Porting has evolved immensely over the years, both for intake manifolds and cylinder heads. What started with a hand-guided die grinder flinging iron filings, has turned in to precision CNC-driven porting of even the highest-end aluminum castings.

As is often the case with anything engine-related, prep work before the porting even begins is paramount to success. Hughes Engines, ever at the forefront of the formula for performance, has perfected a great many preparatory methods, one of which is intake port marking.

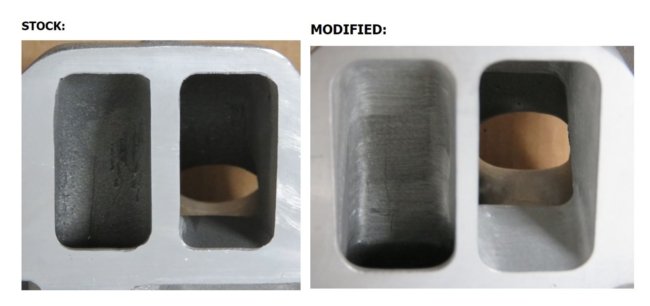

Marking ports for massaging is the first step towards a surge in CFM and simple intake port matching can actually provide a surprising bump in flow numbers. Many aftermarket intake ports are woefully inadequate, sized on the smaller side of the application range rather than the larger. Hughes estimates a deep port match can up airflow from 15 to 45 CFM depending on the intake.

“There are some manifolds, such as the small block Edelbrock Performer (a dual plane) and the Weiand Accelerator that have reduced the cross-sectional area, at the gaskets, to the small 318 port sizes. Naturally, when they are properly opened up to the 360 port size, the flow increases will be considerably more, but they are very low to start with.”

“There are some manifolds, such as the small block Edelbrock Performer (a dual plane) and the Weiand Accelerator that have reduced the cross-sectional area, at the gaskets, to the small 318 port sizes. Naturally, when they are properly opened up to the 360 port size, the flow increases will be considerably more, but they are very low to start with.”

However, to get those gains, the ports must be marked correctly. Here again, Hughes has the proper procedure:

1. Stuff wadded up damp newspaper into each of the intake ports until the port is about ½” short of being completely filled.

2. Install the heads on the block with a used head gasket the same thickness as the ones to be used for final assembly. Snug down the heads with 2 or 3 bolts.

3. Glue the intake gaskets (used ones are ok) to the cylinder heads taking care to square the gasket ports to the head ports.

4. Install the intake manifold. Make sure the bolt holes in the manifold are large enough to allow the bolts to start with your fingers. If not, cut them out.

5. Spray machinist dye, with a straw, deep into each port and quickly follow up with a blast of air from your air compressor.

6. The machinist dye will blow back against the manifold face leaving a true pattern of the cylinder head port on the manifold for perfect alignment.

7. Send the manifold to us with the dye marks intact.

Just those seven simple steps can set you up to singe all the stoplights you see. Visit Hughes Engines online or give them a call at (309) 745-9558 to get your flow fixed.