We know the leader in 5/6-speed Pro-Fit kits is American Powertrain. There are many of you that have bought a kit from American Powertrain and installed it per the directions and it drives flawlessly. During installation you followed torque specifications and have driven it a couple times without any issues, so what more is there to do? Well, now you need to make sure it stays driving flawlessly.

Many of these items we are going to talk about may seem minuscule and probably think I do not need to that. Well, catching a slightly loose bolt, or leaking throwout bearing before its catastrophic is a big deal. You do not want to find out that you did not measure correctly for your Hydramax setup and now you are out of fluid and 400 miles from the house. We would not happen to know this by experience or anything.

Above: A car lift makes this job much easier. You can do everything we do on jack stands as well.

We have had our American Powertrain Magnum 6-speed installed over 6 years. Due to motor issues or changing parts, it has been tore out and reinstalled more times than we liked to admit. After your initial installation or any time that the transmission is removed and reinstalled, you need to be extra cautious of leaks, loose bolts and more. You might get by with one test drive and all is well. The next time that loose bolt falls out and then you have catastrophic damage.

We threw Project Orange Crush up on the lift and started our maintenance process with a visual check. We were searching for leaks, bare metal where something might be rubbing and/or missing hardware. A thorough visual inspection can help reveal a problem or it might not tell you anything. This should be done as much as possible.

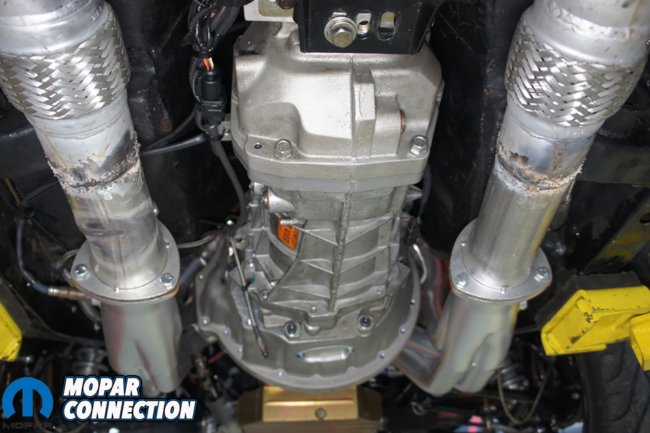

Above Right: Taking a peak of the undercarriage of Project Orange Crush. Above Right: We take closer look at our driveshaft and clearance of our exhaust.

During the visual inspection we like to take a closer look at our electrical connectors. Make sure they are plugged in securely. Sometimes pull them apart and apply some dielectric grease and snap them back together. We also make sure that the wires are tied up and out of the way of moving parts, exhaust, wheels, etc.

Since we are not going to pull the transmission all the way out, we like to pull the inspection plate off the bottom of our Quick Draw Brand bell-housing and take a look inside. We have a cheap Amazon bluetooth inspection camera that come in very handy for visual inspections.

Above Left: We previously spilled some fluid from removing our shifter and see some residual ATF on our reverse lockout solenoid. Above Center: No major leaks that we see on our transmission. Above Right: We make sure all of our connections are zip tied up and out of harms way.

Inside the bell-housing you want to look for any grease being slung, chunks of material and anything wet. Nothing should be wet and if it is no matter how minuscule you might think it is, there is an issue. Ask us how we know. While you are looking inside the bell-housing, it is alway a good idea to have a second person press and release the clutch so you can watch it work smoothly and without any leaks.

On our Magnum 6-speed, the rear seal of the transmission is prone to leaking. It is an easy seal to replace thankfully. Just like any seal, years of driving and storage can dry and harden this seal making it leak. Check the condition of the rear seal and potentially change it out if it feels hard, leaking or just for preventive maintenance.

Above Left: Small inspection hole on the Quick Draw Brand bell-housing from American Powertrain. Above Right: A couple 7/16 bolts hold on the cover plate.

Another place to visually look for leaks is inside the vehicle too. Since we have a hydraulic clutch setup, misalignment, over pedal travel, and more could cause the master cylinder to leak out of the back and into the interior.

While you’re on the inside of the car, pull your shifter boot off and check your shifter and shifter stick. Make sure your shifter stick is tight, no leaks around the shifter mechanism and/or no clearance issues with shifter.

Also, look over your clutch pedal and linkage. Have a second person cycle your clutch pedal up and down while you watch. It is good to visually see it working properly and not over extending, binding, or anything else. The clutch pedal and linkage should actuate smoothly and have a proper pedal stop and not just let the master cylinder bottom out.

Above Left: You can see our shim pack and our Centerforce DYAD pressure plate. Above Right: Under the cover plate is a 2″ inspection hole so we can see if anything is leaking and the Hydramax bearing is working properly.

Once we were done with our visual inspection, it was time to putting a wrench on what bolts you can. A loose bolt can be difficult to spot with a naked eye. Putting a wrench on them and checking torque will tell you the real truth. If applicable, have the torque specifications handy for your drivetrain. You might not think a bolt is loose but could be out of torque spec or be in the process of loosening up.

One suggestion that we have seen in the past is marking as many bolts as you can. This allows for a quicker visual check and that you have peace of mind that none of the bolts have loosened. We do not do this enough ourselves and will be looking to remedy that with better metal paint markers soon.

Above: Our clutch linkage is working properly and all tight.

We understand that you are not going to disassemble your drivetrain and reinstall it, but you want to check every bolt you can access. We like to start at the front of the vehicle and work back. We start with our Baer brakes and Reilly Motorsports AlterKtion suspension, then onto the American Powertrain Magnum 6-speed and finish up at the rear checking out Baer brakes and Street-Lynx suspension.

Once you have checked for loose bolts and made sure everything is torqued properly, its time to move onto fluid maintenance. Our cars probably wont see enough miles to need a fluid change very often or ever. Although you might not drive it enough, the hot and colds from storage and amount of time might warrant a fluid change sooner.

Above Left: We used a dirt track shifter boot which is held on by snaps for easy access. Above Right: You can see some ATF at the bottom of our American Powertrain White Lightning shifter. Ended up being a rip in the internal boot in the shifter.

We like to change out our fluid every couple of years. It is only a couple quarts of fluid and we get the peace of mind that there is no water or debris running through our transmission. Our Magnum 6-speed has a fill and drain ports. Drain the transmission fluid out and then pump new fluid in the upper fill hole till it drips out.

The other fluid that gets very overlooked is the clutch fluid for the Hydramax setup. Your clutch fluid should not be black and if it is you need to change it out. Changing out clutch fluid can be a pain but will help prolong seals, cylinders and bearings. Dirty clutch fluid can also mean you have an issue going on internally with the hydraulic system.

Above Left: We look over our American Powertrain Hydramax firewall mount and make sure it’s all tight and no leaks. Above Right: We check out reservoir and fluid is nice and clean and no need to replace.

Our clutch master cylinder requires DOT 3/4 brake fluid. We like to run a high temp brake fluid to help withstand any high temperatures. We understand the fluid should not get hot like brakes but there is a chance our stainless clutch line comes loose and lays on the exhaust or something of that nature.

To change the fluid is pretty simple, you need to drain the system of brake fluid and then refill. Once it is refilled, go through proper bleeding procedure for your specific setup and you are done. You can just swap out the fluid in the reservoir if you are in a time crunch. You will still have dirty fluid in the system, but it will be diluted and better than what it was.

Above: When all finished, get out and enjoy the open road. We headed to our first Cars and Coffee event for the year and enjoyed having 6-speeds.

Depending on your garage setup, this whole process can be done in just a couple of hours. When talking with Matt Graves of American Powertrain, he agrees that many of these maintenance items are overlooked year after year until the clutch goes out or something breaks.

Take some time whether it is the off season or middle of show season and look over your drivetrain. The techs at American Powertrain can help out with any questions or help you get any products that you might need. Get out and enjoy your ride and #SaveTheStick.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by