Getting the lead out was the battle cry of the 1970s, and as a result, in the United States, leaded gasoline was gradually phased out. The U.S. Environmental Protection Agency (EPA) began regulating lead in gasoline in the mid-1970s, and the use of leaded gasoline for most on-road vehicles was prohibited by 1996. Banning leaded fuel resulted in significant improvements in air quality and public health.

Above: Local to us was a gasoline station with 87-octane E10 and 90-octane E0 fuels. The plan was to run our 273-equipped ’67 Dart on E10 and then switch to E0 to determine which gasoline would provide the best fuel economy and which would be more cost-effective.

Gasoline’s anti-knock index (AKI) is determined by adding the Research Octane Number (RON) to the Motor Octane Number (MON) and dividing the result by two. With the ramp down of tetraethyl lead as an octane enhancer, gone were the days of Regular 94 (90 AKI), Premium 100 (96 AKI), and Super Premium 104 (100 AKI) gasoline.

Alcohol, specifically ethanol, has been added to gasoline for various purposes for decades. One of the primary reasons for adding ethanol to gas is to increase the AKI of the fuel, which can enhance engine performance and lower instances of knocking. Ethanol is believed to help reduce engine emissions and decrease the overall carbon footprint of gasoline.

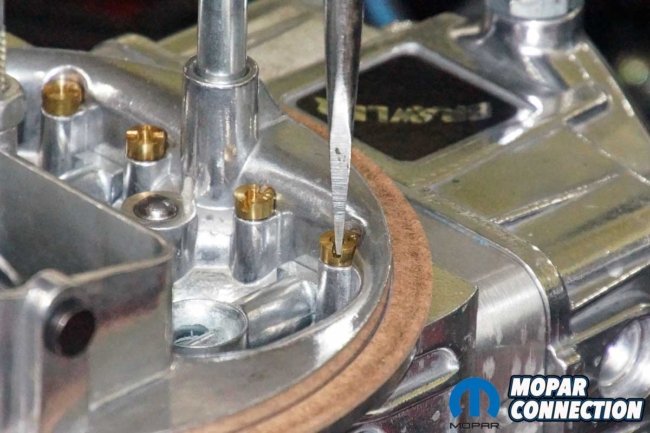

Above Left: A Brawler 570-cfm carburetor was fitted onto the Dart a few years ago. The Brawler is highly adjustable, so we used the adjustability to fine-tune the carb. Above Right: For instance, we swapped the air bleeds to help lean out lambda (air/fuel ratio) to achieve excellent driveability, producing the greatest fuel economy.

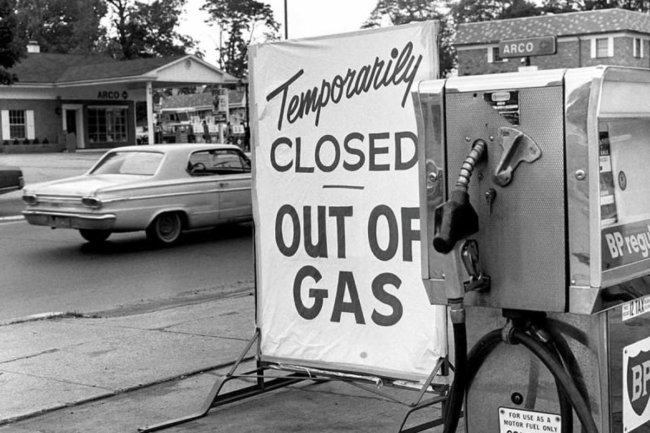

Adding ethanol to gasoline gained significant momentum during the latter half of the 20th century, particularly during fuel shortages or when there was a need to reduce reliance on fossil fuels. Ethanol began as an oxygenate additive in gasoline to reduce carbon monoxide emissions and improve air quality.

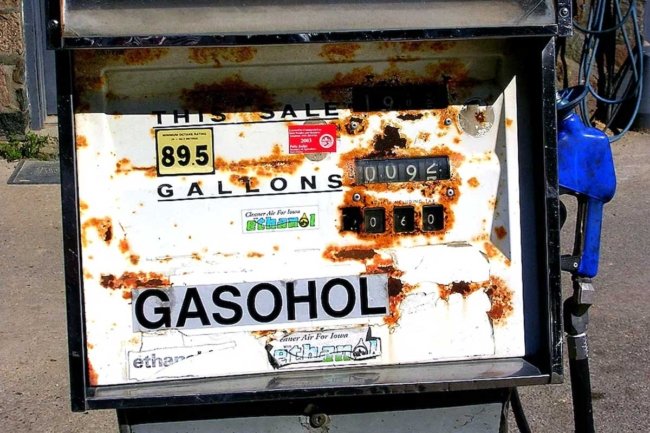

The widespread use of ethanol as a fuel additive in the United States became more prominent during the 1980s and 1990s. Amendments to the Clean Air Act in 1990 mandated using oxygenated fuels in areas with air quality problems, which further contributed to ethanol in gasoline. Adding ethanol to gasoline has evolved from the “Gasohol” of the 1970s to the unique blends of up to 10% ethanol fuel used today.

Above Left: The last step to tuning the carburetor was adjusting the four-corner idle screws. We had already checked and changed the float levels, jets, discharge nozzles, accelerator pump cams, secondary vacuum actuation, power valves, choke, and air bleeds. Above Right: The Brawler fits comfortably atop the Edelbrock LD4B manifold and under a factory air cleaner assembly.

Many states have introduced unleaded fuel without ethanol, and we wanted to evaluate the difference in gas mileage between E0 (pure gasoline with no ethanol) and E10 (gasoline blended with up to 10% ethanol). Generally, ethanol contains 3 to 4% less energy per unit volume than 100% gasoline, leading to a decrease in fuel efficiency of approximately 4.29% when using E10 compared to E0. E0 fuels are blended with higher concentrations of octane-improving chemicals, known as aromatics, which, unfortunately, increase the production of exhaust contaminants.

The test vehicle was a 1967 Dodge Dart with a 273, 904 Torqueflite, and an 8 ¾-inch 2.94:1 geared rear end. The 273 has stock internals but has been fitted with an Edelbrock LD4B manifold and a 570 cfm Brawler carburetor. A Pertronix Digital HP distributor and control box manage the ignition chores.

Above Left: A Pertronix Digital HP distributor, coil, and module handle all the ignition needs on the Dart. The system is highly adjustable, allowing us to dial in the ignition timing. Above Right: Our Sun 404 distributor machine established an optimized spark curve that worked effectively with the 273.

The Brawler was fine-tuned during the summer of 2022 by adjusting the jets, power valves, air bleeds, and accelerator pump discharge nozzles. The ignition timing was also optimized with an initial timing of 16° Before Top Dead Center (BTDC) and a centrifugal advance of 22° for 38° BTDC total timing. The vacuum advance of 15° pushed the timing to 53° BDTC when cruising.

Above: The 273 is stock, except for hardened exhaust valve seats and the Brawler carburetor. The engine’s compression ratio is 9:1, so the low compression would not tax the octane of either fuel being tested.

The plan was to fill the Dart’s gasoline tank with 87-octane E10 fuel from the same Sheetz convenience store and drive around the lovely countryside of central PA. Driving would consist of a blend of city and highway. After running approximately 700 miles, we would switch to 90-octane E0 fuel from the same store. We would again drive the same roads previously driven to reduce the variables.

The costs, miles driven, and gasoline consumption would be factored for each fuel. Before we started the testing, we checked the speedometer’s accuracy on the Pennsylvania College of Technology Mustang Chassis Dyno, and apart from a noticeable variance at 10 miles per hour (MPH), the speedometer was accurate within 1% at each 10 mph increment from 20 mph to 70 mph.

Above: To ensure our Dart’s speedometer was accurate, we tested the speedometer on Penn College’s Mustang Chassis Dyno. The speedometer was on point from 20-70 mph. Our city and highway driving would fall within those speeds. Seeing we were on the dyno, we tested the performance of our fuel economy tune. The engine torque peaked at 182 lb-ft at 3600 rpm, and the peak horsepower was 144 at 4900 rpm.

During our 732 miles on E10 fuel, we averaged 16.30 miles per gallon (MPG), which was 3.4 MPG better than the factory four-barrel 273 engine rating of 12.9 MPG on leaded fuel in 1967. The cost per gallon during our evaluation ranged from $3.499 to $3.869 for an average cost per gallon of $3.665 for the 44.90 gallons purchased. Driving the Dart on E10 fuel cost us $0.2241 per mile based on the average price, gallons consumed, and mileage.

To ensure that almost all the E10 was consumed, we filled the gas tank several times with E0 before starting our comparison. We again visited the same Sheetz store for the evaluation and used the same E0 pump for all the fill-ups.

Above Left: The good ole’ 1970s. Gas shortages and rationing were common in the early-to-mid ’70s. (Photographer H. Armstrong-Roberts-Classic Stock-Getty). Above Center: Ethanol was blended into the fuel to reduce the dependence on foreign oil and return octane to the fuel after removing the lead. However, the fuel, called gasohol, was not greatly embraced at the time because the carburetors were tuned for E0 fuel, and the alcohol had a different stoichiometric value; thus, the engines ran poorly if not re-tuned. (Photographer unknown) Above Right: Signs tried to ease the pain by providing claims of the fuel’s greatness. (Photographer unknown)

Although E0 fuel has a 90-octane rating, our 9:1 compression ratio of 273 did not need or benefit from the extra octane numbers. For the experiment, we did not attempt to optimize the carburetor or adjust the timing to squeeze out the last droplet of fuel economy.

Convinced all the E10 had been burned from the system, we put 685 miles on the odometer running on E0. We were pleased with the nearly one extra MPG the E0 afforded us. However, the cost of the fuel ranged from $4.259 to $4.699 that averaged $4.632 per gallon, which was almost a dollar more than the E10 fuel. We burned 39.76 gallons of fuel for a 17.23 MPG average. The E0 cost over $0.05 more per mile than the E10, with the cost per mile rising to $0.2686 per mile.

Above: The E10 fuel averaged $3.665 ($3.869 on this day – most expensive during the testing). The E0 gasoline averaged $4.632. Although the E0 provided better fuel economy, the cost break point for E0 to be more cost-effective is more than $0.20 more expensive than E10 fuel. Based on the averages of the fuel costs, and even on the day the photo was taken, the price of the E0 is well beyond the $0.20 break, which means the E10 is more cost-effective.

Crunching the numbers, with the E0, we ended up with a 5.889% increase in mileage. Due to the reduced heat value of the ethanol in E10, it should have a reduction of 4.29% in mileage compared to E0, so we did better than expected. However, the cost was a staggering 16.5% greater than E10.

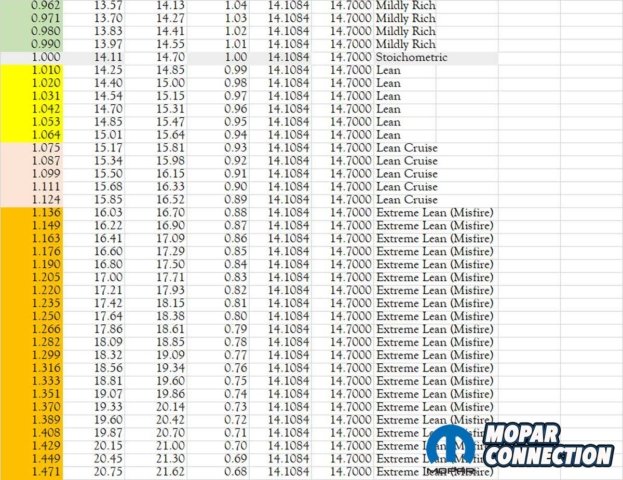

The driveability differences between the two fuels were nearly unnoticeable. When idling, both gasoline blends steadied in a range of 0.885 to 0.920 lambda (refer to lambda charts for air/fuel ratio comparisons), and when cruising, lambda was 1.04 to 1.08. The only noticeable difference was with the E10; when driving 55 to 60 miles per hour with a light-throttle pedal application, a faint repetitive rumble emanated from the engine that was not perceptible with the E0.

Above: The lambda charts show the air/fuel ratios corresponding to the lambda numbers. Although the lambda numbers were similar between the two types of gasoline, the E0 was “leaner” than E10, as shown in the charts.

Although costly, a great advantage of E0 comes into play for limited-use engines, such as seasonal vintage vehicles that will never see wintertime driving. Not only does E0 have higher octane, but it also has long-term storage capabilities of up to three years. The lengthy storage characteristics are due to the lack of ethanol, Methyl tert-butyl ether (MTBE), or oxygenates.

Above: The best part of the experiment was the opportunity to drive many of the back roads of central Pennsylvania. The beautiful countryside and the nice weather made the evaluation process quite enjoyable. Almost 1800 miles rolled across the odometer between the E10, transition period, and E0 portions of the testing process.

At the time of the editorial, the price break that would make E0 advantageous over E10 would be if E0 was no more than $0.20 more expensive than E10, but in PA, we are nowhere close to that; thus, E10 is the winner from a cost analysis. We will continue using E10, but toward the end of the car show season, pouring in a tank or two of E0 will be the plan to take advantage of the long shelf life of E0 and its lack moisture attracting ethanol.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by