Every car and restoration has its own story. Some are short and sweet and others are tales of perseverance and the will to keep pushing on no matter what. For Ian Marshall of British Columbia, the story of his 1971 Dodge Super Bee is not for the faint of heart. Ian’s story is the true tale of blood, sweat, and gears. “I was 8 years old when my older brother bought a B5 Blue ‘71 Super Bee 340 equipped with the N96 Ramcharger hood,” recalls Ian. “He owned the car briefly but ‘Mopar or No Car’ was etched into my heart and soul from that point on.

Fast forward to 1986, Ian was working at Expo ‘86 (the 1986 World Exposition on Transportation and Communication) when he purchased his first 1971 Dodge Charger; a tired 318 car that had seen better days. In January 1988, a co-worker of Ian’s spotted a FJ6 Green Go 1971 Charger 500 for sale in Langley B.C. “The Charger had a 383 under the power bulge hood. Since it was a 500, it had the nicer molding and tail light package like the R/Ts. The owner was asking $3,000 but settled for $2,000 so I brought it home,” shares Ian.

The Green Go Charger 500 quickly replaced the 318 Charger and was Ian’s daily driver for two years, going all over the province including on vacation to Vancouver Island and camping trips through the B.C Interior and the Canadian Rockies. On a winter night in January 1990, tragedy struck when falling rain froze into black ice. Ian was approaching an intersection when he hit black ice, locked the brakes up and slid nose first into a pole. He says, “I managed to back up and limp the car home with a leaking radiator, a damaged bumper, hood, and front valance. I parked the car and began my search for replacement parts to fix the car.”

Money was not plentiful so the car sat until Ian was able to save up and purchase a replacement Super Bee power bulge hood with the proper hood insert, a complete bumper assembly, and front valance from a local Mopar parts guy known as ‘Cuda Gary’. Ian had the bumper re-chromed and painted the bumper brackets to look proper before finding a body shop through a co-worker that helped repair the front end and repaint the replacement sheet metal. In 1994, four years after that icy winter night, the green beast was back on the road but as a Sunday driver only now.

In 1996, Ian moved from his childhood home into a townhouse with a single car garage that was just big enough to park the ’71 in. He tells us, “I had to strategically place things in the garage so I could open the driver’s side door of the car. After years of sitting outside exposed to the elements, cancer in the rear quarters was spreading. I knew an old school hot rodder named Don Robinson who was skilled at auto body restoration. Don rented a bay across the parking lot from where I worked so I talked to him about repairing or replacing the quarter panels. Since 1971 Charger aftermarket quarter panels were not available in the late 1990’s, I purchased the solid back half of a 1971 Charger from ‘Cuda Gary’.”

Don agreed to do the work so the Charger went to his shop where he removed all of the rotted metal before graphing the donor quarter panels onto the car. All of the spot-welds on the donor panels lined up perfectly on the car just as they would have from the factory. The rear quarters were shot with a coat of primer and then Ian drove the car back home. “Not too long after, my mother passed away from lung cancer in 1998. At least she had a chance to see pictures of the car restoration. I prevented the spread of cancer in my car but unfortunately, my mother’s cancer could not be stopped,” shares Ian.

During a townhouse complex garage sale in 1999, Ian met someone who turned out to be ‘the mechanic from hell’. Seeing the ’71 sitting in his garage, the guy struck up a conversation about the car. Ian mentioned how the 383 needed a rebuild and that he wanted to upgrade the drive train. The mechanic knew his stuff and offered a freshened up 383 Magnum and rebuilt 8 ¾ Sure Grip rear end for a deal that Ian could not refuse. “I wanted to store the original engine block and rebuild it a later date so the replacement 383 he was offering was perfect. I agreed to the deal and took the car to a house he was renting close to where I live,” says Ian. This is where things went south.

“He had my car for four months and was slowly fencing in the property also guarded by his pit bulls. I was starting to panic and thought I would lose the car. He was not answering his phone and I was worried; something didn’t seem right. I was so desperate that one day I jumped the fence to find out what was going on. I finally spoke to him and the freshened-up engine was in the car, so I thought things were going to be fine. More time passed, and I pleaded with him to finish the work he started but heard nothing but excuses. It was at this point that I told him I was taking my car home as-is.”

Ian called up a tow truck friend of his and went to retrieve the car, which was in a number of pieces. The car no longer had a rear differential, leaf springs or drive shaft and the guy sold his triple core radiator to someone else. To make things even worse, Ian’s original 383 was missing. “I lost money and parts of my car. It was a deal I could not refuse but it ended up being too good to be true and a life lesson. It turns out that he was a mechanic that robbed from one job to work on another but never finished what he started. Not long after I hauled my car out of the guy’s yard, he packed everything up and disappeared. After doing some digging and speaking to the local news station, I found out that I was on a long list of people that fell victim to the mechanic from hell.”

With the car now safe back at home, Ian proceeded forwards with the next leg of the journey; this one spanning another 6 years. Since the car did not have a drive train, Ian decided to start scraping every inch of undercoating from the underside of the car. After spending countless weekends removing all of the undercoating, Ian sanded and painted the underside of the car inside his townhouse garage. As he was detailing the undercarriage, he started sourcing and replacing all of the missing parts for the drive train as well as a replacement radiator. “I powder coated and painted every part that I bolted under the car and detailed or replaced every nut and bolt. I then mounted high flow exhaust manifolds, new head pipes, Magnaflow mufflers and tailpipes capped off with the awesome ‘flamethrower’ exhaust tips found on the 1971 B-bodies. It was so clean that you could eat off the undercarriage,” shares Ian.

Finally on a warm summer night in 2006, he mounted the tires back on the car, took it off the jack stands and pushed the car into the driveway. However, the excitement was short lived. Ian says, “At the end of the evening, I was pushing the car back into the garage and ruptured my Achilles tendon. The sheer weight of the car and a lip at the entrance of the garage put so much strain on my Achilles tendon that it snapped like an elastic band. It was so loud that the neighbor heard it snap. Since I was an industrial first aid attendant, I knew exactly what happened. As I stood on one foot, the neighbors came over to help me push the car into the garage. I ended up in the hospital emergency room that night and had surgery the next day. During the next 6 months, I endured a cast, a walking boot, and tons of physio.”

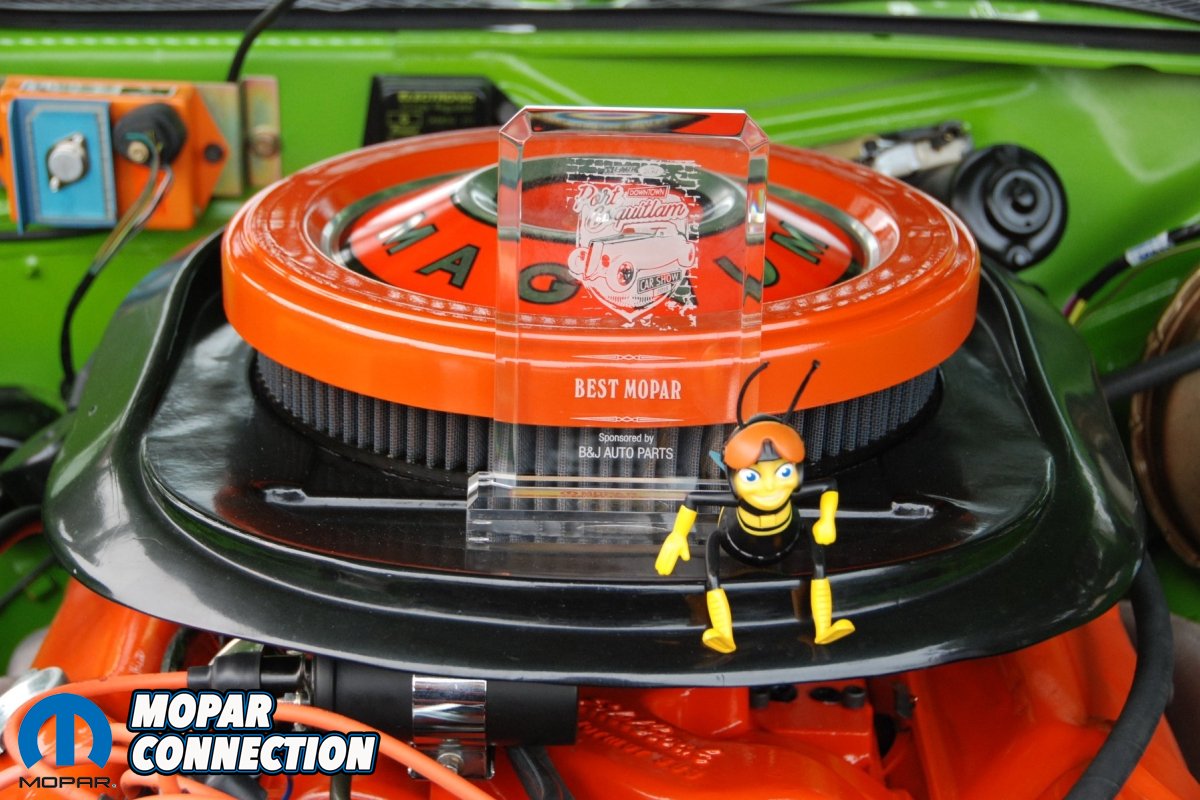

During the next 4 years, he worked on detailing the engine and the engine bay as the car sat dormant in the garage. Almost 10 years had passed since the car was torn apart and at this point, Ian didn’t even know if the engine the mechanic from hell put into the car would run properly, let alone at all. With the help of a co-worker and fellow Mopar friend, Ian bolted on a new Holley 670 CFM Street Avenger carburetor and a Mopar electronic ignition system and brought the engine to life in the summer of 2010. At least the mechanic from hell had done one thing right. Knowing that it ran, Ian continued detailing the engine and then painted the inside of the trunk.

During the entire journey, money and time never went together. “I did not have deep pockets and tried to do a budget restoration. I wondered if I would ever finish what I started. My sister’s boyfriend Al Lodge is an auto body repairman at the dealership where they work. Al had over 25 years of experience in auto body repair and is a perfectionist and true artist in his trade. One day, I asked Al if there was a chance that he could help me finish the bodywork and paint the car. He agreed and after getting the go-ahead from the dealership body shop manager, the Charger was in the right hands for the first time,” says Ian.

For a year and a half, Al worked on the car in his spare time blocking and sanding every panel on the car. In February 2012, Al and the body shop manager stayed late one night and painted the car in a shiny new coat of Green Go. After four base coats and three clear coats, the car was one solid color for the first time in fifteen years! “There is no way I could have finished the car without Al’s help and perfectionism,” Ian shares.

The car was finally ready to leave the body shop but Ian realized he didn’t have enough room to put the car back together in his tight garage. He tells us, “The general manager where I work let me assemble the car in our production bay. It made things a lot easier. For the past 15 years, I had purchased and stored numerous restoration parts for the car. My vision was to turn the car into a Super Bee clone.”

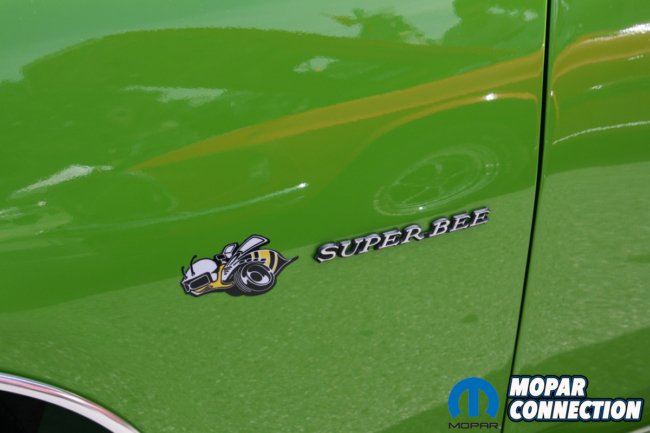

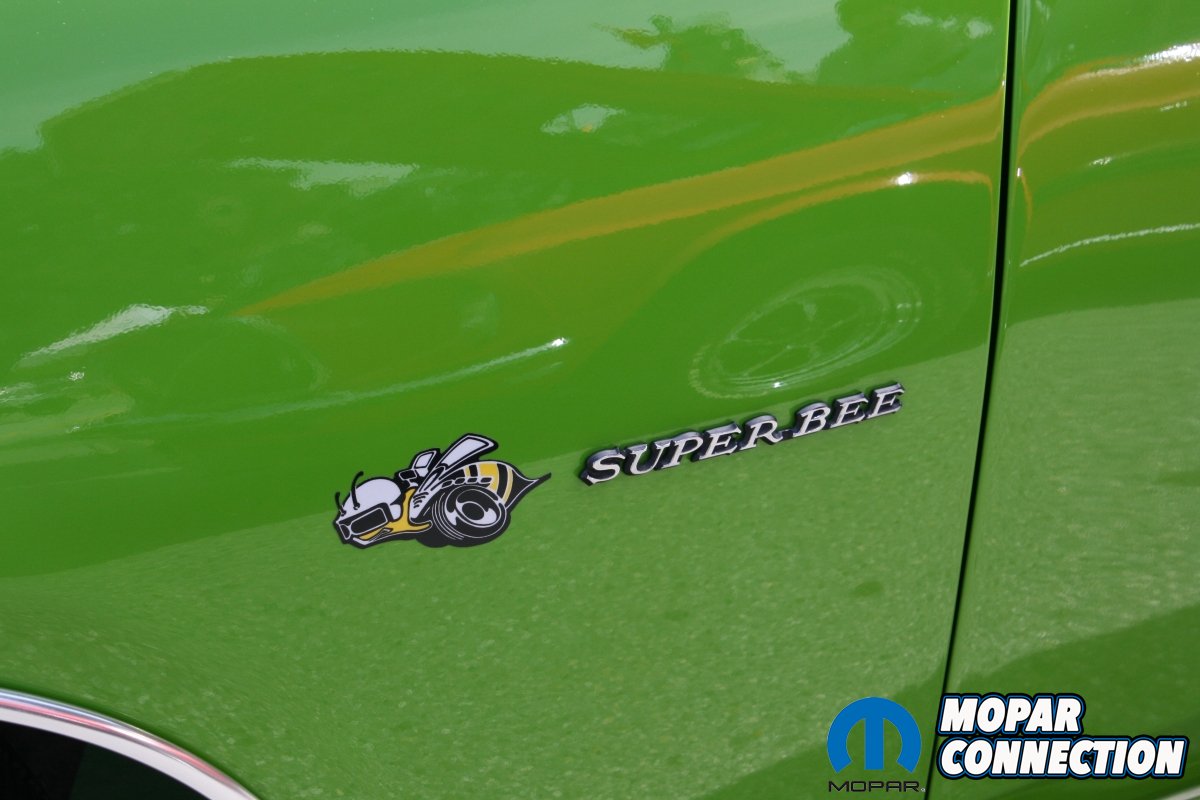

“In the bay at work, I detailed the interior and installed the front and rear bumpers, moldings and weather stripping before installing the Super Bee parts such as the rear Go-Wing, front spoiler and aftermarket rear window louvers. With those done, I then installed the Super Bee stripe kit and emblems before installing the Super Bee hood insert that I painstakingly masked and painted. It felt like Christmas unpackaging each part and putting it on the car.”

He continues to say, “I faced adversity every leg of the journey right down to the end. When I was completing the car, I was suffering from severe sciatica (back pain caused by a problem with the sciatic nerve) that lasted four months until a CT scan revealed I had a bone spur, bone fragment, and a herniated disc that caused the complete compression of my sciatic nerve. I saw a neurosurgeon and within one week I had emergency spinal surgery. That was another bump in the restoration time line.”

“When I think of the car, I think of ‘Tupelo Honey’. It’s described as rare, seasonal, and utterly unique. Tupelo honey is symbolic of unrelenting perseverance. For years, my goal was to make it to big Mopar show local to me with the car; something I finally did in July 2012. Since 2012, I have been honored and privileged to win awards at different car shows, including ‘Best of Show’ at the local Mopar show this past summer. I am proud that I persevered and never gave up when quite a few other people would of. My Super Bee is not perfect but proudly wears the Bee stripes; real or not. I continue to improve the car mechanically and visually every year. Like most car enthusiasts, a restored car is never really finished. I even had Robin McQueen over at Automolove.ca design an awesome banner of the car which proudly hangs on the wall next to it! It has been a unique and rare journey like Tupelo Honey.”