The good doctors at Hughes Engines don’t go about their work with scalpels and sutures, but the brand of surgery they perform on aluminum cylinder heads is impressive nonetheless. Lightweight performance heads are great, but come with significant investment.

Unfortunately, some builders don’t extend that investment into ancillary components like valves, springs, and pistons. And some just have all the bad luck. Either way, any kind of shrapnel-inducing failure within the cylinder is sure to do damage to the soft underbelly that is an aluminum head’s chamber.

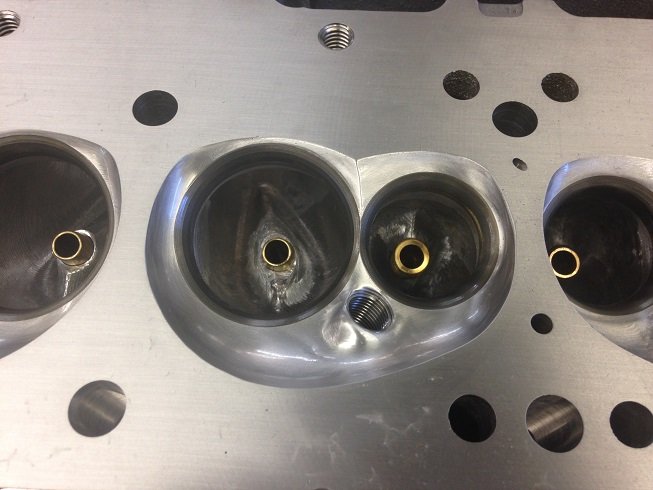

While many might consider it junk afterwards, Hughes can and actually has repaired the gnarliest of scars on these precious pieces. Hughes TIG welded the entire are to fill in the bulk of the dents and dings. A rough machining came next, followed by touch-up welding to take care of any remaining divots.

In the pictured example, it looks like the intake valve head decided to take a ride on the dome of a piston. The chamber, seats, exhaust valve, port, spark plug hole, and guide were all affected, but the diagnosis was not terminal.

Once the chamber was finish machined and polished, the guides and port were addressed. The end result is a beautiful chunk of audacious aluminum that’s ready to pound the pavement atop any motor worth its mettle.

The only costs to the customer are for time and materials. Every job is different, so call Hughes at (309) 745-9558 to get your chamber cosmetics quoted and corrected.