A Mopar racer must have confidence in the engine powering their ride to succeed on the track. For decades, Indy Cylinder Head has assembled engines that enthusiasts desire for street or drag racing.

Indy Cylinder Head builds the best Mopar engines and manufactures them from their initial design, pouring the molds, completing the machine work, and assembling the engine from a bare block. The dedication and talent of Indy Cylinder Head’s employees will allow you to put your Mopar in the winner’s circle.

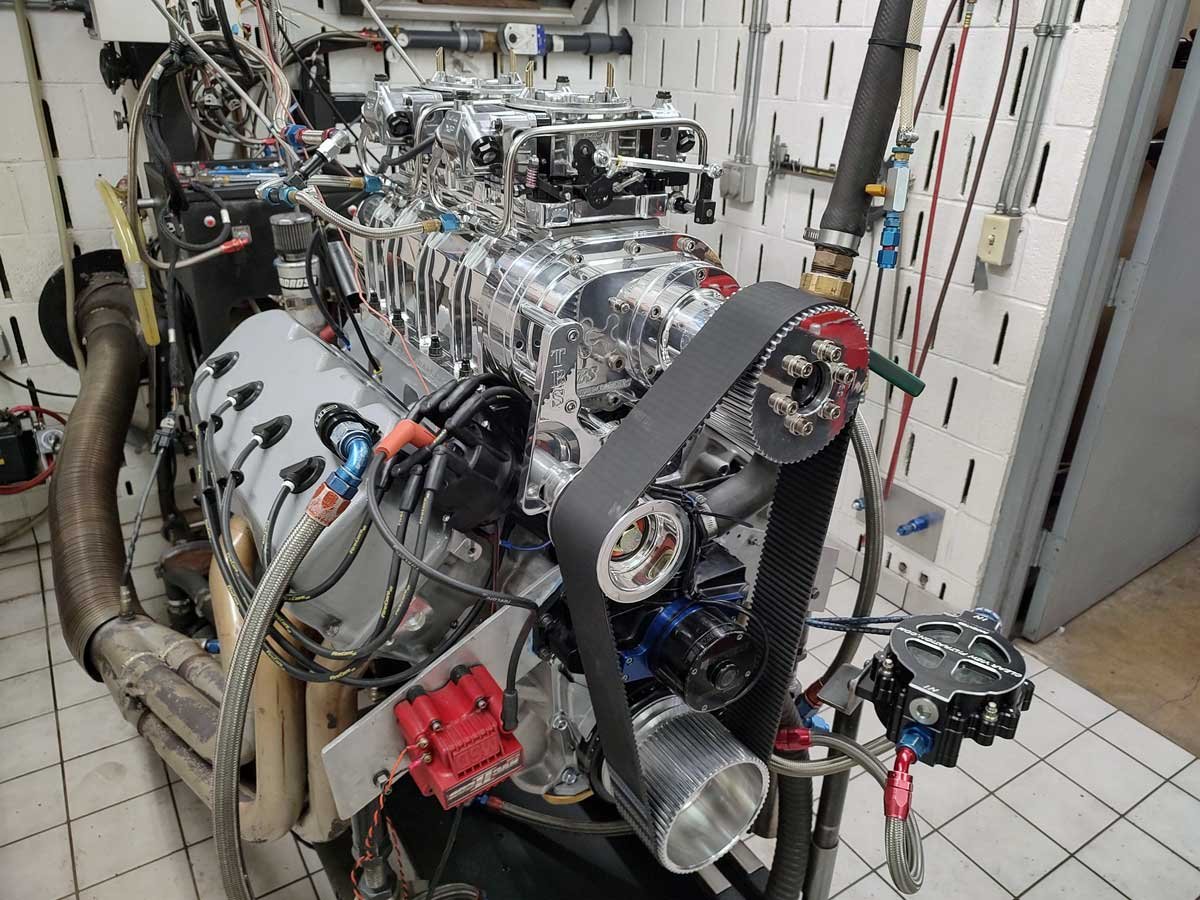

Above: Indy Cylinder Head, a pioneer in the industry, has been delivering high-performance engines for decades. In a recent stride, Indy has focused on crafting a series of unique supercharged big block Hemi and wedge engines, offering a broad spectrum of power from streetable to massive horsepower, setting them apart from the competition.

A current trend at Indy Cylinder Head and with head engine builder Ken Lazzeri is supercharged big block engines, either Hemis or wedges. Lazzeri shared, “We build them in four different configurations.” Indy has created supercharged engines for street, street/strip, bracket race, and “get after it” bracket race.

“Every engine is a custom build. Some will need different oil pans and systems, carbs, and head combos, so these engines have no set price. We always gather the customers’ info on their car and what they need so that we can make a well-detailed quote.” – Ken Lazzeri

Above: Indy has several supercharged big block options, including traditional 8-71 superchargers sitting atop the engine or front mounted Procharger superchargers. The engines can have a polished or “blacked-out” theme.

Indy has developed a 572 cubic inch displacement (CID) supercharged Hemi Street engine, categorized as a mild street engine. The Hemi has an Indy Maxx aluminum block with a 4.500-inch bore and a 4.500-inch stroke. Indy relies on the durability of a Callies crankshaft and matching connecting rods. A set of 8.25:1 compression ratio Diamond Pistons fill the block’s bores.

Above Left: For Indy’s 572 cubic inch displacement Hemi, which is considered a mild street engine, Indy utilizes a Blower Shop 8-71 High-Helix Street blower. Above Right: The supercharger looks excellent on top of the Hemi, and the polished look adds to the performance vibe.

A fully CNC-ported pair of Indy 426-SR Hemi heads are bolted to the block. Indy uses a Comp Cams solid street roller camshaft that actuates BAM roller lifters with bushed wheels. The pushrods actuate sixteen Indy roller-tip rockers. The camshaft specifications and the rocker ratios are specific to each application.

Indy Cylinder Head employs an Indy supercharger intake to mount a Blower Shop 8-71 High-Helix Street blower. The supercharger is 10% underdriven to work with 89-octane fuel. A pair of 750 Holley boost reference (self-tuning) carburetors control the air/fuel ratio. A custom street oil system for the customer’s vehicle is fabricated. Lastly, the Hemi was given a “polished-out look.”

Above Left: The 572 Hemi was tuned for 89-octane gasoline to meet the customer’s needs. The underdriven supercharger could have been overdriven for increased performance if the engine had run a higher-octane fuel. Above Right: In its current tune with a 10% underdriven supercharger, the Hemi pumped out 900 horsepower at 6200 rpm and 900 lb-ft of torque at 3500 rpm.

A recent 572 Hemi built by Indy was sent to a customer in Hawaii. Due to the poor fuel quality found on the islands, Indy detuned the engine, but it still pumped out 900 horsepower (hp) at 6200 rpm and 900 lb-ft of torque at 3500 rpm.

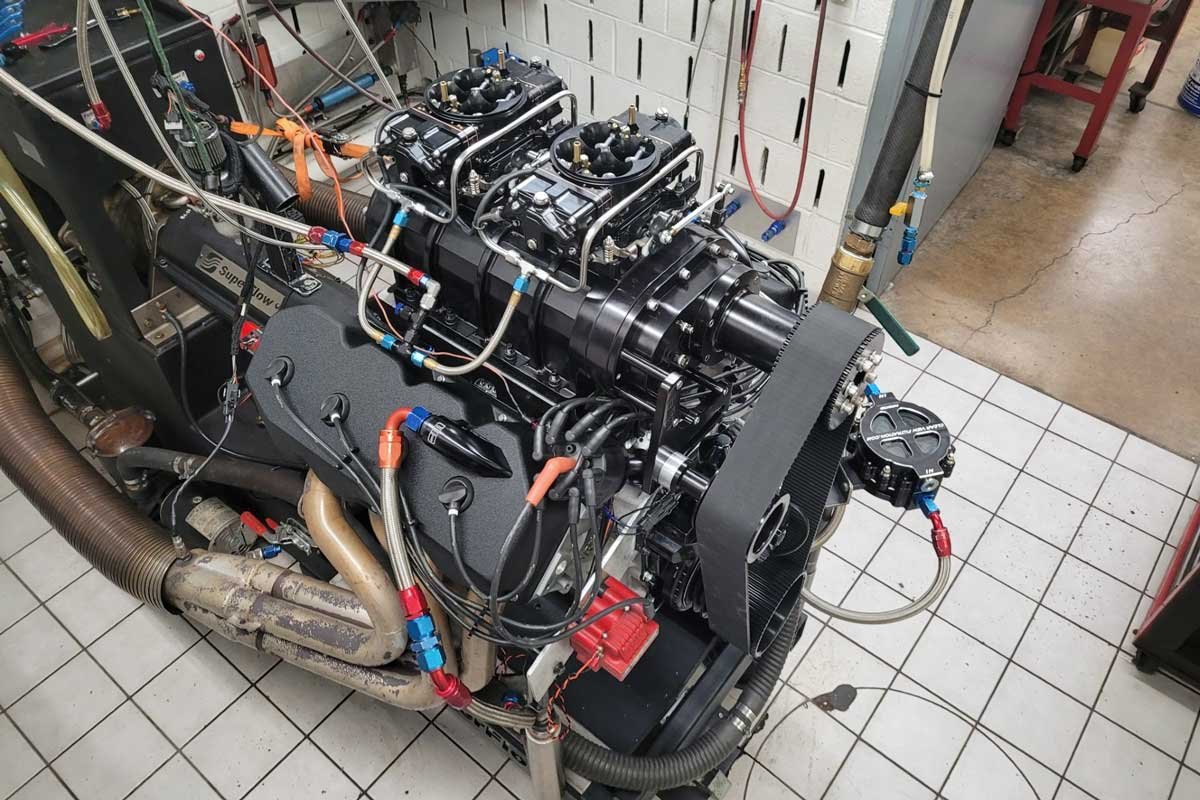

Above: Stepping up, Indy bolted together another supercharged 572 Street Hemi with an increased compression ratio and an overdriven supercharger. The engine ran comfortably on 93-octane gasoline.

Another 572 Hemi Street engine that Indy has bolted together is more aggressive. As in the previous 572 build, Indy uses an Indy Maxx aluminum block and Callies crank and rods, but with an increased compression ratio set of 8.75:1 Diamond pistons. A pair of Indy 426-HI-PO Hemi heads with full porting and 2.400-inch intake and 1.94-inch exhaust valves provide an easy 485 CFM.

Above: Once strapped on the engine dyno, the supercharged 572 Hemi easily exceeded 1000 horsepower peaking at 6600 rpm.

A pair of 950 cfm APD billet boost reference carbs sit on the Blower Shop 8-71 blower. The engine comes with a blacked-out look. Running on 93-octane fuel regulated to 6 to 8 psi pushed the Hemi’s output to 1100 hp at 6600 rpm and 950 lb-ft of torque at 4300 rpm.

Above: On the dyno, the 572 made a stress-free 1100 horsepower at 6600 rpm and developed 950 lb-ft of torque at a streetable 4300 rpm.

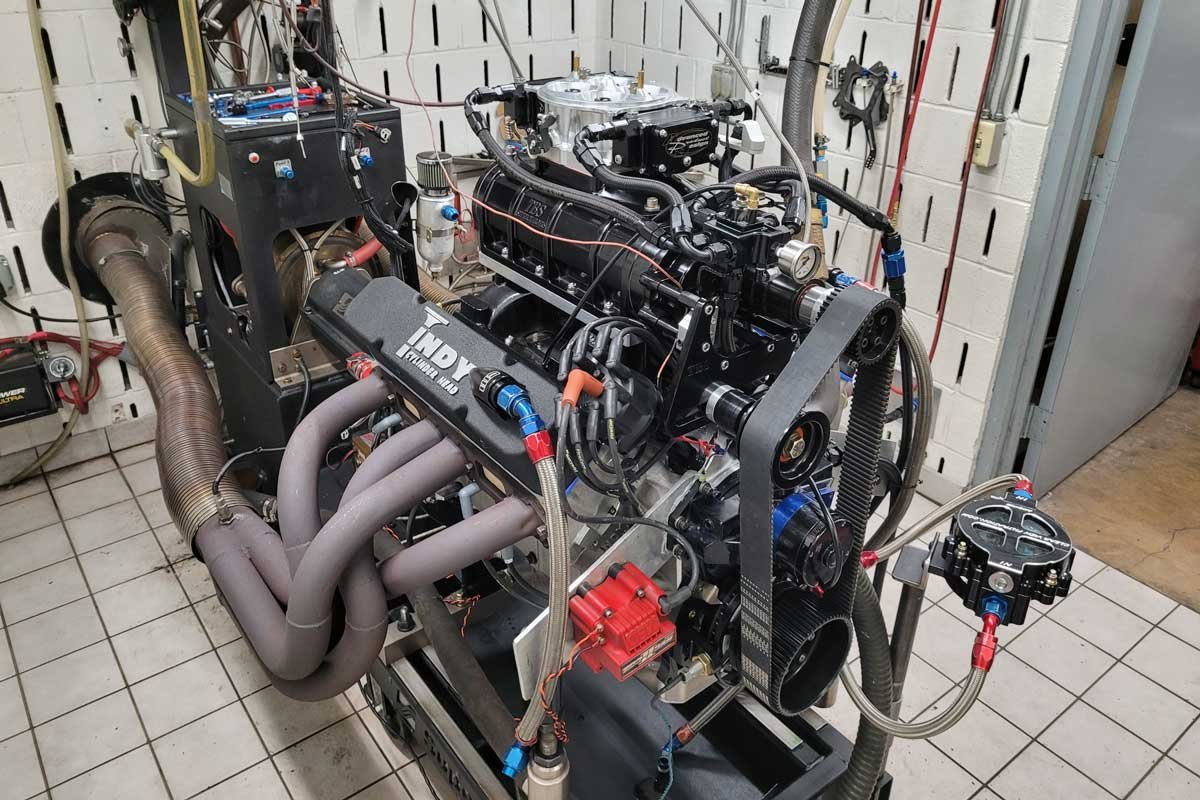

Moving up to the bracket or quick classes, Indy has a nice 572-cid race wedge. Lazzeri shared, “This is a very popular go-fast engine, but this combo can be built as a Hemi or a small block platform with the use of Indy’s unique blower manifolds.” The 572 Race wedge has the same 4.500-inch bore and 4.500-inch stroke Indy Maxx aluminum block as the previous builds. The engine employs a Callies crankshaft, GRP aluminum rods, and 14:1 Diamond pistons.

Above: Indy developed a supercharged 572 race wedge engine for the bracket and quick classes. The high-compression wedge runs on alcohol and is designed to create power between 1200 to 1500 horsepower.

The heads are the tried-and-trued Indy 440-1 CNC 345 heads that Indy has made since 1992. A Comp Cams solid roller camshaft R112 (0.740/0.740 (I/E)—duration @ .050 285° I and 296° E) operates a set of bushed BAM roller lifters and T&D 1.6:1 roller tip rocker arms. The wedge has an Indy Mod-Man supercharger manifold designed for a Blower Shop 250 billet blower. The combination uses a 64-tooth bottom pulley with a 33-tooth top pulley.

Above: The high-compression wedge running a Comp Cams camshaft with almost three-quarters of an inch lift produced 1373 horsepower at 7400 rpm and 1150 lb-ft of torque at 6200 rpm.

An APD billet 1750 CFM alcohol carburetor flows fuel at 6 to 9 psi. A custom race oil system keeps the engine internals lubricated. The engine is finished with a blacked-out appearance. The supercharged wedge produces 1373 hp at 7400 rpm and 1150 lb-ft of torque at 6200 rpm. The engine will easily propel a door car to 4.55 seconds or a dragster to 4.35 seconds in the eighth mile.

“The next engine is our favorite combo right now. It is so reliable and makes stupid big power – and does it all without spinning over 7500 rpm,” Lazzeri stated. The engine is a 540-CID Procharged wedge with a 4.500-inch bore and a 4.250-inch stroke. The combination utilizes an Indy Maxx aluminum solid block and a Callies billet crankshaft. A set of GRP “big boost” aluminum rods swing 10.5:1 double-coated Diamond pistons. Indy 440-1 CNC 345 heads with 2.25-inch intake and 1.81-inch exhaust valves sit atop the block.

Above: If there is a favorite supercharged engine at Indy, it is this Procharged 540 wedge. The engine runs on alcohol, is reliable, has excellent power, and does not spin over 7500 rpm.

A Comp Cams solid roller camshaft R114 (0.740/0.740 (I/E)—duration @ .050 280° I and 300° E) moves BAM roller lifters and actuates T&D 1.6 roller rockers. The 540 utilizes an Indy 440-3X intake with full porting. An APD billet blow-thru alcohol carburetor running 15 to 20 psi feeds a Procharger F1X-112 supercharger with a 135-gear set. The engine can be ordered in a blacked-out or polished look. The combination will result in 2000 to 2200 horsepower, moving a door car to a 4.10 to 4.20 second elapsed time in the eighth mile. With the same engine, a lighter dragster may dip into the 3.90s.

Above: The Procharged 540 wedge produces between 2000 to 2200 horsepower. With that kind of power on tap, expect 1/8-mile elapsed times in the low 3.90s to 4.20s, depending on the vehicle used.

The last engine is a 540 Procharged Hemi. Lazzeri mentioned, “Every Mopar person in the world would want this Hemi engine.” The combination starts with a 4.500-inch bore, 4.250-inch stroke Indy Maxx solid aluminum block using the new X-block casting with 9/16-inch main studs and reinforced deck.

Above Left: The ultimate of an all-out supercharged racing engine is this Indy Procharged 540 Hemi. Above Right: On the dyno, the 540 Hemi’s output is 2200 to 2500 horsepower running on alcohol fuel.

A Callies billet crankshaft with 2.200-inch journals spins 7.100-inch GRP “big boost” aluminum rods and double coating 10.5:1 Diamond pistons. Indy installs a pair of 426-1RA CNC-295 aluminum Hemi heads onto the Maxx block. The heads receive a full CNC porting and flow 500 CFM with titanium 2.400-inch intake and 1.94-inch exhaust valves. The same Comp Cams 55-millimeter diameter roller camshaft used with the previously discussed 540 wedge is found in this engine. Indy 1.6:1 intake and 1.55:1 exhaust rocker arms actuate the valves.

Above: With over 2200 horsepower under your right foot, a dragster should efficiently run mid-3.80s to 4.00 seconds in the 1/8 mile. The blacked-out appearance adds to the stealth look, but the zoomies show an all-out performance design.

An F1X-112 Procharger with a 135 gear set pushes air through an APD billet blow-thru alcohol carburetor bolted to a fully ported Indy 426-4 Big Volume intake manifold. The engine offers a polished or black-out appearance. The Procharged Hemi develops between 2200 and 2500 horsepower. Expect a door car to drop into the 3-second zone in the eighth mile, and a dragster will run about 3.85 seconds.

Above: On the dyno, the 540 Hemi made 2200 horsepower at 7500 rpm and 1510 lb-ft of torque at 7300 rpm. Every Mopar owner desires an engine like this Hemi.

Indy Cylinder Head specializes in everything Mopar. The company manufactures each piece and can create custom parts for any desired engine combination and horsepower output. For more information about the new supercharged engine series or any engine or engine part, give Indy a call at 937-708-8563, send an email, or drop by the Xenia, Ohio shop to see what Indy can do for you.