Recently, Mopar Connection Magazine switched Project Brazen from a 50/50 mixture of water and Inorganic Acid Technology (IAT) antifreeze (green in color) to a waterless coolant from Evans Cooling Systems. Evans is a leader in the cooling industry, and it established the first commercial waterless engine coolants. Evans has provided non-aqueous engine coolant products to the marketplace for the last 20 years.

Above: All engines come with water-based coolant. However, there are plenty of concerns with water-based coolants. For example, project Brazen runs green coolant, but it will be replaced with Evans coolant, which does not contain water.

Today’s coolants resemble the colors of a rainbow and have additives based on each manufacturer’s specific requirements, yet they all still require a significant percentage of water. Though water-based coolants have been used for nearly one hundred years, there are a few disadvantages.

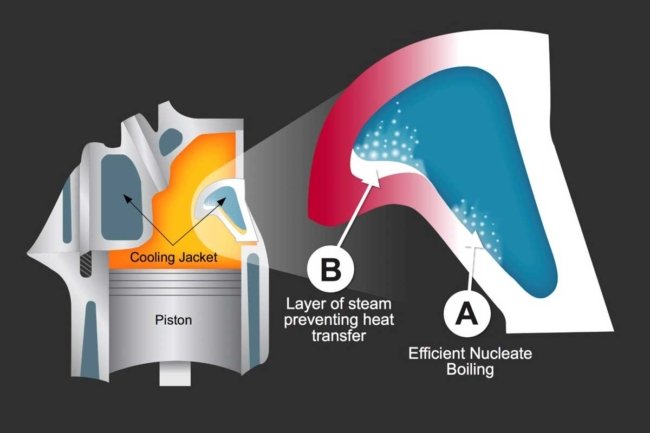

Water-based coolants can boil when they encounter hot cylinder walls, even though the coolant remains in a liquid state under pressure. The result is tiny insulating bubbles forming, which reduces the cooling efficiency.

The bubbles result from Nucleate boiling, a boiling that takes place when the surface temperature (of the coolant jacket) is hotter than the saturated fluid temperature by a certain amount but where the heat flux is below the critical heat flux. The bubbles can also lead to cavitation, cooling system component pitting, erosion, and poor cooling.

Above: A significant concern with water-based coolant is the micro boiling of the coolant where it contacts the hot water jacket casting. The micro boiling reduces the heat transfer from the engine’s cylinders to the water jacket. Evans Coolant does not boil when it contacts the hot water jacket casting, so it more efficiently removes engine heat.

Additionally, the water in the coolant can damage the cast iron or aluminum cooling system components, especially when the coolant has not been exchanged for an extended time and becomes acidic. Adding antifreeze to water only slightly increases the boiling point, so the cooling system requires a radiator pressure cap to increase the boiling over protection appreciably.

Yet another concern is electrolysis, which occurs when stray electrical current routes through the engine coolant. Lastly, the coolant will need to be exchanged at specific service intervals.

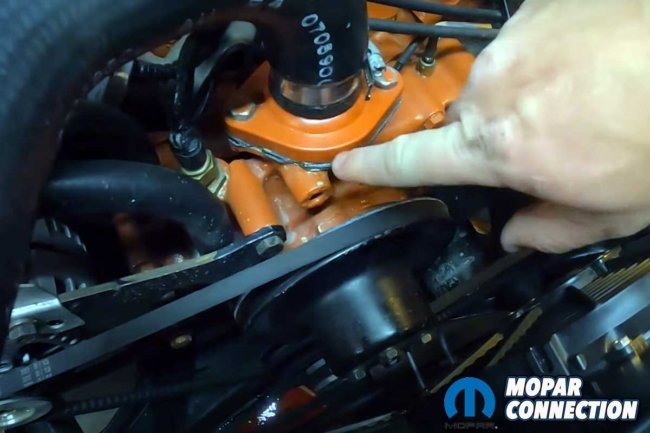

Above: Evans coolant does not require high-pressure radiator caps to achieve excellent boil-over protection. With less pressure, the hoses and gaskets are less stressed and less prone to failure.

Evans coolant can address each shortfall of water-based coolant. An internal combustion engine’s cooling system operates comfortably below Evans’s coolant boiling point.

As a result, the Evans coolant will always remain in contact with the engine’s metal surfaces, which protects against insulating pockets of vapor, corrosion, and cavitation erosion. In addition, electrolysis is minimized because Evans waterless coolant has less than one-third the electrical conductivity of water-based coolant.

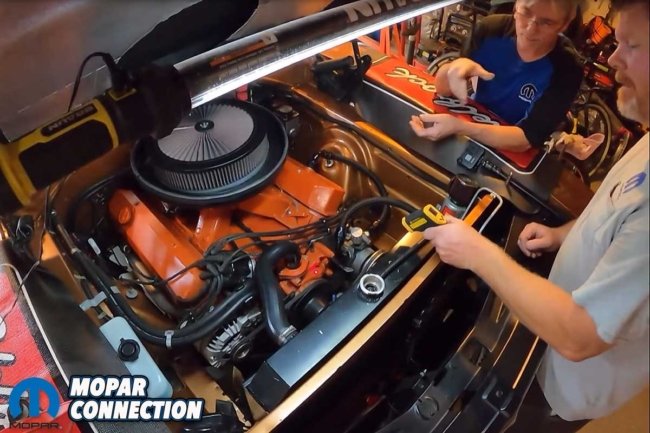

Above: A quick temperature check with the engine running provided a baseline for the water pump housing temperature. With the addition of the Evans coolant, the temperature may go up slightly, but the Evans products extract more heat than the water-based coolant.

When addressing the reasons for switching to Evans coolant, Mike Tourville stated, “One of the things is the maintenance-free aspect. It [Evans coolant] lasts the engine’s life and never has to be changed. And with lower pressure, no vapor, and avoidance of hot spots, the seals, gaskets, and hoses will likely last longer with less stress.”

Above Left: After draining the green coolant from the big-block wedge, a vacuum cleaner, with the hose on the cleaner’s outlet, was placed in the open thermostat housing. With the radiator petcock open, the air forced out additional coolant. Above Right: After several attempts to get the best results, the maximum amount of antifreeze and water was removed.

Evans coolant will not necessarily reduce the engine temperature. In some engines, it may, but most engines will run at the same temperature or slightly warmer (10-15°F) than the water-based coolant. Tourville explained,

“While some are initially concerned about running warmer with Evans, it must be understood that the two liquids – water-based coolant and Evans – operate differently, and you cannot apply the same expectations and physical characteristics. While the [Evans] coolant may get hotter, the metal temperatures are under control as they are constantly bathed in liquid, and not vapor.”

Above: With the maximum amount of green coolant out of the cooling system, Evans Prep Fluid was added to the cooling system. After the system was topped off, the engine was run. The Prep Fluid encapsulates any remaining water in the cooling system and heater core (if equipped).

With specific applications, the engine may run cooler without the thermostat. Tourville stated,

“Evans runs better with a greater flow, and removing a restrictive thermostat can improve flow and allow the coolant to run cooler. The more resistant the flow, the hotter Evans will get, but even if it gets hotter, it will not form vapor, pressure, or boil out. For example, a single pass radiator provides greater flow, where a double or triple pass may be more restrictive, and the coolant may run warmer.”

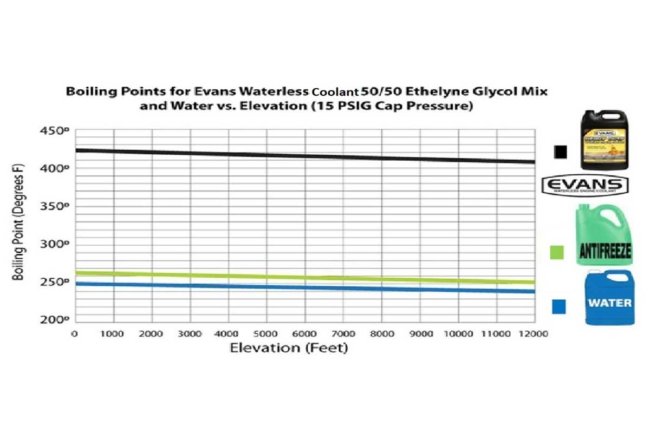

A 50/50 coolant mix has boiling protection between 215-225°F. With a radiator pressure cap, the boil-over protection may increase by about 40-50°F (3°F per 1 psi cap rating – case in point, a 15-psi cap is approximately 45°F). The water-based cooling system has a limited operating temperature range, even with a pressurized radiator cap.

Above: After draining the Prep Fluid, the system was again blown out, and the final product was poured into the cooling system. Evans High-Performance Waterless Coolant was perfect for Brazen.

However, Evans coolant has an extended boil-over protection scale. Evans coolant will not boil until 375°F, a full 100+°F over the water-based products. In addition, although 50/50 water-based and Evans coolants have freeze protection to -40°F, Evans coolant will not solidify or expand, protecting from freeze bursts.

Evans coolant does not have a problem with scale formation as water-based coolant can. Because Evans coolant boils at such an elevated temperature, a high-pressure radiator cap is not required for boil-over protection. “We usually recommend using the same cap (OEM cap from manufacturer), normally a 15- or 16-pound cap. [There is] no need to change. Some use a 7-pound cap, and that is ok too. Nothing will change as Evans typically operates at about 2-4 pounds of pressure,” Tourville noted.

Above: With the High-Performance Coolant in the system, the water pump temperature was almost identical to the green coolant. However, the cooling system is now more efficient because the Evans coolant removes heat.

With Evans coolant in the cooling system, the engine may warm up faster than with water-based coolant. That means interior heat occurs sooner during the cold winter season. For owners living in chilly weather environments, the faster warmup benefit may also increase their fuel efficiency rating by up to a half-mile per gallon.

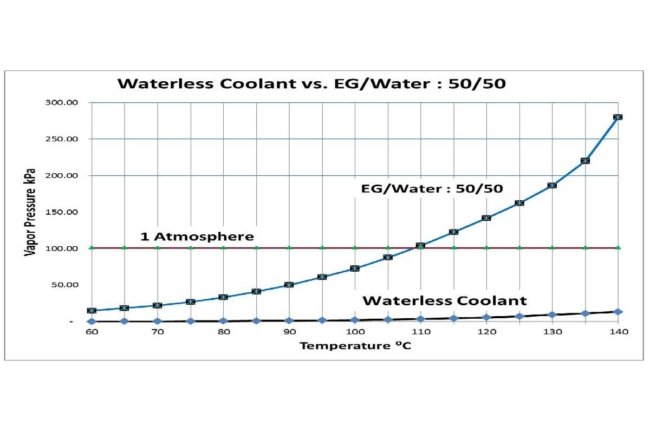

Above Left: Evans products have an incredibly high boil-over protection compared to antifreeze or water. Above Right: As temperature increases, a liquid’s vapor pressure increases. In the above example of 50/50 coolant, the vapor pressure equals atmospheric pressure at a temperature of 110°C. At this point, the coolant will boil. However, the Evans coolant will never increase to a vapor pressure that equals atmospheric pressure (at an engine’s average operating temperature), so the coolant will not boil.

Based upon the advantages of Evans coolant over water-based coolant, which Evans product is suitable for your application?

High-Performance Waterless Engine Coolant: This can be used in cars and light-duty trucks. It also is acceptable for boats, light aircraft, light-duty diesel, LP, and CNG engines.

Collectors Choice Waterless Coolant: This is for the preservation of classic and vintage cars, especially for cars that sit for long periods, that are subject to corrosion and electrolysis.

Powersports Waterless Coolant: This should be for motorcycles, ATVs, snowmobiles, and other off-road Powersports applications.

NPG Waterless Engine Coolant: This is for racing venues that allow propylene glycol-based coolants, not ethylene glycol-based coolants. The coolant is not for routine use. Adaptive equipment may be needed for specific high-performance applications. Contact an Evans Cooling Systems representative for additional information about the NPG coolant.

Prep Fluid: The Prep Fluid is used as a waterless flush to remove the remaining water-based coolant from the cooling system before installing Evans waterless coolant. Prep fluid is 100% compatible with all Evans waterless coolants.

Above: After the Evans coolant was installed correctly, a refractometer was used to determine the water content of the coolant. After calibrating the tool, a small coolant sample was placed on the refractometer’s lens, and the water content was displayed on a screen that could be viewed through the instrument. According to Evans, Brazen’s coolant was perfect; the water content fell into the acceptable range.

Suppose the benefits of Evans have grabbed your attention. In that case, Evans products can be purchased online directly from the manufacturer or picked up locally at multiple outlets, which can be found on Evans’s website.

Besides an inexpensive refractometer, changing to an Evans waterless coolant can be completed with hand tools and should not take more than a few hours. To understand the exchange process, follow along as our editor, Kevin Shaw, transitions Project Brazen to Evans coolant.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by