At the 2023 Carlisle Chrysler Nationals, it seemed as though factory air conditioning (AC) was installed on most of the vintage-era vehicles on the show field, even though that certainly was not the case. After noticing the first black V-twin compressor, we saw them everywhere. We were suffering from what is known as the Baader Meinhof Phenomenon (spoken as bah-der-myn-hof), which is the experience in which something you see for the first time starts to “appear” everywhere.

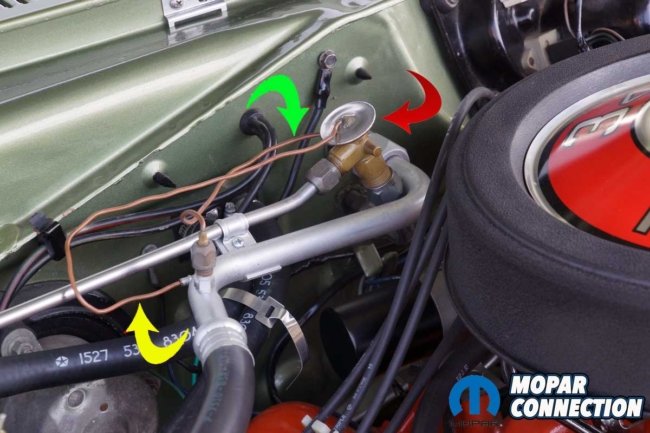

Above Left: Chrysler successfully used the RV2 compressor from 1961 to 1980. All the air conditioning (AC) systems, except A-bodies until 1974, had an evaporator pressure regulator (EPR) system. The system required three gauges on the AC gauge set. The three fittings were low-side (blue), high-side (red), and EPR pressure (yellow). Above Right: A-bodies had a cycling-clutch system, which required only two gauges. There were only two fittings: low-side (blue) and high-side (red). The system has been retrofitted to R134a refrigerant based on the non-factory fittings and caps.

The first factory-installed air conditioning was installed in a 1939 Packard. The system was large and clumsy, but many of the components used in modern vehicles were installed on the Packard. The compressor ran whenever the engine ran, so turning off the compressor (for the winter) required removing the belt. Additionally, trunk space was limited due to the trunk-mounted evaporator and blower motor assembly.

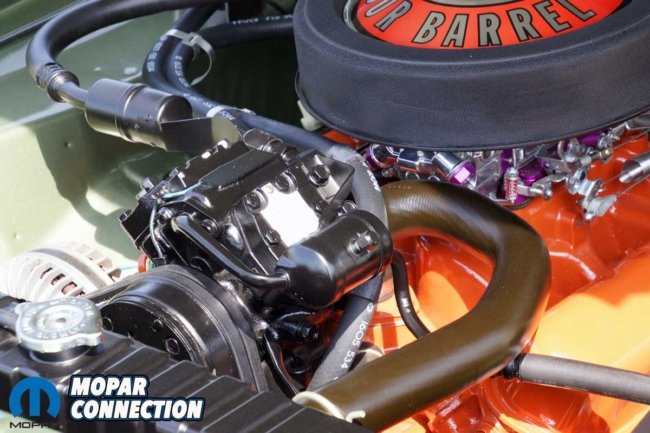

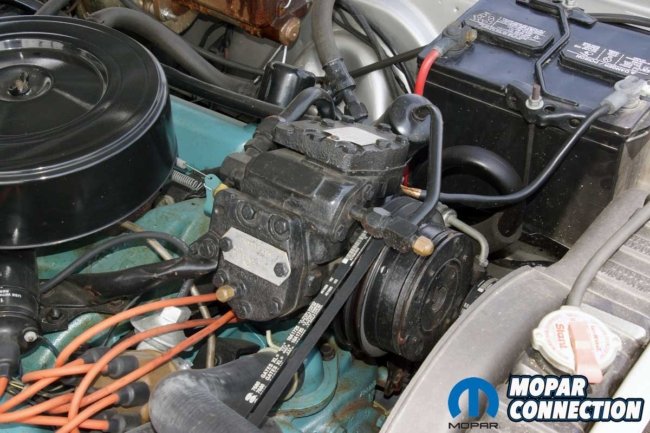

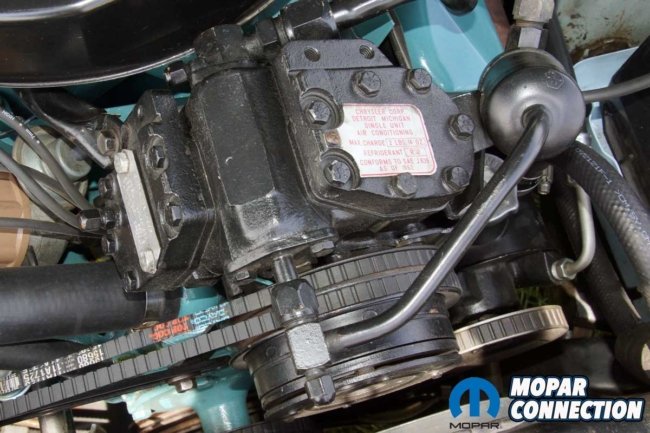

Above Left: The RV2 compressors fit nicely on all engines: small blocks, big blocks, and even slant sixes. Above Right: Many RV2 compressor drive pulleys employed a two-belt system, depending on the engine and the system’s demands.

The installation of factory AC on Chryslers did not show up until the early 1950s, and the development had not progressed much from 1939 due to the industry focusing on building products for World War II.

To inform its mechanics about the progression of Chrysler products, in 1947, Chrysler started its Master Tech Service Conference program. Each month Ross Roy, Inc. produced a new educational topic, which provided training materials (service reference book, film strip, and record) to every dealership’s service department to hold training sessions with its technicians.

Above Left: Both the EPR and the cycling-clutch systems relied on a thermostatic expansion valve (TXV) (red) to provide the system pressure drop of the R12 refrigerant. The TXV dropped the high-side pressure from about 200 psi to 30 psi on the low side. With the lower pressure on the low side, liquid R12, which has a low boiling point (-21.6°F), would change state and take on heat. The TXV had an internal valve moved in one direction by low-side pressure (green) and the other by expanding or contracting trapped refrigerant in a capillary tube (yellow) to provide the restriction. Above Right: The cool discharge air exited at knee-located ducts. The duct arrangement was common on A-bodies—other models employed dash-mounted louvers.

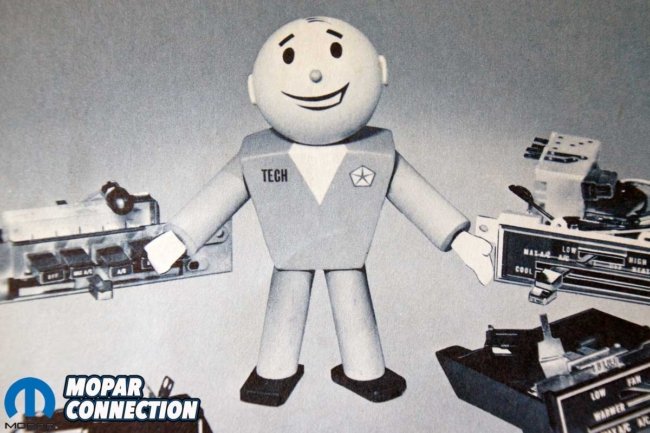

On the accompanying record was the voice of a lead mechanic instructing an apprentice about the subject, and to help stir the conversation and enhance the learning, a small wooden figure named “Mister Tech,” with his gruff, raspy voice, spoke in simple terms with the Chrysler trainers. Tech remained the face of Chrysler training until 1975.

The first training session that covered AC was the 1954 Airtemp Air Conditioning session no. 79. Between 1954 and 1976, Chrysler had fifteen additional learning sessions that introduced and presented updates dedicated to air conditioning.

Above Left: The AC system has been retrofitted to R134a based on the low-side fitting (blue) and high-side fitting (red). Notice the EPR fitting (yellow) is unmolested. Hopefully, the person that retrofitted this system removed the EPR and converted the system to cycle the clutch based on temperature. All EPRs are calibrated for R12, and R134a operates with higher pressures, which are incompatible with the non-adjustable EPR valve. Above Center: The blower motor is serviceable from the engine bay. Also in the photo are the TXV, heater control valve (lower right), and vacuum canister (lower center). Above Right: Chrysler used plastic or brass caps for the fittings, as shown on this Mopar.

The early Chrysler systems had a belt-driven compressor, condenser, trunk-mounted evaporator, thermostatic expansion valve (TXV), receiver, strainer-drier, and sight glass. The earlier system compressors were supplied by Tecumseh (1955-57), Copeland (1957), and finally, the famous Airtemp V-twin V2 (1958-through early A-bodies). The updated V-twin RV2 was found on nearly every Mopar from 1961 to 1980, though some Mopars came with two-cylinder, inline Tecumseh compressors.

Although R22 (Freon) refrigerant was found in some early AC-equipped DeSotos, R12 (Freon) was used through the end of the RV2’s production. By 1996, Mopars and the industry moved to R134a (Suva), which was used as a “drop-in” replacement refrigerant to replace R12. Decades later, R134a started being phased out of new cars in 2014, and by 2021, R1234yf (Solstice) became the latest industry standard.

Above Left: The receiver drier (green) stores liquid refrigerant as it exits the condenser and moves toward the TXV. Inside the receiver drier is a desiccant that attracts moisture, which is terrible for the system because it causes rust, freezes, and is incompatible with refrigerant oil. All the r12 receiver driers had a sight glass and a high-pressure cutoff switch. Above Right: The receiver drier (yellow) could be found in the engine bay or in front of the radiator/condenser assembly. The original receiver driers had an XH-5 desiccant, but when retrofitting to R134a, an XH-7 or -9 was required. XH-7 and -9 desiccants will also work with R12.

Interestingly, many owners of the Airtemp air conditioning systems at Carlisle shared with us, “The AC doesn’t work,” or “It needs R12.” There are a few things the owners could do to diagnose and revive their air conditioning.

The RV2 systems worked well on the refrigerant for which they were designed, Freon. However, the condensers in the ‘50s, 60s, and ‘70s Mopars were somewhat inefficient. With the benefits of newer technology, the factory serpentine-type condenser could be replaced with a better flowing parallel-flowing condenser, which can remove heat more effectively. At the same time, a more efficient condenser design would lower the high-side pressure, reducing the torque required to rotate the compressor and lessening the noise and vibration of the compressor.

Above Left: The RV2 compressor was a V-twin design, similar to a Harley-Davidson engine. The compressor was 10.5 cubic inches. Above Right: Before the V2 and RV2, Chrysler used a few different models, including compressors from Tecumseh, as found on this ’55 Chrysler 300.

Mopars since 1962 were equipped with evaporator pressure regulator (EPR) systems, except for A-bodies before 1974. Those A-bodies had a clutch-cycling switch to regulate the evaporator temperature.

The EPR valve prevented the evaporator from freezing by bypassing internal system pressures. EPR valves were designed and calibrated from the factory to work with R12’s system pressures. Retrofitting the R12 system with R134a (less expensive, more available) requires the removal of the EPR valve (located at the inlet to the compressor). A thermo-sensing clutch cutout switch needs to be installed. The thermostat prevents the evaporator from freezing by monitoring the temperature instead of the EPR valve regulating the system pressure.

Above Left: The early AC systems separated the sight glass from the receiver and strainer drier. Above Center: The early systems had the evaporator in the trunk rather than under the dash. Small scoops were mounted to the vehicle on either side near the rear window to get fresh air into the AC blower box. Above Right: For recirculated air, two grills provided cooled, dehumidified air to the blower box. A large duct returned the cold air to the vehicle’s interior.

Additional improvements include doing some work to insulate the vehicle. When it comes to our old cars, they could be better at keeping heat out. Adding tinted glass (if possible) and applying quality insulation on the floor pan, firewall, roof, and pillars will go a long way to minimizing cooling losses.

There are a few options if you are like many of the Carlisle faithful with a non-operative factory AC. Leave it as it is because it looks good at car shows, and the windows roll down. With the earlier suggestions, track down the components needed to repair the system and recharge with R12 or R134a. Lastly, if authenticity is not required, contact the representatives at Vintage Air for the parts or a complete heating and air conditioning (HVAC) unit to update your Mopar’s air conditioning to the 21st century.

Above Left: Airtemp was Chrysler’s air conditioning division from 1938 to 1975. The company focused on all avenues of the AC world, not just automotive. Above Center: The heater control valve stopped coolant movement to the heater core when the AC button was pressed. A vacuum source pulled a diaphragm, which moved a lever to close the passage. Above Right: The refrigerant requirements for the RV2 systems were between 2 lbs. and 6oz to over 4 lbs. for dual unit systems. Today’s vehicles require much less refrigerant to accomplish the same cooling.

Vintage Air has plenty of SureFit™ options for many Dodge and Plymouth models from 1966 to 1974. The complete kits can be ordered for vehicles that came equipped with or without factory AC. Each kit uses Vintage Air’s exclusive fully electronic microprocessor control system, eliminating vacuum connections, cables, and capillary tubes.

Above Left: The control panel was a combination of electrical, mechanical, and vacuum. Based on the mode and temperature selections, the vacuum moved various doors and the heater control valve for the correct cooling or heating. Above Center: The vent temperatures could drop into the upper 30s under ideal conditions, but most of the time, the vent temperature resides in the low 40°F range. Above Right: Every engine bay-mounted AC component can be seen except for the condenser.

A high-capacity copper/brass parallel-flow condenser and aluminum plate-and-fin evaporator provide instant temperature changes for maximum system performance. The kit has a blower fan with infinite speed adjustments from the lowest to the highest outputs. A high-volume defrost mode directs moisture-free heated air to keep the windshield clear. The HVAC box fits behind the dash, and the system works with the factory controls.

Top Left: Aftermarket AC systems rely on a Sanden compressor. The multiple-piston design provides excellent cooling while being extremely efficient. Top Right: The aftermarket locates the receiver drier in the stock location. A high-pressure cutoff switch protects the system from excessive high-side pressure. Bottom Left: The system still uses a TXV, but it is designed to react more quickly to changes in cooling demand. Black tar tape insulates the capillary tube from engine heat. The system utilizes R134a. Bottom Right: The factory vacuum-operated heater control valve remains with some aftermarket systems.

Complete kits include everything in the evaporator kit plus all under-hood components such as compressor engine brackets, condenser with supports, preformed refrigerant lines, receiver-drier, fittings, hardware, and installation instructions.

The compressor with the kit is one of several high-quality Sanden units with a V- or multi-groove pulley, depending on the system selected. Each Sanden compressor is a swash-plate design with multiple pistons. A Sanden compressor provides sufficient pressure and decreases engine load. It dramatically improves the cooling function and features a stable, efficient, vibration-free, and reliable operation.

Above Left: Sanden compressors are a swash-plate design, which allows for a compact design. The compressor requires less engine bay room and is substantially lighter than the RV2. Vintage Air sells them in a natural or polished finish. Above Center: Vintage Air offers complete kits for several popular Mopars. The kit has everything needed to convert a vehicle to modern, efficient air conditioning and heating. Above Right: Vintage Air has components to complete or repair an AC system. R134a barrier hoses, fittings, O-rings, and a receiver drier are included in this kit.

Each compressor’s main body is made of high-strength aluminum material, which is durable, rigid, and wearable. It will not crack, break, or leak. Such high quality ensures a long-time use for each compressor kit. The compressors are offered in a natural or polished finish. Each compressor has been examined and tested carefully before its delivery. Just make sure to add the proper amount of oil before installing.

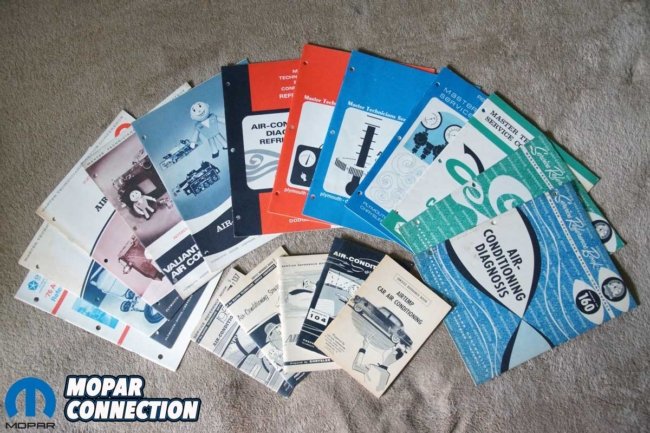

Above Left: Chrysler made sure its mechanics were updated on air conditioning. Between 1954 and 1976, Ross Roy, Inc. developed sixteen Master Tech Service Conference learning packets. Above Right: The world-famous “Mister Tech” was the face of the Master Tech series from 1947 to 1975.

If a SureFit™ kit does not fit your needs, Vintage Air offers its Builder Series, heater-only systems, hose and fittings, compressors, brackets, and additional accessories, including cooling fans. Check out Vintage Air for all its products. The option is yours, roll down the windows, rebuild the system with factory parts or update to cutting-edge air conditioning with Vintage Air products. Regardless of what is selected, it is imperative to beat the heat.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by