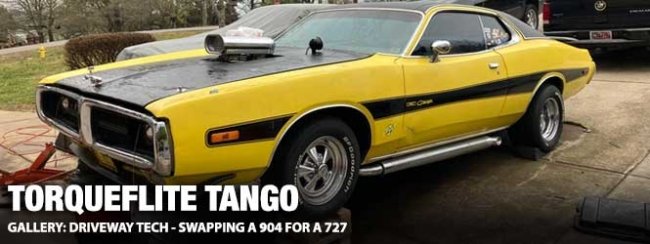

Whether installing a new engine or upgrading your current engine, consideration should be given to what updates are necessary to bolster the drivetrain to handle the increased engine power. Mopar Connection Magazine took the time to improve the transmission in our 1973 Dodge Charger.

With a freshly built 373 cubic-inch displacement engine (a stroked 318), an A727 Torqueflite would be better suited to handle the increased engine output over the factory A904. A transmission is critical in putting the engine’s power to the ground safely and efficiently.

Above: To remove the A904 from our ’73 Charger, we raised the front wheels with several 2x4s placed on top of each other. The stack was just tall enough to allow the K-member to clear the transmission.

We decided a brand refreshed A727 would be stronger than the stock A904. To start the removal of the A904, we lifted the front of the car using homemade wood stands constructed from 2x4s. After raising the front tires approximately two feet off the ground, we only had a half-inch clearance to slide out the deep pan equipped A904 from under the Charger.

Above: We scored an A727 Torqueflite transmission (top) for our ’73 Charger to replace the factory A904 transmission (bottom). The A727 is four inches longer than the A904.

The A727 transmission has been the go-to for countless cars for over sixty years due to its reliability and strength. The A904 has a less widespread pedigree in high-performance applications. The A904 was initially designed specifically for the slant six, and Chrysler upgraded it over the following years to accommodate the 273 and 318 V8 engines. On the other hand, the A727 was placed initially behind big blocks in 1962.

Before attempting the swap, we wanted to determine which transmission was in the Charger. The A904 has a square pan with one corner cut diagonally, while the A727 has a similar square shape and diagonal cut but with an additional small kick-out near the dipstick location by the bell housing.

Left: The A904 fits nicely between the headers. The factory cross member and the speedometer cable are attached to the transmission. Right: The A727 fits onto the same factory cross member and transmission mount, and the speedometer cable threads onto the transmission.

Like all auto manufacturers, Chrysler desired to keep production costs low, so there is a fair amount of component interchange between the A904 and A727 transmissions. Either transmission will attach to a small-block engine. Both possess the same bell housing bolt pattern, and the flexplates also interchange.

We sourced a neutral balance converter for the A727 and re-used all the factory fasteners from the A904. The transmission cooler lines are the same between the two transmissions and only need to be bent slightly and rerouted on the A727.

Above Left: The yokes for the two transmissions are different. The bottom yoke is for the A727, which has a 30-spline output shaft. The upper yoke is for an A904 with a 27-spline output shaft. Above Right: The two transmissions require different length driveshafts. The shorter unit is for the A727, while the longer shaft fits an A904.

The cross member and mounting locations are the same on either transmission, and the factory speedometer cable works with both as well. However, the speedometer gear in the tail shaft may have to be changed to establish the correct speedometer reading. With our specific application, a column-shifted automatic, the shifter levers on the transmission will also directly swap over from the A904 to the A727. On some swaps, they will need to be changed.

Above: The A727 was equipped with a deep cast pan designed by B&M.

For an A904 to an A727 swap, several things will have to be changed. The A904 transmission is 31 inches long from the bell housing to the end of the tail shaft, and the A727 is 35 inches. The length difference requires a shortened driveshaft when installing the A727. The physical length of the driveshaft is one of many considerations. The spline count of the transmission output shafts is also different.

Above Left: Of the two torque shaft brackets, the longer one (left) is the A904 bracket and is ½-inch taller than the A727 bracket (right). Above Middle: We installed a new Mancini Racing bracket on the housing of the A727. Above Right: The factory linkage worked as intended, without interference concerns.

The A904 has a smaller 27-count output shaft, whereas the A727 has a 30-spline shaft. For our 1973 Charger, the A904 driveshaft is 55 inches long from center to center of the U-joints. With an A727, the driveshaft is 50 ¾ inches.

If retaining the factory appearance is essential, factory parts must be sourced for the swap. Unfortunately, they can often be hard to find. For the 71-74 Chargers, all the factory linkages for A904s and A727s are the same, except for one bracket. The torque shaft bracket that attaches to the transmission is one-half inch shorter on the A727 and cannot be exchanged with one from an A904.

Left: A comparison of the dipstick tubes provides a view of the differences between the A904 (left) and the A727 (right) dipstick tubes. Right: The new A727 dipstick and tube fit perfectly around the A727 bellhousing.

The factory A904 bracket can be cut one-half inch shorter, or a new one can be purchased from Mancini Racing (Part No. MREHF50910). The new bracket came with two different-sized bolts, 5/16-18 and 3/8-16, for different applications, and it was finished in a factory coating. Also included was a new shifter bushing that stiffened up the shifter on the column. All the factory column shift linkages fell into place after bolting the new bracket to the transmission case.

The last part we installed to complete the transmission swap was a new A727-specific dipstick. We selected one from Mancini Racing (Part No. MREBU3301). The Dipstick was not car-specific and was held down by a bell-housing bolt.

On our initial test drives, the new Torqueflite transmission passed our expectations. The A727 provided us with crisp shifts, and with all the linkage set up properly, the column shifter pushed the transmission though the gears when manual shifting was demanded.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by