In general, the automotive industry is packed with figures. Aftermarket performance parts have a slew of numbers that seem as though they could be compared with one another, but the simple answer is that, often, they cannot. In many cases, comparing one component to another is like equating apples with oranges.

Above: World Products employs a SuperFlow 1020 fully computerized flow bench to determine the airflow of each cylinder head. Interestingly, companies use multiple techniques to assess cylinder head airflow. Because each method is different, the results cannot be compared. World Products has developed its flow bench standards to eliminate confusion among its heads. Airflow numbers are great; however, the Bill Mitchell Products website noted, “we don’t race flow benches.”

For example, the output performance of one camshaft with an advertised duration of 296° differs from another with the same advertised duration. The reason is the difference in the acceleration lobe ramps of each camshaft. Camshaft manufacturers developed a duration measurement at a specific tappet lift, such as 0.004, 0.006, or 0.050 inches. However, each manufacturer selects its lift number, which can negate an accurate comparison of the camshafts.

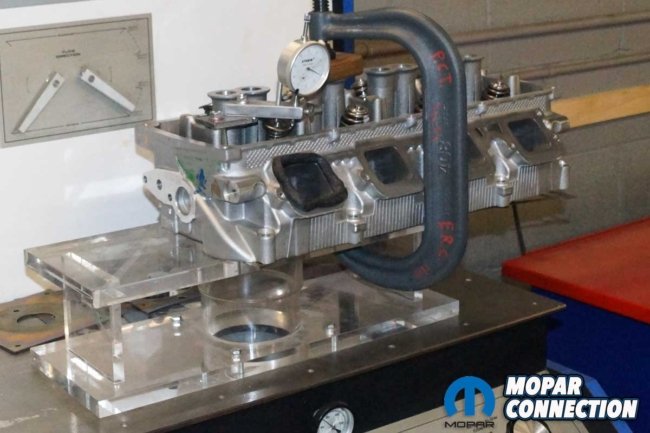

Left: World Products uses one-inch entry plates for the airflow. Brzezinski Racing Products entry plates are designed for many cylinder head applications. (Photo by Brzezinski Racing Products) Right: The entry plate smooths the air flow entering the cylinder head. (Photo by Brzezinski Racing Products) Ignore the fact that both cylinder heads are not Mopar pieces.

Cylinder head flow numbers are the same way. While using these numbers is the standard for advertising in the performance industry, comparing one head to another is only helpful if the flow of each head is measured on the same flow bench. If different flow benches are used, too few variables can be controlled, and the results can be wildly different.

A superior engine cannot be built using flow numbers and fancy ads. So, while some head manufacturers try to impress with flow numbers, World Products builds engines, and Bill Mitchell Products provides the actual horsepower results.

Left: Unlike World Products, some flow bench operators use clay of various thicknesses to help guide the air entering the intake port. The depth of the clay is not one inch thick. (Photo by Richard Holdener) Center: Again, the use of clay helps with the entry of the air into the port. Each support stand is designed to fit the combustion chamber, and a head gasket is used to seal the head to the stand. (Photo by David Hakim) Right: Yet again, clay guides the air into the port. The thickness of the clay is significantly greater than in the previous photos. In each case, the clay depth may change the flow numbers. While none of the clay techniques are perfectly acceptable, the entry plates are repeatable from test to test. (Photo by Johnny Hunkins)

World Products has identified the following general practices which can have a dramatic effect on flow numbers:

1. Were the heads flowed at 25- or 28-inches of water?

2. What was the thickness of the intake entry plate?

3. Were exhaust flow tubes used?

4. Were the cylinder head bowls blended before it was flowed?

5. What size was the chamber when it was flowed?

6. What valve style was used – a Pro Flo, tulip, or nail head?

Left: The combustion chamber volume is checked before World Products tests a cylinder head on the flow bench. We tested the volume of each combustion chamber on our 5.7L Hemi heads. Center: The airflow should be measured with the bowls blended and the combustion chamber volume equalized. We completed all the porting and blending before any tests were performed. Right: World Products does not use exhaust flow tubes on the cylinder head. We also do not use exhaust flow tubes on our heads.

World Products has developed procedures to standardize its cylinder heads’ airflow tests. It employs a SuperFlow 1020 computerized flow bench calibrated to the Society of Automotive Engineers (SAE) standards. Each head is flowed at 28 inches of water, and a one-inch entry plate is installed onto the cylinder head. No exhaust tubes are used.

Each World Products aluminum cylinder head has a performance valve job and an essential bowl blend. In addition, the combustion chambers are cc’d (measured in cubic centimeters) and equalized, as necessary, before flowing. Lastly, what style of valve will work best is a matter of testing the flow of each of them while in the head.

Left: World Products uses 28-inches of water depression for testing. We test at the same depression. However, others will test at 25-inches of water depression, which will provide different results. Right: Ultimately, it comes down to using the same flow bench and repeatable techniques to offer the same results. World Products’ six steps to accurate testing make evaluating the heads it sells an orange-to-orange comparison.

With the insight provided by World Products, it is now evident why it does not post the flow numbers of its cylinder heads. Rather than participating in the misinformation game, Bill Mitchell Products relies upon the word of mouth of its thousands of satisfied customers.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by