“Luck is when preparation meets opportunity” is a famous quote credited to the Roman philosopher Seneca. However, a better excerpt could be “prepare, evaluate, and put yourself in the best possible position to benefit from luck when it comes your way.” Semantics aside, J.D. Rudisill, owner of Finale Speed, and his team developed and implemented a carbon fiber 1970 Dodge Charger at the precise time. As good fortune would have it, the Charger garnered the attention of the Direct Connection brass.

In August 2022, at the Dodge Speed Weeks, Dodge CEO Tim Kuniskis announced Finale Speed of Yukon, Oklahoma had been licensed to build carbon fiber 1970 Dodge Chargers for Direct Connection. The carbon fiber-bodied Charger can be made into a complete running vehicle, all handled by Finale Speed. J.D. points out:

“We are in the custom car business, where the customer’s expectations are the priority. Some clients are comfortable with certain things (parts of the construction) and would like to try (them) themselves. It is an honor to build these cars and have the trust of Mopar and its clients. We are pleased to work on a case-by-case situation.”

The carbon fiber Charger bodies are engineered to factory specifications. Yet, each Charger comes with a late-model drivetrain to provide modern muscle car performance with a facade of the original muscle car era.

Of all the Mopars built over the years, why a 1970 Charger? J.D. explained, “The 1970 Charger is one of my favorite cars. The 1970 Charger has an aggressive look; it screams muscle car, big horsepower!” Each Charger built by Finale Speed starts as an original 1970 Charger with a vehicle identification number (VIN) and a title. By having both, registering a Charger in any state should be straightforward and hassle-free.

Once a Charger is sourced, it is disassembled, cleaned, and modified for the late-model drivetrain and the carbon fiber panels. The Charger’s original upper firewall, steering column bracket, door hinge area, and package tray remain intact, but the rest of the Charger is fabricated.

The unibody is replaced with a Salvaggio Chassis constructed by Wisconsin-based Dave Salvaggio, who holds several patents for carbon fiber manufacturing processes. He has produced multiple award-winning SEMA muscle cars since 2006. Furthermore, he has constructed many Hollywood movie feature vehicles.

J.D. stated, “The carbon fiber bodies are attached to the Salvaggio Chassis at Brothers Composites, a Wisconsin-based company. Then Brother Composites handles the metal inner structure welding and bonding the inner rocker panels to the frame rails.”

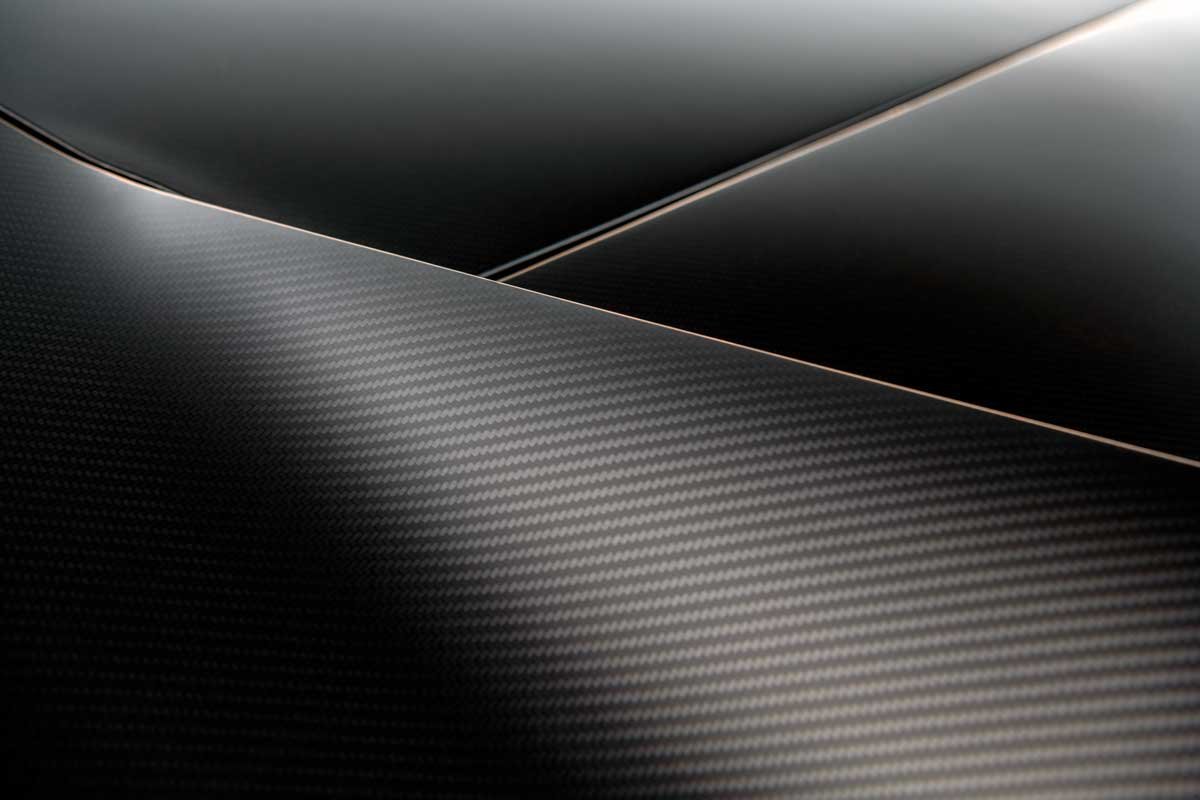

Finale Speed utilizes prepreg autoclave-cured carbon fiber to strengthen the Charger. Traditional high-pressure autoclaves have always been favored for manufacturing carbon fiber prepreg composite and are widely used in the aerospace industry. Prepreg composites can provide ultra-lightweight carbon fiber components that offer excellent aesthetics with zero air voids, which can only be achieved using the autoclave manufacturing method.

The Charger’s floor pan is a modular unit formed of carbon fiber. The trunk floor will be one-piece carbon fiber, with the trunk sides custom-made and wrapped in vinyl, showcasing the audio components. Additionally, Finale Speed has replacement carbon fiber panels (exterior and interior) should an unfortunate incident with the Charger occur.

Finale Speed stuffs in a 6.2-liter Hellcrate supercharged 717 horsepower Hemi engine to motivate the Charger. The Hemi comes with a Mopar Front End Accessory Drive (FEAD) kit, which includes an alternator, power steering pump, pulleys, and all the mounting hardware. The Hemi is attached to a Tremec T56 Magnum 6-speed manual transmission to multiply the engine’s torque. The torque then passes to a 3.89:1 geared posi-traction 9-inch rear end.

Finale Speed employs Detroit Speed products for the front and rear suspension. “After many years of trial and error, the combination has proven to be very reliable, but if a client requested a specific change, we would always listen. That is the great part of a custom car,” J.D. revealed.

The front suspension design is a short-long arm design that exceeds anything Mopar offered in 1970. The Detroit Speed control arms, k-frame, and rack and pinion bring the Charger into the 21st century. To accompany the Detroit Speed parts, a pair of Ultimate Performance/JRI coil-overs maintain the Charger’s ride height and control the spring oscillations. The front end has fully adjustable ride height, caster, camber, and toe measurements to fine-tune the Charger’s performance and ride quality.

For the rear suspension, Finale Speed incorporates a Detroit Speed unequal-length four-link design with a Panhard rod. The four-link suspension allows for wheelbase modifications with the bottom links. In addition, the top left link permits pinion angle adjustments, and the top right link is designed to install preload if necessary to remove any deviation from straight-line acceleration. Lastly, the Panhard rod provides adjustability to raise or lower the rear roll center.

The Charger’s interior is just as impressive as its exterior. The seats are custom leather-wrapped TMI Highback seats, which provide a modern-looking seat with thick thigh bolsters and a supportive back. While the seats are stylish and comfortable, they are designed to keep the occupants properly located during high-performance events.

In addition, the headliner is constructed of an impressive high-line synthetic material called Alcantara. “We are currently working with a local company on each vehicle so the client will have the ability to pick the way the interior is finished out,” explained J.D.

In keeping with the carbon fiber theme throughout the Charger, the instrument bezels are made of carbon fiber and trimmed in black Alcantara. Housed in the cluster will be an array of gauges, including a 200-mph speedometer, to monitor the engine’s vitals and charging system.

A unique carbon fiber console is in development, and it will house a double din touchscreen to control the interior creature comforts and the audio system. Speaking of the audio system, Finale Speed fits a high-end Mosconi 5-channel amp, four Focal Component speakers, and a Focal subwoofer into the Charger. The amp and subwoofer are strategically located in the finished trunk. The result of the layout is a sound quality as good as any modern system.

The rolling stock for the Charger consists of Forgeline three-piece wheels, 18x12s on the rear and 18×8.5s on the front. The tires are all Z-rated, with 335/30/18 tires on the rear and 245/40/18 tires on the front. Finale Speed will work with the client to achieve the desired wheel appearance. As seen in the photos, a client can order a “steelie” wheel finished with dog dish caps, or Finale Speed offers an upgraded wheel option constructed of carbon fiber.

Lastly, to bring the Hemi Charger to a halt, Finale Speed utilizes Wilwood 14-inch Aero disc brakes on all four corners. The front calipers are a 6-piston design, while the rear units are a 4-piston arrangement.

Finale Speed hopes to complete 18 to 20 cars per year. The nine-person team will work on two Chargers at a time, and with the team’s dedication to perfection, each Charger will take several months to complete. J.D. proudly explained, “We strive to push the boundaries and create the most sought-after muscle cars the world has ever seen. Our team takes 2500 hours to craft each vehicle with uncompromised precision and attention to detail.”

If a carbon fiber masterpiece endorsed by Direct Connection is desired, Finale Speed is currently accepting orders. After that, the company will meticulously work to construct a one-of-a-kind Charger built to its client’s aspirations. So act now to get a Charger of the past, present, and future.

2022 Sema Show Podcast (Interview starts at 12:43 minutes)

Video Introduction starts at 9:30 minutes

How much is the 70 charger?

The bare roller is $200K.

70 charger great…now time for a barraduda!

So the car is all carbon, BUT no one says how much the completed car could weigh. I realize that options could and would change the weight. How about a span or an about?