A little while ago, Mopar Connection Magazine published a feature on Holley’s rolling laboratory ’66 Dodge Charger. The B-body served as a solid template from which to begin developing a wide swathe of the company’s quickly expanding third-generation Hemi engine swap catalog. Besides a quickly failing battery, the first-generation Charger was a solid driver that deftly maneuvered through downtown Bowling Green, Kentucky traffic as well as chirped the tires at ease whenever the throttle was goosed.

What we may have left out was the matching fire engine-red ’99 Dodge Dakota R/T that accompanied our test drive of the Charger. That same rainy morning made for less than ideal conditions for the kind of aggressive driving we had in mind that day, so we refocused on both vehicles overall drivability. Similar to the Charger, Holley hunted down the cleanest, most complete specimen the team could find to perform its trial fitting.

This shortbed was picked up for a reasonable $6,500. Again, the completeness of the truck was the most appealing factor. Sure, it was an original 5.9-liter Magnum-equipped R/T, but most of the factory running gear was destined to be replaced shortly. Simultaneously, a 6.4L Hemi was sourced from a wrecked ’15 Challenger Scat Pack. Wanting only the powerplant itself, Holley fitted the modern Hemi with their Gen III Hemi VVT and SRV harness for Terminator X and X Max systems (558-132).

Using the Terminator X served another purpose as it controls the Hughes Performance-built 46RE 4-speed electronically-shifted overdrive transmission. Only a separate control harness for Terminator X and X Max (58-473) was needed to make the gearbox shift. A Hughes lock-up converter, B&M deep transmission pan (10280), cross member (BHS542) and Holley’s 46RE transmission adapter (BHS529) were needed to button up the transmission.

The Hemi itself didn’t require much save for some minor bolt-ons: Hooker long tube headers (BH2374), Holley conversion motor mounts (BHS541), a K-member filler plate (BHS543), alternator bracket (97-368) and Holley’s Power Steering Kit, which includes a Saginaw Type II pump, brackets and pulley for 2014-up 5.7L and 6.4L (97-382) ensured that the steering was on point. Holley’s Frostbite brand provided fan and shroud kit (FB502H) to cool a then-prototype radiator, which will be made available shortly.

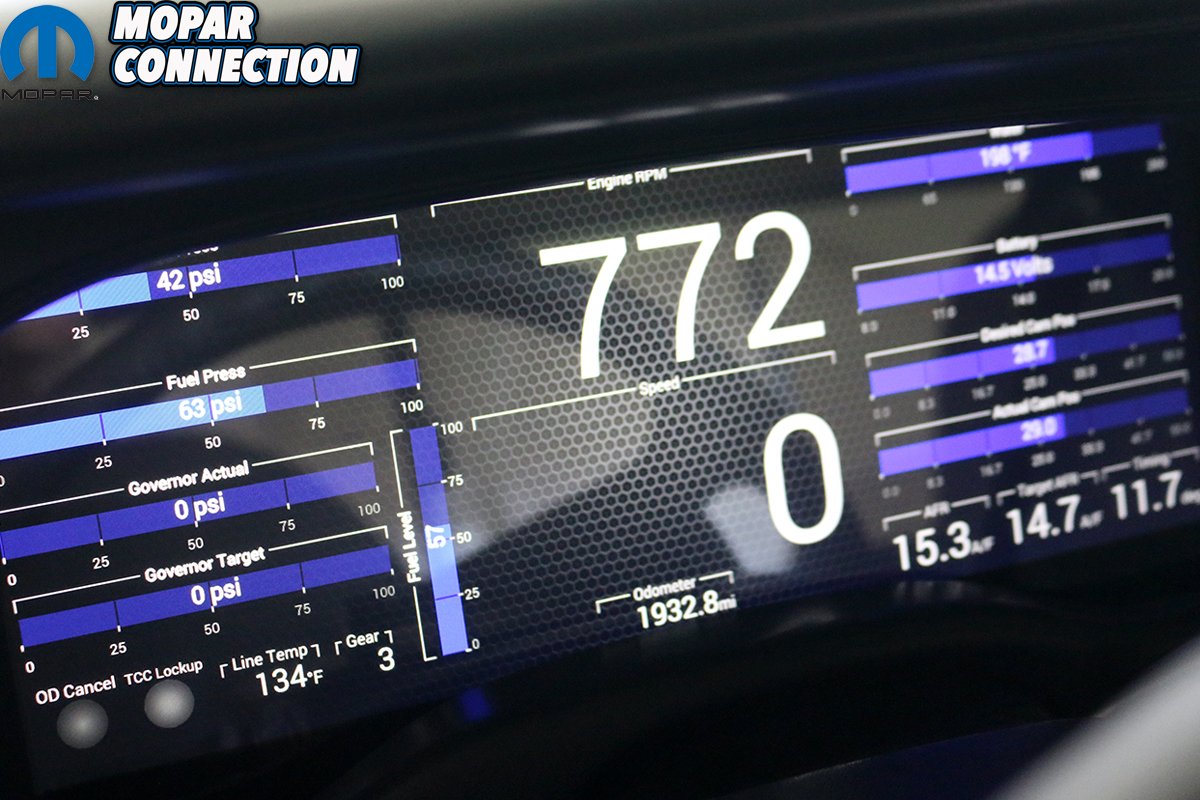

Moser Engineering rear axles replace the factory axles and are spun by an Inland Empire drive shaft. Although riding on drag radials, the Dakota would wheel hop like a monster were it not for a set of Calvert Racing Cal-Trac bars. The final piece was a sly piece of customization, replacing the factory gauge cluster with a Holley EFI 12.3-inch Pro Dash. Drivers are able to toggle through a handful of layouts and gauge readouts providing every inch of data you could possibly ask for.

The completed build is weirdly deceiving. The entirety of the truck feels as if Dodge had never ceased producing the mini-truck, only graduating its engine offerings over the years – all except the small “Hemi” call-outs on the fenders and cleverly replacing the “5.9” with “6.4” in the decals. Very little of Holley’s Dakota alerts the observer that this is not a factory-built car, and that’s exactly the target Holley was aiming for.

Slipping behind the wheel, the Gen III Hemi growls to life and mellows to a baritone burble at idle. Shifting through the gears, the Hughes Performance 46RE rolls through the gears effortlessly. Romping on the skinny pedal returns with a roar and a quick downshift. It was still pretty wet out, so we didn’t stand on the Dakota as much as we would’ve liked to but that’s OK. What we got was enough to convince any bystander that the lightweight pickup meant business.

We drove the Dakota through town, rolling up and down the shift pattern as midday traffic ebbed and flowed. Hard stops didn’t have the truck roll over its nose or feel weirdly imbalanced. Rather, the Dakota served as a very mild commuter, which suddenly made us want to build one for our day-to-day activities. Mini-trucks were always a bit anemic; even the 5.9L felt a little watered down until heavily modified. For those living in more lenient emission states, a Gen III Hemi swapped Dakota could be a perfect fit.

And as Holley’s Bryan McTaggart emphasized, all of the products used can be purchased by customers to replicate their own build. “The whole idea was to show people what they could do using Holley’s performance catalog,” McTaggart explained. “It’s a proof-in-concept sorta thing. We did it, now you can.” Mopar Connection has covered John O’Malley’s “Hellkota” build for a while now, and while a Hellcat-powered Dakota might be pretty “out there” for most folks, a 5.7L or 6.4L could definitely be in the cards.