In what seems like a lifetime ago, this author at one time labored as a flat-rate dealership technician. As a bumper-to-bumper Lexus tech, there was always plenty of work: including new car maintenance and used car vehicle repair of all the manufacturers. On top of work in the shop, constant update training was a regular part of the job.

Due to many customer complaints involving noise, vibration, and harshness (NVH) along with water leak concerns, there were plenty of opportunities to attend several NVH classes each year at the Chrysler, Ford, General Motors, and Toyota/Lexus training centers. All the manufacturer’s training classes provided similar diagnostic methodologies, tools, and repair techniques, which provided the confidence needed to “fix it correctly the first time.”

NVH, just like at the dealership, tops the list of concerns of many automotive enthusiasts. When we modify our Mopars, the parts installed often push the vehicle’s performance parameters beyond what the factory engineers envisioned and designed into the cars. Because of these changes, we must essentially re-engineer our car to ride smoothly, quietly, and safely without NVH concerns.

So, what is NVH? A simple answer is noise, such as a drone, beat, road sound, or squeal, is any sound that is considered objectionable by the customer. A vibration is a shake, shimmy, shudder, or tremble that can be felt or heard. Finally, harshness is an aggressive suspension feel or lack of “give” in response to a single input.

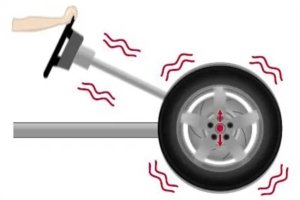

As more muscle cars are equipped with low-profile performance tires and rack and pinion steering, the quantity of road vibrations transmitted to the steering wheel has dramatically increased. Often, the trembling can be rectified by using a quality road-force balancer and match mounting the tires to the wheels. Road force is a load-roller pressed against the inflated tire to simulate the force of the road while gathering the combined uniformity of a wheel and tire combination.

Above Left: Tire and wheel combinations often are the cause of NVH problems. Properly installing the tire on the wheel without damage to the tire or wheel is critical (machine on right). A road force balancer (machine on left) will measure the sidewall stiffness and provides information to better match the tire to the wheel. Above Right: Dealership technicians often have access to vibration analyzers to diagnose NVH concerns.

Match mounting is an installation process where the tire balancer selects a tire’s optimum position on the wheel to provide the least tire and wheel runout. If the vibration persists, Borgeson Universal Company has developed steering system vibration reducers that provide minimize (or eliminate) the trembling felt in the steering wheel. Additionally, the reducers increase the overall life of the steering components and afford slack-free, performance-oriented steering feedback.

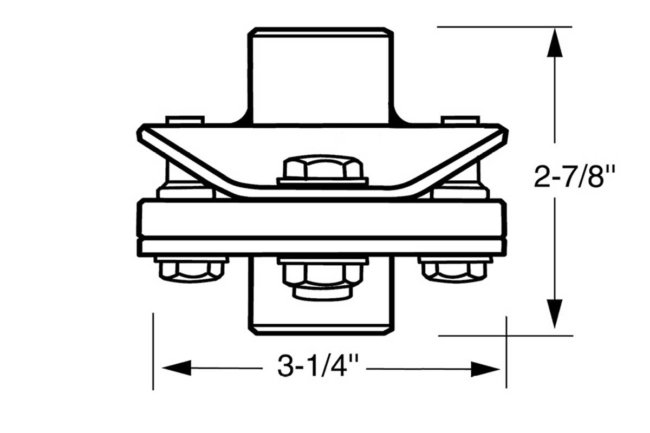

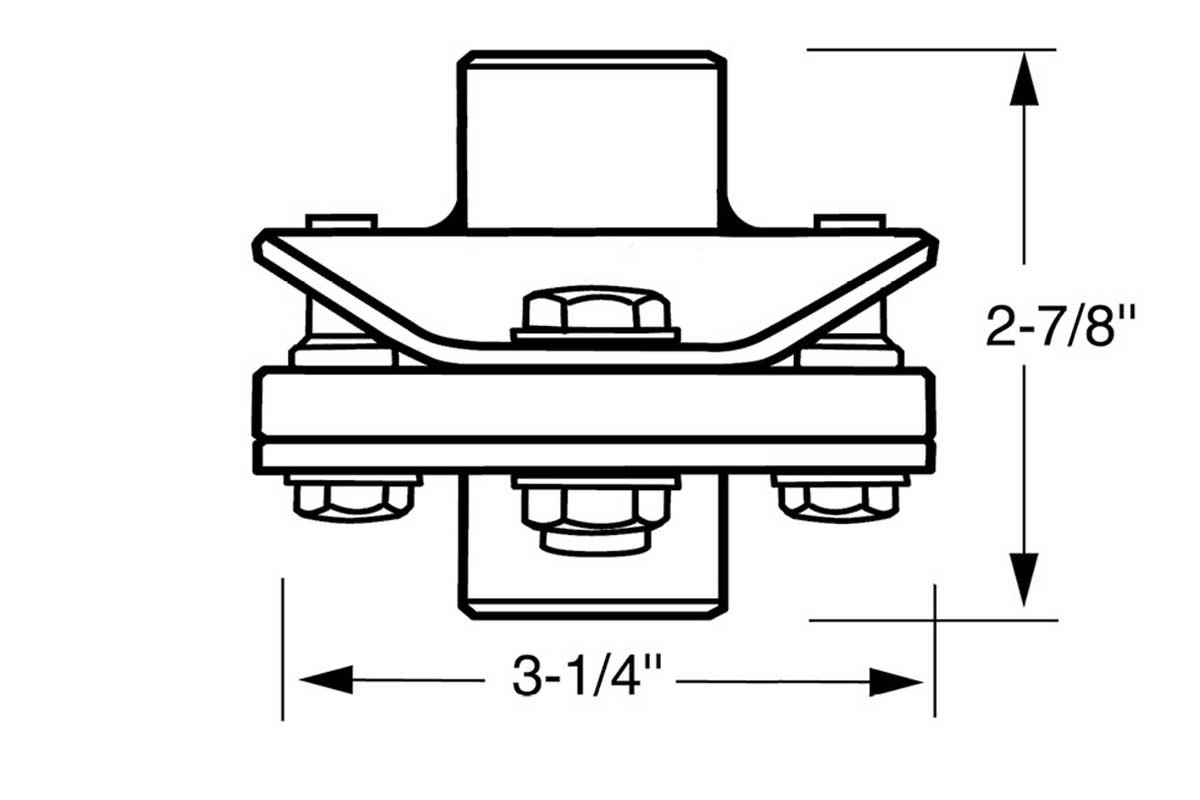

In 1988, Borgeson introduced its first vibration reducer. After years of updates and improvements, the vibration reducers are compact and can work in limited spaces of the engine bay. Each vibration reducer is designed with a metal-isolating urethane compound fitted into a housing constructed of steel, stainless steel, or polished stainless steel. The reducers can be ordered in a variety of spline counts suitable for almost any purpose. To obtain the proper guidance with your project, Borgeson suggests contacting one of its representatives with the intentions for your build.

Above Left: A Borgeson vibration reducer will substantially reduce or eliminate vibrations transmitted up the steering column when placed correctly in the steering system. Above Right: A Borgeson OEM-style rag joint provides vibration reduction, but it has limited uses because of its requirements of the steering column shaft and steering box input shaft to be on a similar plane.

Vehicle vibrations can be felt in the steering wheel and the seats. Additionally, a vibration, known as a compelling force, may cause a part unrelated to the vibration to resonate, resulting in a bothersome noise. When it comes to vibration, there are three options: eliminate, isolate, or tolerate. Eliminating the compelling force is always the main task.

Still, often, the force cannot be removed, so in those cases, the resultant vibrating body is isolated from the compelling force. In the case of a steering system, the Borgeson steering shaft vibration reducers isolate the quivering. In all circumstances, elimination or isolation should be the objective. Only a hardcore enthusiast will tolerate a vibration for an extended amount of time.

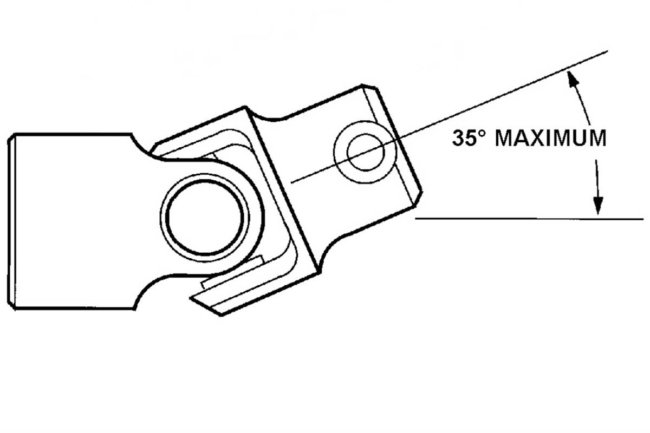

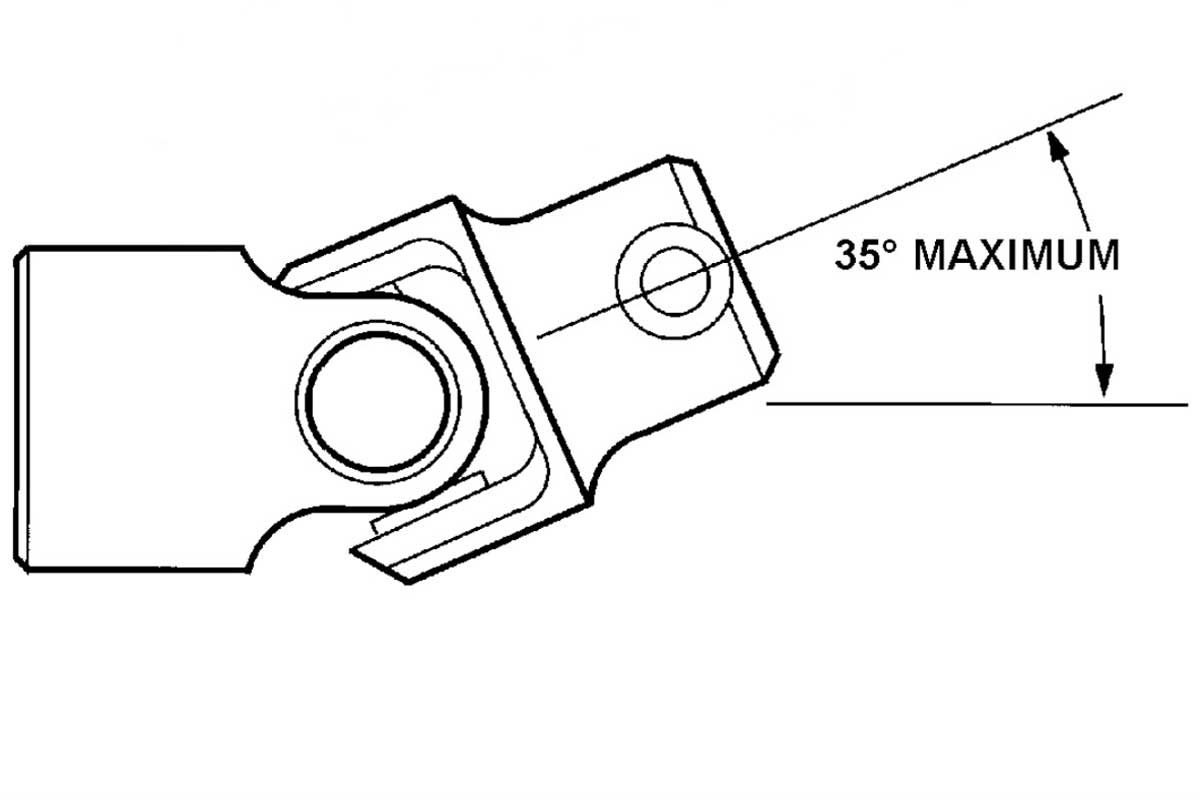

Above Left: The Borgeson vibration reducer can operate at a working angle up to 35°. The column steering shaft and the steering gear shaft can be on different planes but still operate smoothly. Above Right: The rag joint was found on many OEM applications. For assistance about which vibration control would work best with your build, it is recommended that you contact Borgeson’s representatives.

A steering vibration reducer can be an OEM rag joint or a vibration-reducing u-joint design. A rag joint provides a slight flex for a steering shaft within a few degrees of the same plane as the steering gear input shaft. While it is effective in vibration damping, having the steering shaft and steering gear at the same angle can be challenging to achieve. Conversely, a vibration reducer u-joint can operate at an angle between the steering shaft and the steering gear of up to 35°. With an ability to work at such angles, a vibration reducer makes better sense with many builds.

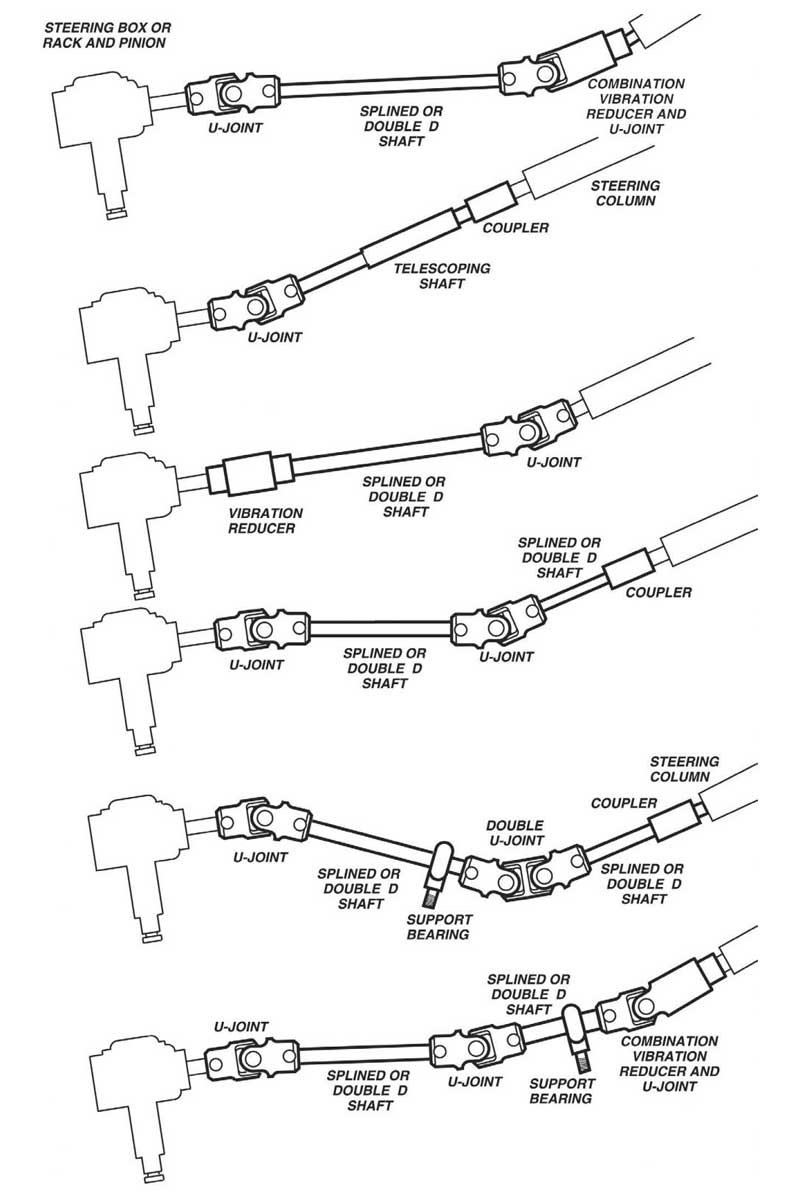

Borgeson recommends mocking up the steering system with the engine, oil pan, starter, exhaust components, and steering box (or rack and pinion) installed. This minimizes additional fabrication work required if the engine and other parts were installed later in the build. With the engine and other parts mounted in the engine bay, the steering column, the shaft (or shafts), u-joints, and support bearings can be assembled and phased to provide an efficient, interference and bind-free layout. Borgeson recommends keeping the steering design as simple as possible, using minimum shafts and u-joints to function effectively. Simplicity will result in a cost-effective build that is fun to drive.

Above Left: Borgeson offers bearing supports that resemble Heim joints. They are fully adjustable to provide the best shaft location for the steering system. Above Right: For a cleaner look, Borgeson has universal bearing supports that have a polished housing.

A shaft support bearing must be installed if the steering system has more than two universal joints so that the shafts are prevented from uncontrolled looping or whipping action. In a three u-joint system, Borgeson recommends placing the support bearing as close to the center u-joint as possible. If one shaft is significantly longer than the other, the bearing should support the longer shaft.

It is important to note that a shaft with a u-joint on each end must have the two u-joints phased adequately with each other. Phasing consists of the forks of the yokes closest to be in line with one another. Phasing will reduce premature wear or, in severe cases, binding of the steering system.

If your vehicle requires only two u-joints, the vibration damper can be installed at the end of the steering column or the steering gear. However, in a system with one or more shaft support bearings, the vibration reducer must be located on the column side of the supports. For example, if a shaft support was installed on the column shaft and a vibration reducer was installed further down the shaft, the support could transmit vibrations up the column.

While there is so much more to NVH than touched on in the editorial, remember that every vibration can be caused by misaligned or worn couplings, bearings, or gears, unbalanced rotating components, and improper component torque (looseness).

Additionally, parts rubbing against each other, aerodynamic or hydraulic problems with fans, blowers, and pumps, unbalanced magnetic forces in motors, resonance, and eccentricity of rotating components such as belt pulleys or gears can lead to vibration concerns. These vibrations must be eliminated, isolated, or tolerated, and for the utmost satisfaction with your ride, the vibrations should be eliminated or isolated. For additional information about vibration reducers, contact Borgeson or check out its tech tab on the website.