Mancini Racing now offers the new COMP Cams® HRT camshafts for the Dodge Gen III-IV Hemi. These Hemi camshafts are some of the most technologically advanced and powerful cams on the market. The Comp Cams “Low Shock Technology” lobe designs come standard with their revolutionary Micro Surface Enhancement™ (MSE) surface finish. Comp Cams splits their HRT Hemi cams into two groups: the 2003-2008 non-variable valve timing (VVT) and the 2009-2019 w/VVT.

The Low Shock Technology features lobe profiles designed with maximum performance in mind, yet improved valve train stability at higher (than stock) RPM. This technology will provide less strain on the valve springs, which will increase the spring durability while reducing the load losses associated with performance camshafts.

Comp Cams has introduced their HRT series of camshafts for the Gen III Hemi. They have divided the camshafts into the 2003-2008 non-VVT and the 2009-2019 VVT series. These camshafts provide excellent performance increases over the factory camshaft regardless of which stage (three stages) of camshaft is selected. Comp recently tested an Eagle 5.7L on an engine dyno and the results were spectacular.

Comp’s MSE finishing process is a standard feature with all the HRT camshafts. The finishing process increases the strength and performance of the camshaft by greatly reducing the peak roughness of the camshaft lobes. The surface finish of a camshaft influences two major areas of the engine performance. These areas are endurance (anti-wear characteristics) and power. The camshaft endurance will increase as the cam lobe’s bearing surface area (BSA), the effective area of the lobe that contacts the lifter wheel, increases.

Comp Cams has tested their camshafts and found improvements in the effective load bearing area by as much as 250%. The improvements in bearing load are due to more of the lifter roller making greater contact with the lobe, and thus, the lobe can withstand greater loads. The horsepower (hp) will increase because the lifter roller follows a smoother lobe, which will cause fewer interruptions in the motion of the lifter resulting in reduced lifter friction as the roller rides on the cam lobe.

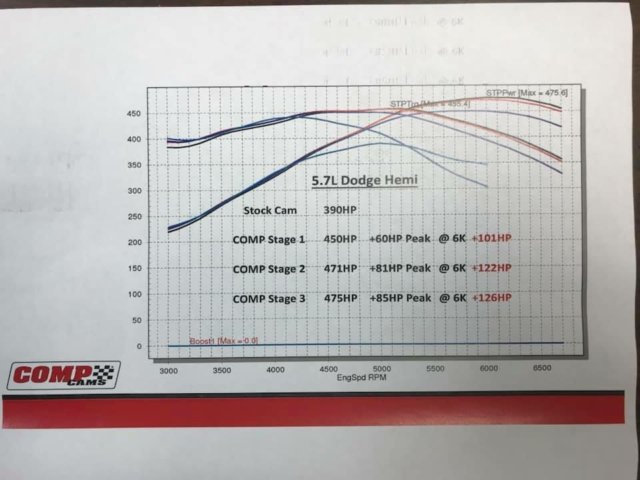

Comp Cams recently tested the HRT series (Stage 1, 2, and 3) camshafts on a 5.7L Hemi strapped to an engine dyno. The baseline was performed on a stock Eagle 5.7L with a non-MDS cam, Dynatec headers (production headers that will fit most LX- and LD-platforms) and a FAST 87mm throttle body. For the testing, the VVT phaser was locked.

Not to be left out, the pre-2009 Hemis also have a selection of HRT camshafts from Comp Cams. If a new camshaft for your Hemi is desired, check out Mancini Racing for the latest in camshaft technology.

The testing was completed in three stages. The Stage 1 camshaft used the stock valve springs with a .520/.515-inch lift (intake/exhaust) that was acceptable for 1700-6200 RPM range. The Stage 2 camshaft required Comp springs to work with the .596/.582-inch lift and an RPM range of 1900-7000 RPM. Lastly, the Stage 3 camshaft pushed the limits a Hemi with stock pistons. The Stage 3 cam had a .632/.619-inch valve lift and an RPM range of 2100-7400 RPM.

The stock 5.7L provided 390 hp. When the Stage 1 camshaft was slipped into the Hemi, the peak horsepower rose dramatically up to 450 hp. The subsequent camshaft stages increased the peak horsepower up to 471 hp (Stage 2) and 475 hp (Stage 3). At 6000 RPM, Comp found a horsepower increase of 101 hp (Stage 1), 122 hp (Stage 2), and 126 hp (Stage 3) over the stock 5.7L at the same RPM.

If there is an interested in double digit-peak horsepower increases and triple-digit horsepower increases at 6,000 RPM for your 5.7L Hemi, give the reps at Mancini a call. They will be happy to find a budget friendly Comp Cams’ camshaft option to provide an impressive horsepower bump for your Hemi.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by