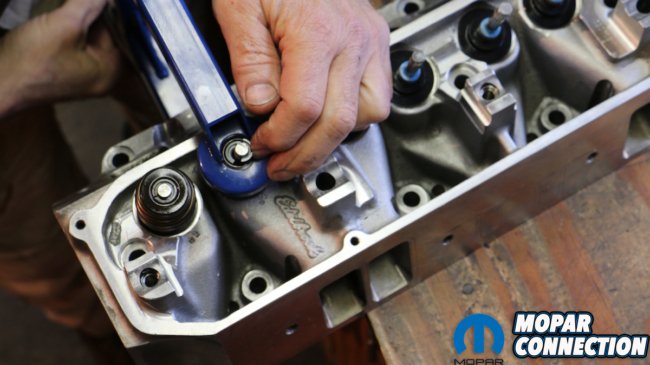

Hiding under every set of cast aluminum, chrome, or Hemi orange valve covers on any Mopar engine are one of those simple yet out of sight, out of mind components: valve springs. Dutifully slamming valves closed in a never-win war against the camshaft, valve springs can make or break (literally) any valvetrain. Hughes Engines is a big proponent of beehive springs and wrote up an easy-to-read technical article to explain why.

When using beehive springs in place of conventional springs the open pressures can be reduced by at least 10%. This is because the retainer and valve spring (especially the upper coils) are so light, due to their small size, that less open pressure is required to control the retainer, springs and valves. The weight loss can be in the neighborhood of 75-100 grams removed from the valve side of the rocker, which is the most important side. This weight loss is better (and a lot less expensive) than switching to titanium valves. More RPM = faster – beehive springs!

Spring surge is a big problem in straight-type (non-beehive) springs. The surge is harmonic resonance or vibration in the spring created when it is rapidly compressed and released, as in a running engine. SpinTron testing has shown that straight springs move around a lot (an unbelievable amount) in a running engine, due to these harmonics. You can actually see the retainer wiggling around in the breeze, like it was waving goodbye.

Sometimes, locks (keepers) float around loose in the retainers. In the surging springs, you can see the coils spread apart and compress together of being compressed or released, indicating the varying spring pressures at max lift or on the seat. Scary stuff. What this tells you is that accurate valve control is a nightmare and an accident waiting to happen.

Well, there is relief available for flat tappet cam and hydraulic roller cam users – beehive springs! The beehive springs have very little, if any, harmonic resonance, due to their varying diameter from top to bottom. The beehive springs have many features that make them a better spring choice. The tapered design does not have the harmonic resonance capability of the straight design, virtually eliminating that problem.

The small diameter at the top of the spring allows a very small, lightweight retainer (9 grams vs 36 grams) to be used. Not only is the retainer lighter, but the single beehive spring will replace a much larger and heavier dual spring assembly.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by