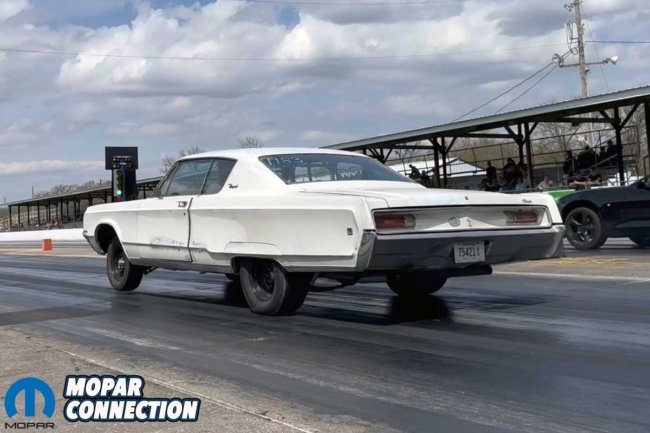

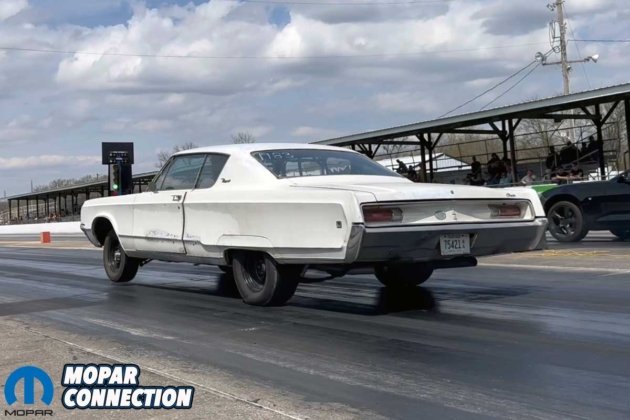

Are you trying to cut your 60-foot times at the track? Sure, there are 4-link setups, mono-leaf setups, and other devices like Cal-Tracs to help control rear-end movement, but the “old school” stuff works great, too. Super Stock springs and pinion snubbers worked for years and still do, and they are cost-effective.

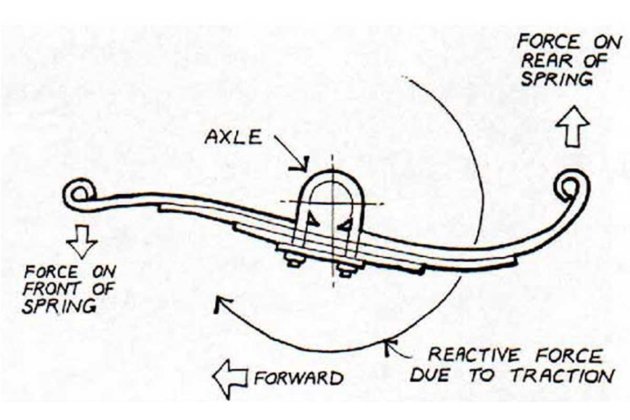

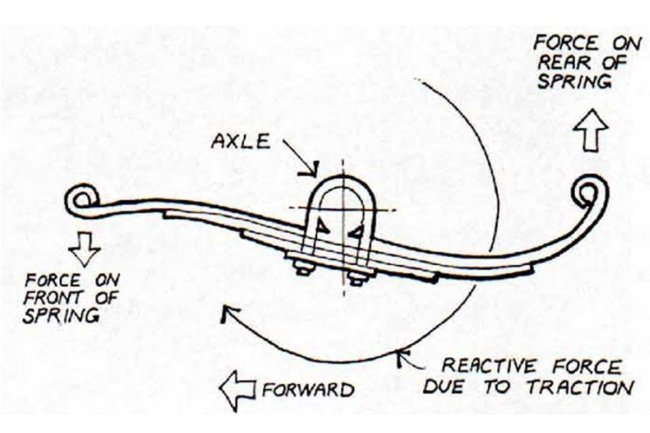

Above: Axle wrap occurs under hard acceleration. The pinion gear tries to walk up the ring gear, resulting in an axle housing that tries to rotate upward. The upshot is a leaf spring that twists into an “S” shape. That is wasted torque, and wheel hop can occur when the spring attempts to return to its standard shape.

Leaf springs are a concern, especially when it comes to straight-line performance. When you depress the throttle in your hot rod, the leaf springs inherently “wrap” as the axle housing rotates upward under hard acceleration. The pinion tries to walk up the ring gear, turning the spring into an “S” shape rather than its normal arc contour.

A sticky tire on a good track makes the axle wrap and leaf spring deformation even more severe. When this happens, some of the torque applied to the rear axles is lost as the springs flex and wrap, absorbing energy that should propel your Mopar off the starting line.

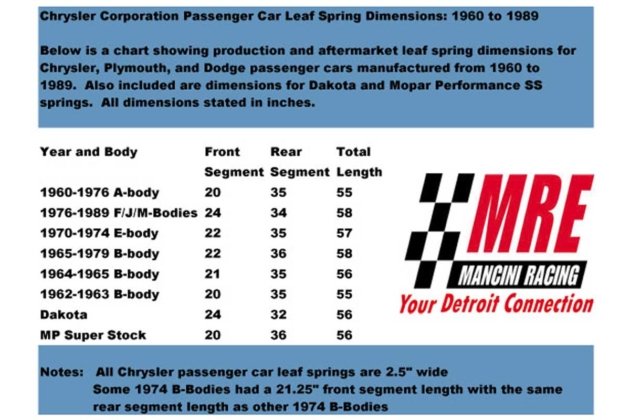

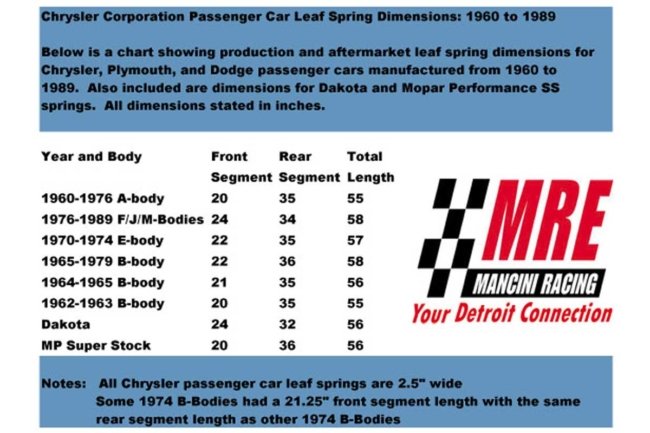

Above: The Chrysler leaf spring dimensions chart includes all the desirable Mopars from the 1960s through the 1980s. (courtesy of Mancini Racing)

A pinion snubber helps minimize some of this motion as it mechanically limits how far the axle can tilt upward. Heavy springs with a different geometry to restrict this movement are the other key pieces of the equation. And that is precisely what the Super Stock springs are: heavier springs with an altered geometry, which shortens the front half of the spring from the axle mounting point to the front hanger eye.

Once you dial in your Super Stock spring setup, respectable 1.35-1.6 second 60-foot times are achievable. In addition to the springs, you can tinker with different pinion angles, using an adjustable snubber and good shocks to optimize your setup.

Above: The dimensions of the factory E-Body leaf spring (top) compared to a 3200lb Super Stock spring. The Super Stock spring is substantially shorter. The arc of the Super Stock spring is much tighter as well.

Some enthusiasts have even better success adding additional clamps in the front portion of the springs and removing clamps in the rear. We use this setup at the track, which repeatedly propels our small block-powered 3700lb ‘Cuda (with driver and fuel) to 1.50 short times.

If you are considering a Super Stock spring swap, the first thing to understand is that different model cars/years have varying spring lengths, but all Super Stock springs are the same length. They all have a 20-inch-long front section and a 36-inch-long rear section (the altered spring geometry mentioned earlier).

Above Left: The stock hanger (top) works with the factory leaf springs. However, with the Super Stock spring’s front segment (distance from hanger bolt to axle housing alignment pin) being shorter in length, the hanger must be enlongated. The Super Stock hanger has two mounting points for the leaf spring. That provides options for the instant center. Above Right: QA1 double-adjustable shocks provide great suspension tuning to control the leaf springs.

What do you do to install them? It is simple: different front spring hanger brackets accommodate for the various lengths of the springs for your chassis. It is critical to order the correct front hanger brackets for your car, or you will end up with some incorrect geometry, with the rear end not positioned correctly (front to rear of car), incorrect driveshaft articulation, and rear shackles at an odd angle (forward tilted).

Mancini Racing carries all the different hanger brackets and ensured we had the correct brackets for our ’73 ‘Cuda and ’70 Satellite Drag and Drive Cars.

The next thing to understand is that springs have different weight ratings, ranging from 2800lb to 3800lb. It is recommended that you order a spring with a rating close to your vehicle’s weight, although there is nothing wrong with experimenting with different spring rates on your car.

Above Left: To minimize the axle wrap, we picked up a pinion snubber. As the axle moves upward under hard acceleration, the snubber, which is attached to the axle housing at the pinion, will hit the floor, thus stopping the upward motion. Above Right: Because of the limited space to adjust the jamb nut, WAF Racing designed and adjustable pinion snubber wrench.

We first ran a 3200lb spring on our 3700lb ‘Cuda (with driver and fuel) and are now trying a 3600lb spring to see if we can improve our 60ft time. As expected, the 3200lb springs ride “softer” on our car than the 3600lb spring. Both springs can ride comfortably on the street with fine-tuning of adjustable shocks.

Mancini Racing and Summit Racing are great places to source the springs—they are affordable and offer fast shipping. We have had excellent luck with both single- and double-adjustable shocks from QA1. Of course, the double-adjustable versions offer the most tunability.

Another “Mopar-ism” to be aware of is that the 2800lb and 3200lb springs have small rear bushing diameters, fine for A-Bodies but smaller than what you find on B- and E-Bodies.

So, if you plan to run the lighter-weight spring on a B/E body, you will also want to visit Mancini Racing for some conversion shackles, which have a big bushing on the frame side and a small bushing on the leaf spring side.

Unfortunately, they only offer shackles that are 3.5 inches long, which suits B-Bodies, but E-Bodies have 4-inch shackles, so we made our own.

We opted for a Proform Parts adjustable snubber, which offers unlimited adjustability since it is a threaded shaft instead of pre-set holes for pins. Although the adjustability is excellent, it is difficult to adjust when installed on the car because it requires such a large wrench in a tight space. We employed the design and manufacturing capabilities of WAF Racing to whip up a compact wrench for the task.

Above Left: Many people assume the rear end of a Mopar will sit high with Super Stock springs. Our ’73 ‘Cuda has just the right altitude (attitude) with a pair of 3200lb springs and a 28-inch-tall tire. Above Right: Our big Newport sporting a 512-cube big block can get air under the front tire. That is quite a feat for the two-ton C-Body, but the Super Stock springs (custom-made copy that emulates the SS springs) make all the difference. The Newport’s 60-foot times are in the 1.65 second range.

Once the new springs are installed, check your pinion angle. It will likely change, so be prepared to measure and order shims. Luckily, the shims are easy to install on a Mopar. On most cars, if the U-bolts are long enough, you can loosen them, letting the axle rise and slipping shims in or out.

You can also experiment with bushing materials. Less movement is more when it comes to the best 60-ft times. Factory-style rubber bushings will provide the most compliant ride, but polyurethane bushings will stiffen everything up a bit. There is also the option of a solid aluminum bushing in the front spring eye (at the hanger) to firm up the suspension.

Above: We turn up the wick with this Procharged 408 small block ’71 Dart. It consistently has 1.35-1.45 short times, even on a track enhanced with fall foliage on the surface.

Although there is plenty to do for the leaf spring swap, it is not difficult. There are many minor points to be aware of to make your swap as smooth as possible. The “old school” tech offers plenty of adjustability, and once dialed in, it just performs. We use our cars for Drag and Drive events and have thousands of miles on Super Stock springs and adjustable shocks even with the rear segments of the leaves unclamped and towing a trailer. Best of all, we have no complaints.