Recently, Callies Performance Products and Energy Manufacturing struck a deal with FCA to cast Gen II Hemi and wedge blocks to fill “a serious lack of supply for both blocks.” While it is fantastic to have new castings and a host of new supporting components produced, Mopar Connection had an interest in what castings are currently available and from whom. We contacted Bill Mitchell of Bill Mitchell Products (BMP), Richard Bradshaw of Bulldog Performance, Ken Lazzeri of Indy Cylinder Heads, and Heath Norton of Callies Performance Products about the current block offerings of each company.

To keep the costs down and to allow the castings to fit into production vehicles, the manufacturers cast their blocks to accept most of the Original Equipment Manufacturer (OEM) parts, positioned in the factory locations. Examples of the components are the starter, oil pump, engine mounts, fuel pump, dipstick, oil pan rails, and cylinder heads. All the manufacturers have improved the block oiling systems and have expanded the cooling capacity. Each company utilizes screw-in core plugs in their aluminum blocks. It is advisable to contact the companies for additional block details not covered in depth in this editorial.

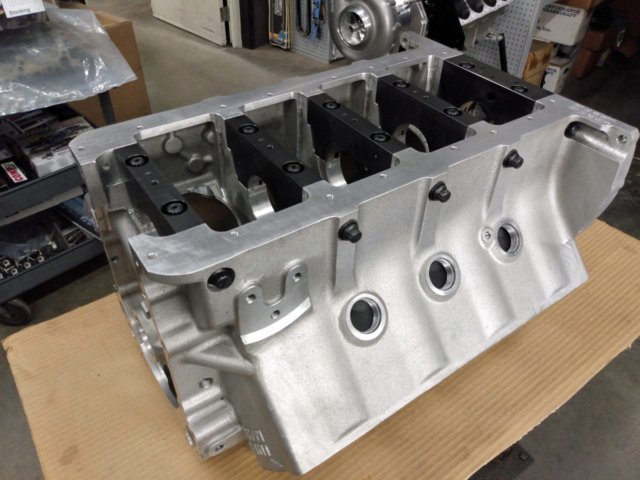

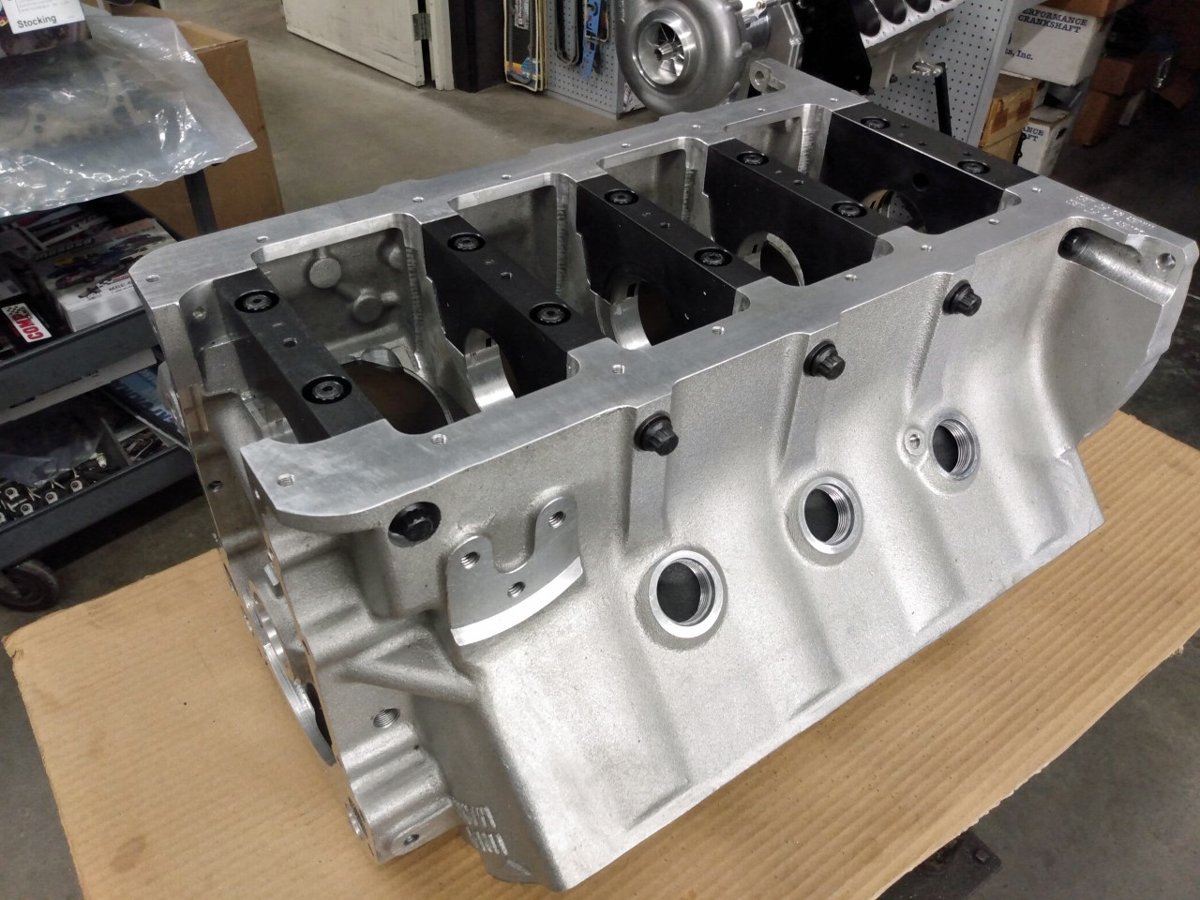

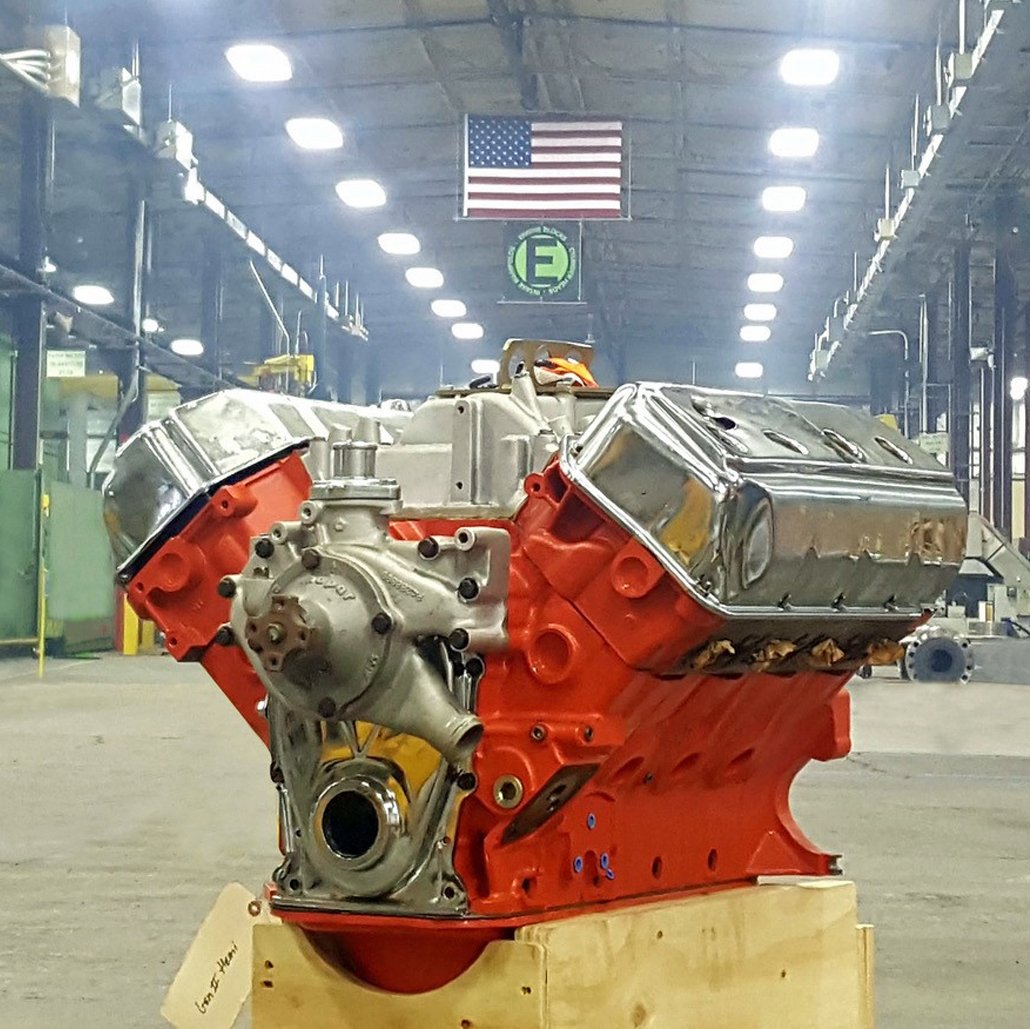

Above left: Bill Mitchell Products (BMP) designs Hemi blocks with the factory deck height, a cylinder bore of 4.250- or 4.500-inches, and a stroke of 4.500-inches. The casting can accept a maximum bore size of 4.560-inches and a stroke up to 4.750-inches (with additional clearance machine work). All the BMP blocks come standard with Bronze lifter bushings. Above right: BMP casts Hemi and wedge blocks, and these are fresh from the foundry. The wedge blocks have the engine mount ears cast into the blocks. This pallet of blocks has three wedges and one Hemi on it. The blocks are cross-bolted on the front four main caps with ARP hardware.

Bill Mitchell Products (BMP)

At one time, BMP owned World Products. World designed cast iron and aluminum versions of the Gen II block approximately twelve years ago. Mopar Performance purchased the iron version tooling and then contracted World to produce the Mopar blocks. This arrangement lasted about four years until the two parted ways. Mitchell disclosed, “World kept the aluminum tooling and continued to make blocks until some recent foundry changes. We are now just getting this block up and running again after those changes.” The new foundry is a modern, state-of-the-art facility. Taking advantage of the short downtime, BMP made modifications to the tooling to increase the features of the block castings. All the BMP castings are available as an aluminum version.

BMP’s block castings are available with a rough bore of 4.250- or 4.500-inches and a stroke of 4.500-inches. The castings accept a maximum bore size of 4.560-inches and a stroke up to 4.750-inches with additional clearance machining. The blocks employ a cylinder wall thickness no less than 0.200-inches of aluminum behind the replaceable ductile iron sleeves. The block can be cast with a raised camshaft design and accepts machining for a 60mm cam bearing. The deck height is the factory 10.720-inches. “The blocks require honing of the cylinder and lifter bores, a line hone of the mains, and machining the finish deck height,” confirmed Mitchell.

Above left: The design of the BMP blocks allows them to work with all the factory components, such as water pump, oil pan, dipstick, cylinder heads, etc. The blocks have a cylinder wall thickness of more than 0.200-inches of aluminum behind the replaceable ductile iron sleeves. Above right: The block can be cast with a raised camshaft design and accepts machining for a 60mm cam bearing. All the core plugs are a screw-in design. The factory or an aftermarket distributor will fit and operate correctly in the BMP block. For maximum strength, every BMP block casting utilizes 357-T6 aluminum. Each BMP block is designed with cross-bolted nodular iron main caps and use the factory rear main seal. After April 2020, the blocks will be available with billet steel caps.

BMP uses a factory rear main seal, and as after April 2020, the blocks will come with billet steel caps. To cover the Mopar purists and the drag racers that may put a Powerglide behind the block, BMP offers a block drilled to accept Mopar or Chevrolet transmission bolt patterns. Mitchell conveyed, “For added strength, the BMP casting uses 357-T6 aluminum rather than the typical 356 aluminum. The weight of our aluminum blocks with a 4.500-inch bore tips the scales at 135lbs.” All the blocks come standard with Bronze lifter bushings, and the blocks are cross-bolted on the front four main caps with ARP hardware.

How much horsepower (hp) can the castings withstand? Mitchell declared, “This is a loaded question, which gets asked every day. You can’t just throw a number on a block or any part. Parts don’t just fail at a given horsepower. Your tune-up, application, and load are huge factors in determining maximum HP thresholds. However, we have feedback from customers running over 2000hp.”

Above left: Bulldog Performance currently offers a cast-iron block. A Bulldog Performance block cast in aluminum will arrive this spring. Both blocks have the first four mains cross-bolted. The main caps are nodular iron or billet if additional strength is required. Above right: Bulldog Performance can machine the block for a 55mm or 60mm camshaft bearing, and Bulldog can cast the block with a raised camshaft design. The Bulldog Performance cast iron blocks are NHRA Stock and Super Stock legal. Bulldog designed their blocks to operate with the factory parts.

Bulldog Performance

Bulldog Performance has offered the Gen II Hemi block for about two and a half years. They currently provide a cast-iron block with an aluminum version of the casting to arrive in May 2020. Bulldog’s cast-iron block utilizes the factory-type tap-in core plugs. The casting is NHRA legal for Stock and Super Stock eliminator.

Bradshaw testified, “Quite a few (customers) have bought a block from me for drag racing. They are tight-lipped about any advantages they have found with the blocks.” The castings operate with the factory parts that each competitor must use, as required by the sanctioning body.

Above left: The Bulldog cast-iron bore sizes are rough cast at 4.245- or 4.495-inches, and a 4.625-inch stroke fits into the block without modifications. The block can accommodate a 4.750-inch stroke with additional machine work. The deck height is 10.720-inches (stock Hemi/440), or a deck height of 9.98-inches (stock 383/400) is also an option. Above right: Bulldog Performance designed a rear main cap with the rear main seal incorporated into it. This integrated rear main seal provides exceptional sealing, which reduces the pesky oil drips from the transmission bell housing area. Bulldog has a billet main cap option for additional strength.

Bulldog Performance offers 4.245- or 4.495-inch bores with a maximum bore of 4.600-inches with their cast iron and aluminum blocks. Bradshaw stated, “A 4.625-inch stroke fits in the block, and a 4.750-inch stroke operates with some additional machine work to the block.” At a 4.500-inch bore, Bulldog keeps the cylinder wall thickness at 0.250-inches, and the aluminum casting has slip-in iron cylinder liners.

The deck height is the OEM measurement of 10.720-inches (a 383/400 block deck height of 9.98-inches is also an option). Bulldog Performance can machine the aluminum block for a 55mm or 60mm camshaft bearing, and the block can accommodate a raised camshaft design. Bulldog offers a special seal incorporated into the rear main, and there is a billet main cap option. “I know of a twin-turbo setup with our block making about 2700hp,” Bradshaw declared.

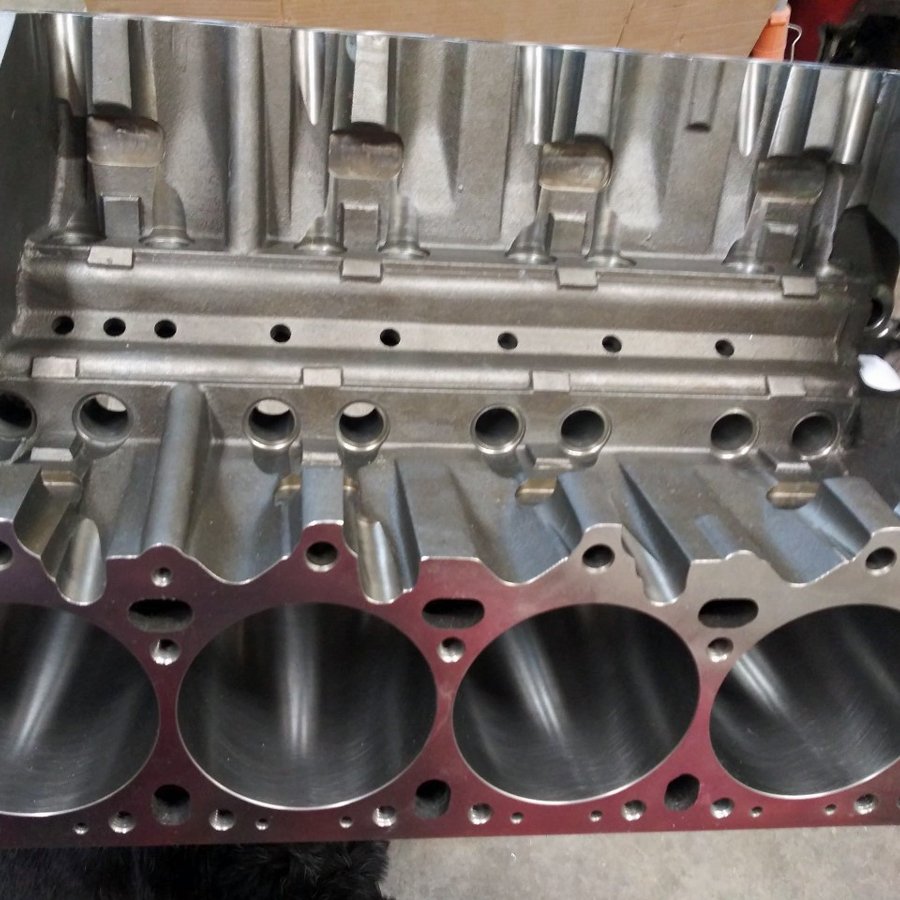

Above: This is an Indy Cylinder Heads Indy Maxx aluminum water block. The Indy Maxx aluminum block can be purchased as a solid block as well. The blocks feature Siamese dry sleeve construction with a sweat sleeve installation, and with a 4.500-inch bore, there is a 0.300-inch thickness between cylinders. The block sleeves are available in different thicknesses.

Indy Cylinder Heads

Indy Cylinder Heads has been casting and machining their own Gen II Hemi and wedge blocks in-house since 1995. Currently, they offer the Indy Maxx aluminum block in water and solid designs. Available soon is the Indy Maxx aluminum “X block” with a solid or water version. All the designs are available as a Hemi or wedge, and the blocks feature Siamese dry sleeve construction with a sweat sleeve installation. With a 4.500-inch bore, there is a 0.300-inch thickness between cylinders, and each block is available with different sleeve thicknesses.

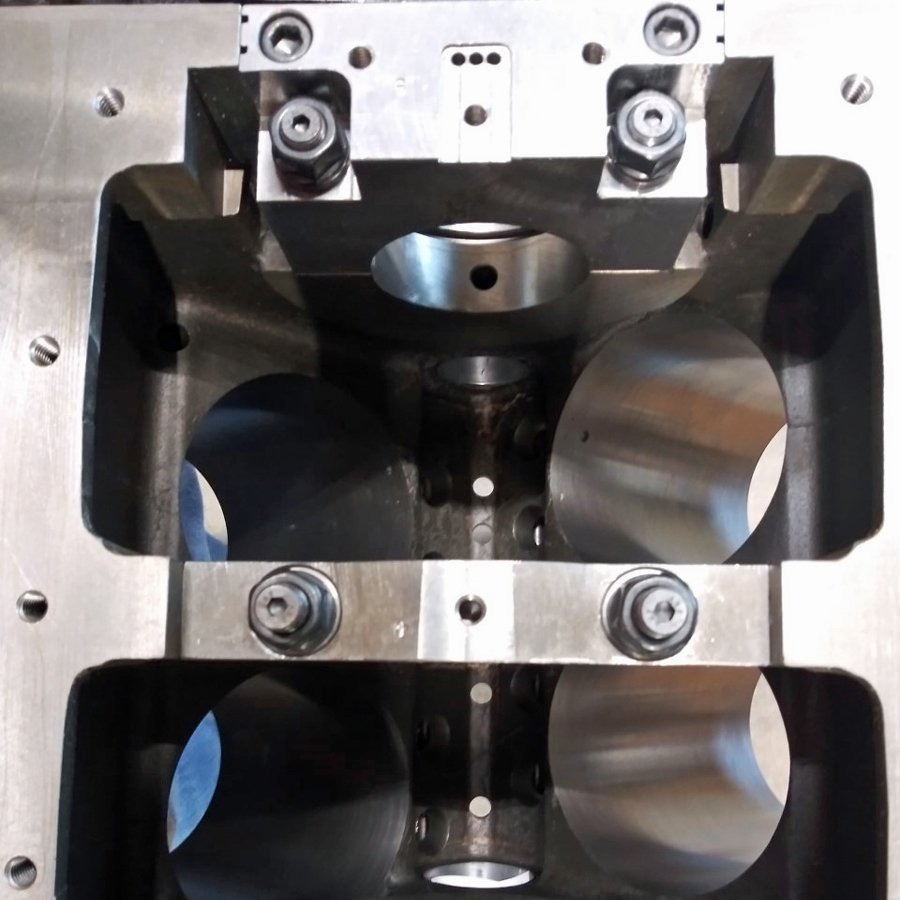

The position of the camshaft is in the standard location or at an optional 0.250-inch raised location. The blocks have three cam tunnel options (standard, 55mm, or 60mm). Steel billet main caps and 1/2-inch main studs are used on the Maxx block, while the Maxx X block utilizes 9/16-inch main studs with huge (7570) billet aluminum main caps. All the blocks come with 1/2-inch cross bolts on all five caps and have added support ribs in the valley.

Above: This Indy Cylinder Heads Indy Maxx aluminum water block has billet steel main caps. The position of the camshaft can be in the standard location or an optional 0.250-inch raised position. The blocks have three cam tunnel options (standard, 55mm, or 60mm). Steel billet main caps and 1/2-inch main studs are used on the Maxx block. Additionally, the mains are cross-bolted with 1/2-inch bolts on all five mains.

The standard Indy Maxx block is available in the 400-deck height of 9.98-inches, and the Hemi/440 has a deck height of 10.720-inches. The mains are available in either 2.750-inches (440 mains) or 2.625-inches (400 mains). Strokes range from 3.38- to 5.00-inches, which means engines from 383 to 655 cubic inches. The bores range from 4.250- to 4.600-inches. Each block features an isolated main oil gallery to prevent oil leakage around the lifters, and there is a pushrod oiling option.

The blocks come with camshaft bearings installed, and the mainline finished. There are options to complete all the machine work (bore, plate hone, square deck, stroke clearance, O-ring groove the deck). A fully machined water block weighs 133lbs, and the solid blocks tip the scales at 155lbs.

Lazzeri stated, “In any big horsepower engine, you must first have the proper parts for the intended use, and most importantly is the proper tuning. As a guideline, we recommend the water block for the 500 to 1800hp range, the solid block 1500 to 2500hp range. Although not yet tested, we expect the new Indy Maxx aluminum X block to be a game-changer at 2500hp plus.”

Above left: Available soon, the Indy Maxx aluminum X block. It will be available in a solid or water version. The block casting has additional reinforcement, which is visible in the valley area. Each block features an isolated main oil gallery, which prevents oil leakage around the lifters. Pushrod oiling is an option with the Indy blocks. Above right: The Indy Maxx X block utilizes 9/16-inch main studs. The block employs huge 7570 billet aluminum main caps for maximum strength. The Indy Maxx X block, just like the Maxx block, uses 1/2-inch cross bolts on all five caps. Indy Cylinder Heads has not tested the Indy Maxx X block, but 2500+ horsepower is the expectation.

Callies Performance Products (Callies) & Energy Manufacturing Ltd. (Energy)

In January 2020, Callies and Energy announced a licensing agreement with Fiat Chrysler Automobiles (FCA) to manufacture and distribute the 426 Hemi and the 440 wedge cast iron blocks. The arrangement stipulates that Energy produces iron blocks (and cast iron and aluminum cylinder heads) while Callies (a sister company) will manufacture rotating assemblies as well as supportive components. Callies will act as the sales point for all the new castings.

The FCA blocks will all carry Mopar part numbers, and the castings use the original OEM tooling and Mopar engineering data. However, the tooling will not produce a questionable 1970s block, but rather, the tooling and molds are a heavy-duty version owned by FCA, in which Bill Mitchell provided valuable input.

Above: Callies and Energy announced a licensing agreement with Fiat Chrysler Automobiles (FCA) to manufacture and distribute the 426 Hemi and the 440 wedge cast iron blocks. Energy will produce the iron blocks, and Callies (sister company) will manufacture rotating assemblies and supportive components. The tooling and molds for the new blocks are a heavy-duty version designed with input from Bill Mitchell. The blocks will begin shipping in the third quarter of 2020.

The FCA Gen II Hemi blocks will have finished bore options of 4.250- and 4.500-inches. Also, the rough-bore Hemis with 4.245-inch bores come with or without lifter bores cast in the block. The wedge blocks have a finished bore of 4.500-inches or a rough bore of 4.310-inches. The maximum bore for all the castings is 4.500-inches, and the block can accommodate a 4.750-inch stroke. Both the Hemi and wedge blocks have a deck height of 10.725-inches, and the camshaft is in the factory position. The block has additional strength cast into it without adding a significant amount of extra weight. Lastly, the blocks are NHRA approved for the Stock and Super Stock classes. New block orders will begin to ship in the third quarter of 2020.

Wrapping It Up

With the production of Gen II blocks by Bill Mitchell Products, Bulldog Performance, Indy Cylinder Heads, and now Callies and Energy producing Mopar Gen II blocks, it appears there will be plenty of blocks available. With the various options offered, these four manufacturers will provide the optimum block to meet the specific need of each Mopar enthusiast. When the time comes to purchase a new Hemi/wedge block, consider Bill Mitchell Products, Bulldog Performance, Indy Cylinder Heads, or Callies/Energy for their time-proven products and years of experience.

Yeah but: Keith Black!!

Plenty of blocks huh. I had an Iron Gen 2 Hemi on order from Bulldog, purchased through Ray Barton and paid in full for over two years. I finally gave up and got a refund. I think they send them all to their preferred customers, and the guys buying one block who want to build their first hemi are left high and dry.

Yes Joe, there was a problem with these blocks but primarily during the time that it was sold almost exclusively through Muscle Motors. For a period there, MM had shut its doors and many were left “out in the wind” waiting for anything – engine, parts, blocks, etc. And yes, “preferential treatment” has been the MO for most all of the engine builders and block producers, not just Bulldog. There are horror stories similar to this for Mopar, KB, World, Dart, etc.

Will, I’m sorry to hear about your delay. I literally just got off of the phone with Dick who said that he has had to refund several customers because of delays. When asked “What caused delays?” he explained that new ownership at the foundry has resulted in a handful of blocks being cast weak, and even some showing cracking. These blocks were caught by the machinist and sent back to the foundry. This has caused several months is backup, as you can understand. Some customers are in a hurry, others aren’t. Thankfully, these weak blocks are NOT getting to the customers and are being caught early.

Bill Mitchell aluminum block is the choice I made after weighing the power limits of the factory iron block, even with the addition of a first class aluminum cap and girdle system. My thoughts were “Why build a 600-700 HP and torque motor, hoping someone would check through enough blocks to find the best one, and then invest all that money to build an engine that is running close to its power output limit, thereby having a ceiling that if I want more power, I’d have to start over again from the block” Bill Mitchell himself got on the phone when I called one time only, asking when they were transitioning to the billet steel caps. He also said the shop I’m buying the block through, who is also going to finish the build for me, is one of his best representatives. ALL of this, plus other products I’ve bought from this shop for work being done to my Roadrunner now, gives me GREAT confidence that I chose the right company AND the best source for my block. Hopefully I will have it completed and installed by 10/2021 if I can get the money together to build it out.

Constant communication and great pricing, knowledgeable recommendations, and a wide variety of well known products in the high performance aftermarket, as well as a tremendous depth of experience and personnel with MOPAR specific NASCAR and Drag Racing experience assure me that I am getting the best value for my hard earned investment in the block and the 541 cu in stroker that I only want to build ONCE, and then with standard maintenance, enjoy for cruising around and occasionally putting someone else “on the trailer”.

Kevin Shaw, thank you for your variety of articles that I look forward to reading. At 58 years old now, but being a Mopar fan since my police officer dad stood on the gas in his stock 69 Roadrunner back in 69, on the interstate, and caught a speeder who had blown by us, only to be caught less than a mile into the pursuit, yeah-I’ve been a Mopar fan from that first experience! Right now, major work on my 70 V-code Roadrunner is happening that is bringing a variety of systems and upgrades into the mix. Vintage Air, CVF Wraptor serpentine belt and accessories system, Hydramax hydraulic throwout bearing conversion, HitMaster launch control, the new RTX series Dakota Digital gauge system I first read about a few weeks ago right here, and prompted me to sell my VHX gauges that were still new and sealed, but were about to be installed, USCT subframe connectors and torque boxes, QA1 K-member and front suspension…So much of what I’m doing is influenced by what I read here, or the articles you write confirm the choices I’ve made. Keep up the good work, but always remember the power and thus responsibility you have in the information you post here, people are reading these articles and acting based in some degree to what you write here.

Thank you for the kind words, and I’m very glad you had a positive experience with Bill Mitchell. He’s a rock solid dude and I’m certain you’ll be very happy with your purchase. (And sorry for the VHX gauges, but I’m sure you’ll be happy with the new RTX ones!)

Just got the 65 GTO back w/the VHX gauge system and it’s nice, but my reasons for spending so much more for the RTX level setup are just looking more and more justified the more I learn.

Initial setup and changes?? WAY, WAY easier with the RTX and HDX.

I just found out that Richard Bradshaw contacted the customer I was mediating with, and the customer has been refunded his money. Too bad the customer didn’t post that the issue has been resolved. That’s one reason why I stepped in, because I don’t like seeing a manufacturer or business that is working so hard to do something for the “Mopar Nation” defamed on the internet.

I hope Bulldog gets squared away and has nothing but blessings and success with their iron and aluminum (beastly strong looking) blocks!

It sounds to me bulldog not going to be in business very long!!

sent DICK BRADSHAW a check for $1500 SEPTEMBER 4th 2020 to order a hemi block. he said he was 6 weeks behind. it is now December 19th 2021 and he wont answer his phone or return my call. JERRY PAULEY from Kentucky.

We heard Dick sold out over a year ago.