There are several qualified shops that can restore your original, date coded, 6-Barrel carburetors. But if you are wanting them as correct as possible there is only one choice: The Holley Custom Shop. After all, Holley did make them in 1969! The Custom Shop has been restoring carbs since the 80’s. The shop was originally located in Tennessee, but now resides in Bowling Green, KY at the Holley manufacturing headquarters. Their location may have changed but the quality and attention to detail to bring these carbs back to original condition have stayed the same.

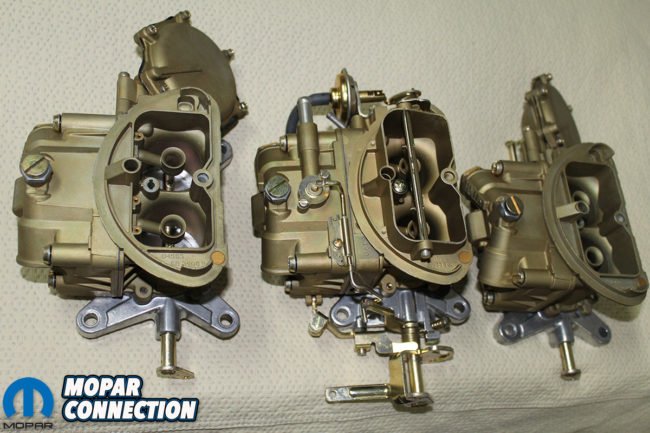

The Custom Shop not only restores Holley carbs but can also restore original equipment produced by other manufacturers. In this article we will focus on the date-coded Six-Pack set up from a 1969½ A12 Road Runner, 4-speed car. From the date of arrival until you’re holding them in your hands, the Holley Custom Shop can have them finished and back to you in 6 weeks. And no, not with new carbs but with your carbs. Wow! That is amazing. We took our set of original 1969½ date-coded 4-speed carbs to the Holley Custom Shop to experience “first hand” what they can do.

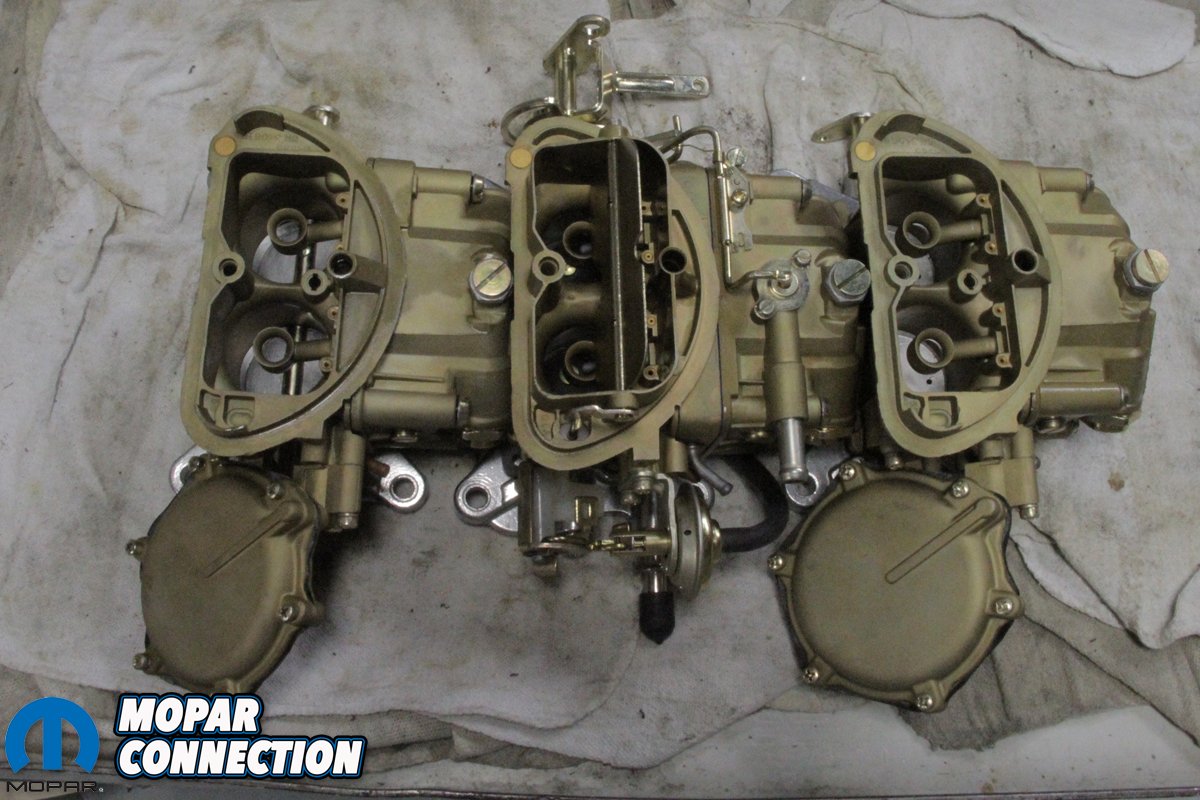

Top far left: Driver’s side of a 1969½ 440 Six-Pack carbs and intake, complete with the hard-to-find linkage. Note the worn original finish with hardly any original plating. Top center left: Passenger side of a 1969½ 440 Six-Pack carbs and intake, complete with the fuel lines and vacuum lines. Center carb was incorrectly plated at one time in its life. Top center right: In 1969 the intake was manufactured by Edelbrock and was made of aluminum. In 1970 Chrysler took over and made the intake from cast iron. Speculation says because of supply problems and cost savings. Top far right: Even though the intake was made by Edelbrock you will find the Chrysler part number cast into the runner.

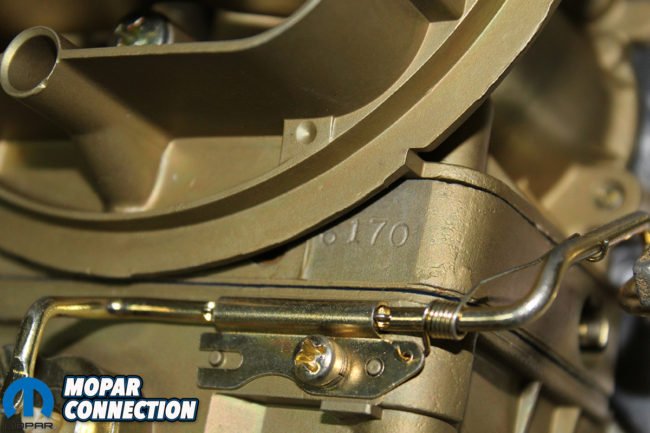

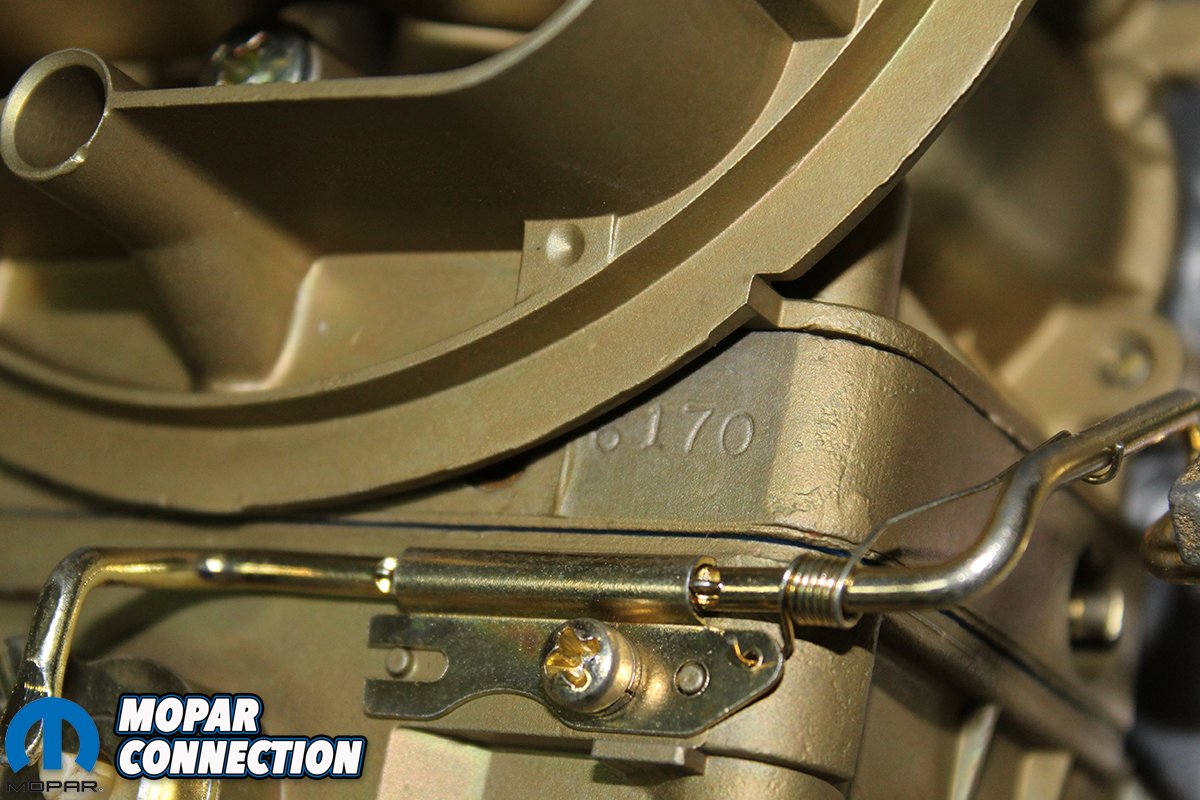

Bottom far left: Fortunately, the bases, linkage, and butterflies are all original and in good working condition. Be sure and check to see that they are not warped or cracked. Bottom center left: Here is the “list number” and date code for the front outboard carb proving this is indeed an original date coded carb. The 0929 date code is the 92nd day of 69 and the List – 4393 is the front carb. Bottom center right: Here is the “list number” and date code for the rear outboard carb. The 1999 date code is for the 199 day of 69 and the list -4394 is the rear carb. Bottom far right: The center carb “list number” and date code are found on the horn of the carb. The 1229 date code is for the 122 day of 69 and the List – 4391 confirms the carb is for a 4-speed A12 car.

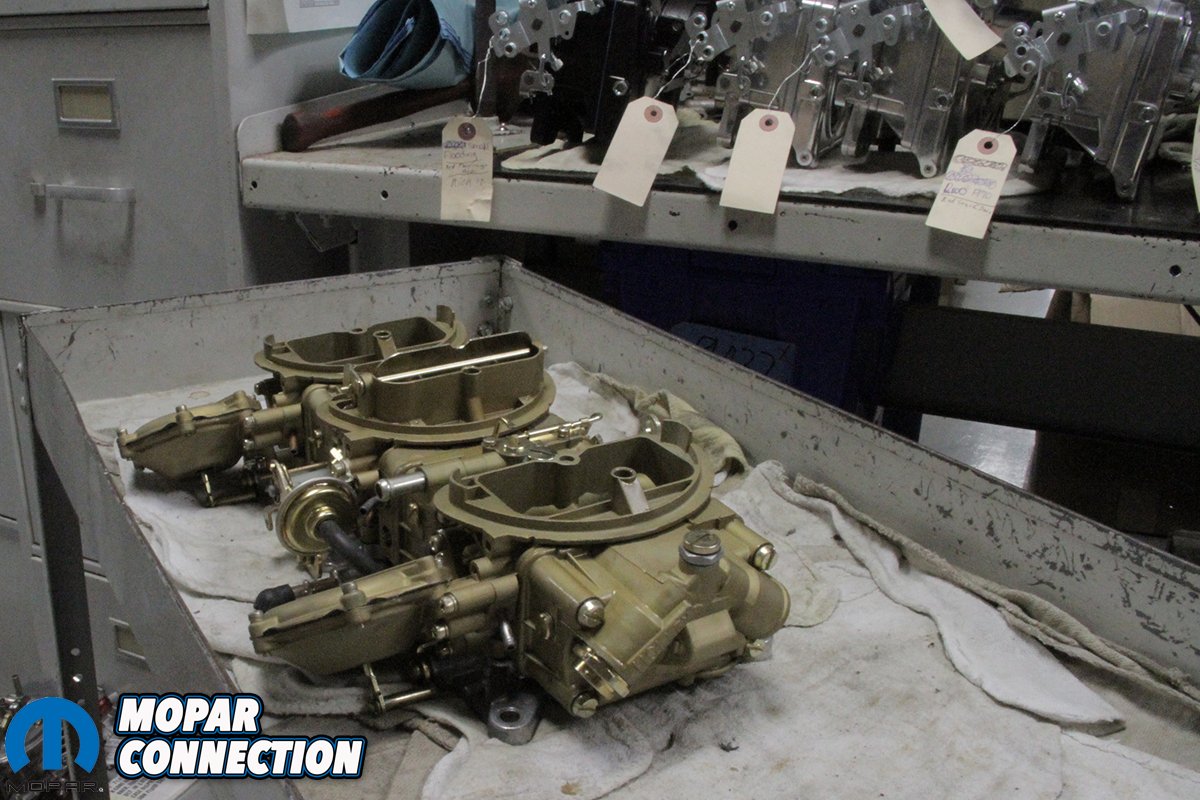

These guys have the process of making sure you get your original carbs back in original condition, and working correctly, down to a science. Upon receiving your carbs, they are assigned a job number, photographed, and disassembled. The technician then analyzes and identifies any damaged or missing parts. These parts are replaced with the correct original equipment (or equivalent) depending on their availability. Then, when you get your carbs back, they will include any parts that were defective or could not be used.

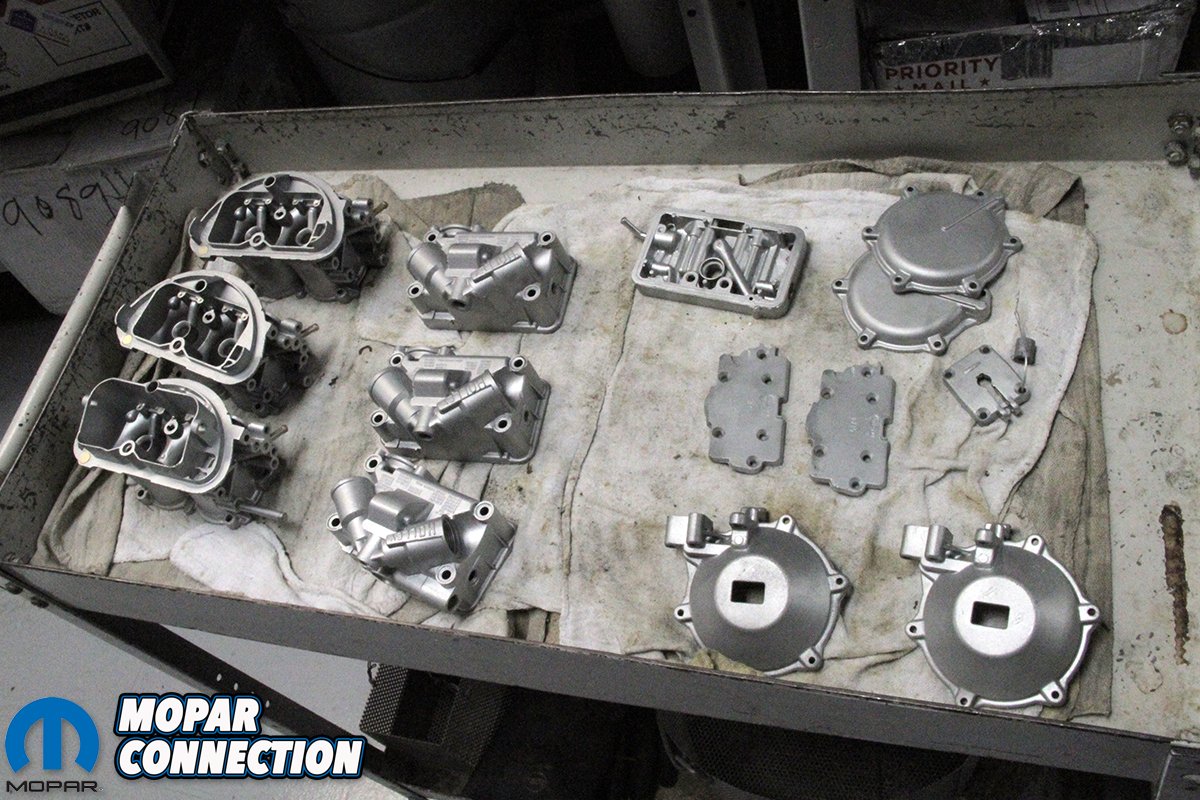

The parts are cleaned using the appropriate process required for each type of metal that each part is made of. This could be either dry media blasted, hydro-media blasted, or immersed in a large vat with media and soap that is constantly being vibrated. Once the parts are all clean, the different plating processes begin.

Left: By labeling, photographing, and assigning a specific job number to each carb, you are guaranteed to get back your original carb in better than new condition in tested, working condition. Right: Any defective or incorrect parts are returned to you with your completed carbs. That way you know exactly what was replaced.

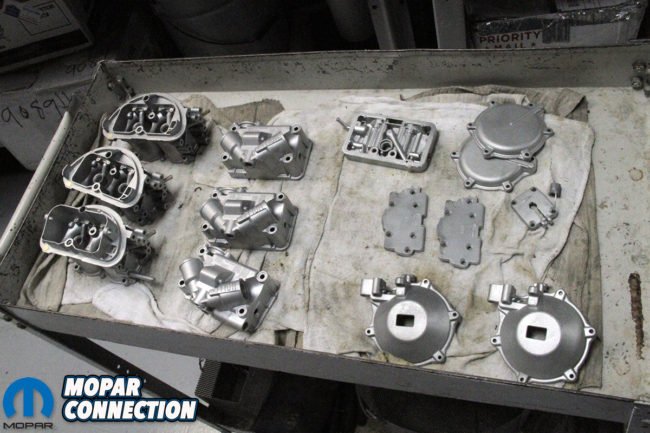

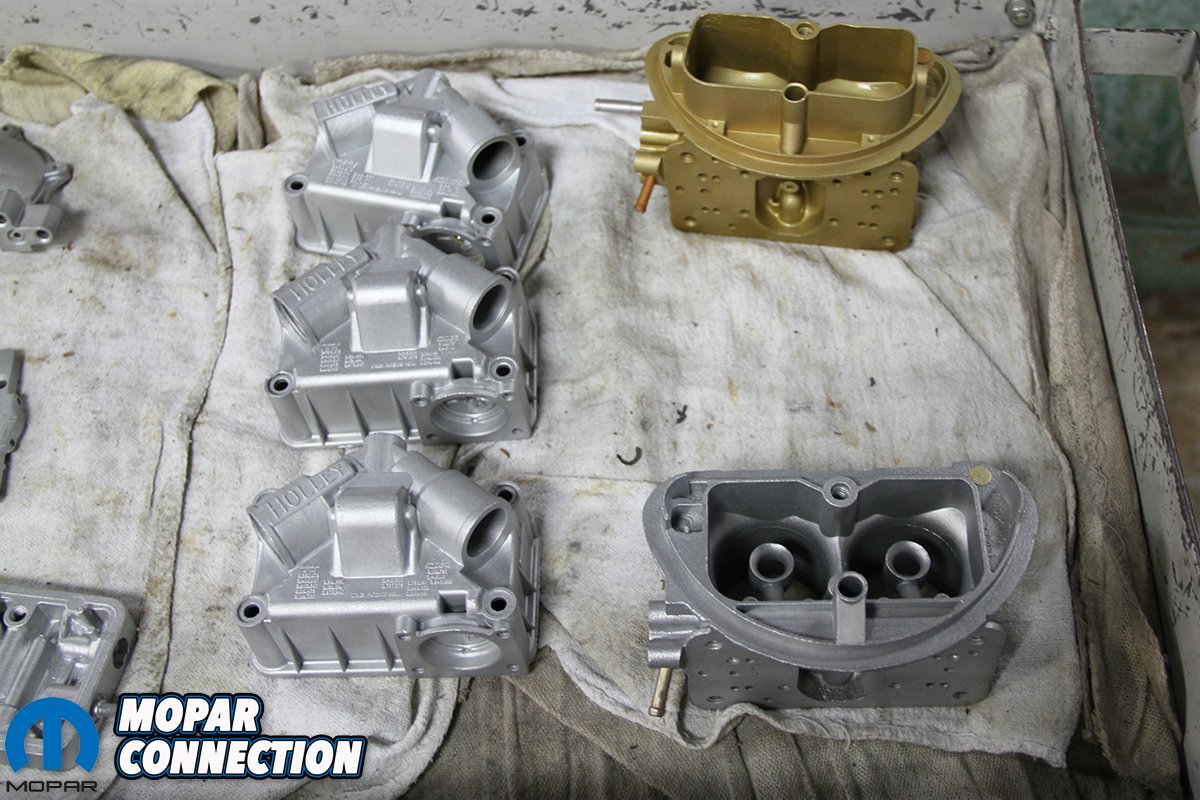

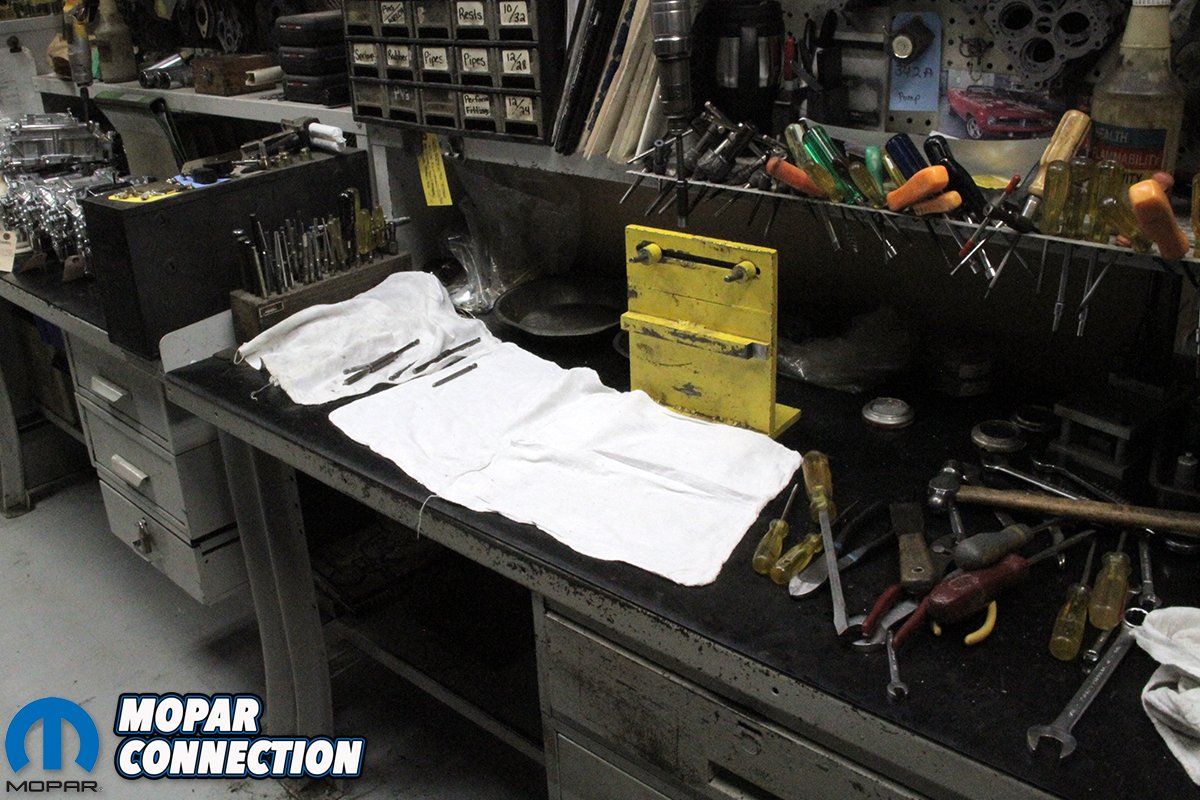

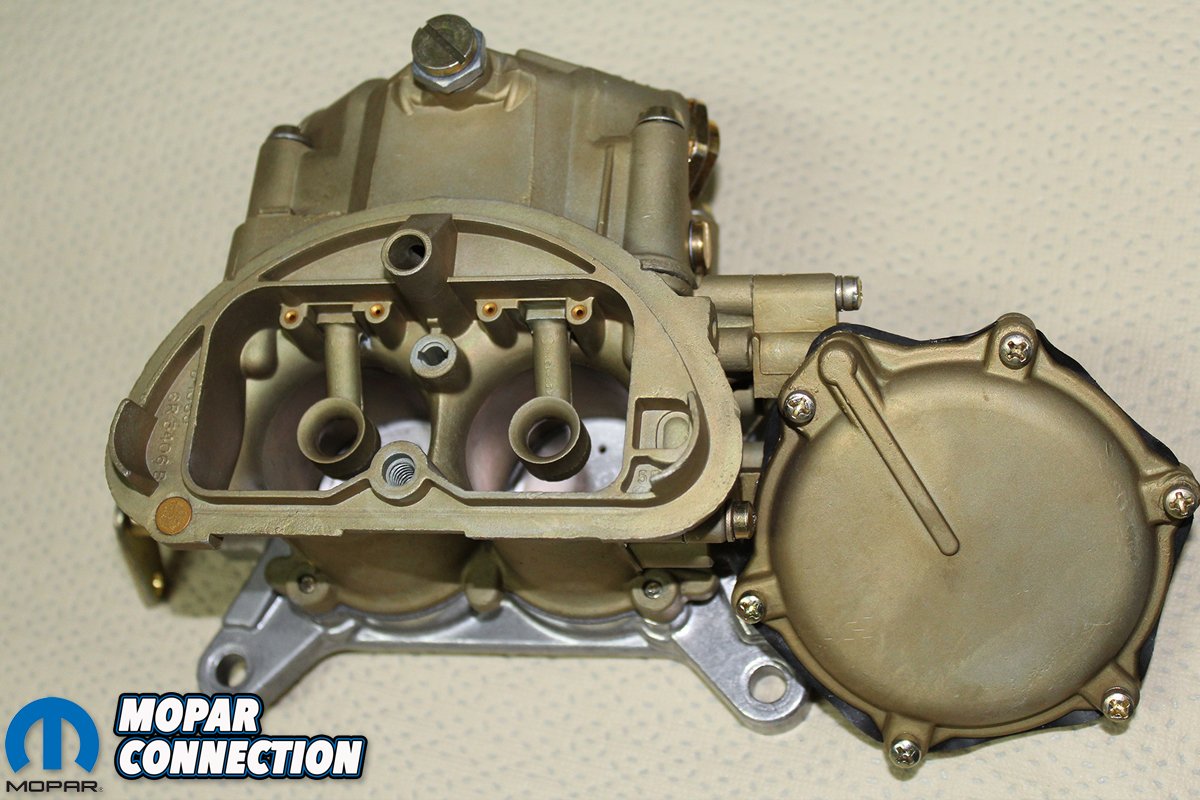

Left: The work area in the Custom Shop is clean and organized and separate from the rest of the factory. As you can see there are various carbs all tagged in the back ground. Extreme care is used to insure that your exact carbs are returned to you after restoration. It is here where the carbs are dis assembled for cleaning and plating. They are also re-assembled here. Right: Using the various forms of cleaning the parts are free of any dirt or previous plating. Most of these parts were cleaned in the vibratory vat and look brand new. The steel parts have been sent out for cadmium plating and these remaining parts will be individually hand plated to insure color match and original appearance.

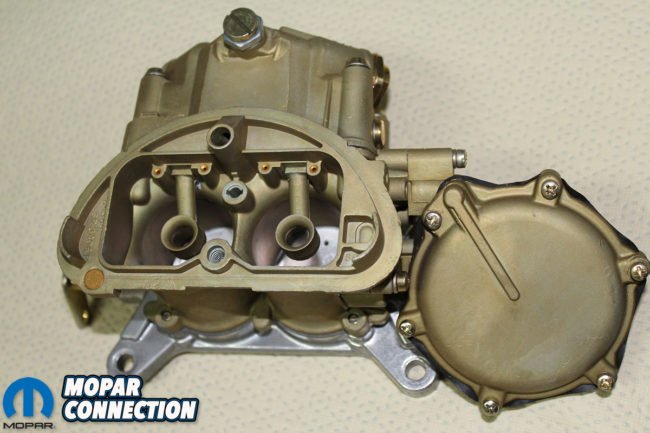

All of the steel parts are sent out to be cadmium chromated and return with a beautiful gold finish. The base is not plated, but all the aluminum parts are individually hand-dipped at the same time, in house, with the correct dichromate finish. This attention to detail and correct plating is what separates the Holley Custom Shop from everyone else. Great care is given to make sure the carbs are all color matched. The light tan, with green and gold highlights is beautiful and most importantly, correct!

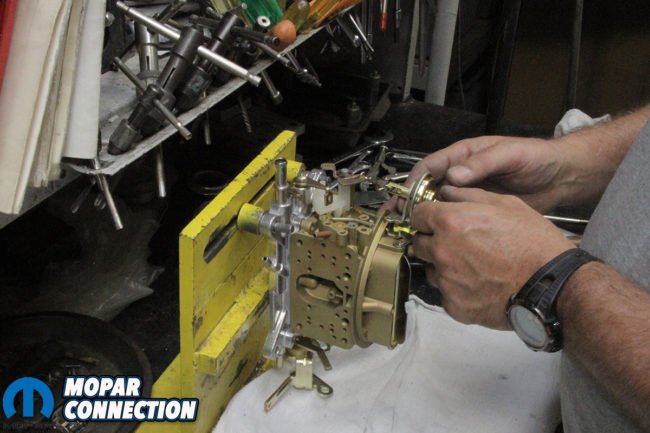

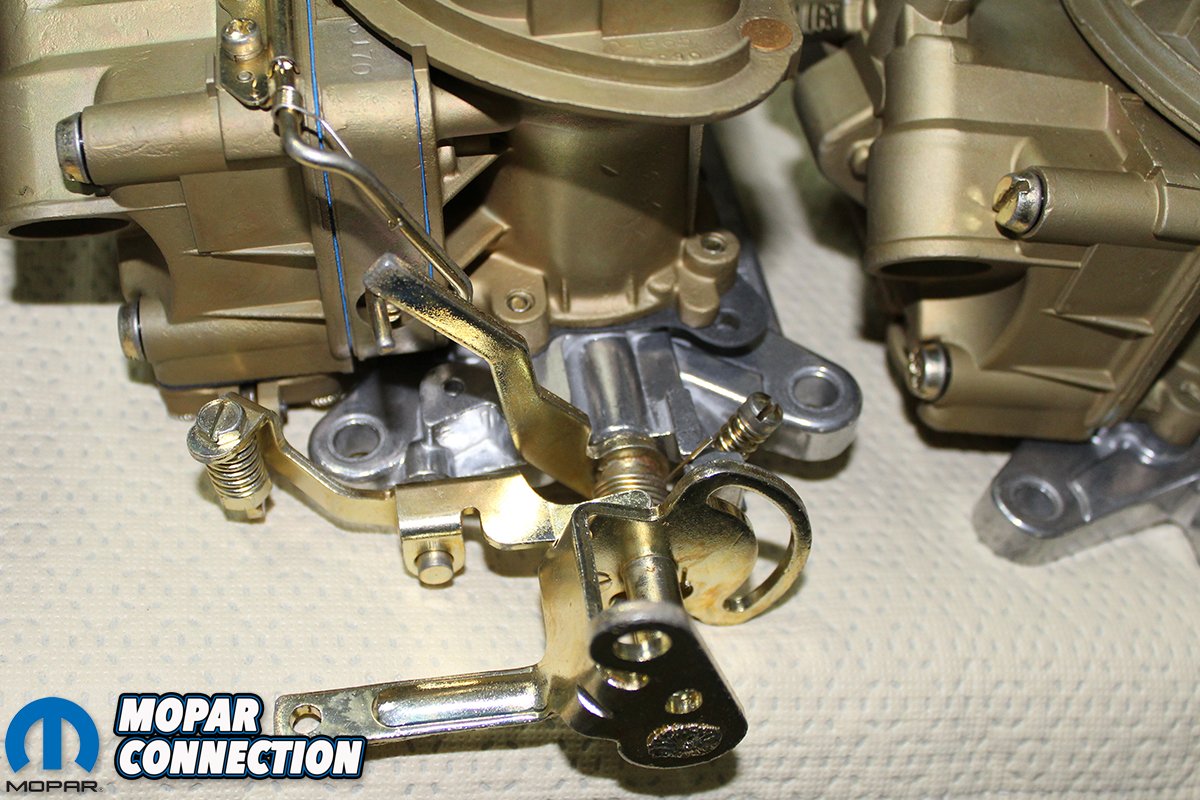

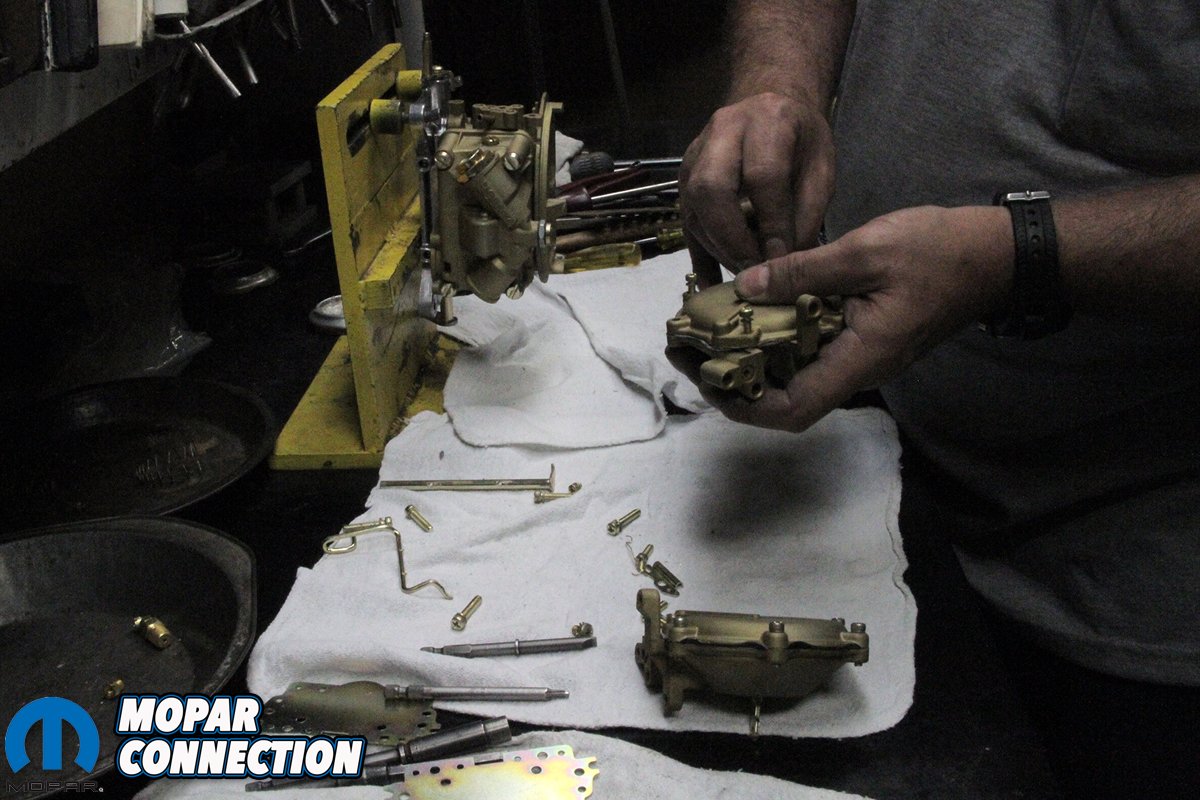

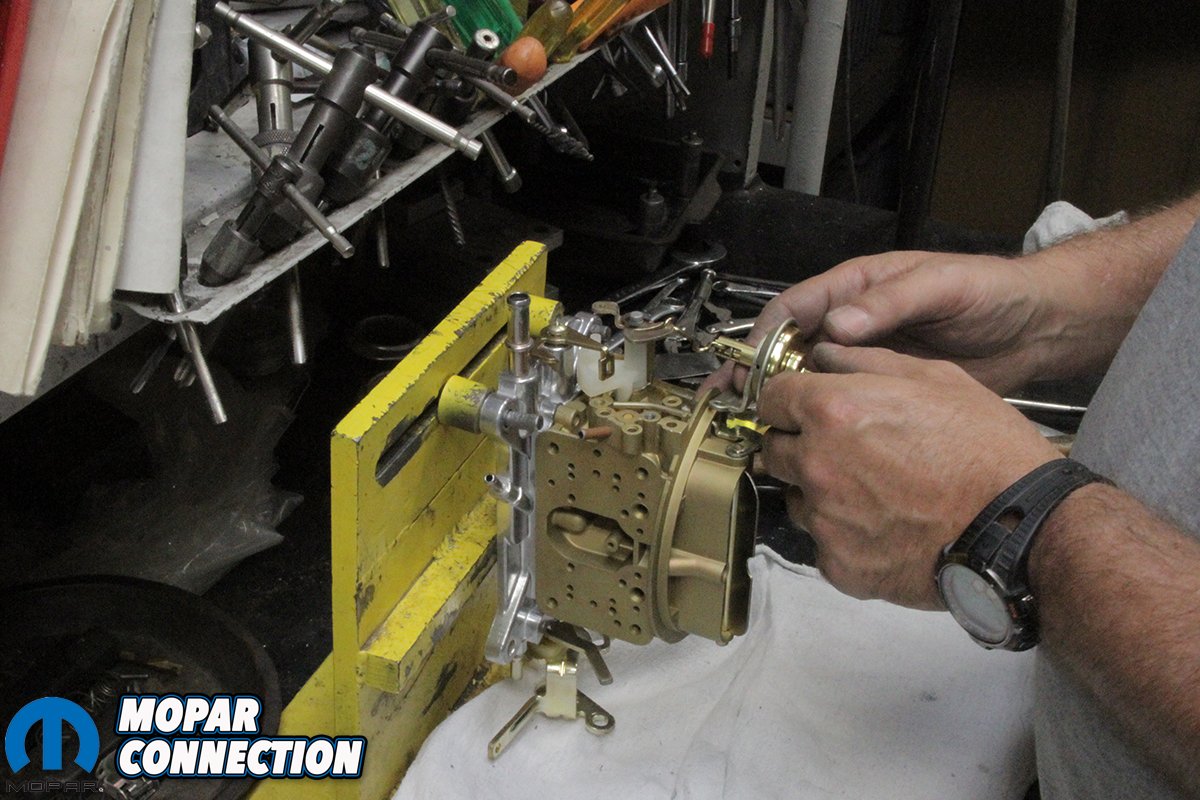

After all the parts are plated, the carbs are reassembled by Greg House. Greg has the manuals to make sure each part is correct for each carb, and the experience to get them back together as original. Once assembled, Greg then puts the carbs on the old school flow bench. All the settings are recorded for future reference in case you have any questions after you get the carbs back.

Left: By having their own plating vats and by hand dipping each part the quality of the finished product is guaranteed. Center: Final dip into the dichromating vat and the beautiful original finish appears after drying. Right: Taking each part individually from submission, to clean, to plated takes time and attention to detail. But as you can see the results are impressive and assembly and testing is still to come.

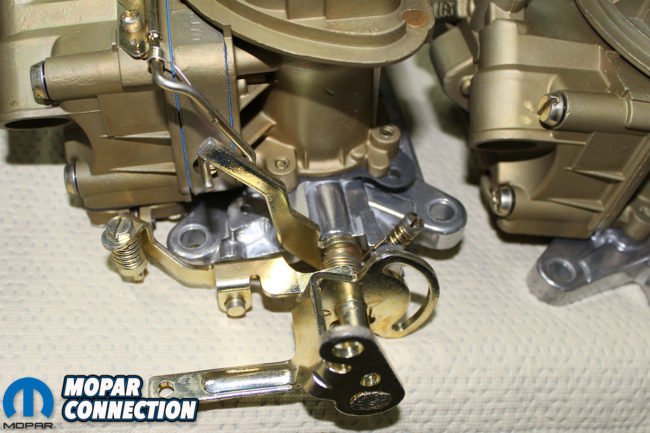

Top far left: All the steel parts, the bolts, linkage, levers, and nuts are back from plating and are reunited with the bases that have been cleaned and polished. The assembly process begins back at the bench where disassembly began. Top center left: The bases have been checked to make sure they are within original specifications before they are assembled. If not, they are replaced. Here the originals are being assembled with the butterfly plates. All these parts and Greg can put them together blind folded (but we won’t have him do that). Top center right: The center carb is all going back together on the bench using an assembly stand. With all the reference books within reach, all parts are replaced when needed. Here a vacuum pod is being installed. Notice the new off white fast idle cam. Top far right: The correct new power valve is installed on the correct metering plate.

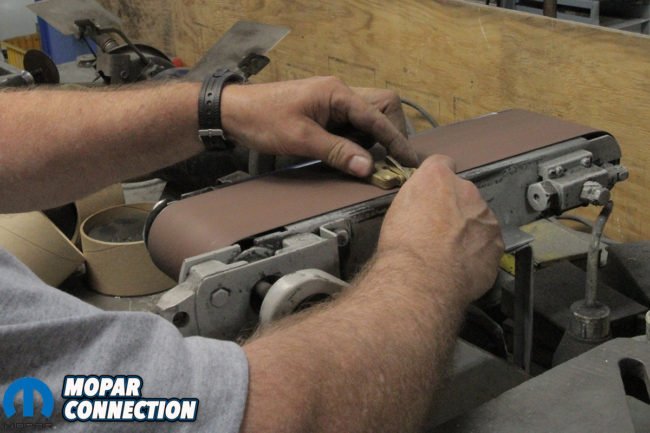

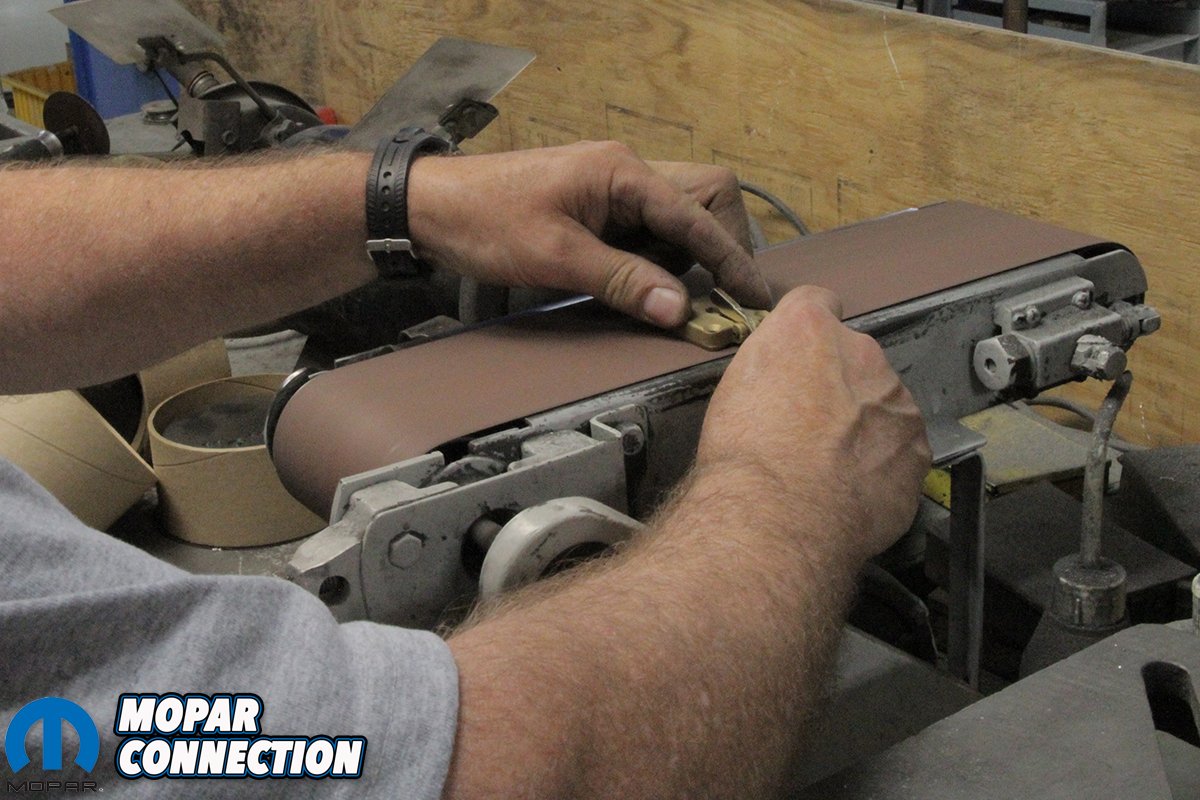

Bottom far left: Along the assembly process every part is checked and replaced if needed. Here the original accelerator pump housing is saved by squaring up the surface on the belt sander. It would be faster and easier to replace it with a new one, but the Holley Custom Shop is dedicated to keeping the carbs and parts as original as possible. Bottom center left: Vacuum pods are assembled. The diaphragms are tested to ensure fully operational function with the correct vacuum. The travel of the shaft is measured to make sure the outboard carbs will open fully for maximum performance. Bottom center right: The center carb is fully assembled. Notice the post 1969½ vent on the center carbs fuel bowl. For the A12 cars the fuel bowl had a rubber flapper for a vent. This was replaced after delivery with a correct vent bowl before installation on the car. Bottom far right: Holley still has this classic and very accurate flow bench. The technician can test, and record all data for future reference in case you have any problems after installation. Center and out board carbs are all dialed in before shipping.

As mentioned earlier the Holley Custom Shop can restore just about any carb to original condition. They can also “plate” “powder coat” any part you desire for your custom application. Your precious carbs are then individually packaged and returned, functional, correct, and beautiful!

Now let’s take this to the next level: The center carb vent on this set of carbs is not correct for the 1969½ application. In 1969, the vent was a “rubber flapper” that vented the fuel bowl. That was changed in 1970 so the vent on the bowl was not just an open hole, but a sealed vent. The carbs also had a paper tag on the vacuum pods. The front carb tag was a “50” and the rear was “51”. The center carb was tagged with a “52” on the driver side of the carb body.

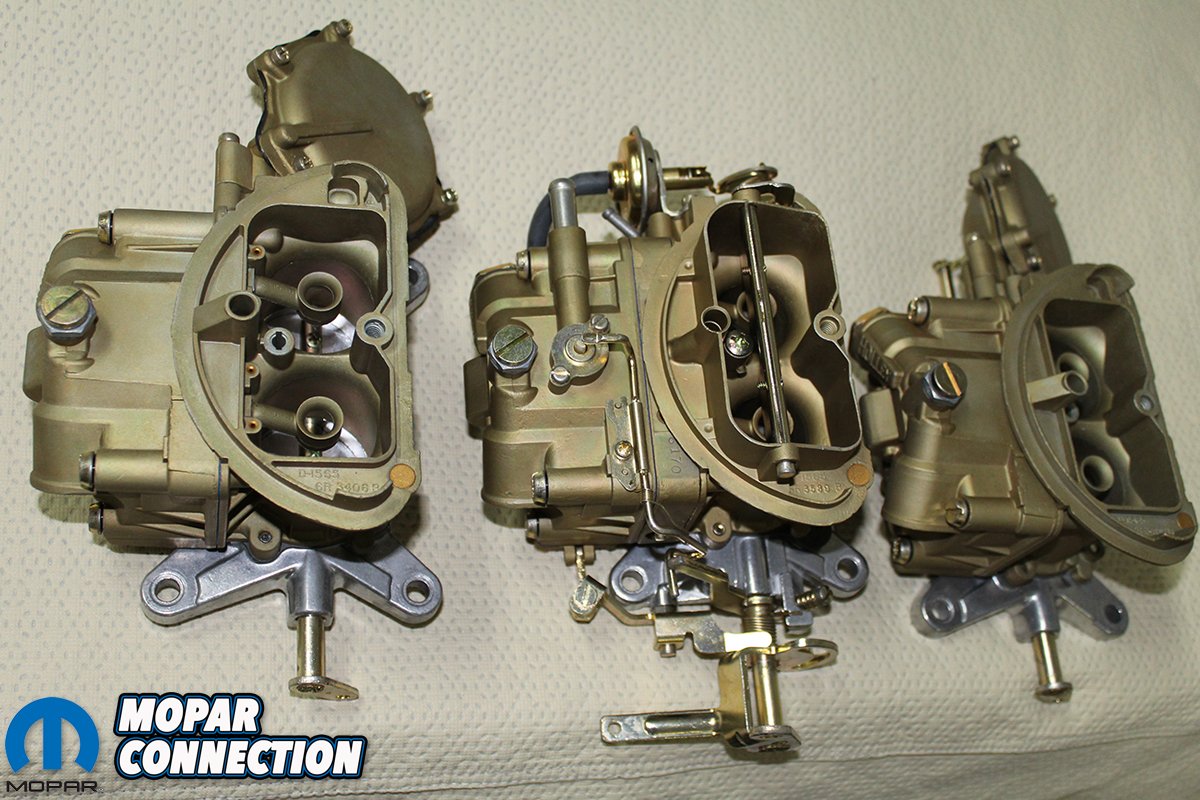

Top left: Another set of original 3×2 Chrysler carbs are restored, tested and ready for packaging to return to the customer. Each carb is individually bubble wrapped and then packaged in individual boxes before finally being combined in one carton for shipping. You can see other precious carbs tagged and awaiting their turn to be brought back to life! Top right: The customer has received the restored carbs and has laid them out for a close inspection. The attention to correct plating f the carbs bodies is evident in the natural light of the garage. Bottom left: There is no doubt with even a close up inspection that these carbs are just like they came on the car in 1969. Well no that is an incorrect statement. They are better than new and will stand up to even the toughest judging venue while giving awesome performance. Bottom right: Notice the correct part number for the original carb on the metering plate and the exceptional attention to detail

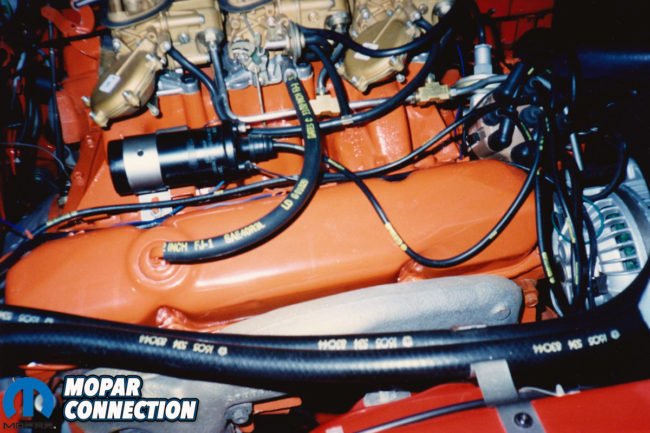

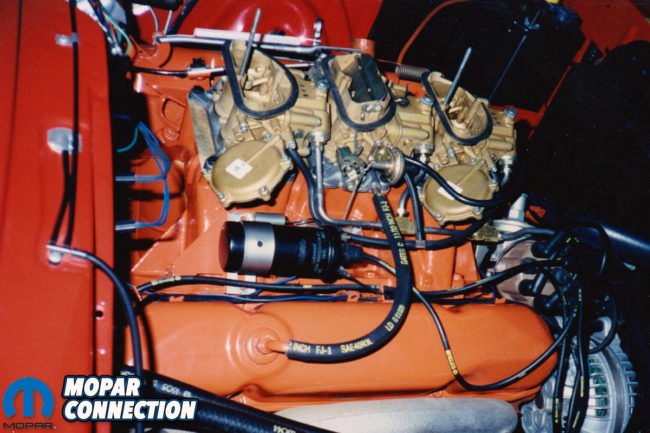

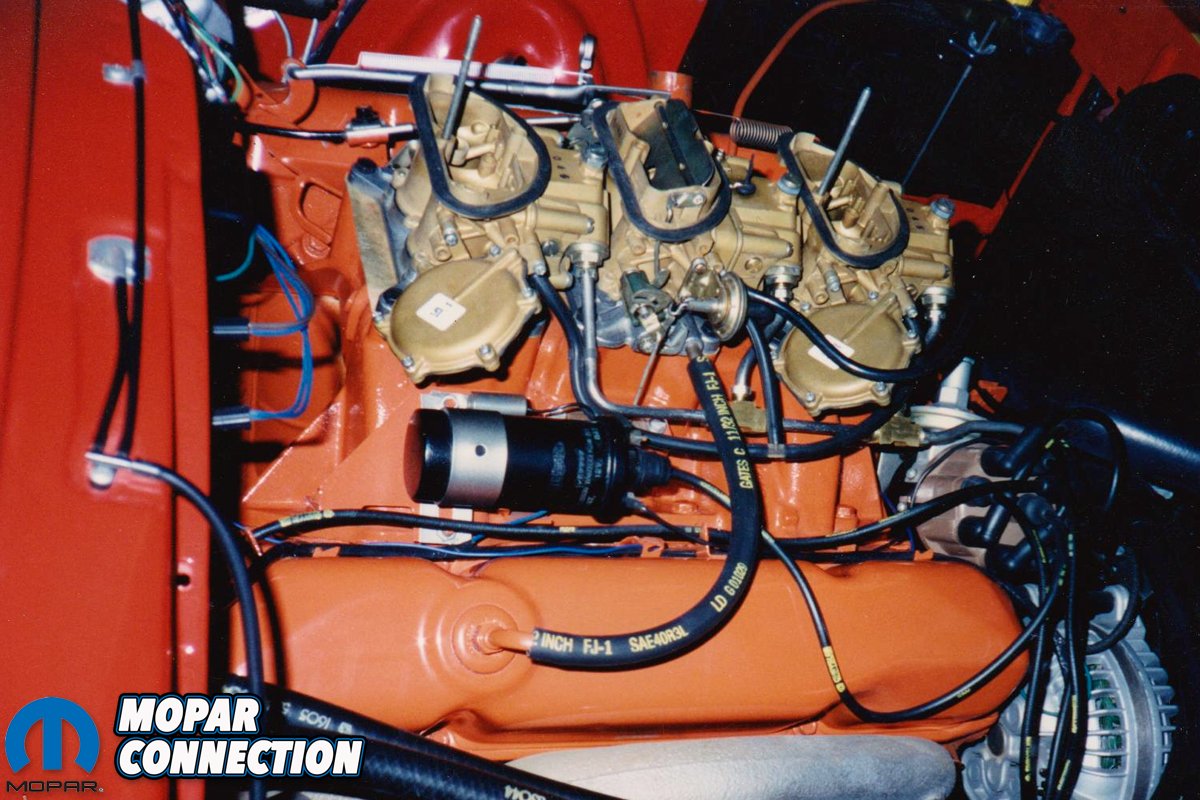

Left: Here are the Holley Custom Shop restored carbs installed on an original 1969 ½ 6bbl road runner. If you are looking for a reference to help you with your restoration this drivers side shot is a gold mine for information as to what is correct. Specifically notice the correct vent on the center carb fuel bowl. In 1969½ the vent was a simple rubber flapper covering an open vent hole. Center and right: Here is the passenger side of this completed restoration. There are so many correct parts documented here. Specifically, hoses, tags, plug wires, non-shoulder black phosphate “M” bolts mounting the carbs to the intake. Thin washers between the intake bolts and the aluminum manifold. “S” clamps on the ribbed vacuum hoses mounting them to the fuel lines. And on and on.

Date codes and part numbers for 6-Barrel/Six-Pack applications. The carbs all have “list numbers” and date codes stamped on them. The date codes are 4 digits. The first three are for the day and the forth is the year. The “list numbers” for 1969½ carbs are as follows:

- Front outboard carb 4-speed and auto – List – 4393

- Center 4-speed carb – List – 4391

- Center auto carb – List – 4392

- Rear outboard carb 4-speed and auto – List – 4394

Let’s say you don’t have an original ’69½ car or carbs. What can you do? Holley still manufactures these great carburetors and are available through many aftermarket dealers or even straight from Holley. They also have some of the best tech support in the industry. So whether they’re original or not, the boys from Holley are the “go to” place for carbs for your awesome Mopar project.

Left: Here is a close up of the front outboard carb. List 4393 is correct and the date code 0929 stands for the 92nd day of 1969. This correct for an automatic and a 4-speed A12 car. On the out board carbs the numbers are stamped on the body of the carb. Center: This is the center carb. The List – 4391 is for a 4-speed and List – 4392 is for an automatic. The date code 1229 is for the 122 day of 1969. The numbers for the center carb on the upper portion of the horn. This carb has some wear on the horn but that doesn’t affect its performance. Right: Now finally the rear outboard carb is List -4394 with a date code of 1999. This stands for the 199 day of 1969. The same as the front outboard carb, they are the same number whether it is a 4-speed or automatic car.

Hello, would you have an oem vented fuel bowl for a center carb on a 1969 Dodge six pack set up?

We’re a magazine, not the actual vendor.