Pushing redline in a small block Mopar is a feeling unlike that which any B or RB engine can provide. The short stroke’s ability to spin up at such an incredible rev rate is what keeps Chrysler cruisers coming back to the venerable 340 and 360 variants even though their bigger brothers are more apt to make big power.

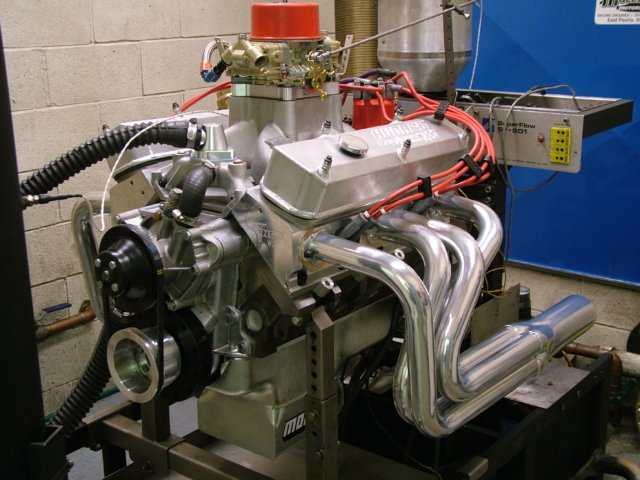

We’ll agree that cubic inches are still king but, given the small block’s pint-sized packaging, an LA or Magnum motor with a serious power-to-weight ratio can be just as fun as anything else. Hughes Engines proved as much with a 700-horsepower, 7,000 rpm 420 ci build that’s downright scary:

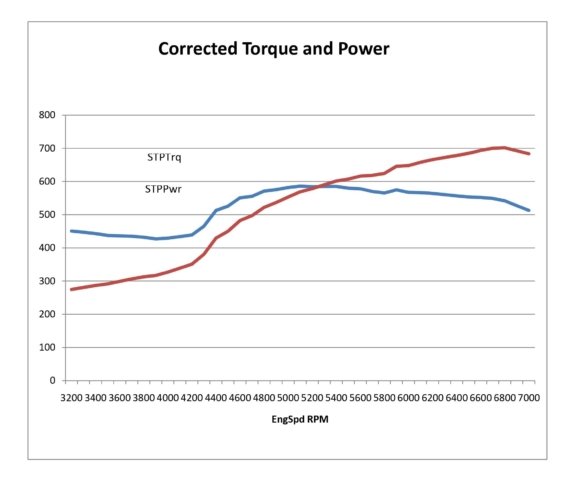

This is “so far” our high water mark for small block MOPARS. As you can see by the Dyno test results it was 701.6 HP @6800 and 585.9 TQ. @5100 RPM. The volumetric efficiency reached 111.5% @ 6700 RPM, also a high water mark for us. Most of our engines are pump gas engines in keeping with what the majority of our customers want, so these high numbers of race engine are very exciting to us.

These power numbers are the results of many tests over several years. Not only that but the engine has a fairly small flat tappet cam and we didn’t get time to play with carb spacers and it was still a little lean on the final pull before we ran out of time on the Dyno. So what we are saying is that there is more HP available.

What did it take to do this?

What did it take to do this?

Block: R-3 Siamese 4.080” with all of our race prepped kit block work.

Crank: Scat forged 4” stroke 340 Mains

Rods: Scat “H” beam 6.125”

Pistons: Diamond custom forged “High” compression & Diamond pins.

Rings: Custom low tension Total Seal/Diamond

Cam: Flat tappet HTL6872AS-6 Hughes, standard shelf cam

Heads: Indy 360-1 (for now!) with Hughes C.N.C.: W/1.6:1 Rockers

Intake: Indy 360-1 1X4 (for now) fully ported by Hughes Engines

Carb: AED Custom built 1000 CFM-4150 type

Headers: 1 7/8 Dyno Headers

Ignition: MSD dist. 6AL

I believe this basic combination is capable of even more power with some time to experiment with camshafts. The 360-1 Head (for now!) have a 1.9 installed height which should allow a roller cam with high .750”+ lift (for now!). This combination might even profit from a Dominator Carb and, we should look at 2” or larger headers – and this is a small block!!!

Notes: Even with these large port Indy 360-1 Heads (for now!); the torque down low @3200 RPM was very strong. You gotta love that Flat Tappet cam. If we would have had more time to play with the carb & collectors, the dip in the curves from 3500 to 4200 rpm could have been fattened up to.

This was with a standard volume oil pump (62 PSI) and the bearings looked beautiful after the testing. Now explain to me again why you think need a roller cam and a high volume oil pump.

Love the small blocks. I used to run a little 340 in a 70 Duster back in the good old days (late 70’s). Loved taking down the 454’s and the big block mopars too. Keep up the great work.