As World War II ended, the automotive industry transitioned from military production to civilian vehicle manufacturing. In this crucial period, Chrysler Motors Corporation took a pioneering step by launching the Master Technicians Service Conference (MTSC). This national technician training series would significantly shape the industry’s future.

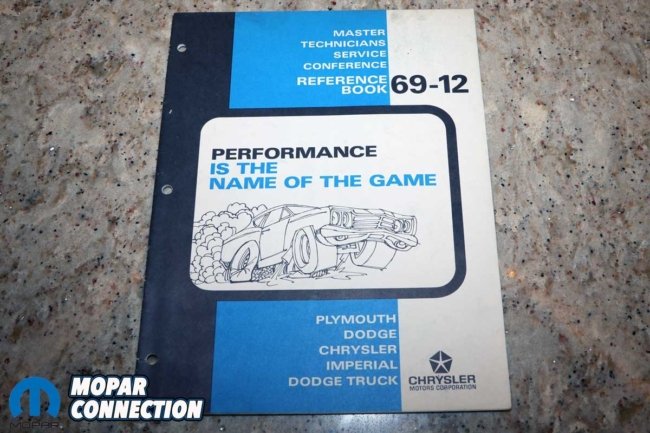

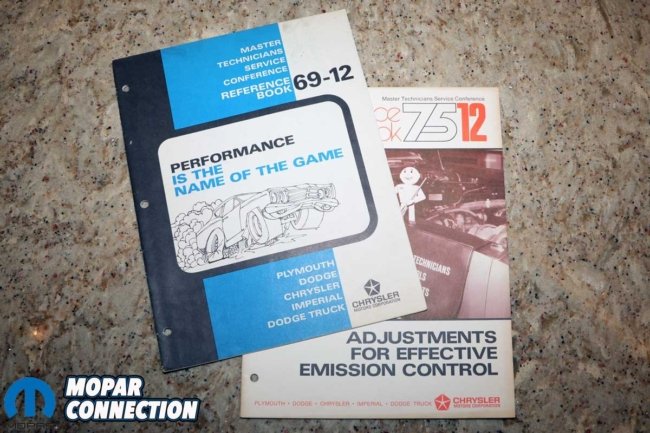

Above Left: Chrysler’s training program, Master Technicians Service Conference, started in 1947. The first 5×7-inch training booklets arrived at the dealerships with a film strip and a record. Chrysler focused on technician repairs such as distributors or the second training session oil consumption. Above Right: For two decades, the training focused on vehicle repair techniques, update training, and new model reviews, but in late 1969, Chrysler dipped into the performance market with a training session on super-tuning its high-performance engines.

From 1947 to 1975, each service department in the Chrysler network (Plymouth, Dodge, Desoto, Chrysler, Imperial, and Dodge Truck) received a monthly comprehensive training package. This meticulously crafted package, which included a targeted training reference book, a record, and a film strip (later a VHS tape), left no stone unturned in ensuring that every aspect of the training was covered in detail, providing a deep understanding of the subject matter.

Above: After its only performance training session, the MTSC focused on tech tips, repair procedures, and new model information. Unfortunately, the muscle car era ended in the early 1970s, and technicians faced never-ending emissions-related training.

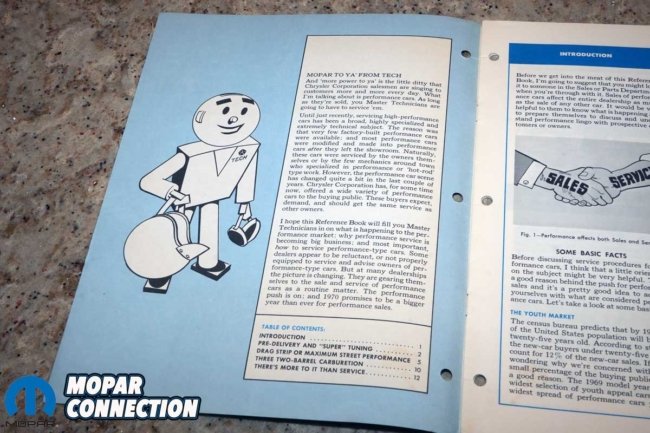

Each monthly training session, whether covering a single topic, a group of matters, or new model coverage, was characterized by a no-nonsense approach. This method, embodied by the wooden character Mister Tech, was designed to provide the ‘Straight Dope’—direct and practical information—that dealership service technicians could immediately apply in their work, instilling a sense of confidence in the effectiveness of the training.

Usually, each film strip had a master technician teaching the monthly topic to a new technician, and Tech stirred the banter to keep the topic moving forward. Over the years, the sessions covered distributors, carburetors, brakes, suspension, air conditioning, drivelines (transmissions and rear ends), tires and wheels, electrical, and new models.

Above Left: For that one shining moment, Chrysler unleashed technical information that taught the technicians to take great running Mopars and make them even better. Above Right: Even Tech got into the action with his helmet and racing goggles. Chrysler went all out in this training session.

While it was customary for Chrysler to provide performance information through technical service bulletins (TSBs) with its performance-oriented devotees, it was out of character for Chrysler to put out a MTSC in late 1969 (69-12 training session) that covered super-tuning of their performance models. The Performance is the Name of the Game training covered how youth enthusiasts purchased performance cars that comprised 20% of the market and how the performance push was on for 1970.

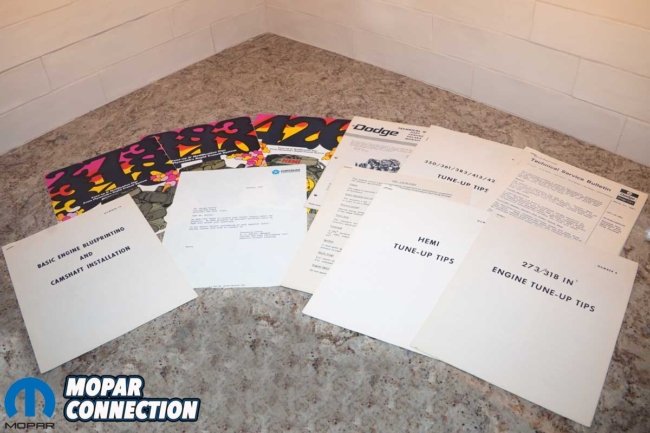

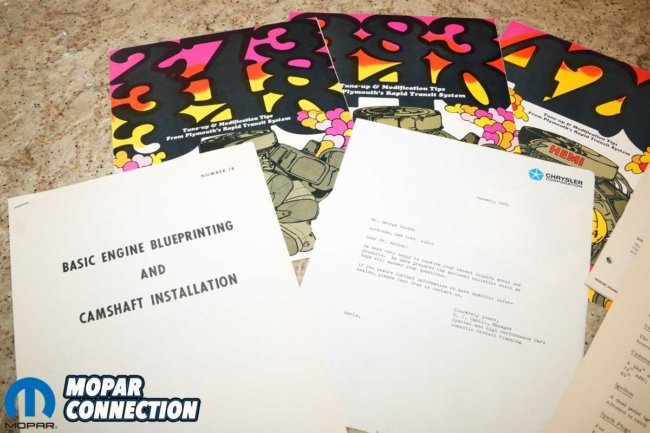

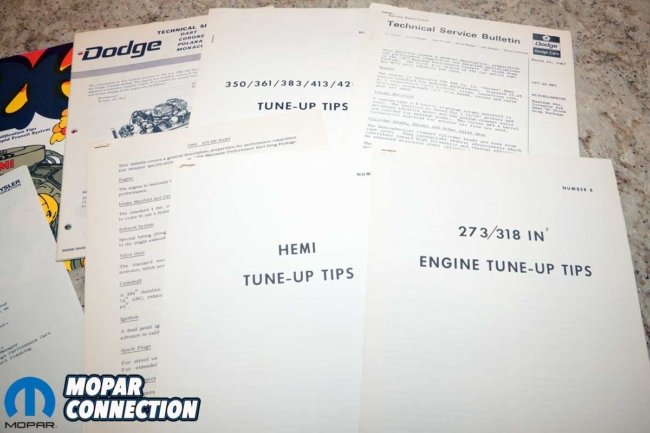

Above: Chrysler always had a way to provide enthusiasts with performance-related information. Some information was in the form of technical service bulletins (TSBs) that technicians would get at the dealership. Additional information was provided directly through Chrysler’s Special and High Performance Cars Domestic Product Planning department. Those in the know could write Chrysler for more detailed information about blueprinting and super-tuning their engines.

Chrysler had many performance cars, including the five Dodges: Charger R/T, Coronet R/T, Super Bee, Dart GT Sport, and Dart Swinger 340. Additionally, Plymouth had the Road Runner, GTX, and Barracuda. The performance lineup of engines included:

• 340 4-bbl.

• 383 4-bbl.

• 426 Dual 4-bbl. HEMI

• 440 4-bbl. (High Performance)

• 440 6-bbl.

Above: Chrysler released three tri-fold brochures that provided instructions on extracting the maximum performance from six of its most popular engines. These brochures were a precursor to the Direct Connection recipe books published in the 1970s.

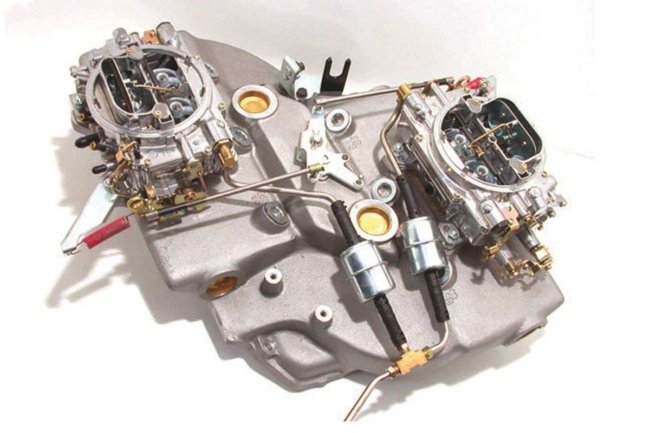

The training session covered performing a “super” tune during the pre-delivery inspection (PDI). The first step was working through the carburetor, setting everything to factory specs to get the engine in top tune. However, the jets and metering rods could be swapped if the customer desired additional performance. The floats needed to be raised to increase fuel volume in the bowls, and lastly, the accelerator pump stroke was lengthened.

With the carb setup, the ignition timing had to be adjusted. A quicker distributor advance was necessary to take advantage of the additional fuel. Switching to a dual-point distributor was also an option. Colder plugs and solid-wire ignition cables could be added to the combination. Finally, the manifold heat control valve needed to be wired open.

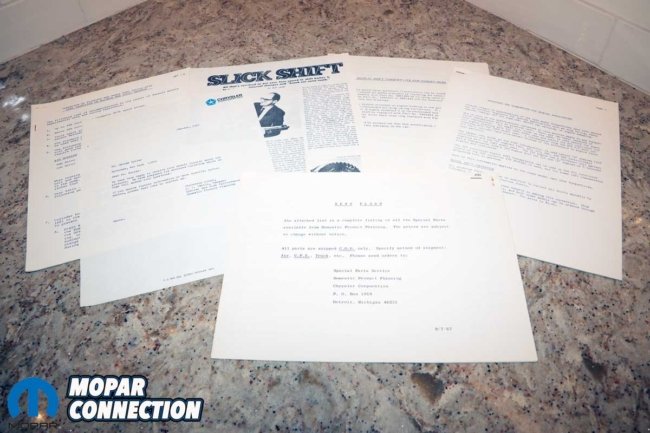

Above: Chrysler shared its racing knowledge for several years with everyone who asked for it. The same technology used in the Stock and Super Stock Mopars was provided to the “little guy” who wanted to mix it up at the strip with the Chrysler factory drivers.

While the above modifications would provide maximum street performance, the session covered the fact that unauthorized alterations or use of parts or materials not approved by Chrysler Corporation voided the warranty. Interestingly, the session went on to cover a series of carburetors and manifolds that Chrysler suggested for race-only applications, even though they potentially voided the warranty but provided a substantial performance increase.

Continuing with the performance upgrades, Chrysler had a transistorized ignition system that worked well with a dual-point distributor (which the customer likely had installed during the PDI) and the addition of a super stock coil. Last, the cooling system could be modified with a torque control drive fan and a small-diameter impeller water pump.

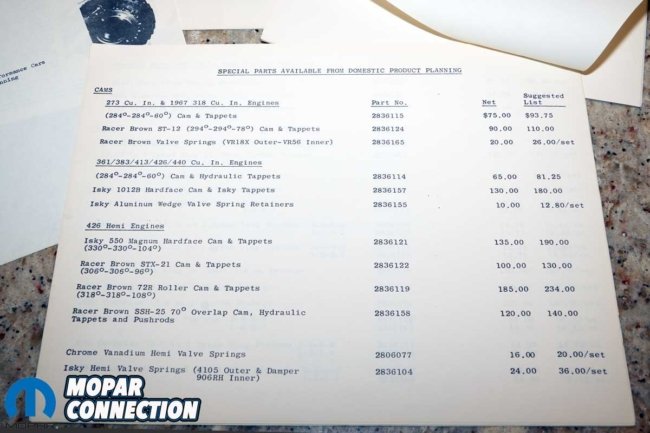

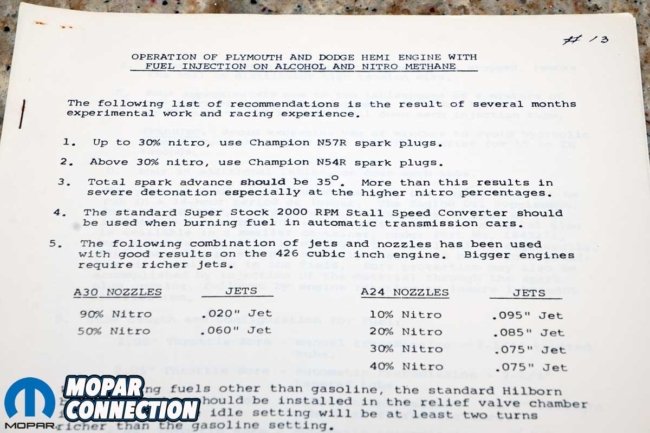

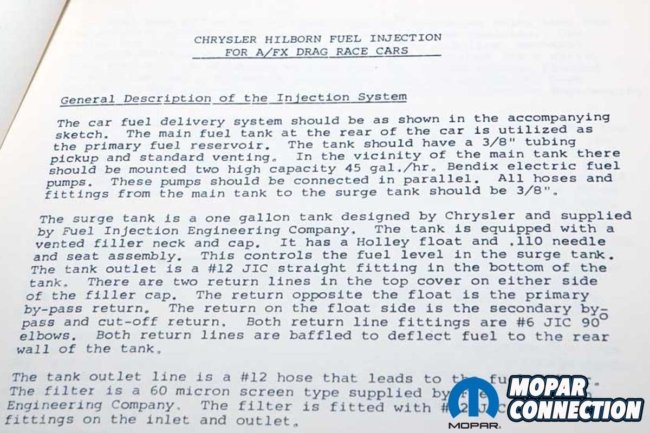

Above: Chrysler provided an extensive list of special parts from the Domestic Product Planning department. Additionally, it had in-depth technical information for those who wanted to run a Hemi on alcohol and nitromethane. Moreover, included with the documentation was how to run the A/FX class with Hilborn fuel injection. I wonder how many people converted to Hilborn injection on nitro based on the knowledge shared by Chrysler?

The session ended with the new 6-bbl engines, which were introduced after the factory service manuals had been printed. So, like a normal MTSC session, the service technicians were provided in-depth information about how to set up and adjust the three carburetors.

Chrysler’s MTSC series continued for another six years but never had a performance-oriented session again. The muscle car era ended at the end of the 1971 model year, and the MTSC training covered emissions components, safety features, and driveability concerns.

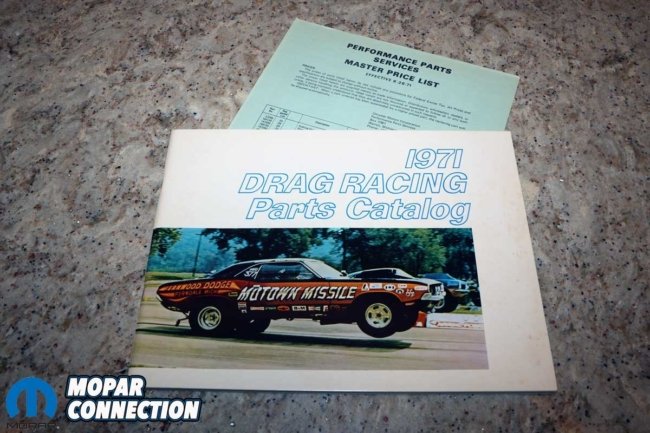

Above: Before introducing Direct Connection, Chrysler’s Performance Parts Services department put out racing parts catalogs (a predecessor to DC catalogs) that provided a list of race application parts and pricing.

By 1974, Chrysler had developed Direct Connection, an easier way for street car fans and drag racers to get factory car parts. When Chrysler launched the program, Mancini Racing was the first Direct Connection Warehouse Distributor. Since then, Mancini Racing has been a leader in providing high-performance parts for Mopar vehicles.

Above: For those looking to upgrade their Mopar today, there is a much greater selection of parts, including carburetors, manifolds, and ignition components. The best thing about these parts is that they will not void your long-passed 5/50 warranty.

While technician training has significantly changed, education is more important than ever. Rather than film strips, records, and reference booklets, today’s training is internet-based, followed by in-person classes. Likewise, the performance industry has transformed, but Direct Connection and Mancini Racing have flourished over the last fifty years.

To keep up with the latest performance products for the muscle car era and late-model muscle, contact Mancini Racing to super-tune your ride because Performance is the Name of the Game.