There’s more to our Hellcat Redeye build than just a supercharger pulley upgrade and some paint. As we shared in a previous article, Metco Motorsports’ Hellcat supercharger pulley was installed utilizing its pin holding tool to remove the stubborn OE pulley.

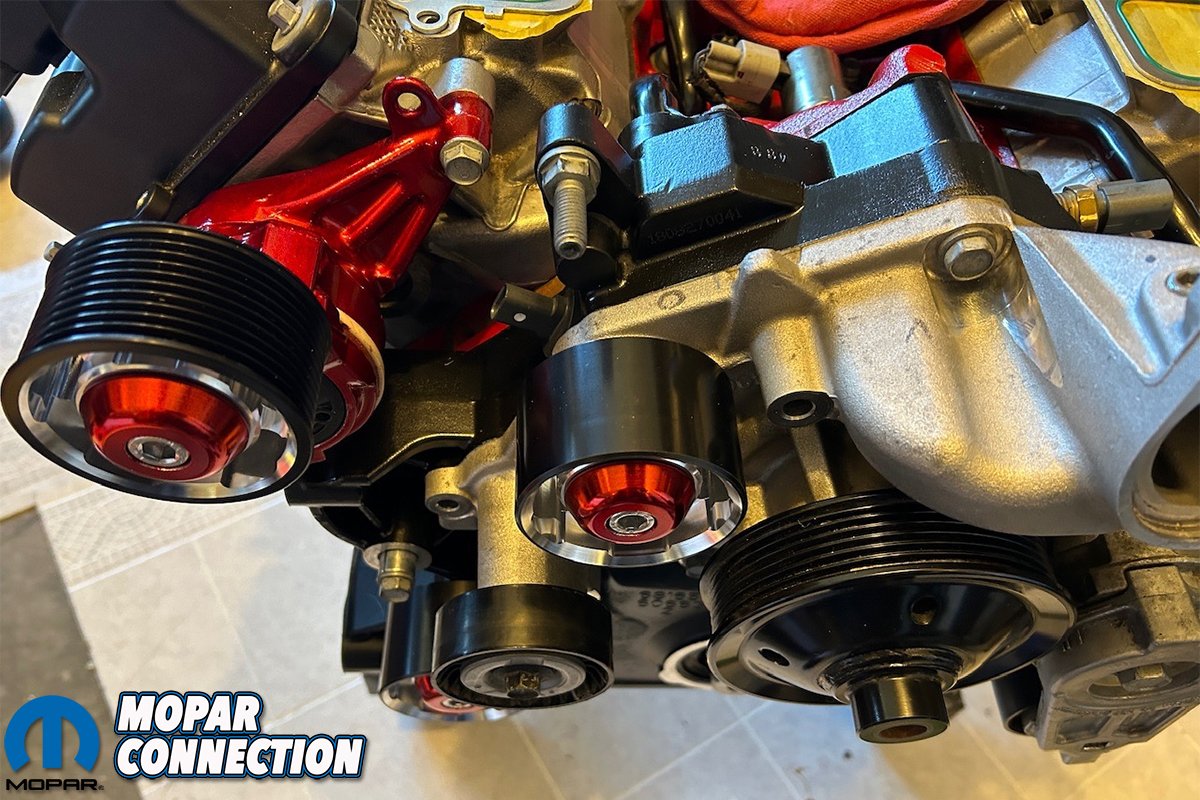

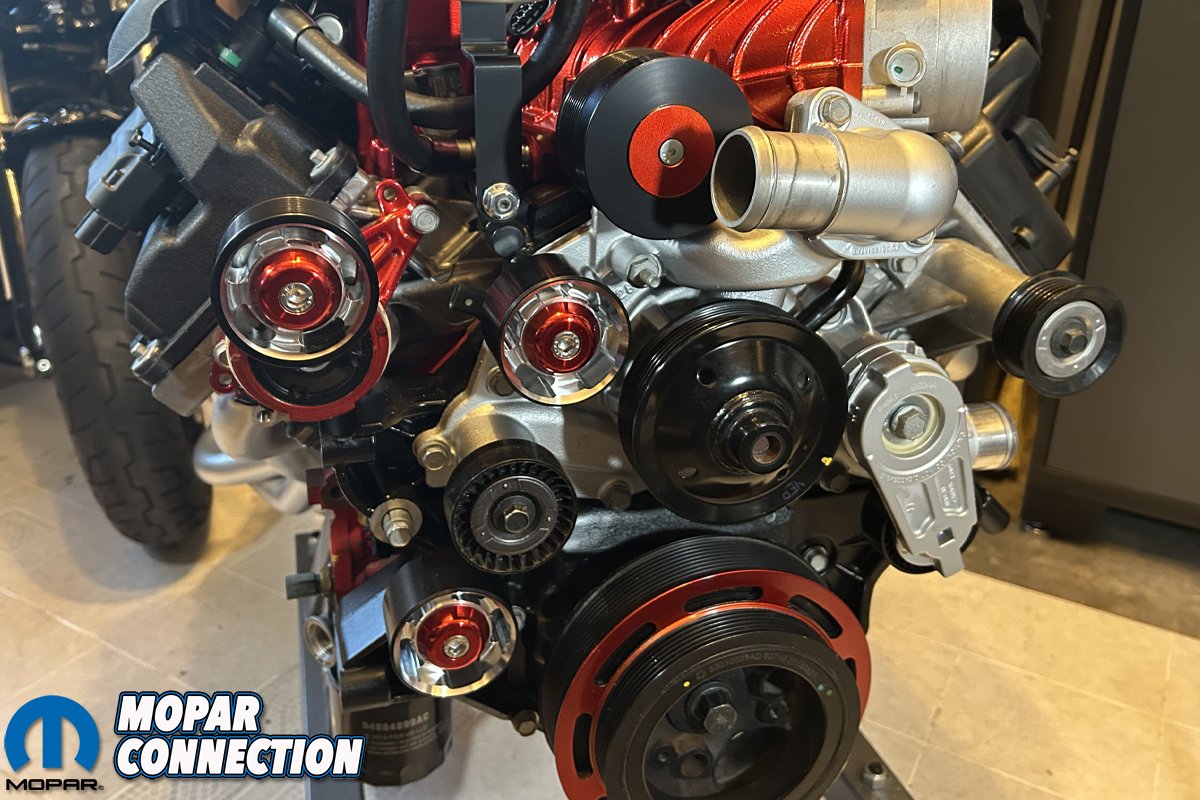

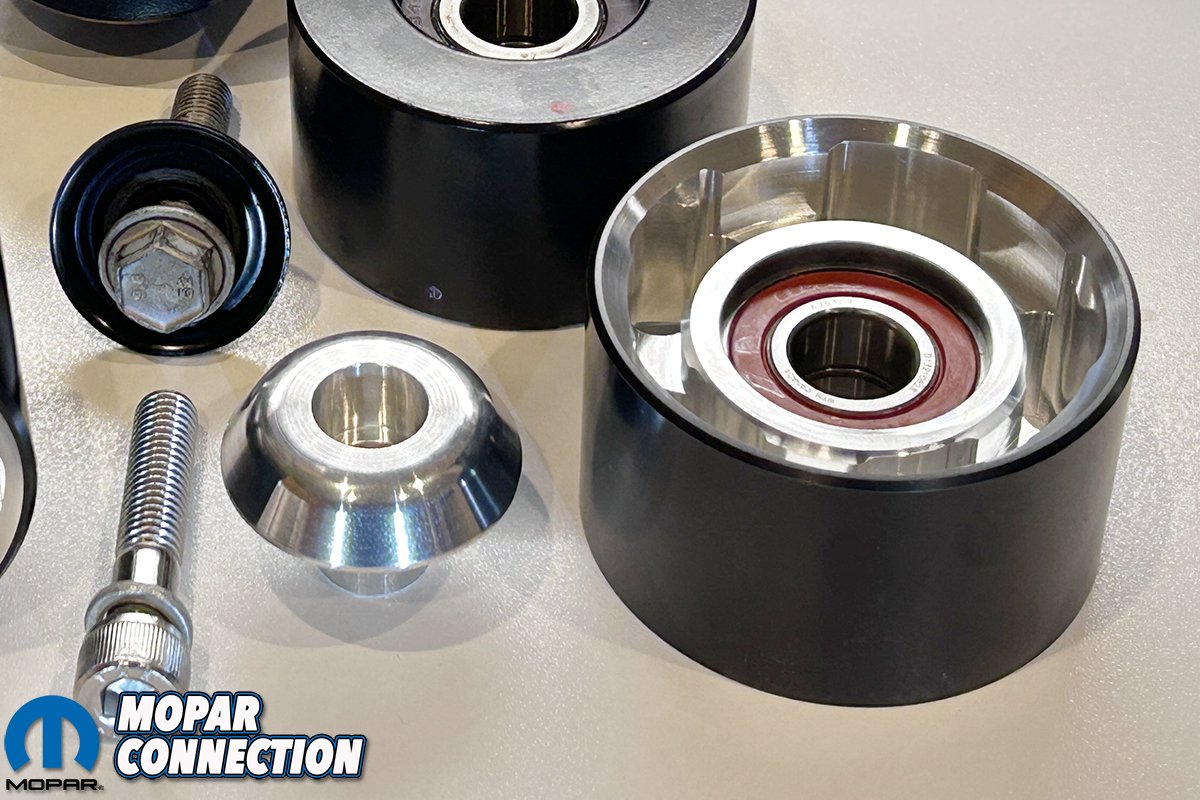

That was a no-nonsense upgrade that will facilitate future pulley upgrades, should the need arise. The ‘more’ part of this article includes the supercharger tensioner pulley, and both idler pulleys, also from Metco. They look great, and they’re built to last: they provide both form and function to our build.

With a typical V-belt system, the tendency is to blast the pulleys and hit them with a rattle can. It’s much like adding aftermarket valve covers: they’re mostly for show. The performance gain, well, we all know that paint and stickers don’t really add horsepower.

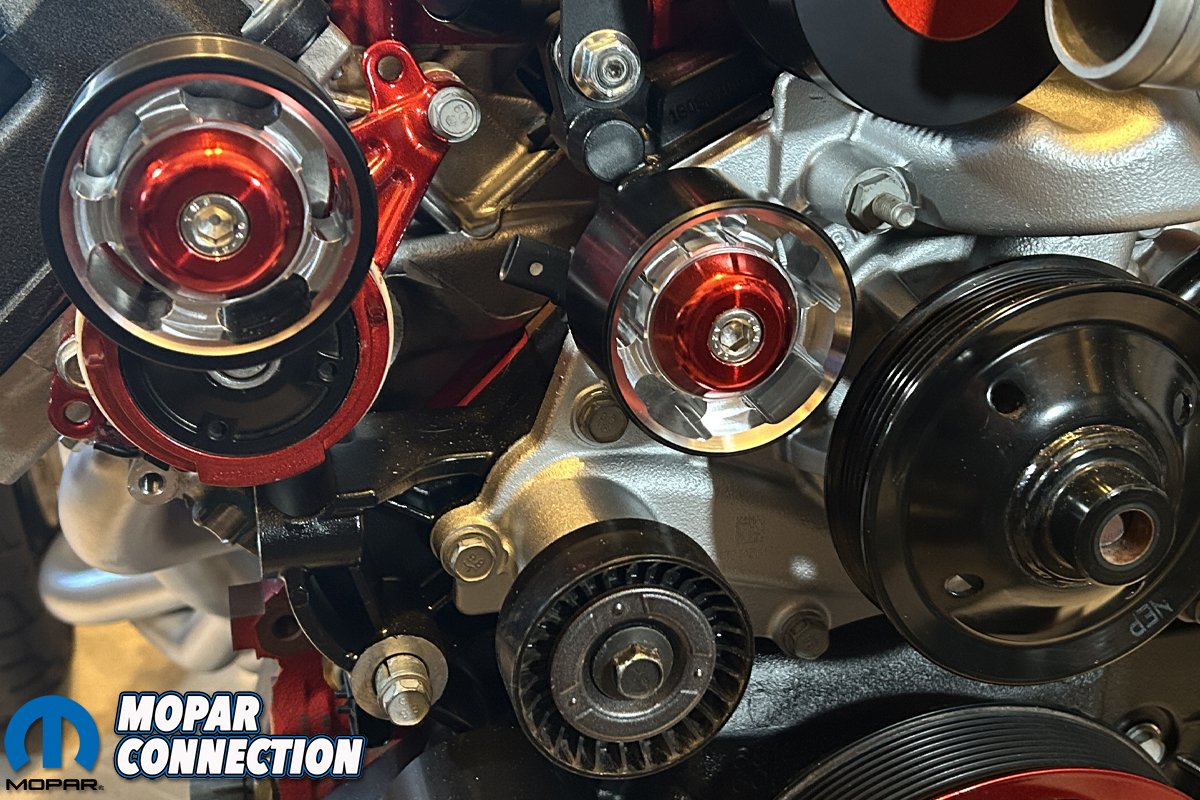

Granted, with a serpentine pulley upgrade, you’re not going to feel any gain in the seat of your pants. But that doesn’t mean there are no gains in other areas, as with these CNC billet pulleys. As mentioned previously, Metco was the first to offer a pulley upgrade for the Hellcat. This trio of pulleys is available for the Hellcat to complement that upgrade.

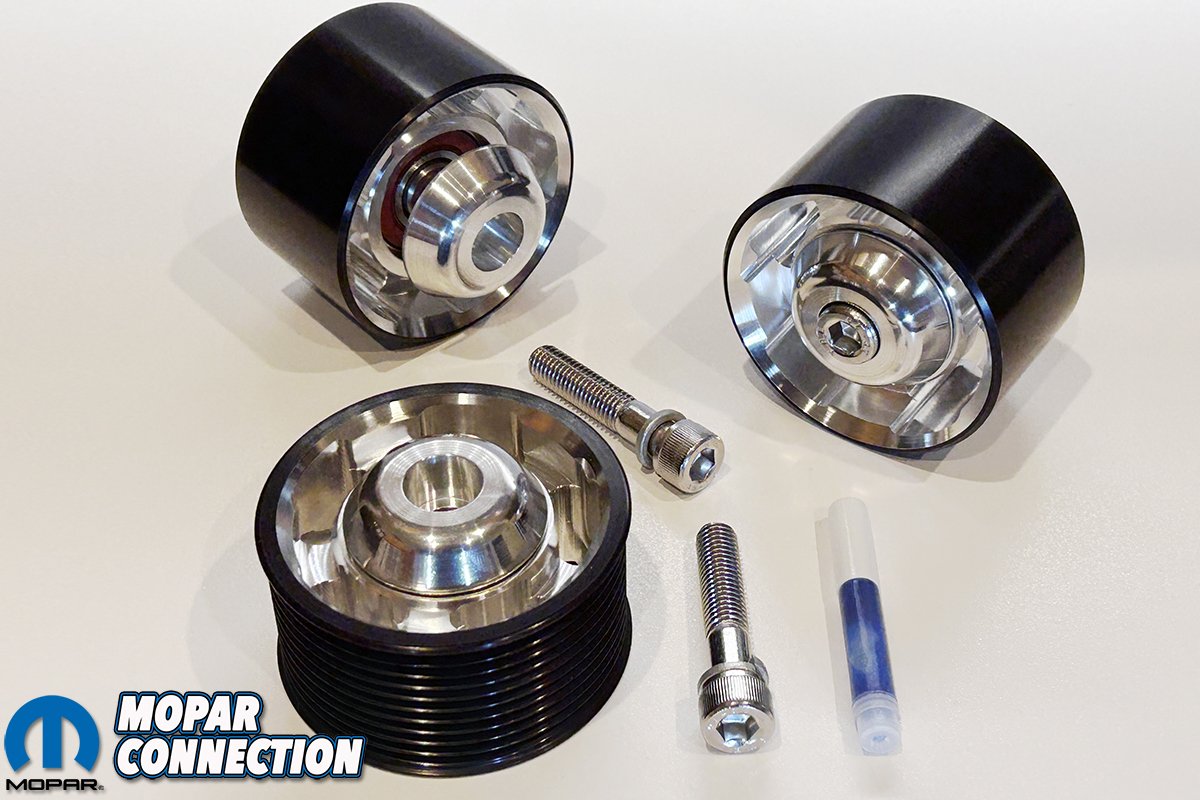

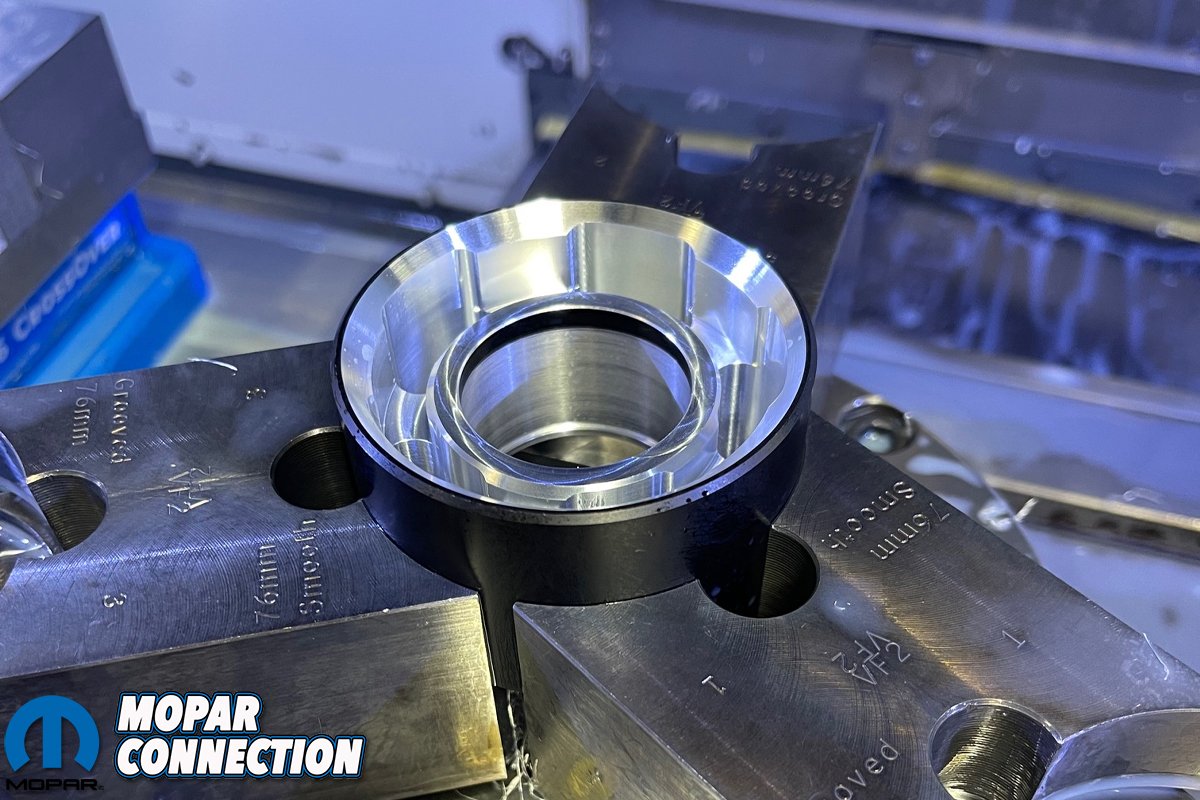

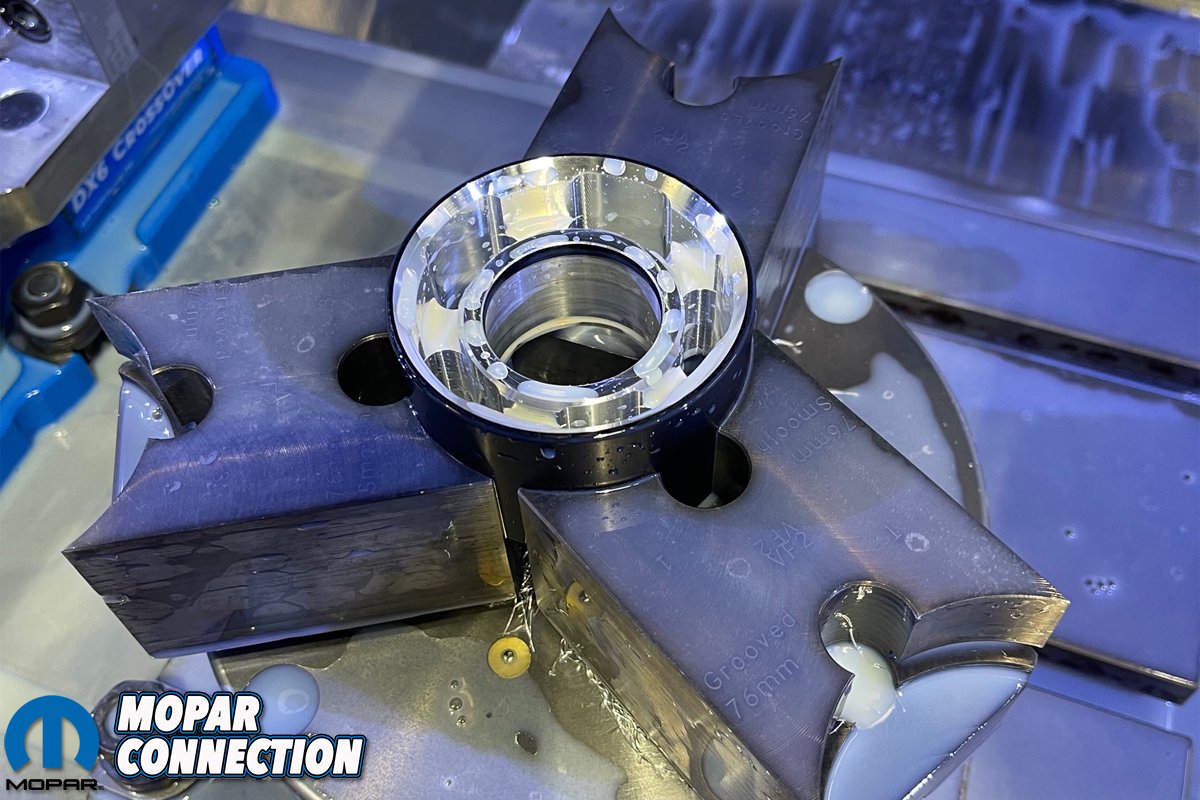

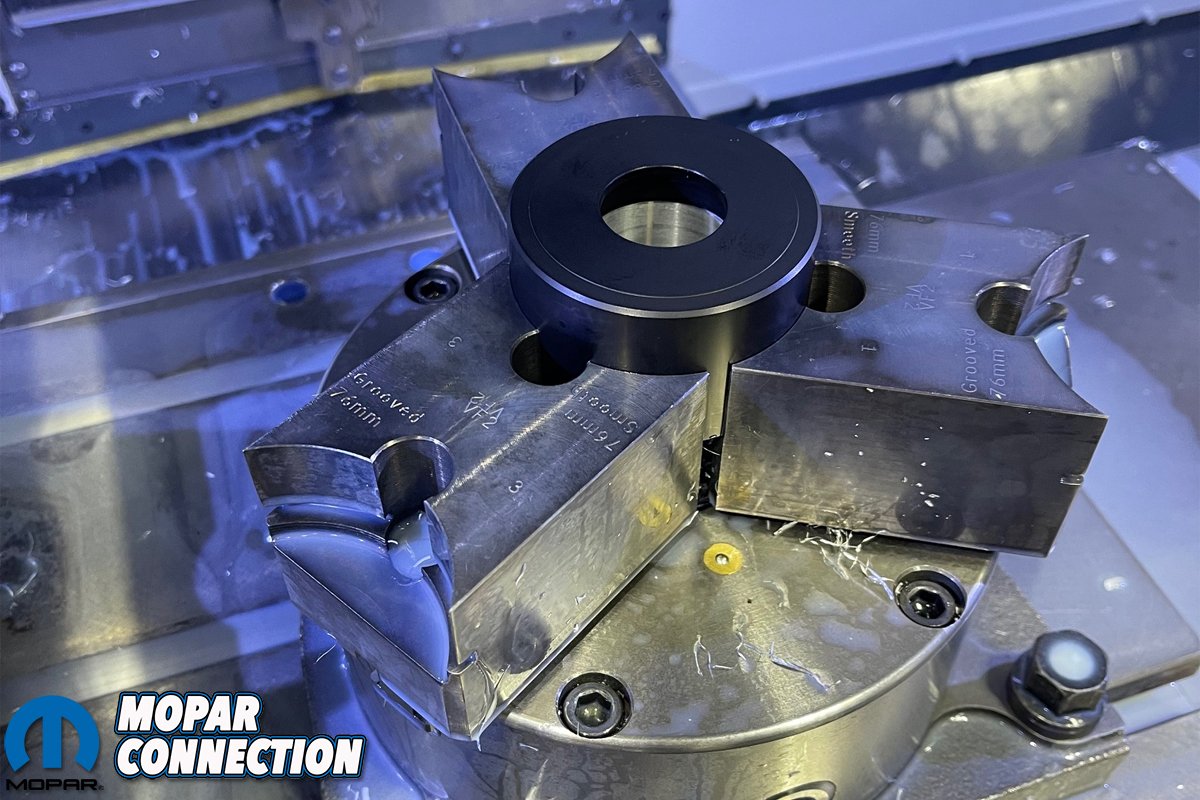

The three pulley set for the Hellcat is machined in Metco’s facility; the first cut is done on its CNC lathe. The pulley blanks are sized, with the belt surface and pulley bore machined to ensure zero runout, before being sent to a specialist for the black coating. Once the pulleys are back at Metco, they’re ready for the final CNC work to be done.

Metco’s Rick Bejarano tells us, “Our pulleys are designed, manufactured, and shipped with the expectation that they will last forever.” In the automotive performance world, that’s something you don’t hear of too often. Regarding the black finish on the pulleys, the concern might be that it would eventually wear, but he assures us that is not the case.

Jewelry for Your Hellcat Engine

“We use a military-spec hard-coat anodizing on our pulleys. This finish actually penetrates the aluminum and makes it significantly stronger,” he tells us. “This finish is expensive, but it will literally last forever, only growing shinier as miles accumulate.”

We’re not sure what the service life is for the OE tensioner and idler pulleys, but even with the low mileage on our engine we can see some wear already setting in. This hard-coat anodizing provides the optimum surface area for the supercharger belt, and in the process extends belt life and reduces belt noise.

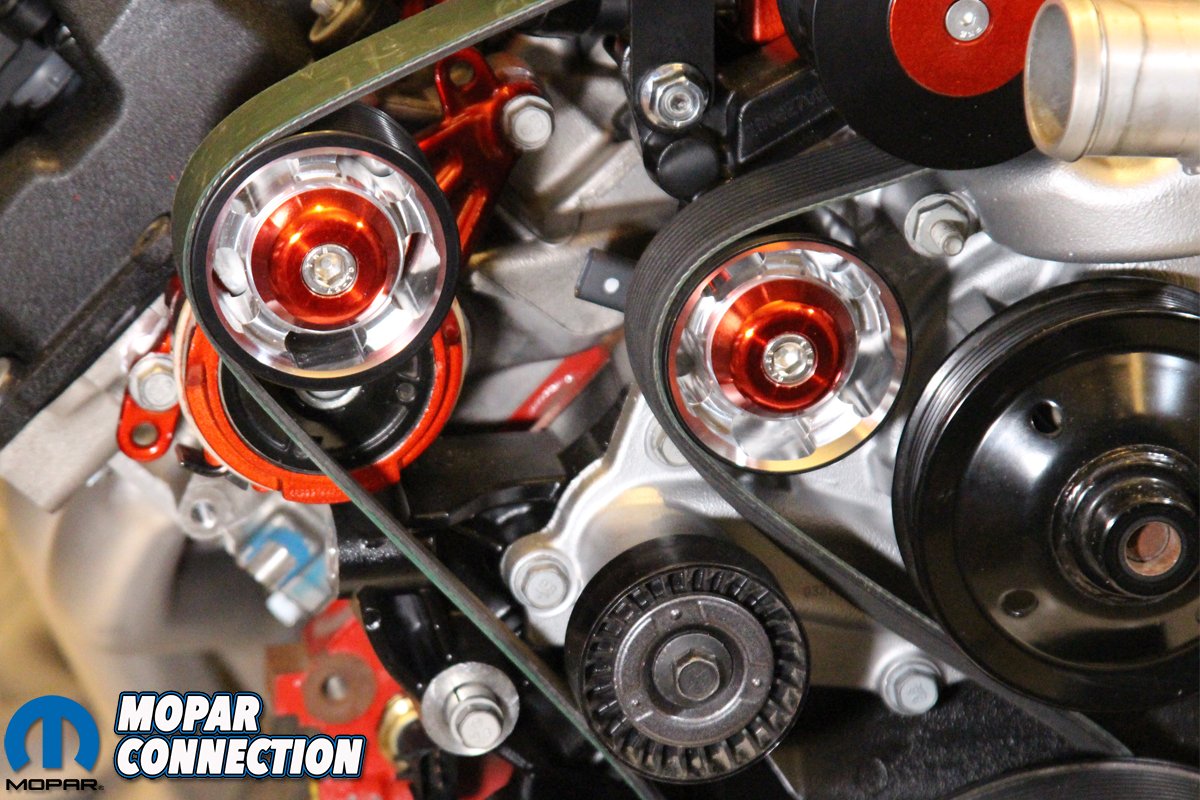

While we loved the looks of the pulleys, we did notice that they were slightly larger than the OE pulleys. “We designed our pulleys slightly larger than the originals for several reasons. One reason is that the 76mm size we use is a standard go-to size for many popular applications,” Rick tells us. “Additionally, the slightly larger diameter of our pulley improves belt wrap slightly at all contact points.”

It became apparent to us that Metco doesn’t skimp when it comes to quality, right down to the bearings that are used on its pulleys. The bearings he uses were carefully chosen for supercharger applications. A detailed consultation with NTN, the manufacturer of the bearings, provides the confidence needed to make such claims regarding the lifetime of the pulleys.

“Our bearings use double oil seals and heavy steel rollers, all in the interest of maximizing the capacity to withstand side load and vibration,” he said. “While they are replaceable, our bearings are maintenance-free and should last forever in a properly set up blower drive.”

After the final round on the CNC, Metco puts the pulleys through a vibratory polish for clean up, and to seal the machined surfaces. The bearings are installed with snap rings, and can be replaced if necessary, however, Rick tells us that would be rare. Before packaging, each pulley is sent through several quality control steps before being spun on a fixture to ensure they meet Metco’s requirements.

Performance Isn’t Just Horsepower

So this begs the question: are there any performance gains when installing these three pulleys to your Hellcat drive system? The short answer is “yes,” but it’s not the kind of performance that puts down bigger numbers on the dyno. The performance is more in line with quality and longevity, plus the pulleys look great when you pop the hood.

Rick tells us, “We have learned an awful lot in over 20 years of manufacturing idler pulleys for supercharged applications. My honest opinion is that there is no one in this industry that takes the care that we do. We cut no corners when it comes to our pulleys.”

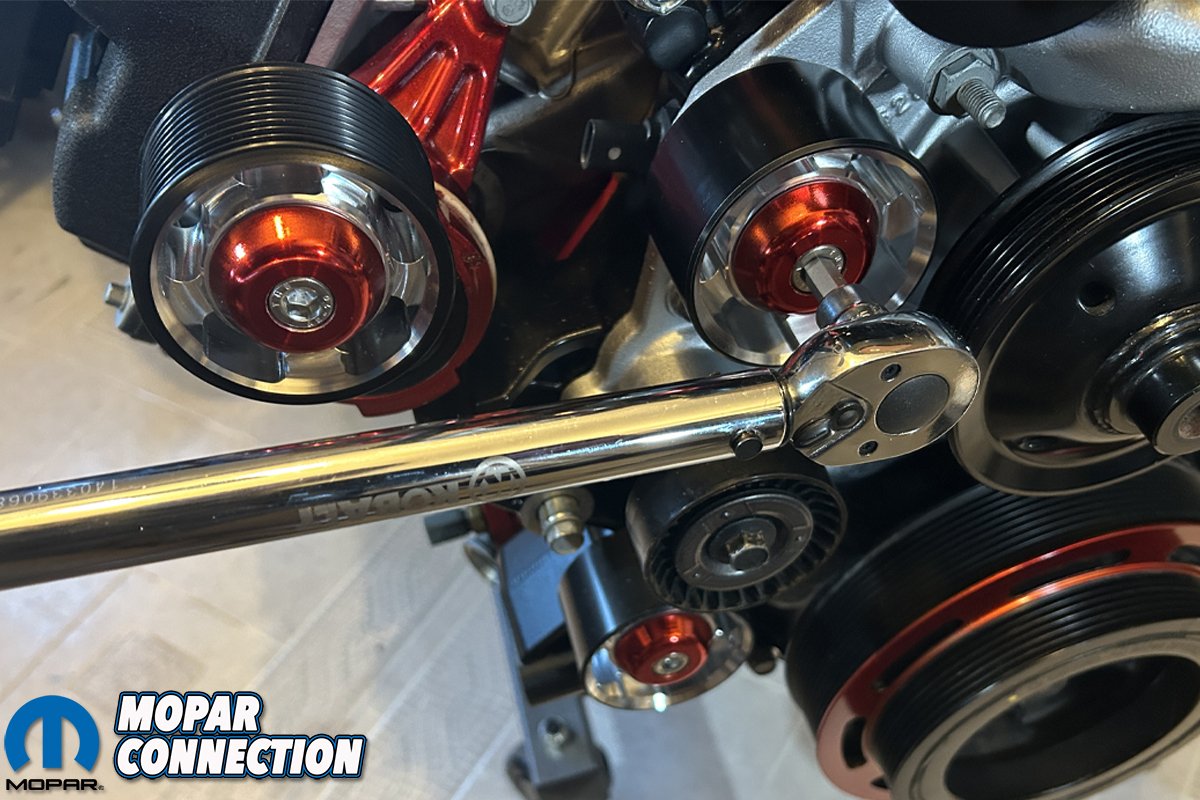

The installation of the pulleys is straight forward, remove the belt via the tensioner, and remove the three bolts that are central to each pulley. New bolts are provided, as is the blue Loctite; the bolts should be tightened to 30 ft-lbs. The best way to replace the supercharger belt is to use the recommended Allen bit on a socket wrench, and put slight pressure on the tensioner pulley.

Rick advises us that when applying pressure on the tensioner, if you notice the bolt turning, it should be loosened and retorqued to spec. Though the pulleys are slightly larger, Rick assures us that the standard belt should be fine, providing the supercharger pulley is the standard 3.35″ diameter.

What About Belt Length?

“We have compiled substantial belt length data for various pulley combinations, and we gladly share this information with our customers. Another important reference when choosing a belt is the tension guide built into the tensioner assembly,” he tells us. He suggests that going shorter to eliminate belt slip can affect every component it touches. “Some belt slip is necessary in a properly set up blower drive,” he tells us.

The factory tensioner has a raised rib cast into it for belt tension. It’s best to have the tensioner centered between the marks, or slightly to the tighter side. The clutch-style OE supercharger pulley will eliminate that belt chirp that is present with a fixed pulley, but Rick assures us that is typical and shouldn’t harm anything.

The Metco pulleys arrived with the billet centers, but we just had to add a little red detail as we did on the supercharger. This left the accessory drive pulleys looking rather anemic; they’re almost begging for an upgrade. How can you resist anything billet when it comes to your engine? It’s jewelry for you engine, and it definitely adds the bling we were looking for.

“We use a military-spec hard-coat anodizing on our pulleys” translation…..we use the cheapest stuff that we could find that kinda works ok, sometimes. silly marketing aside these look great.