Many consider the Slant Six engine a marvel of automotive engineering. It was introduced for the 1960 model year in the Valiant and mid-size Dodge and Plymouth vehicles. Its nickname was earned from the 30-degree tilt of its cylinder block towards the passenger side of the engine bay, a revolutionary departure from the traditional vertical orientation.

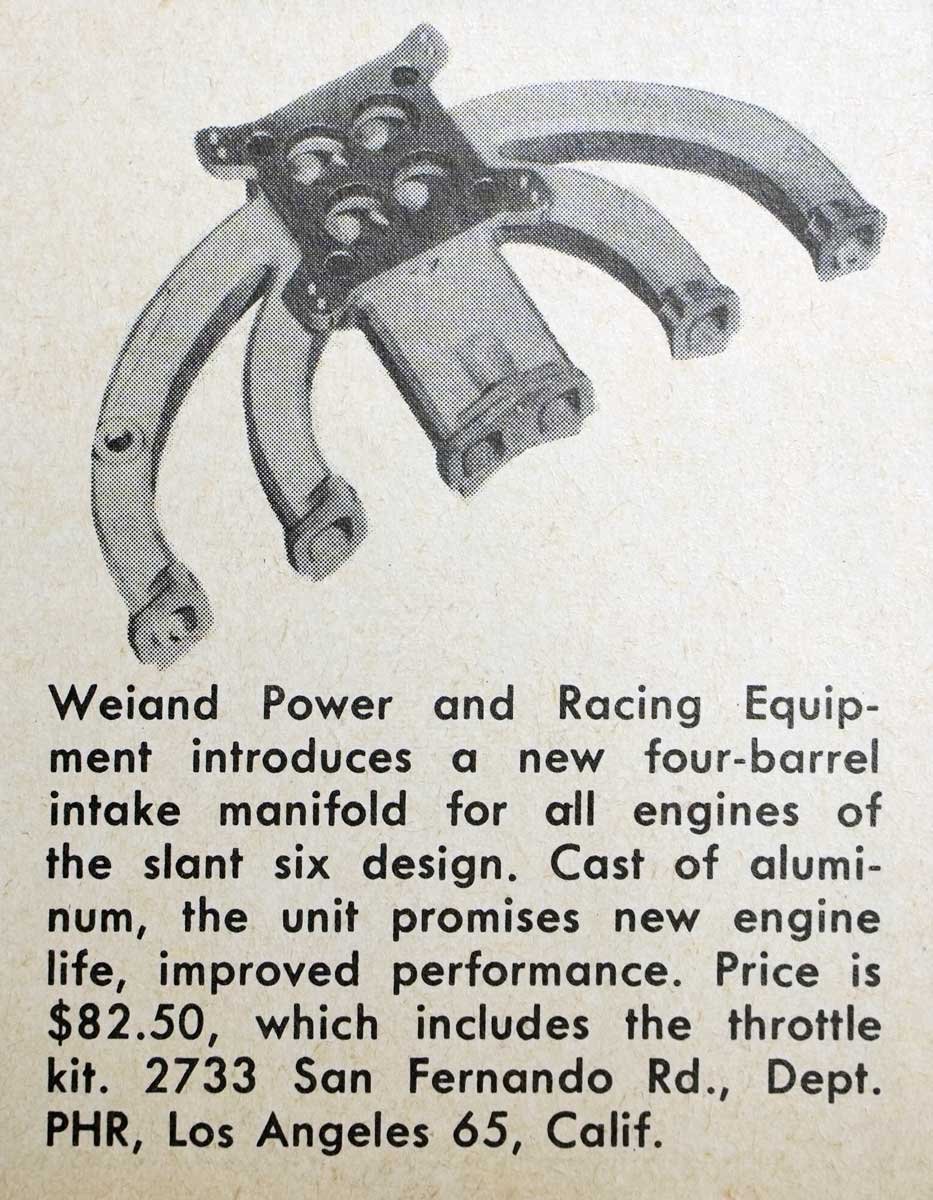

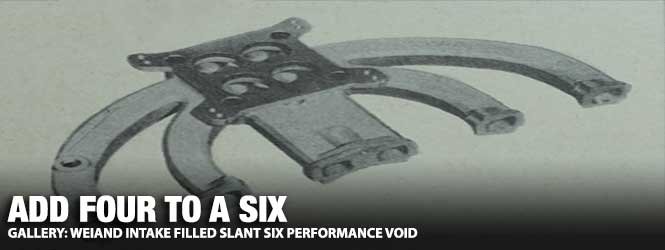

Above: Weiand Power and Racing Equipment filled the performance void after Chrysler discontinued the Hyper-Pak package, which included a long-runner ram intake. Weiand’s four-barrel manifold contained runners similar to Chrysler’s short-runner one-barrel design.

This innovative design reduced the engine’s overall height, allowing it to fit under the Valiant’s hood and into the engine bay due to its shortened length, resulting from an offset water pump. It also enabled efficient intake and exhaust manifolds, producing excellent performance and fuel efficiency.

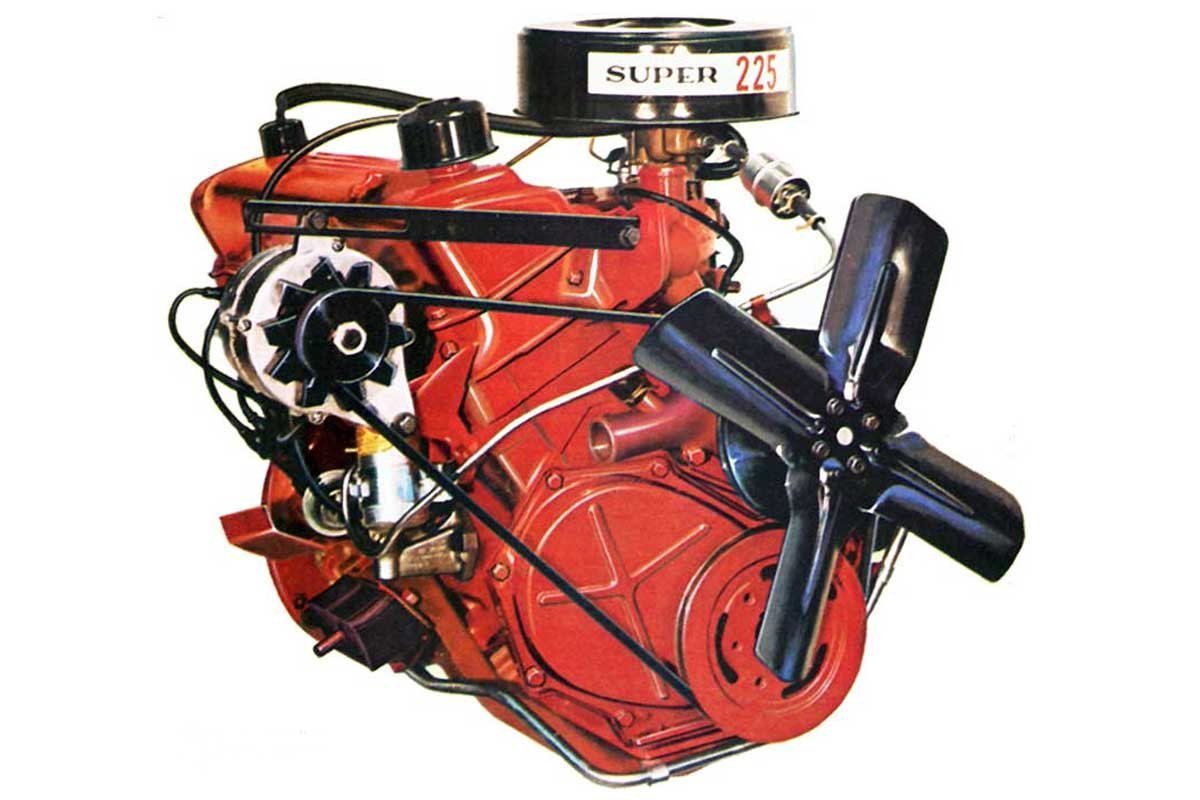

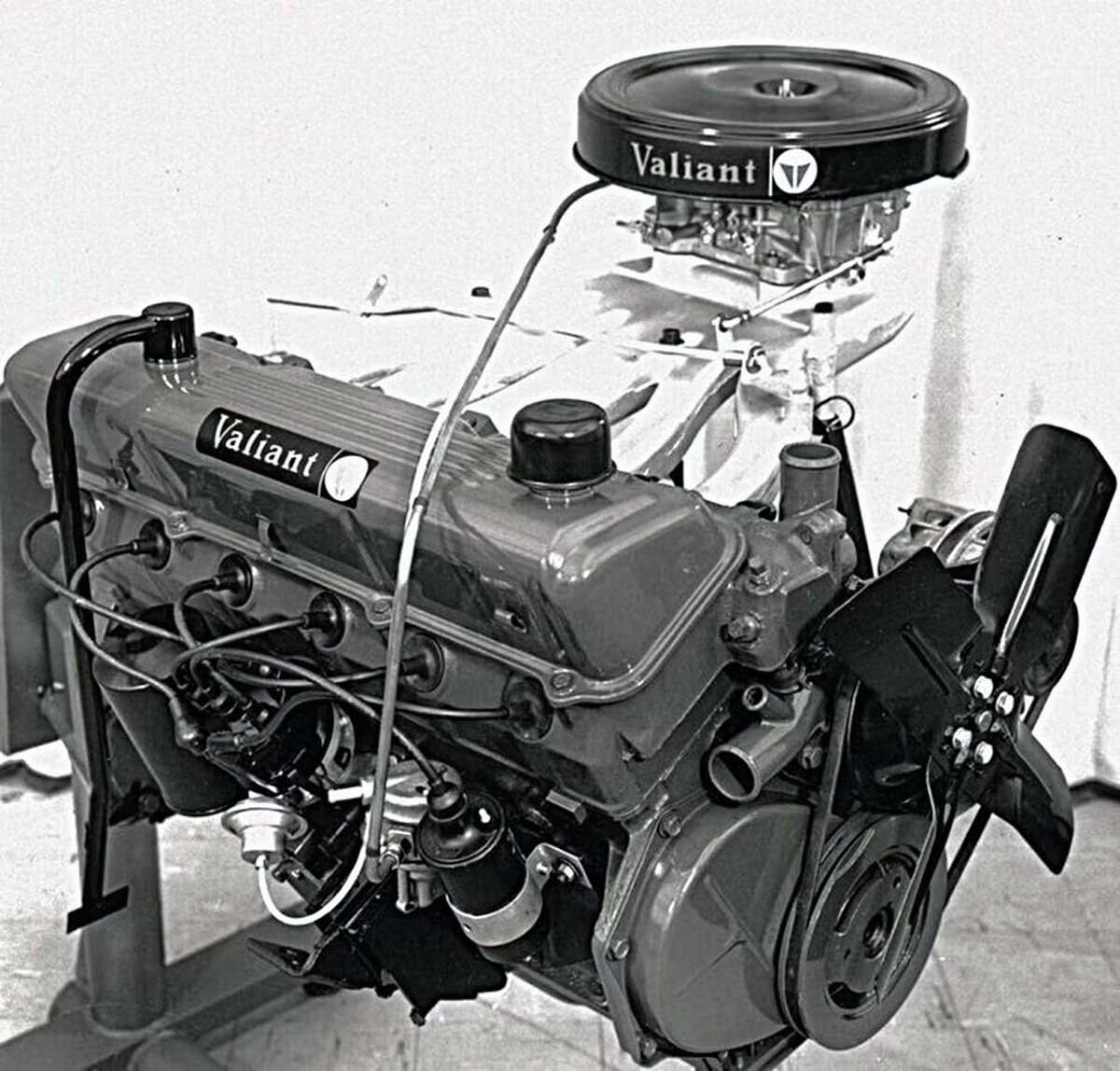

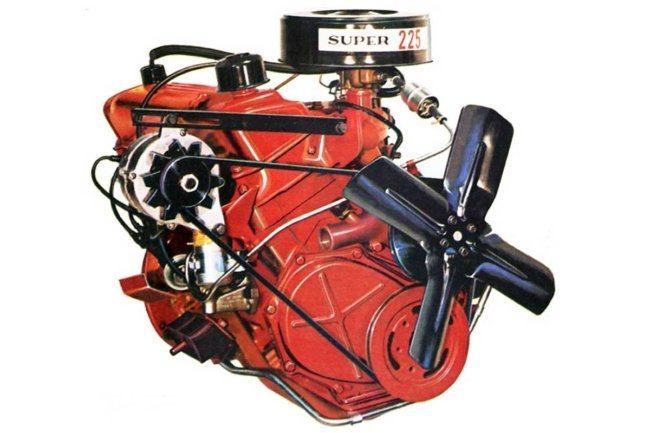

Above: Chrysler introduced its new six-cylinder engine in the 1960 Valiant as a 170 CID with a 30° slant to the passenger side of the engine bay. A larger 225 CID engine, also slanted, was installed in the mid-size Plymouths and Dodges. The engine’s unique slant allowed lower hood lines, and the water pump offset to the driver’s side of the engine resulted in a shorter engine that would fit into an engine bay suited for a shorter V8 engine. (Photo: Allpar.com)

Chrysler initially offered the Slant Six in two cubic inch displacements (CID): 170 CID (low G or LG engine) and 225 CID (raised G or RG engine), both fitted with a one-barrel carburetor. In the December 1959 edition of Hot Rod Magazine, the editors compared the compact vehicles the “Big Three” automakers offered.

Above: Aluminum 225 engines were optional for passenger cars from mid-1961 through the early 1963 models. The early blocks had twelve bosses cast into the right hand side oil galley, resulting from an abandoned idea of using hydraulic lifters that required direct oil fed from the main oil galley rather than splash oil needed for the solid lifters. Later, aluminum blocks (from mid-1962) did not have these bosses. Chrysler produced nearly 45,000 aluminum blocks. Production run difficulties eventually led to the demise of the aluminum block option. (Photo: Allpar.com)

The vehicles reviewed included a 1960 Corvair with an 80-horsepower (hp) 140 CID flat six-cylinder engine, a 1960 Ford Falcon with a 95 hp 144 CID six-cylinder engine, and the 170 CID Slant Six, which had an initially unrated horsepower value (for the magazine article) that Chrysler would later release as 101 hp.

The article highlighted the significant performance potential of the Ford and Mopar engines, igniting excitement among automotive enthusiasts. In contrast, the Chevrolet engine faced limitations regarding performance upgrades due to its design constraints of the air-cooled, horizontally opposed engine.

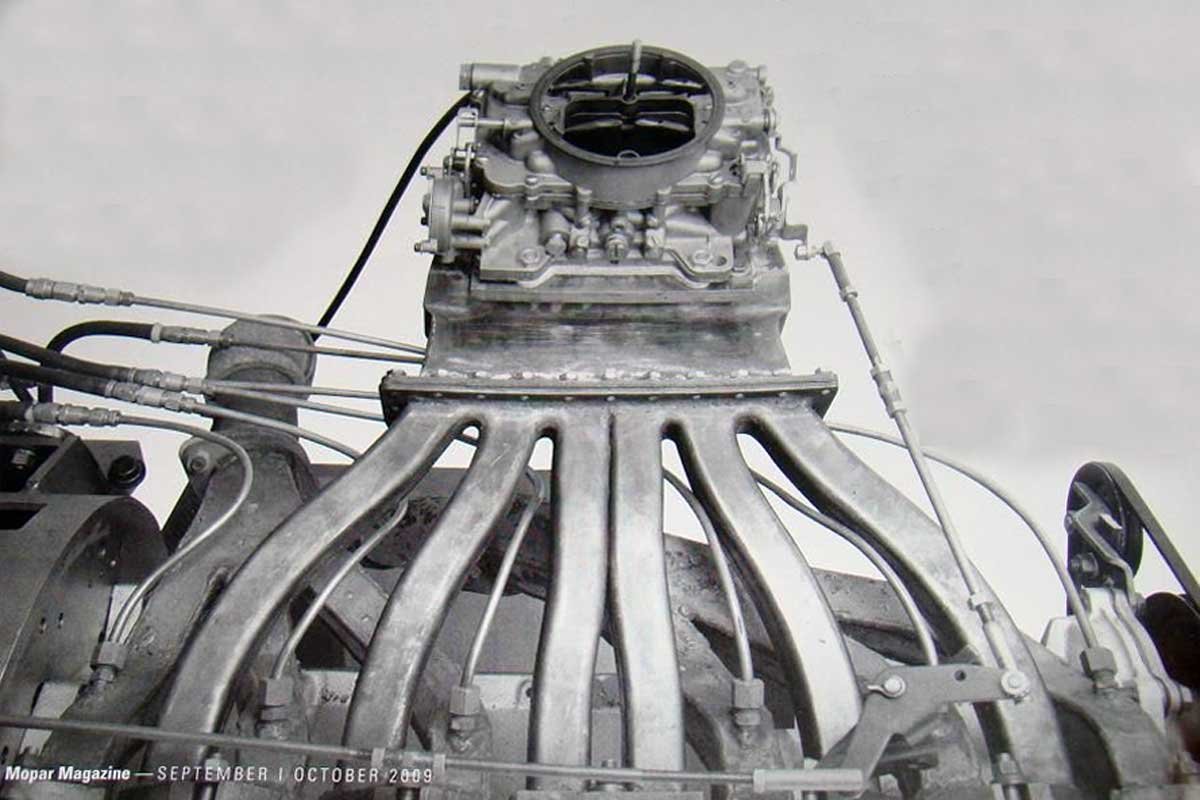

Above Left: Chrysler stepped up the slant six performance to compete in NASCAR’s all-new compact car class in 1960. Two of the most noticeable parts of the Hyper-Pak kit were the long-runner intake manifold and a pair of cast iron exhaust manifolds. (Photographer unknown) Above Right: Chrysler tested multiple runner lengths to determine the best length to maximize the corner exit acceleration RPM. (Photo: Mopar Magazine)

Unlike the competition, Mopar performance upgrades quickly became available once Chrysler executives learned of a NASCAR-sanctioned special race series (Cannonball Compact Car Division) designed for the new six-cylinder compact cars, which included all three major automakers.

Chrysler developed an in-house performance package called the Hyper-Pak for the 170, which was sold as a parts kit in 1960 and 1961 (engineering code A785). The components in the 170 Hyper-Pak LG package included:

• A long-ram intake manifold, which produced increased power around 4,000 to 4,500 RPM

• A Carter AFB carburetor, model 3083, positioned more than a foot away from the cylinder head for a ram-air effect

• A unique air cleaner assembly with a specialized element

• A standard block with custom pistons to achieve a higher compression ratio

• A Racer Brown ST-21 camshaft with a lift of .520 inches, a duration of 286 degrees, and a centerline of 108 degrees

• Corresponding valve springs and matched pushrods

• A set of split cast iron manifolds consisting of a 3-to-1 front and rear manifold

• A single 2.5-inch exhaust pipe connected to an Imperial muffler

• A high-performance 3-speed manual transmission, clutch, and pressure plate

Above: The Hyper-Pak engine in Plymouth Valiants dominated NASCAR’s Cannonball Compact Car Division. Chrysler won both of the initial races at Dayton Beach Speedway. On the road course, Plymouth finished first through seventh; on the high-speed tri-oval, Plymouth finished one, two, and three. (Photographer unknown)

Chrysler’s hard work developing the 170 into a 148 hp 153 lb-ft torque monster started with a historic 10-lap win at Daytona Beach Speedway’s 3.81-mile road course. The first seven positions were all Hyper-Pak Slant Six Valiants, a testament to the engine’s performance. The second race on the same day, a 50-miler on the high-speed 2.5-mile tri-oval, concluded with another display of dominance. Even with three Valiants knocked out of the race due to an accident, the top three finishers were Hyper-Pak Slant Six Valiants. Marvin Panch’s victories in both races were a proud moment for Chrysler and a testament to the slant six’s racing prowess.

Above: Weiand developed the first four-barrel manifold for the Slant Six, the WDP4. An open (shown) or four-hole carburetor mounting flange was available. Interestingly, the carburetor (usually a Carter) could be mounted with the primaries in one of four directions. There are schools of thought that the primaries should be toward the driver’s side, while others believe the primaries should be forward. Only dyno testing and economy evaluations would determine the best orientation. (Photographer unknown)

Displeased with the results of the NASCAR compact class, NASCAR suspended the class after only one year. With no need for a performance Slant Six, Chrysler ended the Hyper-Pak package shortly after the compact competition class was dissolved. A one-barrel carburetor was the only fuel mixer sold on production engines until the Super Six two-barrel option was introduced in 1977. The list of carburetors included:

• Carter BBS one-barrel (1960-1971)

• Holley 1920 one-barrel (1962-1972)

• Stromberg WA-3 one-barrel (1963 only)

• Holley 1945 one-barrel (1974-1980)

• Holley 6145 feedback one-barrel (1981-1987)

• Carter BBD two-barrel “Super Six” (1976-1981)

Above: In 1977, Chrysler added the two-barrel Super Six option for domestic sales. On a stock Slant Six, adding a Super Six setup was probably a better option for performance and economy than a four-barrel manifold. According to Chrysler’s data, upgrading from a one-barrel to a two-barrel was worth 10 horsepower. Mopar Connection Magazine dyno-evaluated a Super Six, increasing seven peak rear-wheel horsepower. (Photo: Allpar)

Shortly after the end of the Hyper-Pak program, Weiand reignited the performance fire with a four-barrel manifold for the Slant Six as depicted in the December 1962 Popular Hot Rodding magazine advertisement. Its unequal runner lengths appeared more like the one-barrel design than the long-runner Hyper-Pak manifold. Nonetheless, it provided the added punch that enthusiasts desired. Coupled with a small CFM Holley or Carter carburetor, a 170 or 225 (or later the 198) could muster upwards of 20-35 hp, but at the expense of fuel economy and efficiency, especially on an otherwise stock engine.

Above: Offenhauser developed a four-barrel manifold nearly identical to the Weiand manifold. However, the Offenhauser was more popular and sold better than the Weiand unit. When viewing the Offenhauser and the Weiand manifolds, the Offenhauser appears to have a larger plenum area, while the Weiand is slightly taller, and the runners are somewhat bigger. (Photographer unknown)

As the Slant Six moved through the emission-choked era of the 1970s, four-barrel manifold sales dropped. This era, characterized by stringent emission regulations, posed significant challenges for all engines, including the slant six. When Chrysler eventually dropped the engine from production (cars—1984, trucks—1987, Mexico—1991), aftermarket manifold sales plummeted, marking the end of an era for the Slant Six.

Weiand, now a Holley Performance company, no longer produces the slant six four-barrel manifold. Nevertheless, it still produces manifolds for the Chrysler small- and big-block engines. Furthermore, Weiand’s components catalog includes oil pans, thermostat housings, superchargers, and related accessories.

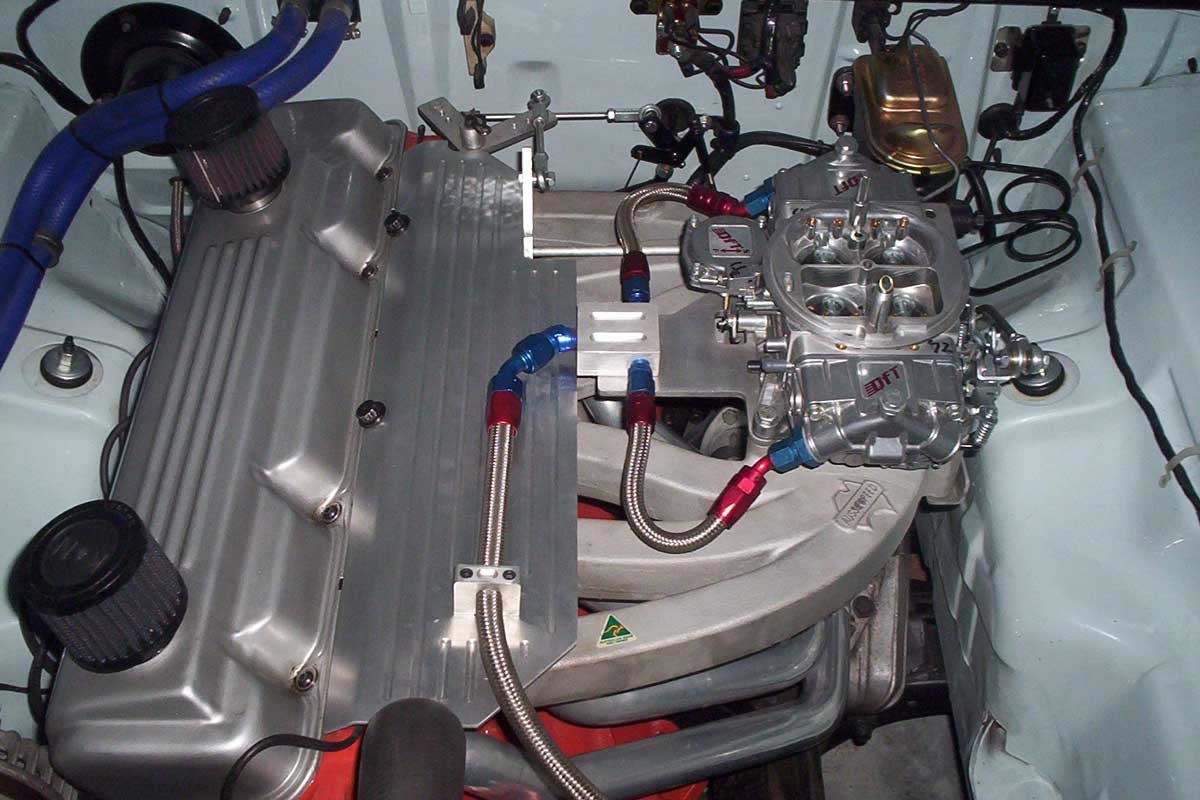

Above Left: 6=8 Clifford Performance Intakes & Headers has developed several four-barrel and dual two-barrel manifolds for the slant six. Clifford also has matched carburetor and exhaust components to maximize the Slant Six performance. (Photographer unknown) Above Right: Aussiespeed Street and Racing Components has recently become the four-barrel manifold manufacturer with the most significant demand. Aussiespeed offers short- and long-runner two- and four-barrel manifolds. The manifolds look as racy as they actually are. (Photographer unknown)

As nostalgia has become the norm over the last quarter of a century, 6=8 Clifford Performance Intakes & Headers accepted the need of Slant Six devotees offering various intake manifolds, headers, and carburetors. Clifford’s dedication to preserving the Slant Six’s legacy is a testament to the engine’s enduring popularity. Also, in recent years, Aussiespeed Street and Racing Components has begun offering short- and long-runner two- and four-barrel manifolds, further contributing to preserving the slant six’s legacy.