Roller rockers rack up a lot of publicity but, for the budget-minded brawler, stamped steel factory rockers are actually pretty serviceable when set up properly. As the Hughes Engines Tech Center explains, one key to valvetrain life is in the interface between rocker and valve stem tip:

The rocker arm geometry when using a stamped rocker arm, such as OEM Big Block, Small Block, or Magnum can affect valve guide wear in dramatic ways. The point at which the stamped rocker arm contacts the valve tip is very important in determining the life of the valve guides, and to some extent, the life of the valve.

The rocker arm must strike the valve stem on the top of the stem, which will cause the valve to move down. The problem is when the rocker arm contacts the valve stem on the edge “corner” first, then moves across the flat top of the stem. This causes the valve to try to “tip over” forcing the valve stem strongly against the guide wall, wearing the guide out prematurely.

This situation was not much of a problem on the Big Block and on the LA small blocks, because the rocker arms were all on one shaft – and the valve stems were larger (3/8”) having more bearing surface for the guide. The Magnum 5.2 and 5.9 engines on the other hand have a lot working against them. Each rocker, valve stem, pushrod, lifter, and cam base circle can affect the geometry on each valve and can all be different.

The stack-up of tolerances in each individual valve train part can easily be different, causing some valve stems and guides to suffer wear when the ones next-door are fine. The problem can be identified and corrected during rocker arm installation and cured very early before final assembly. To check the geometry, identify the valves on one particular cylinder and rotate the crankshaft/camshaft until you are at TDC on the compression stroke. Install the lifters, pushrod, rocker arm, and hold-down hardware. Now, look at where the rocker contacts the valve tip.

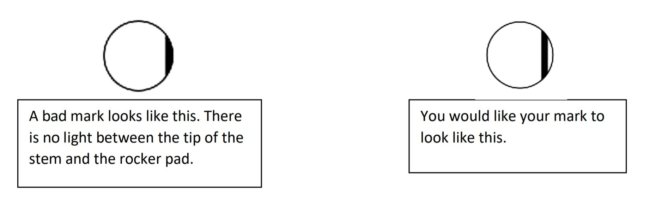

In Figure 1, you can see a tiny bit of light between the valve tip and the rocker pad on the rocker stud side of the valve tip. The rocker will try to push the valve stem down – this is good! In Figure 2, the rocker pad is hitting on the “corner” of the stem, pushing the stem against the guide, causing it to wear – this is bad.

There is yet another way to check the contact point before assembly. Use a felt tip pen (Sharpie) to cover the valve tip and the rocker pad. Assemble as before. Once the rocker hold-down bolt is tight, push the rocker pad to wipe across the valve tip and the rocker pad. Disassemble and look at the marks.

This problem is not uncommon, but it will not affect every rocker. They are all independent of each other, so you should check them all. How to fix the problem: Raise the rocker trunion. A small washer (approximately .040” thick) usually takes care of the problem. If you use a washer that is too thick, you may reduce the lifter pre-load and make the lifter noisy.

Hughes engines has special washers – .038” thick, that fit between the rocker pedestal and the guide plate (Part number 1719). $.50 each, $8 for 16 + shipping.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by