For many residents of northern Ohio, June 22nd 1969 is a day that most will not forget. On that day in Cleveland, Ohio a passing train threw sparks onto the Cuyahoga River that set the river ablaze. The polluted river was filled with oil-soaked debris that instantly caught fire when the single spark touched down. Unfortunately, this was not the first time the river had caught fire. There had been multiple other occasions that started clear back to 1952. Although the fire did not last long, cause much damage or claim any lives, it was the most-covered incident out of the multiple fires that ignited on the Cuyahoga River. This specific occurrence started an environmentally-friendly revolution.

With the shift of industry to technology, waste to recycling, Time magazine wrote about the fire and brought mass attention to Cleveland and the polluted river. With so much controversy on the river and other environmental issues, Congress passed the National Environment Protection Act that became law in January 1, 1970. Since then, the river has been cleaned up and is a beautiful sight today. The river has not caught fire since 1969, but the history of the burning river will not be forgotten. In 1987, Jeanette Ladina started a small company in the suburbs of Cleveland to build tilt steering columns for classic cars. Growing up in the Cleveland area and being familiar with the Cuyahoga River fires, Jeanette decided on the name Flaming River Industries. Fast-forward 30 years and now Flaming River Industries is burning their logo in more than just steering columns.

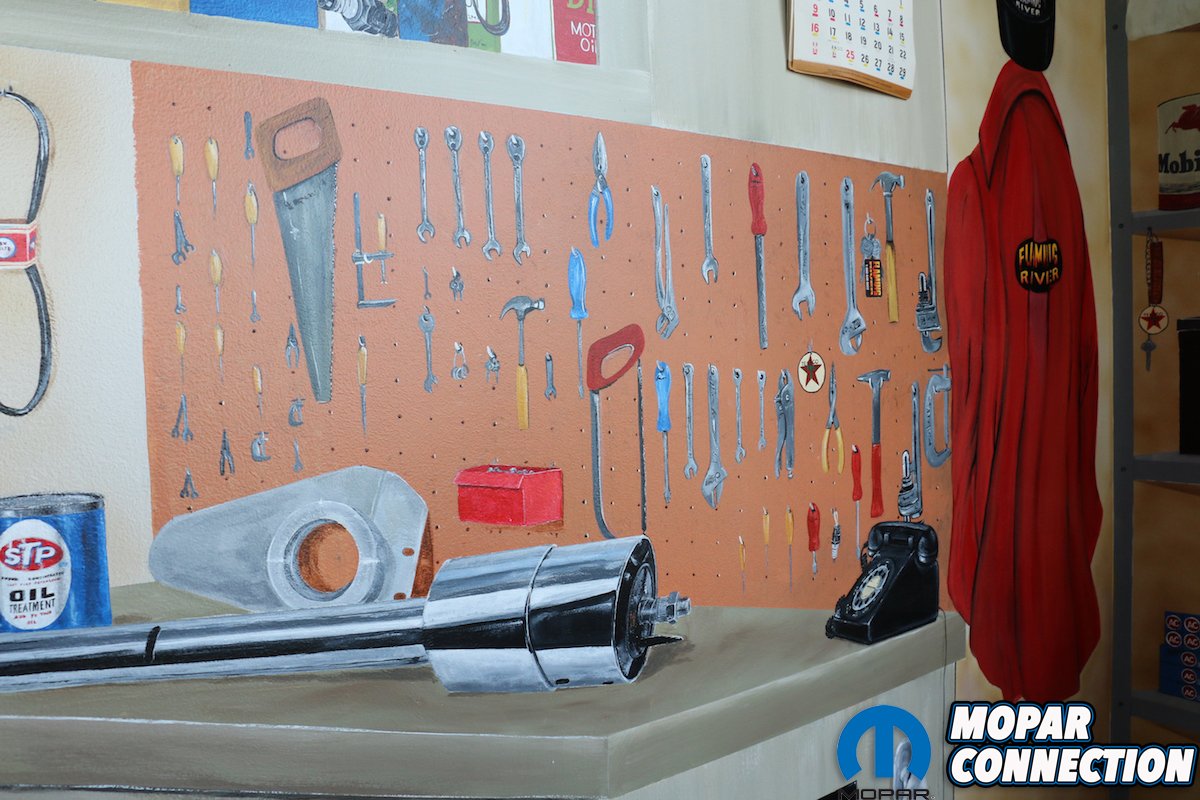

Upon arrival at Flaming River Industries (FR), you are greeted by one of two showrooms. Whether you’re picking up parts or there for business, you may get to walk through Jeanette’s collection of shop vehicles or walk into a custom hand-painted room. We went to the first door we saw and it happen to be the parts pickup area. As we entered, we were astonished at the hand-painted murals. Although the room is not very big, the detail and list of hidden objects that you could find throughout the painting is incredible. We later found out that the painters of the room are actually a husband and wife team that are employed at FR and took them 6 months to complete.

Above left: The extravagant painting that fills the walls of the parts pickup entrance. Above right: You can see the fleet of shop cars in the showroom

Hidden throughout the hand-painted walls was Flaming River signs, spark plugs, shop cars and many other automotive related items to find. They also had a few parts on display in the room along with a 1950 Dodge truck that was easy on the eyes. We expected to see a Chevy or Ford on display but we were very grateful that they sat out their Dodge just for us. (We don’t think they did that just for us but seeing a Dodge in their showroom made our day.)

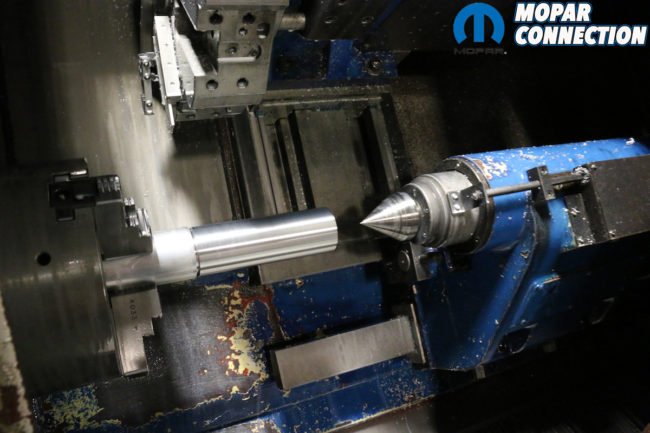

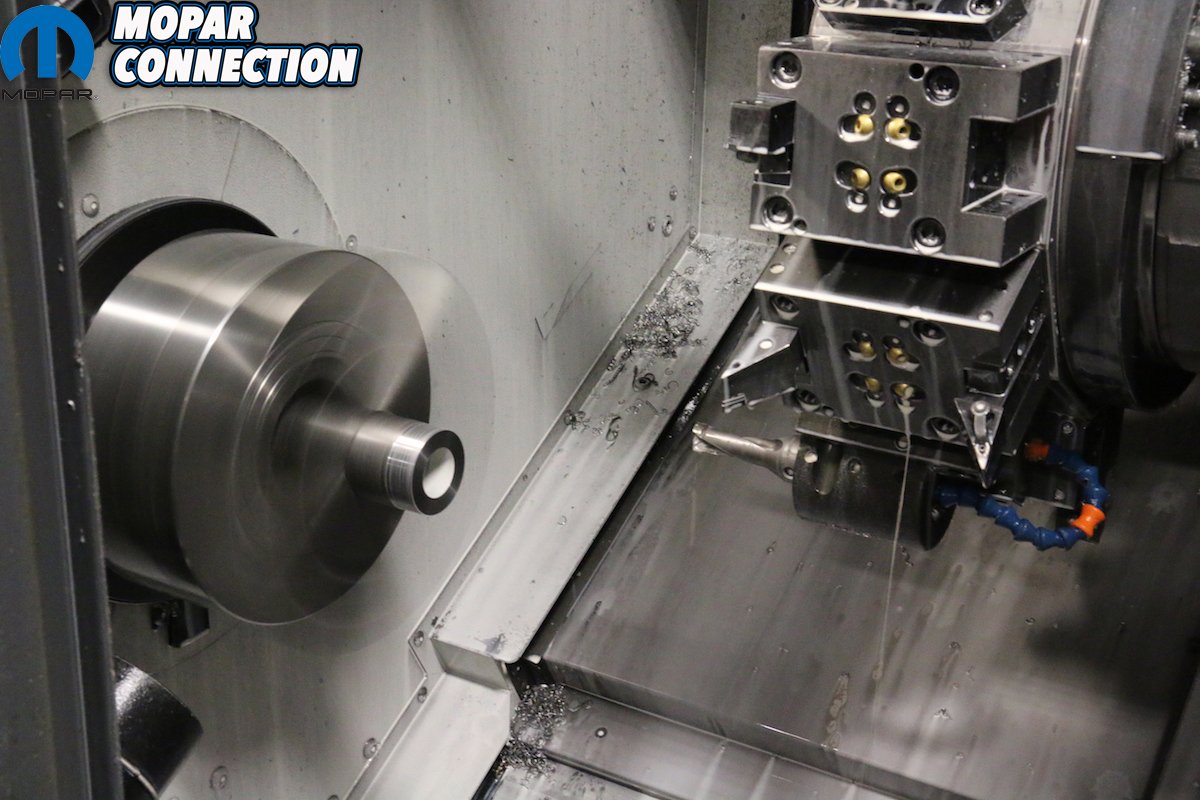

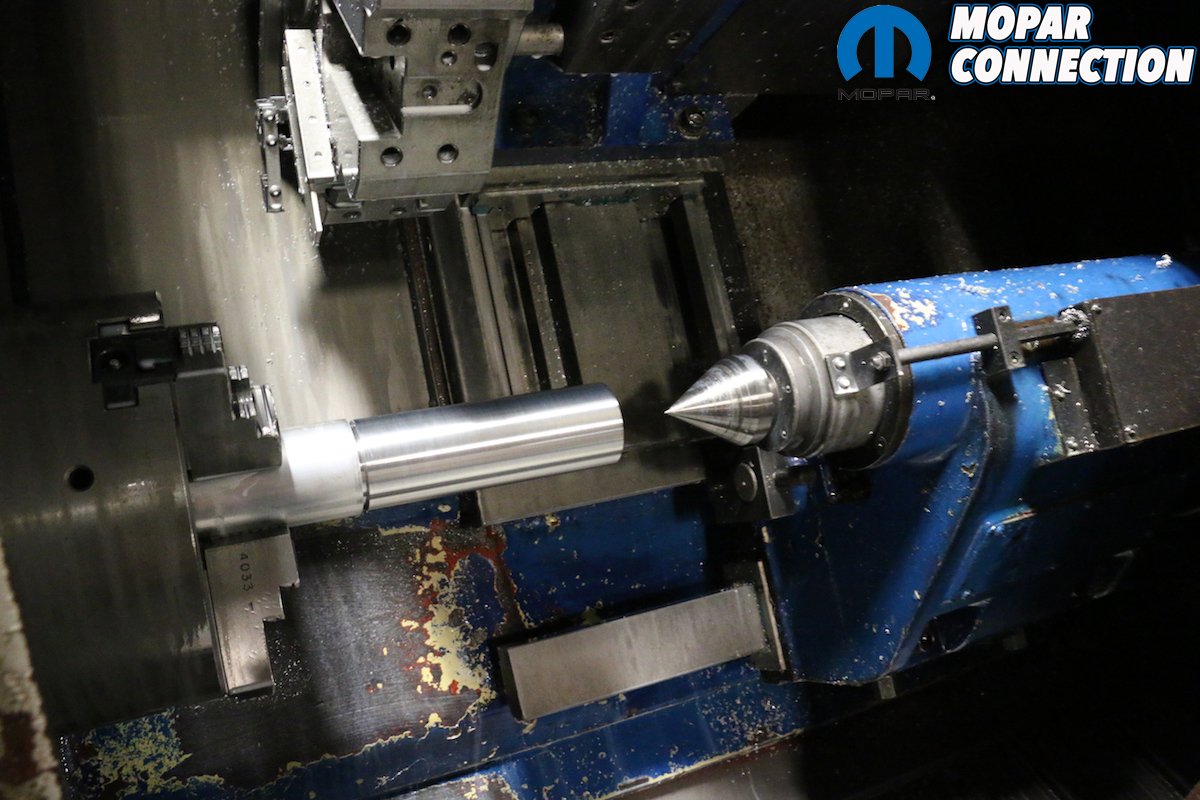

We patiently waited for John Jennings and Mike Close, who were going to be our guides for the day. We entered the offices through the parts pickup doors and walked through what felt like a maze of hallways, desks and doors. As we walked through the offices we noticed a few scattered billet parts, new part drawings and stacks of magazines. We continued our way through the office area until we found the shop doors. Before we entered we put on our stylish safety glasses and headed in. As the doors opened we could see multiple workers running CNC mills and lathes that were producing billet parts like candy. We thought it was interesting that the noise level of the shop was not loud at all. This is not a bad thing because we could actually have a conversation with John and Mike without yelling.

The first area we came to housed a CNC laser cutting machine. They were in the process of laser cutting steering column housing tubes. John explained, “This machine has greatly increased our efficiency of building our steering columns. What this machine does with in a couple minutes used to take 3-to-4 times longer before. The biggest part is the machine makes multiple cuts without removing and repositioning the part.” Not only does the laser cut notches and holes where they need to be, but it also engraves each column with Flaming River’s logo. Steering columns are still FR biggest seller but its also one of their more complex pieces to build.

Above left & center: The CNC lathe getting ready to start carving. Above right: Before and after picture of steering wheel adapter

Above left: Steering boxes awaiting to be assembled. Above right: Steering box getting ready to be cut up and ready for assembly.

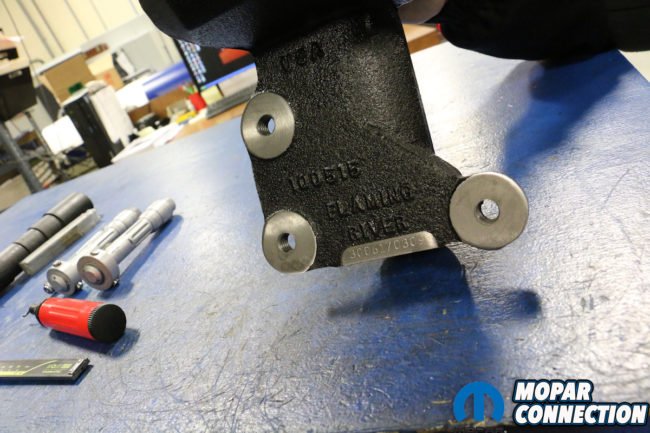

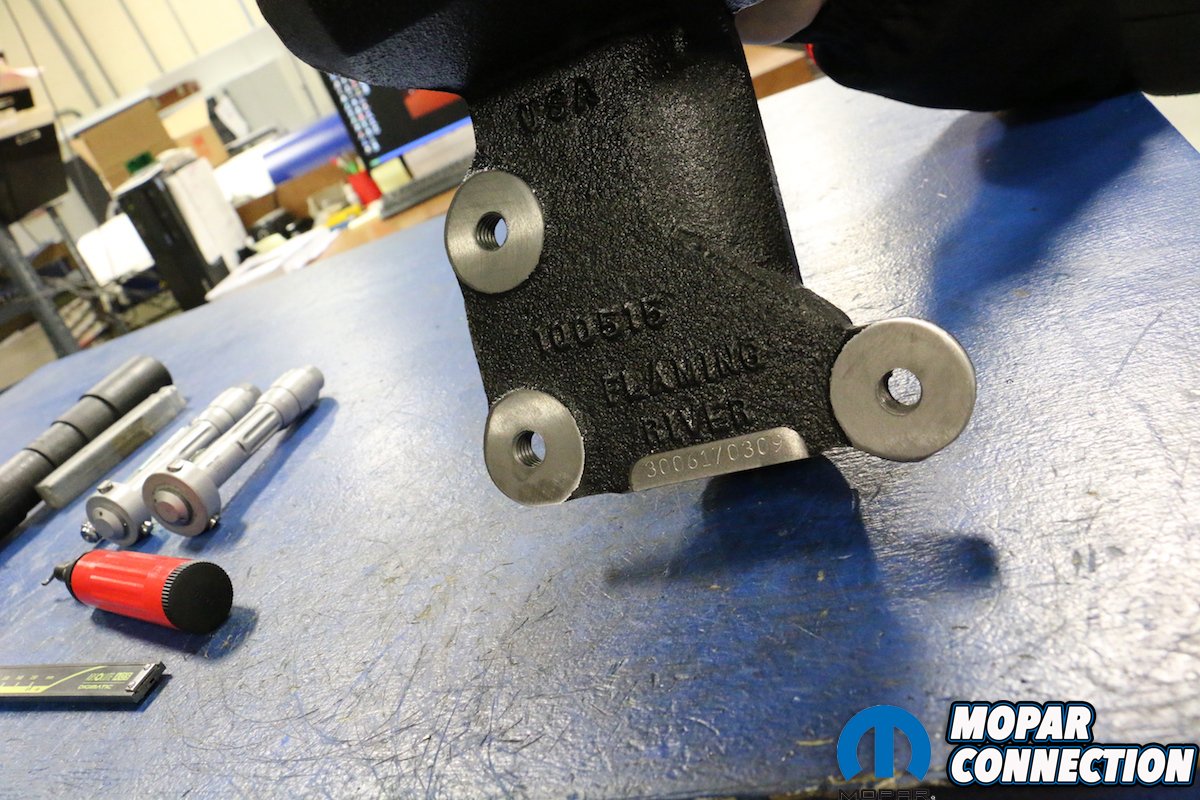

Above left: Every steering box is placed on the computer controlled tester. Above right: Here you can see the serial number stamped on the steering box.

Throughout the whole shop multiple machines were making different pieces for their columns. With the complexity of many moving parts in the steering columns, added with the difficulty of ensuring a factory fitment for a swathe of vehicles, producing each column is not an easy task. They have been able to achieve perfection by making every piece for their columns in house. Whether it is a steering wheel nut, ball joint for the tilt, turn signal lever, etc they produce all the parts right here in the shop. Not only is every part made in house but each column is hand built in house too. Each column is carefully assembled and tested before it leaves the facility. If there is any issue with the columns they are tore back down carefully searching for what went wrong.

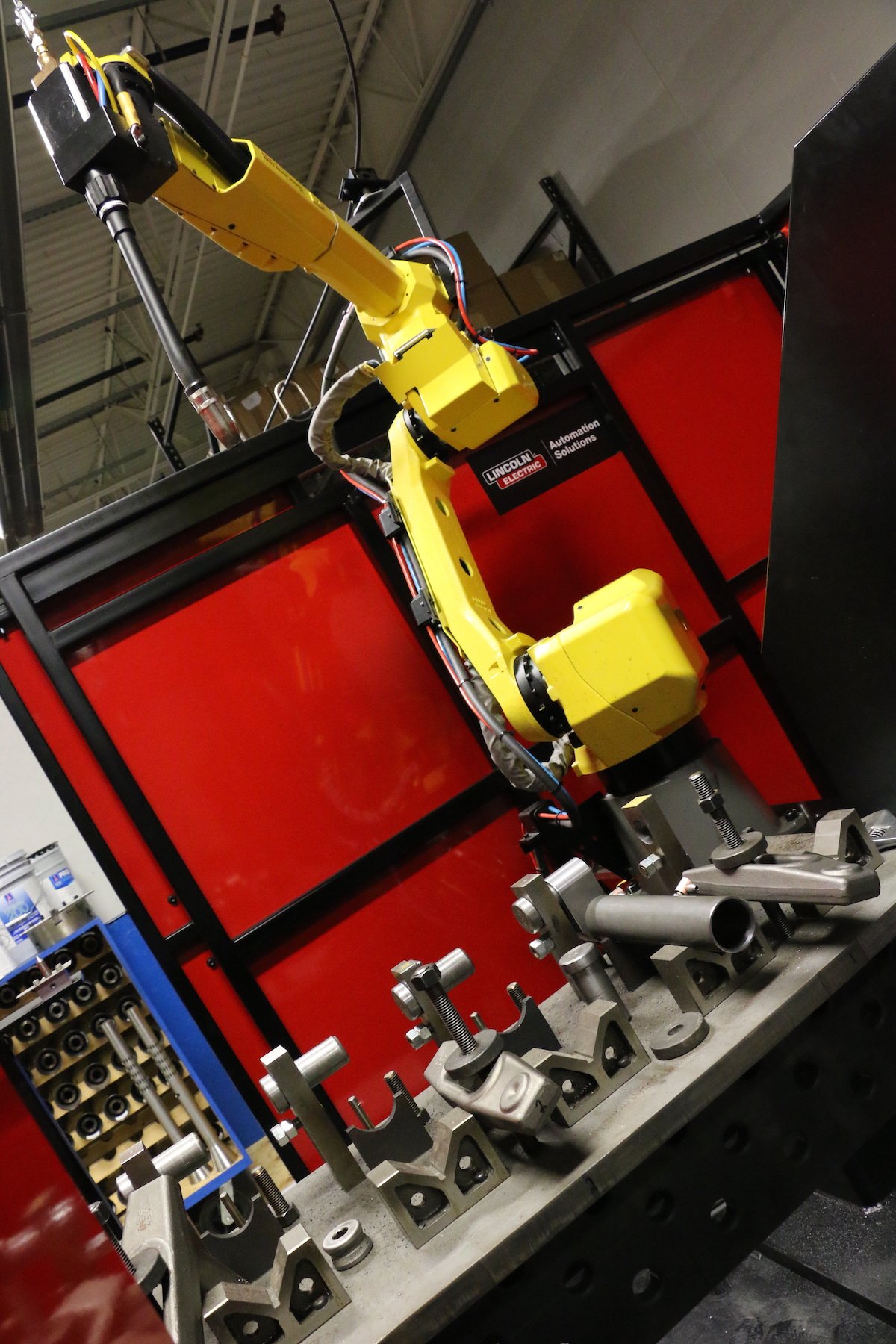

Throughout the facility we saw many workers programming the machines and handling the parts. We did notice in one area that there were a couple of robots. These robotic arms had the sole purpose of welding. Multiple parts that FR produces are still hand-welded but some are better left to the robots. We didn’t get to watch any welding during our time at FR but they were set up to weld the collars onto the steering column tube.

“Running a bead of weld by hand on the outside of a round tube is difficult for even the best welder, but with our robotic arms and rotating tables they will run a perfect bead every time day in and day out without the worry of human error,” stated Mike. The finished tubes covered the floor behind the welding centers. A few of these tubes looked a bit different than the ones we saw earlier. We asked why these had multiple diamond shaped cutouts. Mike explained, “Those are our collapsible tubes. If you happen to ever be in a wreck that tube will collapse on impact 4-inches for added safety. Any of our steering columns can be ordered with the collapsible option.”

Above left: Solid billet turn signal levers being popped out like candy.

Above left: The robotic arm getting ready to go to work. Above right: You can see the diamond pattern at the bottom of the steering column that allows the column to collapse on impact.

While touring the facility we noticed one area of the shop that looked to be abandoned and outdated. There was nothing going on and the machines looked ancient compared to the high tech CNC multi-axis mills and lathes that were scattered throughout the facility. We asked John and Mike what was up with the old stuff. “All of those machines still work and function perfect. Brian Kehoe does all of our custom work manually. When your trying to alter a part or make a custom one-off piece, it takes too long and isn’t efficient to try and program one of our CNC machines. Not to mention its helps that we have a great machinist on the team to get us out of jams.”

We were impressed that such a large company will still build a custom part or modify parts for customers. John said, “We understand there are always exceptions in the hot rodding world and some parts need tweaked or a completely custom part made and having the ability to satisfy the customers need is our goal.” It’s not often that they have many requests for custom parts or alterations but knowing that if you run into trouble FR is there to help anyway they can.

As we continued to move though the facility we stumbled upon a rolling cart full of steering box housings parked beside a CNC machine. We could see that the castings were being machined by the CNC but were curious if they made castings in house and so we asked John, “They have looked into doing castings themselves but there is not enough space currently. Its not completely off the table and might revisit the idea in the future.” However they do use a local company that makes all of their castings which allows them to keep a close eye on quality.

Above left: Welded steering column tubes stack up behind the robotic arms

Above: Shelves of parts ready to be picked and shipped.

Above: A pallet of parts await to be loaded for the next show.

Since we were talking about their steering boxes, John showed us multiple other shelves that were full of steering boxes. We got to see where each box is hand assembled and then tested. The testing area was not some backyard contraption to make sure the boxes turned, it was a high-tech complex computer-controlled machine that tested multiple parameters of each box. The machine runs each box through multiple loads, checking ranges and pressures to ensure they are working correctly. If any metric is even a little bit out of spec, the box is carefully disassembled to figure out why it didn’t pass. Once the boxes passes spec then the computer will center the box, which is then hand marked. This allows the customer to easily identify dead center for installation and alignment of the steering wheel to the box. Each box is then boxed with a data sheet from the results and put on the shelf ready to ship.

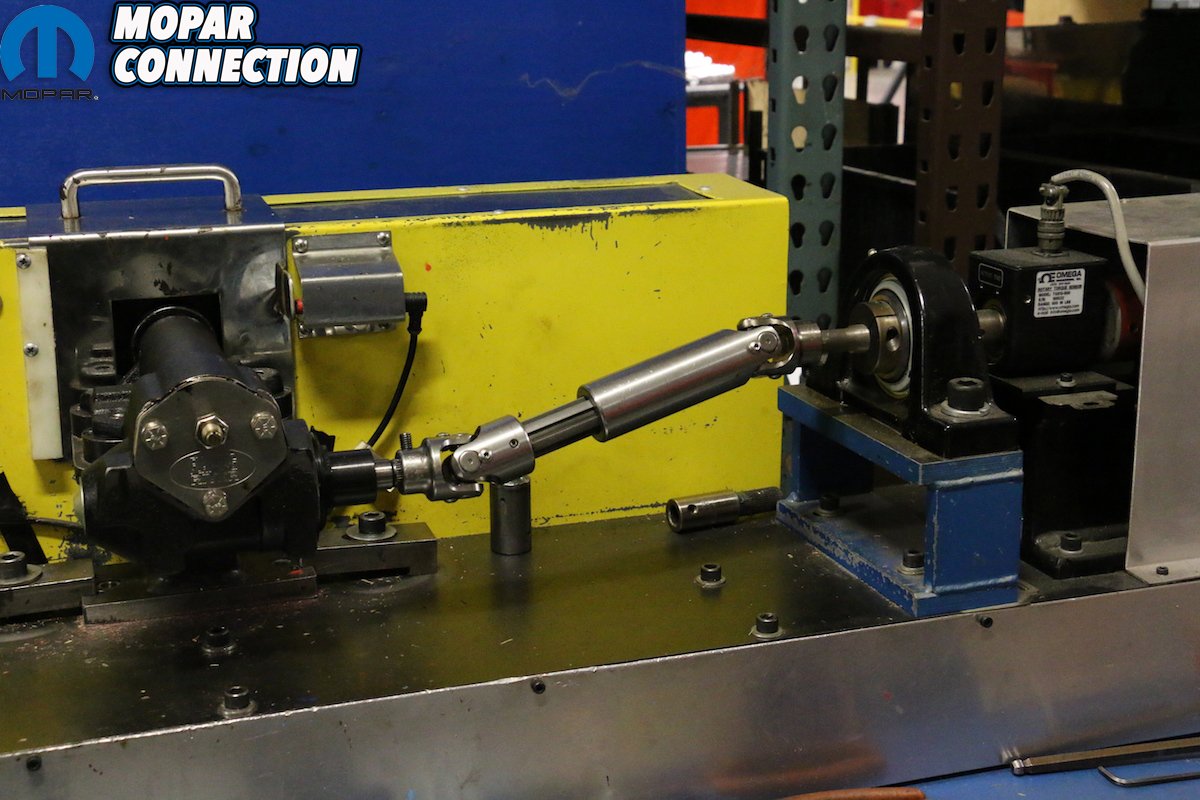

Next we made our way to the rack-and-pinion testing area. Unfortunately, we didn’t get to see any racks being tested due to some parts being replaced on the machine. It was very similar to the steering box test area; they mount every rack-and-pinion they produce, whether it is manual or power. The computer will pressurize the unit if power assisted and then run through similar tests as the steering boxes. It will make sure travel, turns lock-to-lock and pressures are to spec. If anything does not pass, the rack and pinion will be carefully disassembled to find the problem. “Testing every rack and steering box by computer is very time consuming but we know when those parts ship out they can be installed and the customer doesn’t have to worry about receiving a defected part.” Much like the steering columns, the rack and pinion units are all built in house too.

While exploring the facility, we saw numerous multi-axis mills and lathes that were producing anything from one-piece billet turn signal levers, assembly nuts, remote reservoirs, steering shafts and more. As we made our way to the side of the shop, we found ourselves standing in front of a couple garage doors, a rack and their current project car, a 1951 Ford Crestliner. Although its not a Mopar, it is still exciting to see the custom work they have done to the Ford. A couple bays beside it rested an alignment rack, which they use a lot during vigorous testing of new products. John explained, “We have multiple rack-and-pinion kits and having an alignment rack here allows us to measure multiple metrics like bump steer for ourselves and not rely on someone else’s data. We like to control as much of the R&D that we can in house.” We can see where the quality and performance of FR comes from.

Although Flaming River is large company servicing a plethora of vehicles around the world, it still felt like a small town machine shop. The culture at Flaming River revolves around the customer. The staff was very friendly and were all committed to giving the customer the best experience, service and products possible. Everyone on the FR team were knowledgeable about the products they offer and everyone seemed to genuinely enjoy their job. Multiple workers had classic cars of their own and understand the trials and tribulations that their customers go through when installing parts. They all take that extra step to ensure only quality parts make it out the door.