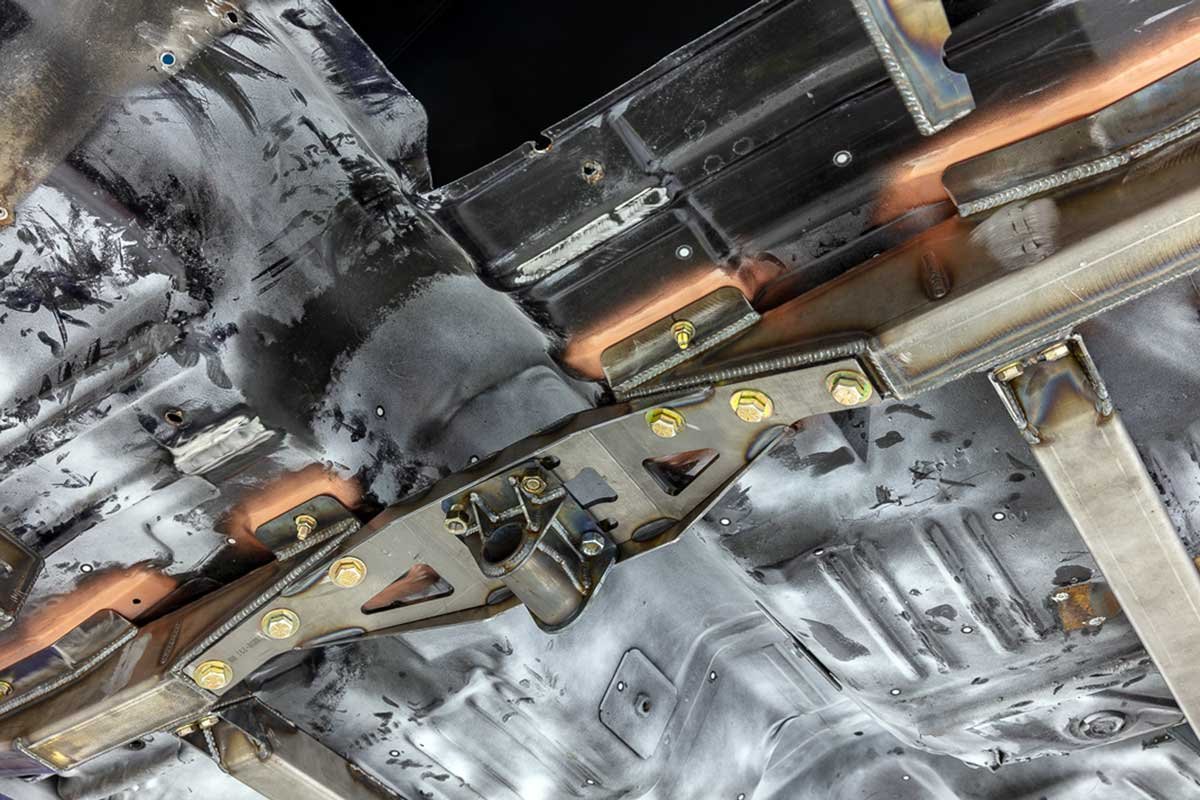

At the rear of the ’68-’70 B-bodies, Speedtech Performance ditched the leaf springs for a TARS that keeps the rear axle and suspension in a proper linear travel plane. Like the ExtReme front suspension, the torque arm rear suspension virtually eliminates the inherent geometric changes. As a result, it keeps the rear tires planted more efficiently than a leaf-spring or 4-link type suspension.

No floor cutting is necessary to fit the TARS to the chassis, and only minor welding is required. The ride height, roll center, and wheelbase are fully adjustable with the TARS installed. In addition, a Panhard bar accurately locates the rear axle and provides adjustability of the instant center. The TARS eliminates pinion angle changes during acceleration and deceleration that are found on leaf spring-equipped vehicles.

An additional benefit of the TARS is a predictable transference of load forces during acceleration and braking, which successfully manages movement along the pitch axis. Like the front, Draco coil-over springs ride on custom valved single adjustable shocks. Once installed, the springs allow for 2.5-inches of ride height adjustment. Lastly, the TARS is available with a 9-inch Ford differential.

To provide bind-free motion of the TARS, Speedtech Performance developed the propriety Articulinks, which, along with Delrin torque arm bushings, elevate the performance of the solid rear axle while maintaining ride comfort. The Superbird rides on 335/30R20 rear tires by adding mini tubs. The tires fit without the need to modify the quarter panel wheel openings.

The EFSF and the TARS can be purchased separately or as a complete system. Also, Speedtech Performance offers a dozen options to round out the front and rear suspension installation. A few possibilities include a Quicktime Bellhousing, custom headers, urethane engine mounts, adapters for the Gen III Hemi, inner fender aprons, and a transmission tunnel.

If you want to make a move and update your ’68-’70 B-body to surpass the performance level of a late-model Challenger or Charger, Speedtech Performance has all the components necessary to get you there. To learn more about the Speedtech products or purchase a subframe or torque arm system, call its representatives or start the ball rolling by contacting them online.