After a long winter of hibernation, many muscle car owners are going to hear the familiar “clickity clack” of a long-dormant valvetrain coming back to life. If the clatter goes away quickly, chances are that the engine just needed to get a little fluid forced back up to the top end after an extended drain-down. If not, then another culprit may be to blame as the Hughes Engines Tech Center explains:

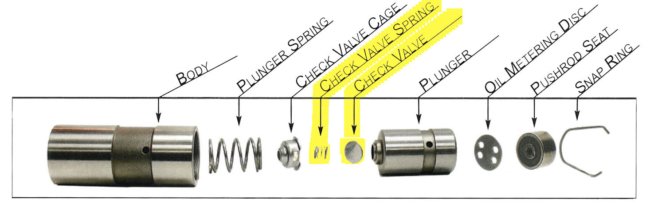

What makes hydraulic lifters noisy? Providing they have the proper pre-load, the answer is easy – dirt. “Say what, boy? Yo momma could eat off my engine!” Well, she probably could eat off of your engine parts, but the check valve in the lifter isn’t so lucky. You will note in the exploded view of the lifter, the check valve (disc) is held up against the plunger by a very light spring (emphasis on very light).

Foreign material (dirt) can easily hold the check valve open as the check valve is only closed by the very light spring. Lifters (well, Hylift Johnson lifters anyway!) are manufactured and assembled under very strict sanitary (that means clean) conditions (I know, I’ve been there), just to prevent dirt from getting into or on the lifters. Is it possible to get dirt into a lifter? Maybe! Is it possible to get 16 lifters with dirt in them? Yeah, about the same chances as Taylor Swift calling you up for a date! Good luck with that!

So, the question is how can the average guy tell if his lifters have been subject to “dirt.” It is easy if you know where to look and what to look for. The lifters have polished areas on their side where they rub against the bore in the block. Normally, this area is polished. Scratches will indicate abrasive “dirt” in the oil. You will need an 8x or 10x magnification to see the scratches. And no, they are not deep enough to catch with your fingernail. Well… if they are, you’ve got some big dirt, like gravel, in your oil.

The polished area on a flat tappet lifter will be in the same area as the roller lifter. However, the flat tappet lifter should be polished all the way around – as it should be rotating. If vertical scratches are evident, this indicates the lifter is not rotating and will quickly wipe out the cam lobe.

Who makes a good flat tappet cam and lifter package today? I have had a few lifter failures (comp cams) after a 1000 miles or so (hydraulic) I understand all these lifters are made in china or India these days.

What can I buy that wont fail? This is for my Dailey driver.