At one point or another, every one of us has considered taking our prized Mopar for a run down the 1320 tarmac, and to get the maximum performance from our ride, we may even consider bolting on some drag radials or slicks. The extra tacky tires stick to the track surface with greater adhesion than street tires, and that extra grip puts a greater load on the drive-line. Most of the time nothing will happen, but as they say, anything can happen.

We recently purchased a 1967 Dart, and while the Dart will not see the drag strip for some time (or ever), we run it on a chassis dyno often, which places a similar type of load on the drive-line. The last thing we want is a U-joint failure followed by a high-speed exodus of the driveshaft, which could lead to vehicle or chassis dyno damage, or worse, personal injury. With these concerns in mind, we found that Mancini Racing offers a bolt-in driveshaft loop that retains the driveshaft in the event of a front U-joint failure.

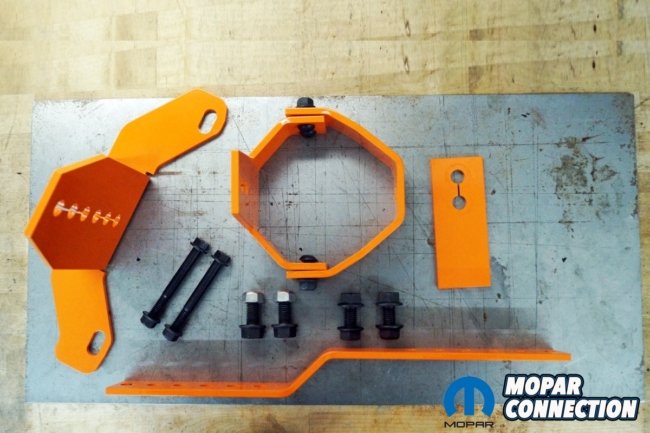

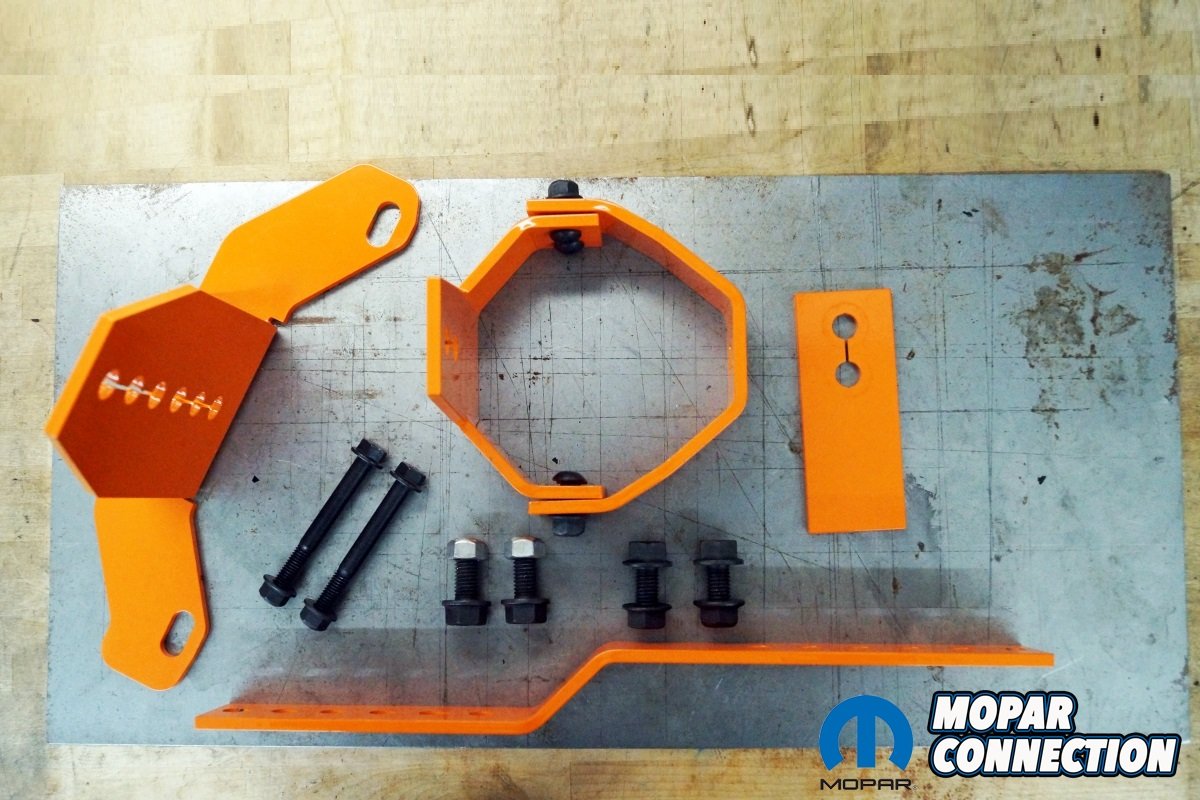

- The hardware of the driveshaft loop is ¼-inch thick steel bent into the proper shapes to encircle the driveshaft, bolt to the transmission cross member, and extend from the cross member to the loop around the driveshaft.

- To attach the driveshaft loop bracket, we were required to remove two of the four cross member fasteners. With the use of a ½-inch drive air gun, the fasteners backed off with little difficulty. Our ’67 Dart spent most of its life in California, so there are virtually no rust concerns.

- Even with the fasteners removed, the cross member was in no danger of dropping from the chassis. We checked the bolts for any damage, and none was found. If the bolts had been in poor condition, new bolts would have been used because the driveshaft loop requires a sturdy mounting point on the chassis.

- The driveshaft loop bracket slipped into place on the cross member. The contours of the bracket fit perfectly, and the mounting holes lined up with the cross-member bolts. The fasteners were hand tightened, so we could ensure the bracket was properly aligned.

- The fasteners were snugged with the air gun. A torque wrench was used to tighten the fasteners to spec. The bracket mounted solidly to the cross member. There was zero deflection in the extension from the bracket.

The hardware of the driveshaft loop is ¼-inch thick steel, which is bent into the proper shapes to encompass the driveshaft, bolt to the transmission cross member, and extend from the cross member to the loop. The Mancini Racing driveshaft loop meets the National Hot Rod Association (NHRA) and the International Hot Rod Association (IHRA) requirements for minimum steel thickness and width to ensure that if a front U-joint should fail, the driveshaft will be properly retained. The driveshaft loop is fully adjustable, so driveshaft clearance can be easily achieved. The adjustability of the loop also allows it to be installed around the exhaust, including an X-pipe or H-pipe, and the park brake cable(s).

The installation of the driveshaft loop was a simple task completed in just over an hour. Our Dart was positioned on a two-post lift, but it could have been easily placed on a pair of jack stands to complete the installation. Once the Dart was in the air, we removed the ¾-inch fasteners from the inboard bolts of the transmission cross member. The driveshaft loop bracket was slipped over the inboard bolts, and the fasteners were reinstalled and torqued to factory specifications.

- The Z-bar was loosely installed to the driveshaft loop bracket. The Z-bar could be installed slightly to the left or right to line up with the driveshaft. The final angle of the Z-bar would be determined once the loop was installed.

- The loop is a two-piece assembly. Four Allen bolts were pushed through the two loop halves and secured with fasteners. The loop is much larger in diameter than the driveshaft, yet it is compact and will fit in the driveshaft tunnel.

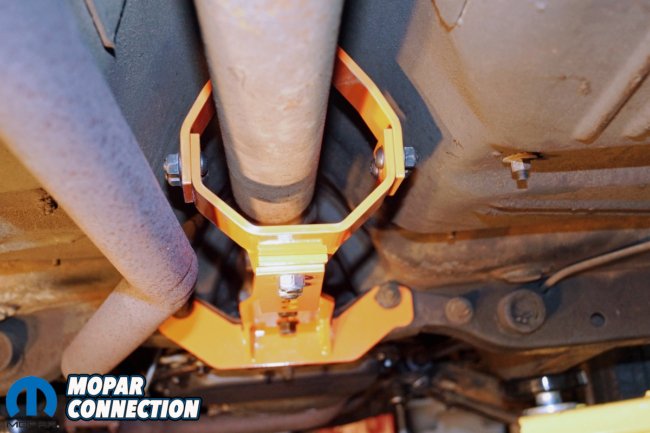

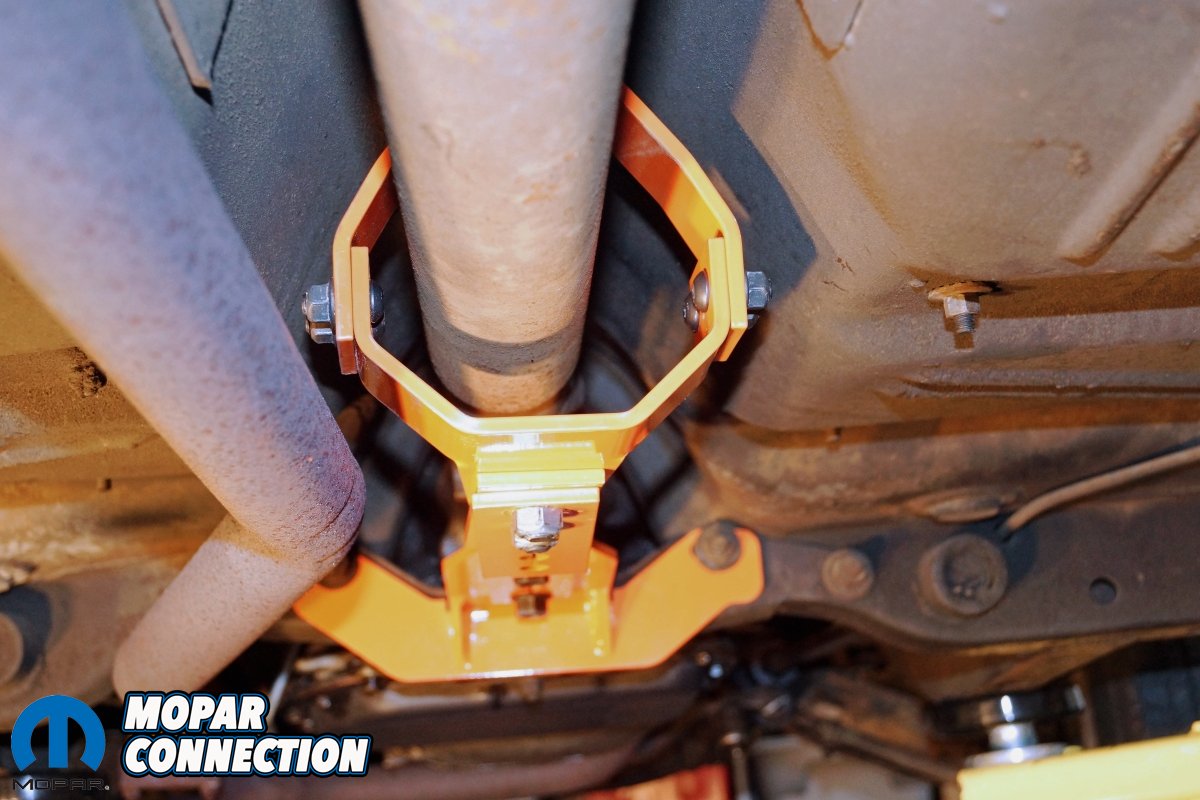

- With the Dart’s weight on the rear wheels, the two-piece loop was secured to the Z-bar. The Z-bar was finessed into place to clear the driveshaft, the exhaust, and the park brake cables. With the Z-bar properly located, the two fasteners at the Z-bar and cross member bracket were tightened.

- The loop was final adjusted around the driveshaft. The provided spacer shim was added between the Z-bar and the loop to raise the loop to safeguard against any interference with the driveshaft. With the adjustments correct, the two fasteners at the Z-bar and the loop were tightened.

- The loop’s location was about 6-inches down from the front U-joint. With the Z-bar secured, the loop’s fasteners were retorqued. All the fasteners were rechecked to verify the correct installation of the driveshaft loop.

The Z-bar was loosely installed on the cross member bracket, and it was adjusted to a position that would allow the loop to be placed approximately 6-inches down the driveshaft from the U-joint. The Z-bar could be moved slightly to the left or right as needed to line up with the driveshaft and clear the exhaust. Before we tightened the Z-bar to the cross member bracket, the loop had to be installed over the driveshaft.

The two-piece loop was disassembled, and the top section of the loop was placed over the driveshaft. The bottom section of the loop was slipped into the upper loop. The use of a 7/32-inch Allen wrench and a 9/16-inch socket and ratchet torqued the four loop fasteners. The loop encased the driveshaft, and it was lined up with the end of the Z-bar opposite to the cross member bracket. With the rear of the Dart supported with a jack stand to compress the rear suspension, we adjusted the position of the loop on the Z-bar to provide the proper clearance around the driveshaft and the exhaust.

- With a jack stand under the rear end, the clearance between the driveshaft loop and the floor is substantial. Nothing comes within an inch of the driveshaft loop. The driveshaft loop meets the NHRA and IHRA safety requirements.

- The Dart will be used extensively on a chassis dynamometer, and this driveshaft loop will provide peace of mind when we are spinning the little 273-cid engine up to 6000 rpm.

- If a driveshaft loop will be necessary for your ride, give Mancini Racing a call. Their driveshaft loop will save you from having to cut up your Mopar’s floor, and it may save your day if a front U-joint gives up while at the track or on the dyno.

- They are still out there. We are the sixth owner of the Dart GT. It was assembled at the Los Angeles assembly plant and sold from Reseda Dodge in LA. It was originally silver, but along the way most of the Dart was painted YY1 yellow. It is a simple 273/2bbl, 904, 7 ¼-inch car with 13-inch wheels and four-wheel power drums. It needs work, but best of all, it is rust-free.

We installed the included spacer between the Z-bar and the loop, and the fasteners were tightened. After every fastener was re-torqued, we removed the jack stand and lowered the Dart to the shop floor. The suspension was jounced, and the driveshaft to loop clearance was checked. There was more than 1-inch clearance in all areas around the driveshaft and the exhaust. After a successful test drive, the installation was considered a success.

The Mancini Racing driveshaft loop fit perfectly, and there was no need to drill or cut up our factory original floor pans. The installation of the driveshaft loop was performed with a combination of air and hand tools, and it provided us with peace of mind four our future performance events. If a visit to the drag strip or a chassis dyno is in your future, check out Mancini Racing for their worry-free bolt-in driveshaft loop.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by