“The best laid schemes o’ mice an’ men,” the Robert Burns quote goes, and so went our day scheduled with two of Holley’s most recent Mopar project vehicles. It’s no secret to anyone who has been paying attention lately, the the world’s largest aftermarket brand (now a family of brands), Holley, has set its sights on Mopar. Particularly, Holley sought to make the third generation Hemi engine the aftermarket equivalent to the LS Chevrolet in ease of installation and use. An exciting prospect to say the least.

Of course, the massive turnout at Holley’s inaugural Moparty in Beech Bend Raceway last September helped fuel that fire as well. Attendance numbers, particularly during the height of the Covid-19 hysteria, were impressive to say the least, and all those in attendance left enthusiastic for the next year. With this kind of momentum behind them, Holley has poured on the gas and charged head-first into the Mopar marketplace. And as means of “proof of concept” the performance juggernaut just rolled out two builds worth a look-see.

Not wanting to wholly restore a ’66-’70 B-body from the ground up, and frankly, needing a running-and-driving machine ready for a Hemi-swap, Holley’s team purchased a very clean bright red (not a factory hue) 1966 Dodge Charger. Originally equipped with a 383 four-barrel and a 727 TorqueFlite, the Charger was an ideal candidate to deploy a veritable avalanche of aftermarket swap parts. Beginning with a 392 cubic inch 6.4L Gen 3 Hemi hoisted from a 2014 Challenger SRT, the Charger also received a Nag1 transmission from a 2010 SRT8 Chrysler 300.

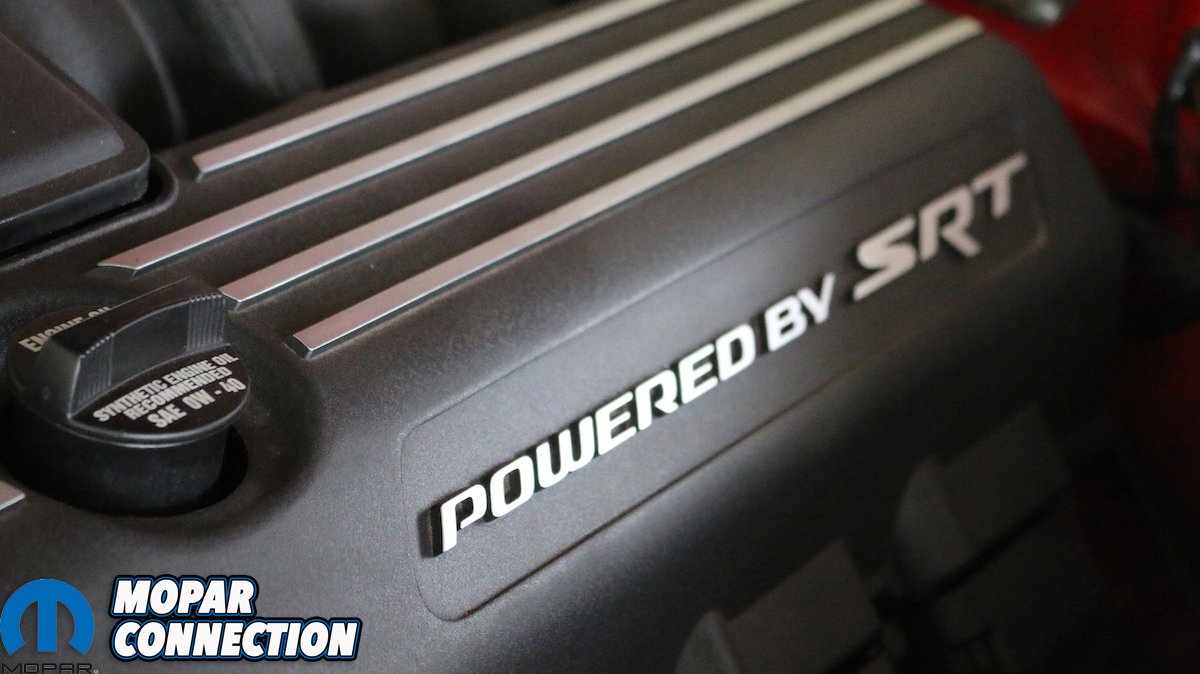

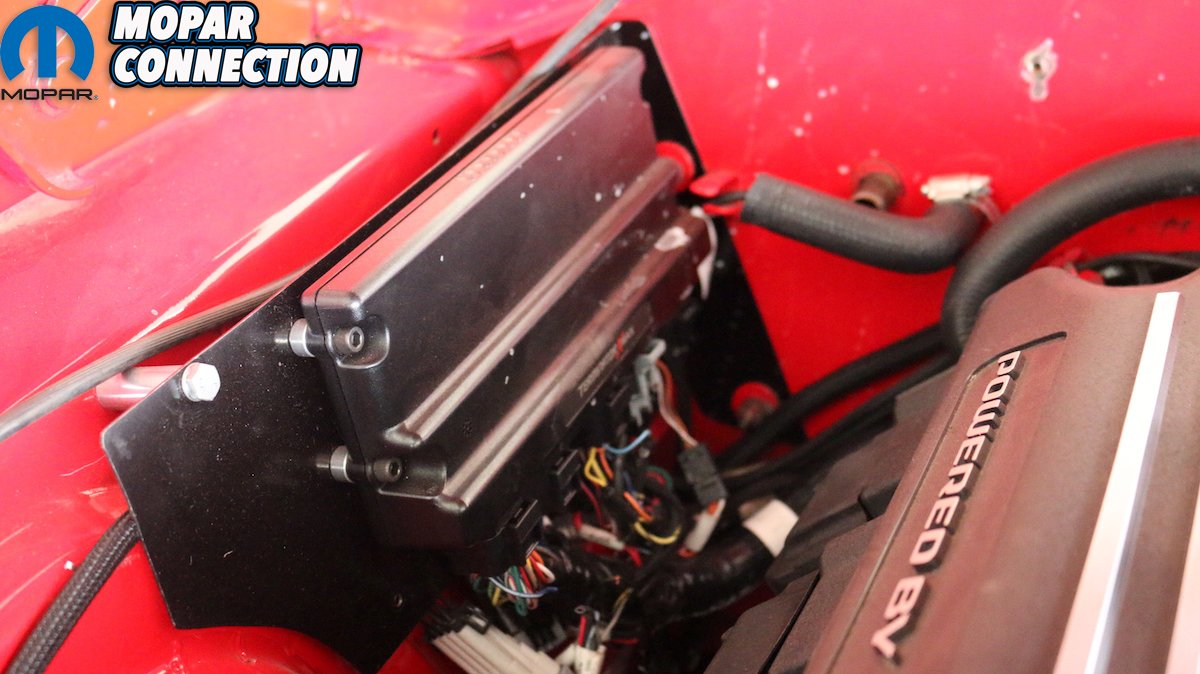

Shoehorning the engine and transmission required a set of Holley’s Engine Mount brackets (BHS531), a pair of Lakewood engine mounts (24096LKW), Holley’s transmission crossmember (BHS532) and Nag 1 transmission adapter plate (BHS535), Holley’s transmission tunnel hoop (BHS539) and a transmission mount (71223029HKR). Running the new G3 Hemi required Terminator X Max (with VVT) and an intake runner control (requires harness) (550-1425 ).

Feeding the Hemi necessitated a Sniper Fuel Tank with an in-tank 255 LPH fuel pump (19-183), a Holley cast aluminum mid-sump oil pan (302-61), a Hays SFI flex plate (40-510), as well as Hooker Blackheart 1 7/8” long tube headers (BH2358) and a complete Hooker Blackheart 3” 304SS exhaust system (BH2361). The automatic employs a standalone Sound German Nag 1 transmission controller.

For most builds, that alone would be enough, but Holley wanted the Charger to ride as nicely as it now ran. So in partnering with fellow aftermarket industry leaders, Holley rebuilt the braking system using a Wilwood Dynalite Big Brake kit (12”) to clear the steel wheels (140-928-D), a Baer ReMaster series billet master cylinder and proportioning valve; Proforged steering components, a Hellwig front sway bar kit (5904), Ridetech HQ Series shocks and a complete Moser Engineering Dana 60 rear differential, using some highway-friendly 3:23 gears.

So when Holley asked Mopar Connection Magazine to drive up and test drive this awesome creation, we jumped at the chance. The plan was simple: meet at Holley’s Bowling Green, KY headquarters, slip in behind the wheel and cruise the Charger over a plotted course, where we could snap some pictures before heading over to grab lunch. Sounds easy, right? Well, that’s where the whole best laid schemes line comes into play.

It wouldn’t stop raining for like, a month. From Ohio down through Kentucky, Tennessee, and into Alabama, the rain wouldn’t let up. A day would promise clear skies on the weather app only to switch hours later into downpours. We honestly rescheduled half a dozen times. Finally, we locked in a day (come hell or high water) and sped up to Holley. The roads were wet, but the rain had cleared for the most part. We were in business.

Well, sorta. When Holley team member, Steve Sparkman pulled up in the Charger he had less-than-thrilling news. The transmission was acting up. We replied, “No problem. Let’s just cruise it to the location and we can shoot video and pictures there.” He agreed and we pulled into downtown traffic. Sure enough, the Nag1 wasn’t behaving and would need to be plugged into the computer for a diagnostic. That’s OK, it was a working prototype after all.

Then came the smell. At first we thought we had passed by an open sewer or a “honey truck,” but the acidic sulfuric stench began to burn our nostrils. As we lulled into the Beech Bend Park, the intensity increased. It was the car. Steve wheeled the red Charger under the pavilion (as the drizzle increased into light rain) and killed the engine. We quickly exited and began searching the car head-to-toe; it was coming from the trunk. Steve quickly unlocked the lid and saw the rear-mounted battery swelling, bulging at the sides. Total failure.

Procuring some hand tools, the battery was yanked from its tray and sat dozens of feet away in case it did decide to blow. The deteriorating battery rendered the Charger dormant until a replacement could be installed. Rather than wait for backup, a wrecker was called to carry the Charger home. We snatched the keys to the 392-swapped Dodge Dakota that Bryan McTaggart had driven (more on that swap in a future story) and headed back to HQ. Rain had set in, and most of the office was vacated, so we bid farewell and headed home.

Thankfully, the failed battery was all that the Charger needed. With a fresh battery, the heavy toll on the electrical system was relieved, which helped the transmission controller perform better. While we’ve yet to return to Holley for a test drive, we’ve seen the Charger make plenty of appearances at various events and photoshoots – with an open invitation to return and give the Mopar a good, proper rip around Bowling Green when the sun is out.