Whenever a new technology is developed, it only takes a short time until others benefit from the expertise in ways that were not planned. For example, the Holley engineers have embraced the latest laser scanning technology known as “Laser Imaging Detection and Ranging” or “Light Detection and Ranging” (abbreviated to LiDAR, LIDAR, or LADAR). Holley’s all-new float less Easy Level™ (part no. 19-250) fuel-sending unit is not using LiDAR for autonomous vehicle operation but for fuel level monitoring.

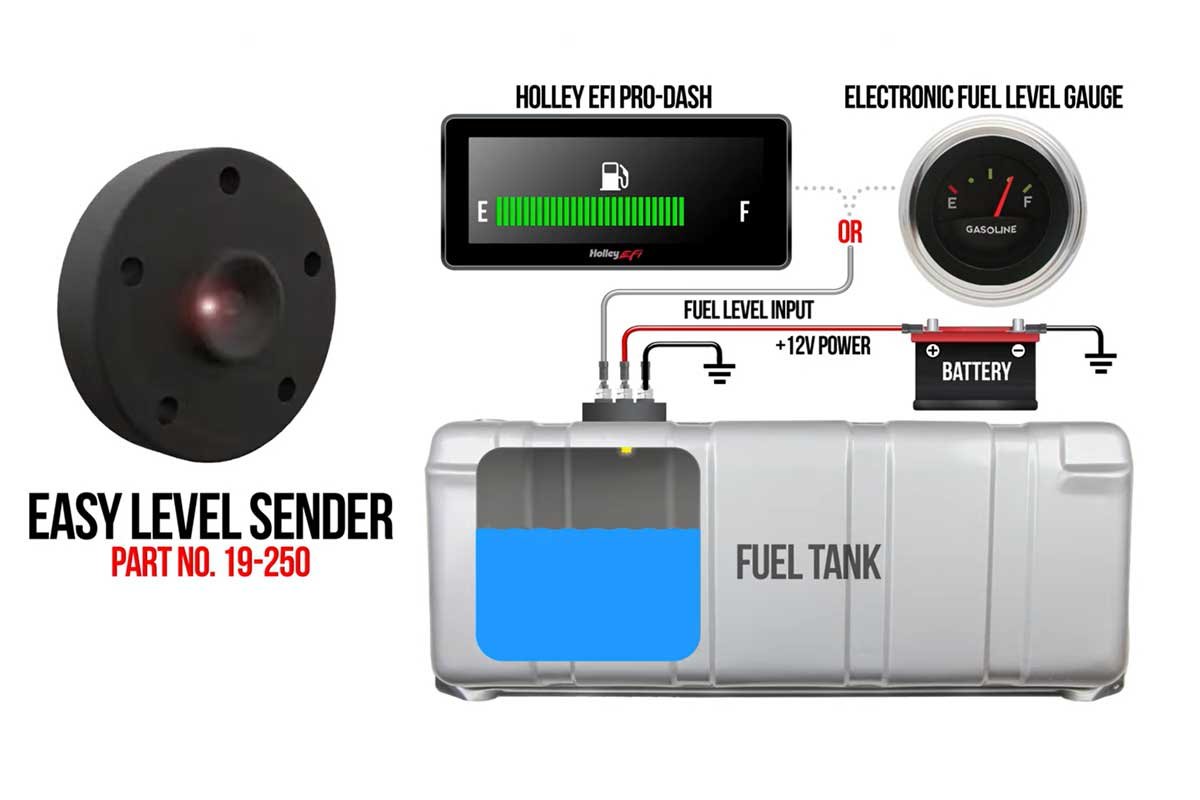

Above: Holley’s Easy Level Sending Unit provides accurate, contactless fuel level monitoring for an electronic fuel gauge or the Holley EFI Pro-Dash. The Easy Level Sender relies on LiDAR laser technology.

So, what is Laser Imaging Detection and Ranging technology? It is a detection system that works on the principle of radar, but it uses light from a laser. Radar laser technology has infiltrated many industries, and the automotive field is a significant beneficiary. Due to the precision of data collection and accuracy for automotive technology, LiDAR is one of the most preferred remote sensing tools.

LiDAR uses a laser to estimate the heights of objects on the ground or, in the case of the Easy Level, the fuel level in the tank. Discrete data is generated from waveforms, and LiDAR points contain an x, y, and z value, with the z value used to yield height.

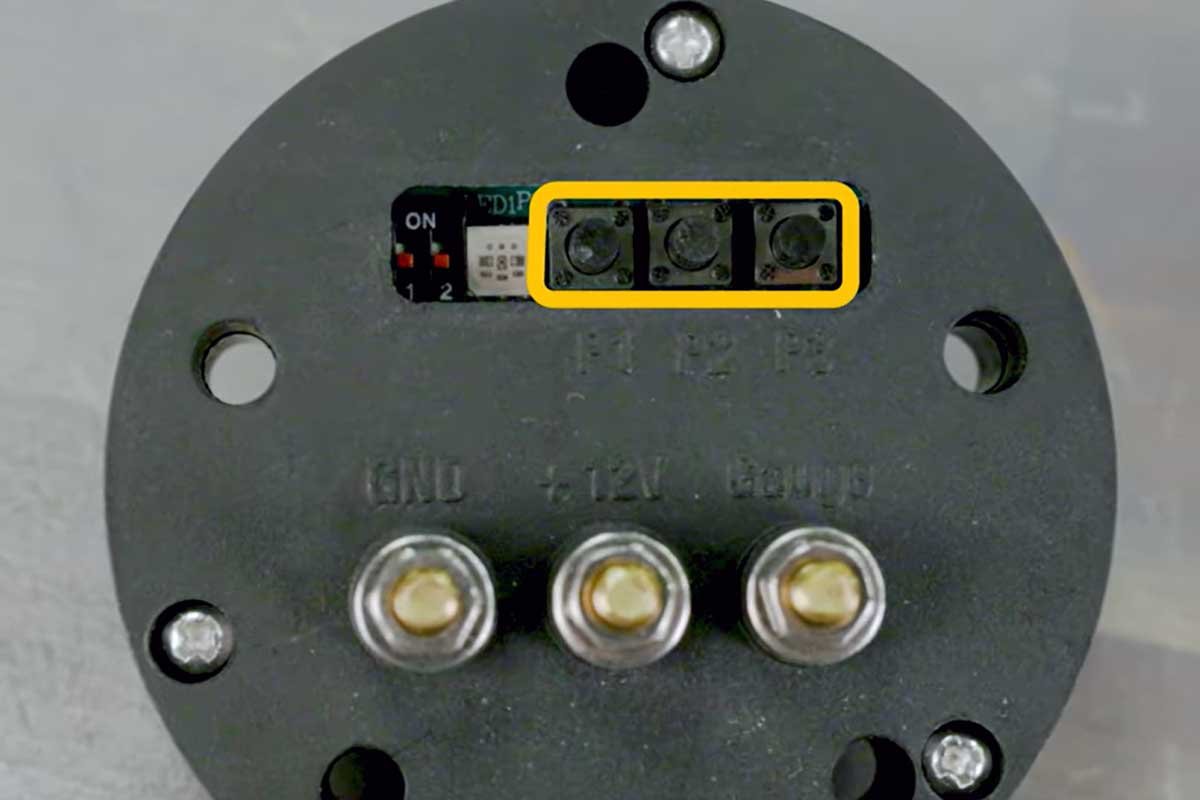

Above Left: The Easy Level sending unit is a compact, self-contained unit that can fit into tight areas. The mounting hardware is included with the sending unit. Above Right: Under a rubber seal are three push buttons and an LED to indicate the selection based on the buttons and sequence selected. Additionally, two DIP switches allow fine-tuning to reduce gauge fluctuation due to fuel slosh.

A LiDAR fuel-sending unit can gather data swiftly and precisely, works in darkness, does not suffer geometric distortions, can be integrated with other data sources, and requires minimum human input.

Holley’s Easy Level sender precisely measures the tank’s fuel level without contact with the fuel. According to Holley, the Easy Level can monitor a fuel tank depth as shallow as four inches or as deep as 39 inches.

Holley has designed the Easy Level to work with short-sweep, full-sweep, and electronic gauges from Classic Instruments, Holley’s EFI Pro Dash, or other aftermarket manufacturers. However, it does not operate with original equipment (OE) style gauges that utilize an ohm-only input.

Above Left: A close-up of the Easy Level shows the three buttons pressed in a specific order or combination to calibrate it and establish the fuel tank depth. Above Right: The DIP switches can be easily accessed and adjusted with the tip of a pencil. Between the three buttons and the DIP switches is the LED.

A benefit of a LiDAR technology fuel sending unit is eliminating moving parts found on traditional sending units. The Easy Level sending unit removes problems with the fuel float, adjusting the float lever arm for aftermarket fuel tanks, interference with tank baffles, or even fitting the assembly into the fuel tank.

The five-bolt flange of the Easy Level sending unit secures into a 2.122-inch bolt circle diameter in any fuel tank. It includes the mounting hardware and rubber gasket.

Above Left: The Easy Level only has three wires. One is a 12-volt source. The second is ground, and the third is the signal to the gauge. Above Right: The technician is bench testing the unit. The Easy Level must be calibrated before installation into the fuel tank.

To wire the Easy Level, the sender requires a 12-volt source, a ground, and a pulse width modulated (PWM) signal to the fuel gauge. The Easy Level can be programmed to determine the fuel gauge’s empty, half, and full positions by pressing three onboard buttons under a removable rubber seal on the housing of the sending unit.

As each button is pressed, a multi-colored light-emitting diode (LED) will illuminate to indicate each calibration has been completed. There is no need to fiddle with the sending unit floats or worry about the floats ever “sinking.”

Above Left: The sending unit fits into a 2.122-inch hole—the bolts thread nicely into the pre-tapped aluminum tank flange. Above Right: After installing the sender, it must be calibrated to the fuel tank. Once correctly adjusted, the rubber plug is reinstalled, and the installation is complete.

On traditional sending units, fuel slosh can cause the fuel gauge’s needle to bounce incessantly. Two DIP switches next to the onboard buttons under the rubber seal can be adjusted on the Easy Level to reduce the gauge bounce. The max operating temperature of the Easy Level is 185°F.

For more information about the Holley Easy Level fuel-sending unit, check out the video and follow along as the Easy Level is calibrated and installed. The video covers the finer points about the sending unit in greater detail. Also, contact the Holley representatives at 1-866-464-6553 Monday-Friday 8 am – 6 pm CST or Saturday 8 am – 2 pm CST for additional information.