Main caps are often a highlight of any block strength conversation and rightly so. Because bolt-on parts like caps and girdles can have such a huge effect on overall strength, their design can be just as important as the design of the block itself. Bill Mitchell Products’ (BMP) engineers know plenty about both and have put the legwork in to create a block assembly with components that are made to work in concert for maximum stability.

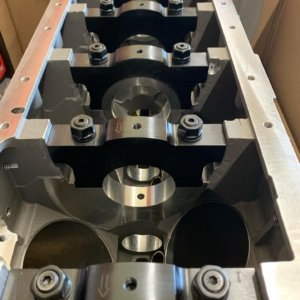

A couple shots of an aluminum block’s cross-bolted caps were recently posted on their Facebook page and they’re pure bottom end beauty. For those not familiar, cross-bolting involves adding extra main cap bolts perpendicular to the two bolts that encapsulate the bearing.

A couple shots of an aluminum block’s cross-bolted caps were recently posted on their Facebook page and they’re pure bottom end beauty. For those not familiar, cross-bolting involves adding extra main cap bolts perpendicular to the two bolts that encapsulate the bearing.

Since those two center bolts are mainly under a tension load (trying to pop the heads off the bolts), the cross bolts add strength in a shear fashion (trying to slice the bolts in half). Both the number of bolts and the fact that the cross bolts are on a different “load plane” add strength to the block by tying the bottom end together in multiple directions.

Block twist and main cap walk can’t be put to an absolute stop, but cross-bolted mains are definitely a huge step in the right direction. While it sounds simple enough, the machining on both the block and the caps needs to be spot-on, so BMP taking care of the pair should ease the minds of the high horsepower hounds.

When I was considering the details of building a reliable street/strip engine, which will probably be 70/30 usage maybe 80/20, but not wanting to compromise any more than neccessary (for the street/reliability side) on power, a stroker motor was the route I had already decided, and it was time to choose a block. What are some characteristics that would provide the power I wanted, especially a wide, fat, flat torque “curve” that makes usable power, “usable” being relative to traction and circumstances, of course. Big displacement was a natural choice! Then there was the issue of making that kind of investment using a factory block, even with the best fortifications, like a girdle and cap system, quality hardware, bore and stroke and the engineering to get the best ratios to get there, so the sum of the parts would work in harmony. Even if I could find a trustworthy builder (I have) that had an inventory of seasoned factory blocks to go through, sonic testing wall thickness, and selecting the best one for my build, I would still be pressing the limits of what the Chrysler RB block would handle, likely require more attention and maintenance, and that would have me at a ceiling that if I were to raise the output from the target of high 6XX-700 HP and torque range for any reason, would have me worried about catastrophic failure, and there goes who knows how much of my investment, and my car would be down for however long it took to repair it. So the revised design in 2019 of the BMP aluminum RB block was the answer for me, with the bonus of taking a lot of weight off the front of my 70 V-Code (non #s drivetrain) Roadrunner. I’m buying mine through Southeast Performance in Tampa, a shop with a tremendous wealth of MOPAR specific experience, and I think the unique design of the Chrysler engine (larger diameter lifters, shaft mounted rocker arms, and so on) requires a builder/designer to really know MOPAR to get the most out of it. A perfect example is that in the power range I want, I will have the natural advantage of a large displacement engine that lends to higher HP/TQ out of sheer size, and flat tappet lifters and cam takes away concerns about long distance stop and go traffic and oiling issues and maintenance that solid rollers may have, as well as the weight, complexity, and RPM limitations of hydraulic roller lifters. Because of the larger diameter of the MOPAR lifter design, I can still have an aggressive ramp to the cam if that is conducive to my goals, without the aforementioned need for a roller lifter.

Although the BMP block can use a 4.5″ stroke without clearancing (572 cu in), I am going to use a 4.25 stroke with the 4.50″ bore (540 cu in) of the BMP block as delivered, which will reduce piston speed and the resulting stresses of the longer stroke a 4.5″ crank would mean. I have a self imposed limit on torque to 700 ft lbs as that is the conservative limit for continuous torque output that my Passon Performance a855 five speed is rated for.

The bottom line is that Bill Mitchell got on the phone with me the one time (so far) that I called them w/a question, and it was about when they were transitioning over from the nodular iron caps to the billet steel caps this article is about, so I would know which one my block would have. Even though the iron caps are fine for my power range, I’m glad it’s going to have these beautiful, stronger than I’ll ever need steel caps. Bill had high praise for Southeast Performance, and I am confident that the BMP block along with the other high quality parts and expert design, machining, and building talents of the Southeast Performance team will leave me with only the concerns of how to harness the power and apply it on the street, and unleash it at the track, and all that is involved with that is being done as much as possible this “round” of service that my Roadrunner is getting now.

Another timely article Kent, thanks!

I wrote a detailed positive comment, but “poof” it’s gone.

Why?

It was never “gone” it just hadn’t been approved yet. Now it is. 🙂

Thanks Kevin. Sorry I jumped the gun, but obviously that comment took some time and effort. Great article and I hope to have the block at the builder soon, and then as budget allows, I’ll get it built up.

If I have it finished and installed by October 2021, I’ll be very happy. Cruisin the Coast is an annual event my wife and I spend the week at, and this year’s event starts in 2 weeks, October 4th thru the 11th.

Did you get it finished in time for CTC? I was there for the week as usual; COVID and the hurricane uncertainty reduced the turnout a little, but a great time as always. I would love to hear how that engine turned out. If all goes well, I will be at CTC this year with my aluminum 433 c.i. 3rd gen hemi-powered ’65 Barracuda.

Got my block ordered from Todd at Marsh performance.He has been great to deal with and help me on my first hemi engine build should be getting block by mid February cant wait.