Several years ago, I did a rear drum-to-disc conversion on my 1969 Dodge Dart for a now-defunct Mopar magazine. With a looming deadline, I installed the Wilwood rotors and calipers. During the process, I hastily bent the 3/16-inch rigid brake lines to fit the contours of the 8 ¾-inch rear end and flared the ends to seat in the factory brake distribution block and each caliper’s fitting.

Left: We installed a pair of 9-inch stainless steel flexible brake hoses from Russell Performance to replace our solid brake lines. Right: To accompany each brake hose, we added a 3AN flare fitting to a 3/8″-24 adapter and a 3AN flare to a 1/8-inch NPT fitting.

I finished the story on time, and the disc brakes worked effectively. They quickly and efficiently slowed the Dart after a 120mph blast down the ¼-mile track. However, a problem arose when it came time to remove the center section to change the fluid or swap the rear gears. The rigid brake lines did not allow for much flex, and removing the calipers would certainly kink or break the brake lines. A better solution needed to be found.

The answer was located on the Russell Performance Plumbing website. Mopar Connection Magazine found the necessary components to allow the removal of the calipers without damaging the brake lines or requiring the opening of the hydraulic brake system. We picked up two 3AN flare fitting to 3/8”-24 adapters (part no. 640291), a couple of US Department of Transportation (DOT) approved stainless steel flexible 9-inch brake hoses with 3AN-to-3AN flare fittings on each end (part no. 656012), and a pair of 3AN flare to 1/8-inch NPT fittings (part no. 642441).

Above: For a previous editorial, a pair of Wilwood rear disc brakes were added to our 8 3/4-inch rear end. Unfortunately, the rigid lines were bent to connect the calipers to the hydraulic brake system. The problem with fixed lines occurred when we needed to remove the calipers to pull the axles and the rear differential. The brake lines are not flexible, so we had to remove the brake line from each caliper.

Before we cover the installation, there needs to be some clarification about the DOT’s approval of stainless-steel brake hoses. All stainless-steel hoses fall into one of three categories:

DOT approved – The hoses have been submitted to and approved by the DOT.

Non-DOT approved – The hoses do not have DOT approval because they are brake hoses that do not comply with the DOT specifications or have not been submitted for testing.

Non-conforming – The hoses are non-approved and cannot be approved because they fail to meet the DOT specifications.

Above: The difference between a DOT and a non-DOT-compliant stainless-steel brake hose is the plastic support at the crimp joint. The stainless-steel hoses are subjected to a “whip test,” which the non-supported hoses cannot pass. Therefore, we selected the DOT hoses for our Dart in case we ever decided to drive it on the street.

How the fittings are attached to a stainless-steel brake hose must meet Federal Motor Vehicle Safety Standards (FMVSS) 106. The standard specifies, “Each hydraulic brake hose assembly shall have permanently attached brake hose end fittings, which are attached by deformation of the fitting by crimping or swaging.” Crimped-on fittings do not possess a means by which an unfamiliar owner or inexperienced technician can harm.

The above statement means that any hose assembly that uses the best fittings, like the nipple-and-cutter Russell ProClassic hose ends, is non-conforming and will not earn DOT approval.

Left: We measured the flexible hose against the brake line. The brake line was marked with a Sharpie to locate the cut point. Center: The fitting in the caliper was replaced with a fitting that would attach to the new 3AN hose end. Right: We cut the brake line to the specified length with a tubing cutter.

A “whip-resistance” stress test often separates which brake hoses earn or do not earn a DOT rating. With crimped-on hose ends, the hose is mounted on a flexing machine and pressurized to 235 psi. The device runs at 800 RPM for 35 hours. When a stainless-steel armored hose is run through the test, the hose tends to bend at the junction between the hose and the crimped-on hose ends.

The stainless-steel braid starts to tear, and the broken stainless-steel braid strands could cut into the inner Teflon liner, causing it to fail. It was discovered that the damage to the stainless-steel hose was negated by adding supplemental supports at the flexing point.

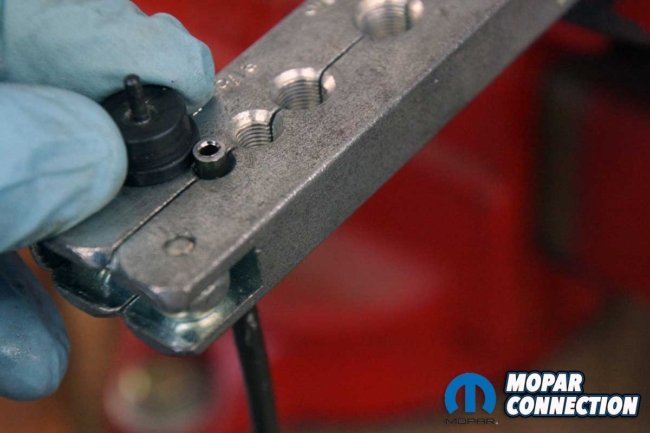

Above: After cutting the brake line, we slipped the 3/8″-24 nut back onto the brake line. Center: The brake line was installed in the flaring tool. We extended the line through the tool to the height of the step on the die. Right: We inserted the die into the brake line and pressed it into the pipe. We stopped pushing the die when it contacted the clamp.

The National Highway Traffic Safety Administration (NHTSA), in August 1996, ruled to allow manufacturers to use the additional plastic supports. As a result, FMVSS 106 was modified to include the use of the supports. Manufacturers immediately sought and received DOT approval, and street-legal stainless-steel brake hoses have been sold since then.

Left: With the die removed, we could see a slight inward bend of the tube. Center: The next step was to continue pressing the line until it was flared outward. Right: The double flare looked perfect.

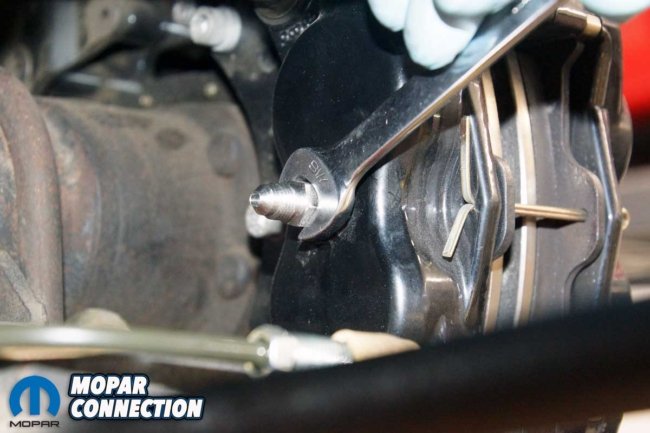

We would need to remove the brake lines from the rear end, cut each line, and re-flare the lines’ ends to install the flexible brake hoses. First, we started on the driver side brake line by quickly removing it. Next, the 3/8”-24 fitting to 1/8-inch NPT fitting in the Wilwood caliper was removed, and a 3AN to 1/8-inch NPT nut was installed.

At the brake line end closest to the caliper, we cut the brake line to a pre-measured length and reinstalled the 3/8”-24 fitting onto the line. A line flaring tool made a perfect double flare to ensure a proper seal. A 3AN flare fitting to a 3/8”-24 adapter was installed on the newly flared end of the line.

Left: The 3/8″-24 nut fit against the flared end. Right: We threaded the 3AN to 3/8″-24 adapter to the nut. It fits well with the flare resting correctly on the adapter’s seat.

We promptly reinstalled the brake line to the rear end. The Russell stainless steel brake hose was fitted between each 3AN fitting. The passenger-side brake hose was modified and reinstalled in the same manner as the driver-side.

With the brake system again sealed, we needed to bleed the brakes to remove any air that had been introduced during the installation of the new hoses. Each Wilwood caliper has two bleeder screws on either side of the rotor. First, we pumped the brake pedal and held it down with a brake pedal depressor tool (used with 4-wheel alignments). Then, with the system pressure increased, we opened the right-rear caliper bleeder screws to purge the air.

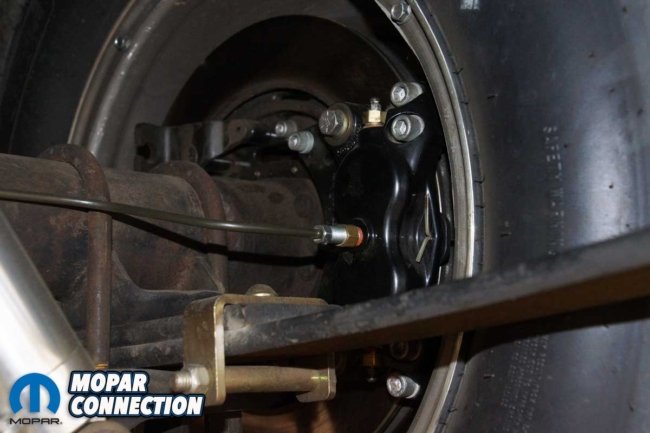

Above: The Russell brake hose was installed between the 3AN brake line adapter and the 3AN fitting in the caliper. Now the calipers can be removed without worrying about damaging the brake lines.

We continued pumping and bleeding the right-rear caliper until only liquid was expelled. Before moving to the left-rear caliper, we checked the brake fluid level in the master cylinder reservoir. The fluid was topped off, and we turned our attention to bleeding the left-rear caliper, following the same procedure we used for the right-rear caliper.

We adjusted the brake fluid level in the reservoir and tested the brakes. The brake pedal was firm, and the brakes operated appropriately. After a short test drive, we rechecked our work, and after not finding liquid expelled from the hoses and adapters, we were convinced the system was leak free.

Above: After installing the Russell brake hoses, we now have a hydraulic brake system completed in an arrangement we should have assembled several years ago. After testing the system, everything was leak-free, and the brakes worked properly.

Adding the Russell Performance parts has increased the ease of differential fluid exchanges. In addition, we can now pull the calipers without any concern about damage to the brake lines. For more information about its product offerings, check all the Edelbrock companies (Comp Cams, TCI Automotive, FAST – Fuel Air Spark Technology), and to get the brake parts we used, click over to Russell Performance Plumbing.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by