The 1970 All-American Racer ‘Cuda came about due to the SCCA Trans-American Sedan Championship for Manufacturers Series (later known as the Trans-Am Series). Initially, the series developed as a class for manufacturers to race assembly line constructed cars.

However, as with all racing, the vehicles evolved to one-off, hand-made vehicles engineered as race-only designs to beat the competition. Accordingly, the Trans-Am Series initiated rules requiring manufacturers to build and sell a specific number of cars to the public to combat the ever-increasing deviation from stock. The vehicles sold to the populace needed to be appreciably similar to the race version; thus, the ’70 Plymouth AAR ‘Cuda was born.

To make the AAR ‘Cuda legal, a minimum of 2,500 units needed to be constructed. The AAR received a potent 340 engine fitted with three Holley two-barrel carburetors atop an Edelbrock intake. The street adaptation had a racy look, and low-restriction side-dump exhaust provided a race car sound. The six-barrel stepped up the 340 to 290 horsepower at 5000 RPM and 335 lb.-ft of torque at 3400 RPM.

In making the ‘Cuda adequate for street use, the factory engineers needed to compromise on the suspension component layout for cost-effectiveness and ease of installation on the assembly line. In addition, the suspension was designed for conditions such as potholes, rain, and other poor surface situations. Finally, for road-worthiness, the cars were relegated to roll center and geometry settings adequate for the street but far from optimized for competitive driving.

Furthermore, concessions were needed for tire fitment and adequate track width to fit significantly offset engines into the engine bay. Moreover, the engineers designed understeer into the suspension to compensate for the limited abilities of novice drivers. Lastly, the most significant limiting factor was the narrow tire width and inadequate traction of bias-ply tires.

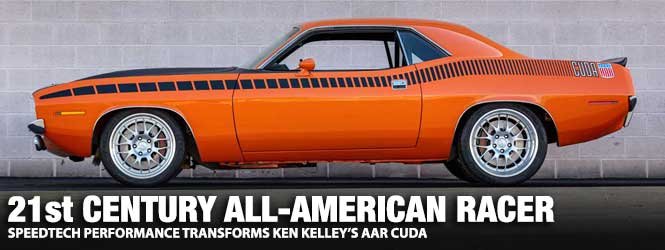

Ken Kelley, owner of Classic Car Liquidators in Sherman, Texas, is a lucky owner of one of the 2,500 AAR ‘Cudas. Kelley desired to compete with the AAR in the Texas Mile, the Ultimate Street Car Challenge, and additional high-performance racing events. However, he knew he could not show up to a gunfight with a knife, even if the knife was a ’70 AAR. So, he decided the ‘Cuda needed to be updated with the latest 21st-century technology.

Kelley entrusted Blake Foster, Roger Maniscalco, and the engineers and technicians at Speedtech Performance of St. George, Utah, to update the ‘Cuda. Kelley wanted the ‘Cuda to have a Hellcrate 6.2-liter Hemi attached to a Rock Standard Gear Magnum Tranzilla T-56, six-speed manual transmission. In addition, for the ultimate 21st-century ride, the suspension needed modernization, and the ‘Cuda needed air conditioning, a decent sound system, and power windows.

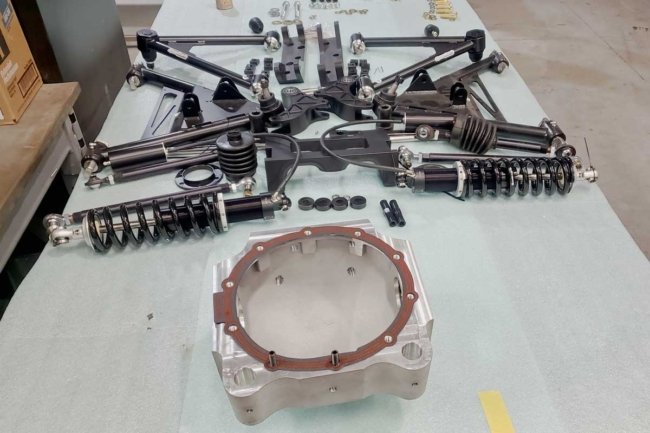

Upon receiving the ‘Cuda, the Speedtech Performance team completely disassembled the car to a shell. Next, the engineers made a digital 3D scan of the entire exterior, including the vehicle’s underside. Finally, the chassis scan data was uploaded into the design environment, allowing the engineers to draft and layout the Speedtech Performance fully welded, boxed, and gusseted ExtReme front subframe and the independent rear suspension (IRS) before ever putting a component on the ‘Cuda.

Any unforeseen troubles could be identified and addressed before complex parts were manufactured. For instance, the engine mounts were offset correctly to mimic the original offset and ensure the transmission lined up with the severely offset tunnel. The tunnel was also modified to accommodate a modern six-speed transmission.

The ExtReme subframe design required custom stainless-steel headers made with 1 7/8-inch primaries dumped into a 3-inch collector, designed by Speedtech Performance. After the headers, the cross-member of the subframe was designed to accommodate a dual Borla ProXS stainless steel exhaust system exiting in front of the rear tires, paying homage to the original AAR ‘Cuda.

The ExtReme subframe is 6-inches narrower than the factory unibody frame rails. Speedtech Performance designed the subframe to bolt onto the boxed weld-in subframe receivers. Extensive use of CAD-designed and laser-cut metal reinforced the ExtReme subframe. The same thoughtful design work and manufacturing process was used to make the weld-in boxes to which the Extreme subframe bolts.

A design feature of the ExtReme subframe is it accepts all Gen3 Hemis, Mopar small and big-blocks, and later this year, the 392 and 426 Hemis. Additionally, the transmission cross-member can be located in several positions to accommodate virtually any manual or automatic transmission.

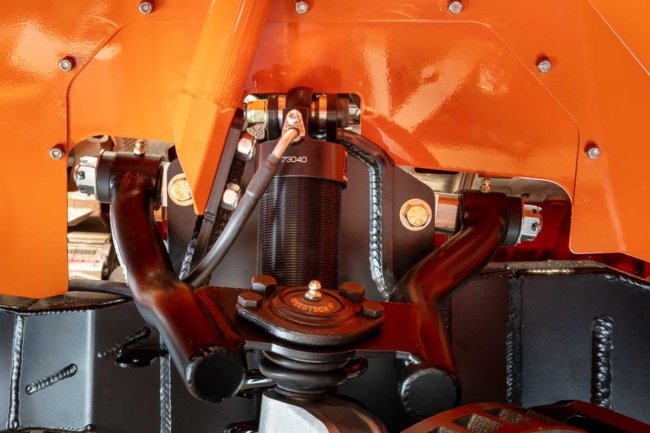

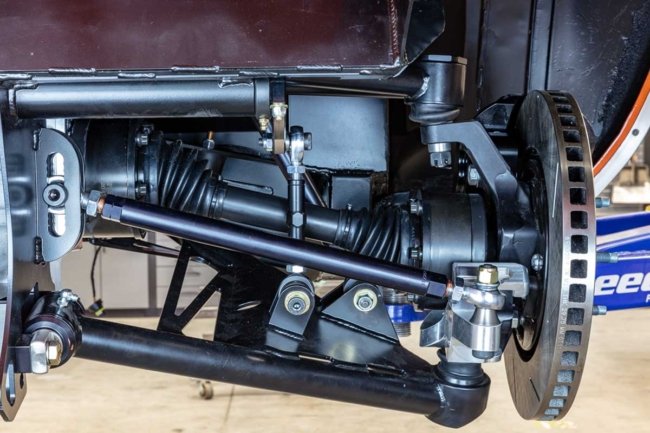

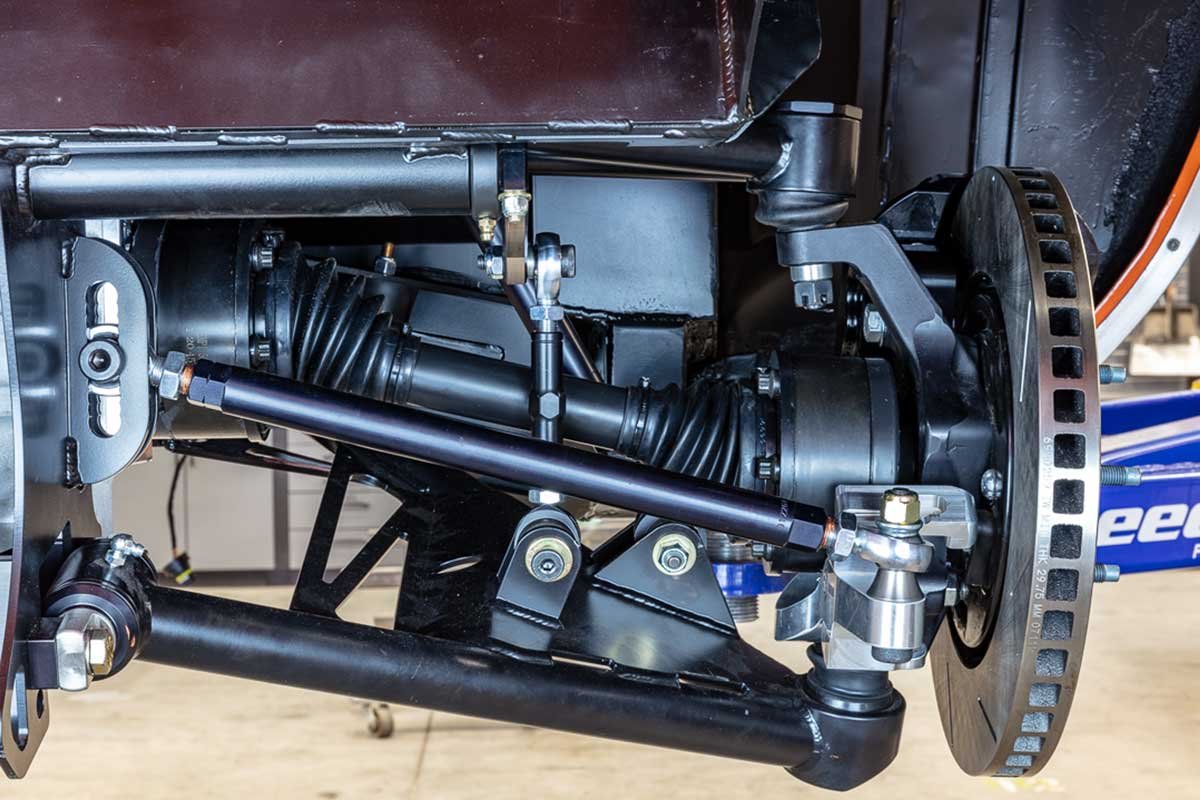

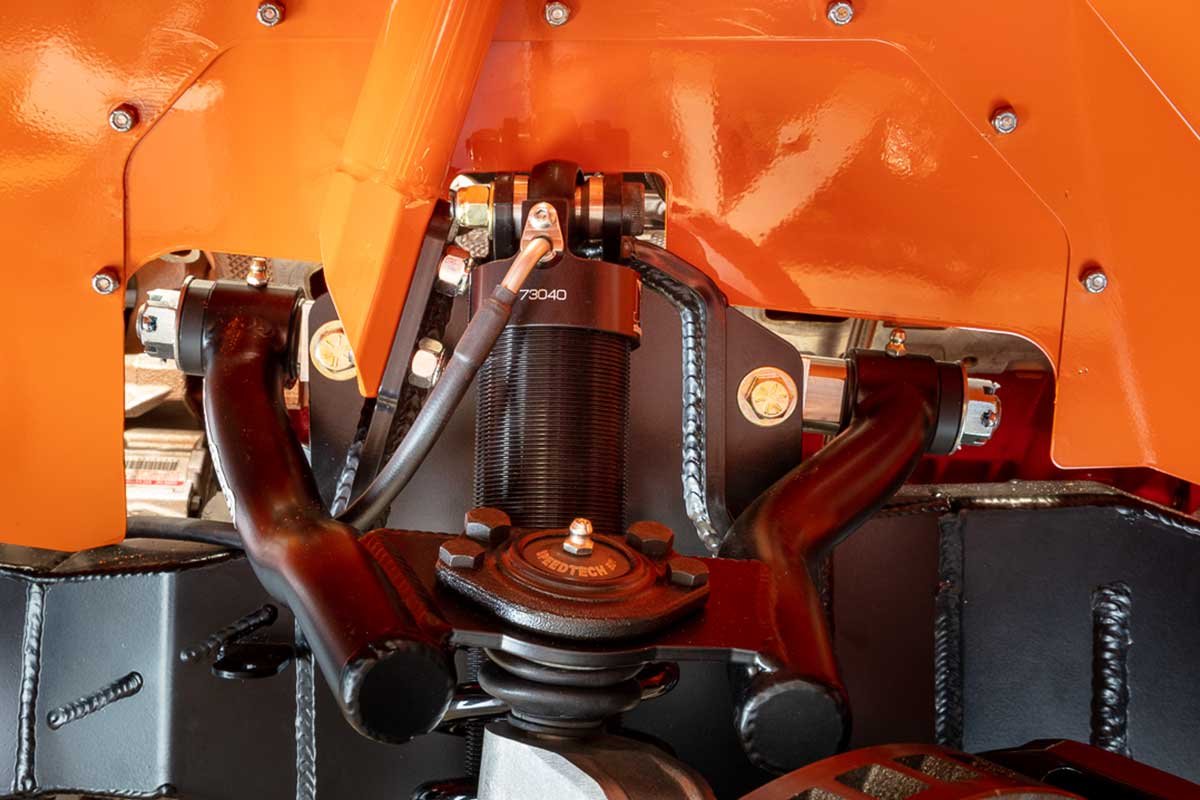

A reduced subframe width allows for substantially-sized tires. Kelley chose 315/30R18 front tires and 18×11-inch wheels without excessive backspacing that fit inside the factory fender wheel opening with no exterior styling changes. Speedtech Performance tubular upper and lower control arms are paired with JRi front coil-overs and a three-piece sway bar. The steering of the ‘Cuda is handled by a Sweet Manufacturing dual ram power rack and pinion.

The forged front spindles are made from high-quality lightweight 7075 aluminum, an exclusive of Speed Performance; this material is more commonly found in high-strength aircraft parts. In addition, the spindles are designed to use sealed maintenance-free double roller bearings, so no wheel bearing adjustments are necessary.

What are the benefits of the ExtReme subframe? First, the front suspension can be adjusted up or down 1.5-inches from its starting point, which is much lower than the stock ride height. The improved motion ratio allows for a lighter spring rate. The caster angle falls in the 6° to 8° range with camber adjustability from -0.5° to -2.5°. The caster and camber gains during front-end travel promote cornering traction, and the bump steer is 0° at 1-inch of compression and rebound.

The caster, camber, toe angles, and bump steer are adjustable on the ExtReme suspension. In addition, the Ackermann angle has been corrected to maximize tire adhesion while cornering. The result is a compliant and firm suspension that provides precise feedback to the driver through the steering wheel and in the seat of the pants.

The ExtReme subframe allows for tighter turns with a 30° turning radius of the outboard front tire, which exceeds the factory by nearly 4°. Lastly, the front roll center is 1.3-inches off the ground, with the Cuda in a static position. As the front end traverses the road, the roll center moves less than 0.75-inches from the stationary vehicle position.

The rear of the AAR is even more exotic. The IRS incorporates a Speedtech Performance cradle, a Dutchman aluminum rear end housing, and a third member with 3.70:1 gears. Kelley elected to forgo the back seat; however, it could have been retained with minor modifications to the seat bottom. The rear suspension has upper and lower control arms with adjustable camber, caster, toe, and bump steer.

A pair of cantilevered coil-over shocks are placed between the rear wheel wells in the front of the trunk. The horizontal coil-over shocks of the IRS significantly reduce the unsprung weight at the ‘Cuda’s rear. Reducing unsprung weight is a critical improvement for handling. In addition, the design substantially improves the motion ratio, which results in the use of lighter springs. As a result, the shocks and springs need to work less to keep the tires in contact with the road surface.

The Hellcrate Hemi has a 2.7-liter supercharger plumbed through a PRC Racing Intercooler. The fuel injectors are fed via Dual Walbro 525 flex-fuel pumps housed in a Rick’s fuel tank. Passing the engine torque to the transmission is a Ram Dual Disc clutch, pressure plate, and flywheel encased in a Quicktime bell housing. A pair of Spal electric fans and an oiler cooler under the front fascia keep the Hemi cool. A factory Hellcrate ECU controls all the engine electronics.

The ‘Cuda’s black-colored hood has billet hood vents, and the rest of the car is finished in a factory Vitamin C orange. The profile of the ‘Cuda has the traditional strobe-style AAR graphics, and peeking through the 18-inch wheels are Baer 14-inch Extreme Plus Rotors with six-piston calipers on the front and rear of the Cuda.

At the time of the story, the interior was going through a color change, but it has the creature comforts Kelley desired. Speedtech Performance installed a Dakota Digital RTX dash to handle the instrumentation, rewired the ‘Cuda with an American Autowire harness, and fitted a Sparc Industries steering wheel.

The ‘Cuda was fitted with custom power windows controlled via a modified OEM AM radio. Kelley had a complete Vintage Air HVAC system installed for the hot Texas days. Lastly, a Bluetooth sound system with Mosconi components, Focal subs, and Alpine Type X speakers provide the tunes.

Kelley expects the interior to be finished in early March. Soon after the completion, the on-track testing and tuning process will begin. The ‘Cuda is confirmed for an Ultimate Street Car Association (USCA) event in late March at the Charlotte Motor Speedway, so the completion date is critical.

However, with the Speedtech Performance ExtReme front subframe and IRS, the additional strengthening frame rails, and all the quality aftermarket components installed, the expectation is the ‘Cuda AAR should surpass the legend of the original All-American Racer.