Classic Dodge trucks seen to be catching on, but we have been curious to why they are not becoming more popular quicker. You can find them fairly cheap, they have V8s, good axles, disc brakes, and much more. To us, they are a perfect candidate for a Gen III Hemi swap.

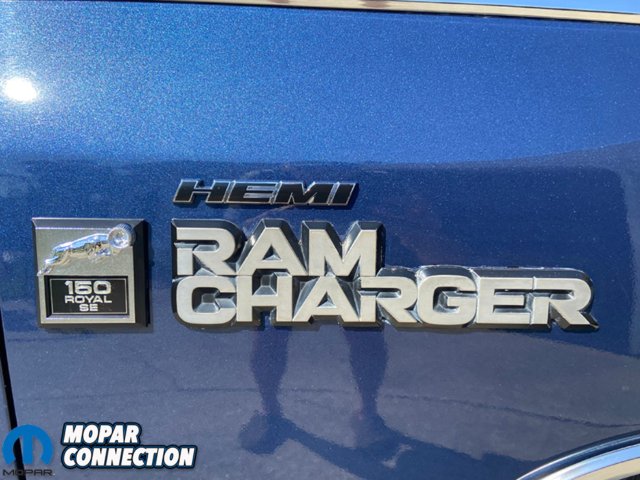

Apparently Wes Exelby also thinks like we do. He picked up a super clean 1984 Dodge Ramcharger and ended up Gen III Hemi swapping it. Although that was not the intentions at first, Wes seems very happy with his decision.

The Ramcharger started life out in Kentucky where Wes purchased it from the original owner. The Ramcharger was well cared for and had under 100k on the dash. It had a repaint at some point, but it was done very well.

Once the car was in Wes’s possession, he was quick to get started modifying it to his liking. The Ramcharger was fairly mechanically sound and Wes’s plan was just to do a couple cosmetic changes and drive it to some shows and around town.

Being it was 2wd, Wes decided that lowering it and putting on different style wheels would give it a good custom look. This would give it just enough of an edge to stand out at shows and turn some heads around town.

Wes picked up some van lower control arms to drop the front end. For the rear he installed longer spring shackles and a front mount kit to get the rear end down to match the front.

With the Ramcharger sitting at a good stance, Wes measured and picked out some Vision Torque wheels in Gunmetal color. He went with 20″ x 8.5″ in the front and 20″ x 9.5″ in the rear. Although 20″ seems big, we think they fit the Ramcharger very well.

This lasted Wes a little while. The Ramcharger had factory disc brakes and super clean interior. It was a joy to drive. The only thing lacking was the 318 was getting tired. It did not have a lot of power from the factory and was getting worse.

Since it already had a small block, Wes looked at rebuilding the 318 or maybe upgrading to a 340 or 360 if he found one. This would be easiest route and make the Ramcharger a little more fun to drive.

After many chats with Wes’s Mopar friends, the cost of rebuilding or upgrading to 360 or 340 really was not that cheap any more. The idea of Gen III Hemi swap was brought up once before, but Wes assumed the cost would be too great.

Now after getting numbers back from just a mild built Mopar small block, the Gen III Hemi swap was looking more feasible.

Although a crate Gen III Hemi was a little out of budget, a lot of junk yard 5.7L Hemis were available. Prices were all over the place and so was the milage on the engines.

Wes kept searching Facebook Marketplace on the daily and eventually one day a semi low milage 2015 5.7L Hemi with the 8 speed automatic out of a Challenger popped up for $2,000. It was four hours away, but very doable.

After making arrangements with the seller, Wes was on his way to pick up the engine and transmission for the Ramcharger. There were a couple small issues with the engine and Wes was able to get the seller to knock off $400.

Wes was very happy with the purchase and was ready to start the journey of making this work in the Ramcharger. He knew he had his work cut out for him, but the spacious engine bay and aftermarket support, he knew it was doable.

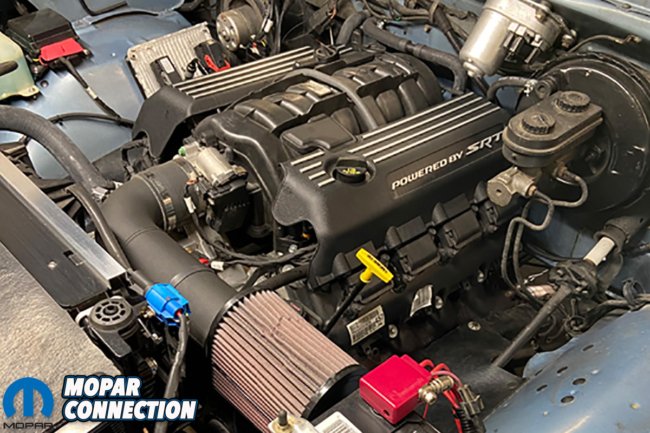

He started with purchasing the engine and transmission management systems. He decided to go with a Mopar crate Hemi kit for a 5.7 and TCU system from Sound German Engineering.

Once the old engine and transmission was removed, the swap could officially begin. Wes started by picking up a pair of Bouchillon Performance Gen III Hemi swap truck motor mounts. He then got the 5.7L Hemi and 8 speed transmission in the truck.

The factory crossmember needed some fabrication to mount the 8 speed transmission. The fabrication was nothing serious and once it was complete, it was time to start figuring out the rest of the hard parts for the swap.

Wes picked up a 2018 Camaro radiator and fan combo. Its sizing fit well and knew it would keep the Hemi nice and cool. After a little fabrication to mount the assembly, it was off to the fuel system.

Wes did not want to change out the factory gauges and worked through multiple fuel sending units to find one that would work with the Tanks INC fuel pump. He also plumbed a Corvette fuel filter/pressure regulator.

The Hemi came from a Challenger that was equipped with electric power steering. After some research and small spacer, a 1999 Jeep Wrangler power steering pump was the answer. He used a remote reservoir and plumbed into the stock Ramcharger steering box.

Now would come the fun of making the 8 speed work in the Ramcharger. First job was figuring out a way to shift the transmission. A T-handle shifter could be used but would be too much work fit in the interrior.

Instead, Wes sourced a shifter dial from a Durango. It was minimal and could fit it perfectly on the existing console. The console resulted in the perfect place to mount all the wiring and TCU for the 8 speed out of sight.

He could shift the transmission but it would need to be connected to the rear axle if Wes wanted to go anywhere. The 8 speed uses a CV style coupler on the Challenger and would not work with our rear axle.

Wes found a Sonnax drive fork adapter that would allow the use of a 1350 style joint. Wes called up Shaftmasters and ordered a 3” aluminum driveshaft with built in plunge feature to work correctly with his rear straight axle.

Nearing the final stages of the swap, exhaust was a small issue. Around Wes’s local town, none of the exhaust shops would fabricate a full exhaust without catalytic converters since the Ramcharger was originally equipped with them.

He was able to get a shop to bend and install the tail pipes, but everything forward was going to be up to Wes. Some Summit Racing welded mufflers and a few 2.5” mandrel bent tubing would allow Wes to complete the exhaust.

One thing Wes did do was use Jeep SRT-8 manifolds. These would flow a little better but more importantly, position the exhaust manifold outlets in the right place.

Wes was rounding third in terms of the swap, but he had one more hurdle that would need to be completed. He did not want to use aftermarket gauges and needed to figure out a way to make the speedometer work.

The factory speedometer on the Ramcharger was cable driven where the 8 speed was electronically controlled. Wes found some solutions but was a little out of budget.

Wes eventually figured out that a speedometer out of a ’90s truck could be electronically grafted to the original cluster. This would be a lot bigger ontaking than Wes had planned.

After some major surgery, it was mated together and works like Wes planned. The dash stayed all original and fully functioning.

The swap took Wes about 7 months to complete. Which in our eyes, is not very long at all. There was a fair amount of custom work that needed to be done, but in the end Wes ended up with a very clean installation.

Wes has enjoyed the increase in power and drivability of the Ramcharger since the swap. He did not tell us, but we assume fuel milage has increased too, which is a major plus with the high fuel prices currently.

Wish Wes had shown costs for the comple 5.7, 8spd swap. What a beautiful Ramcharger!