Alternator selection is obviously critical for the correct function of everything electrical on a modified vehicle. While a race or pro-street car requires high-amperage components like aftermarket ignition, electric fuel and water pumps, and transmission brakes, the added load on the charging system is sometimes an afterthought. When symptoms of an undersized alternator do appear, it can be difficult to decide how to fix it.

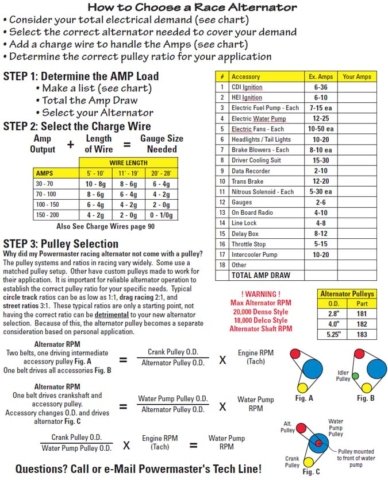

Powermaster put together a step-by-step selection guide to help walk you through the proper paces. The process is pretty simple: determine total amp load, select the appropriate alternator, choose a charge wire, and, if you’re buying a race alternator, decide on a pulley size.

Powermaster put together a step-by-step selection guide to help walk you through the proper paces. The process is pretty simple: determine total amp load, select the appropriate alternator, choose a charge wire, and, if you’re buying a race alternator, decide on a pulley size.

Total amp draw is easy enough to calculate using Powermaster’s chart or component manufacturers’ specifications. From there, browsing through the massive catalog of alternators will lead you to the correct case style and output rating for your application.

Picking a charge wire is simple too as they’ve got another quick reference chart for that. The factory charge wire may or may not be big enough, so be sure to doublecheck. Because pulley sizes and ratios vary so much in racing applications, race alternators don’t come with one installed.

The alternator pulley is considered a separate component of the system and is chosen as such. Selection involves some simple math based on crankshaft or water pulley diameter. Powermaster provides the formulas or you can call their tech line at (630) 957-4019 for assistance.